A multi-channel self-adaptive pressure balance ammunition press forming tooling

A compression molding, self-adaptive technology, applied in explosives processing equipment, explosives, offensive equipment and other directions, can solve problems such as low production efficiency, achieve the effect of improving production efficiency and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

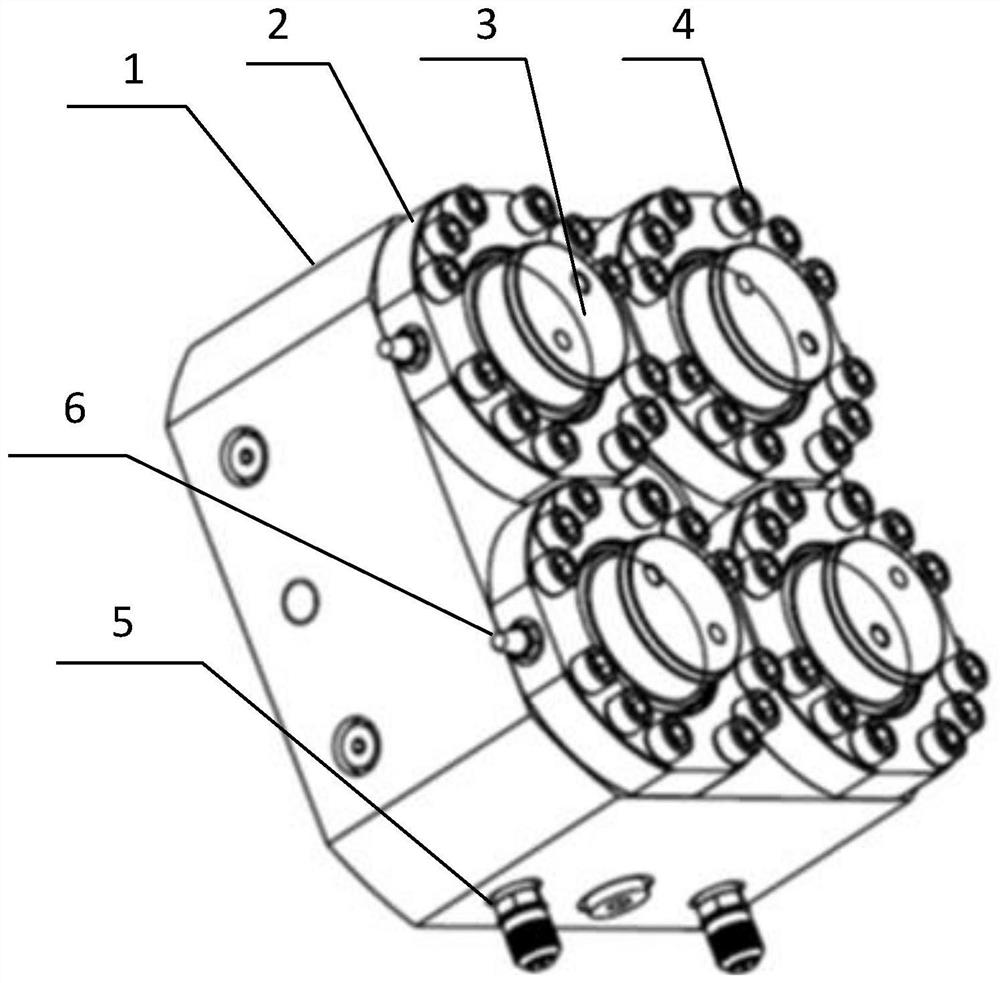

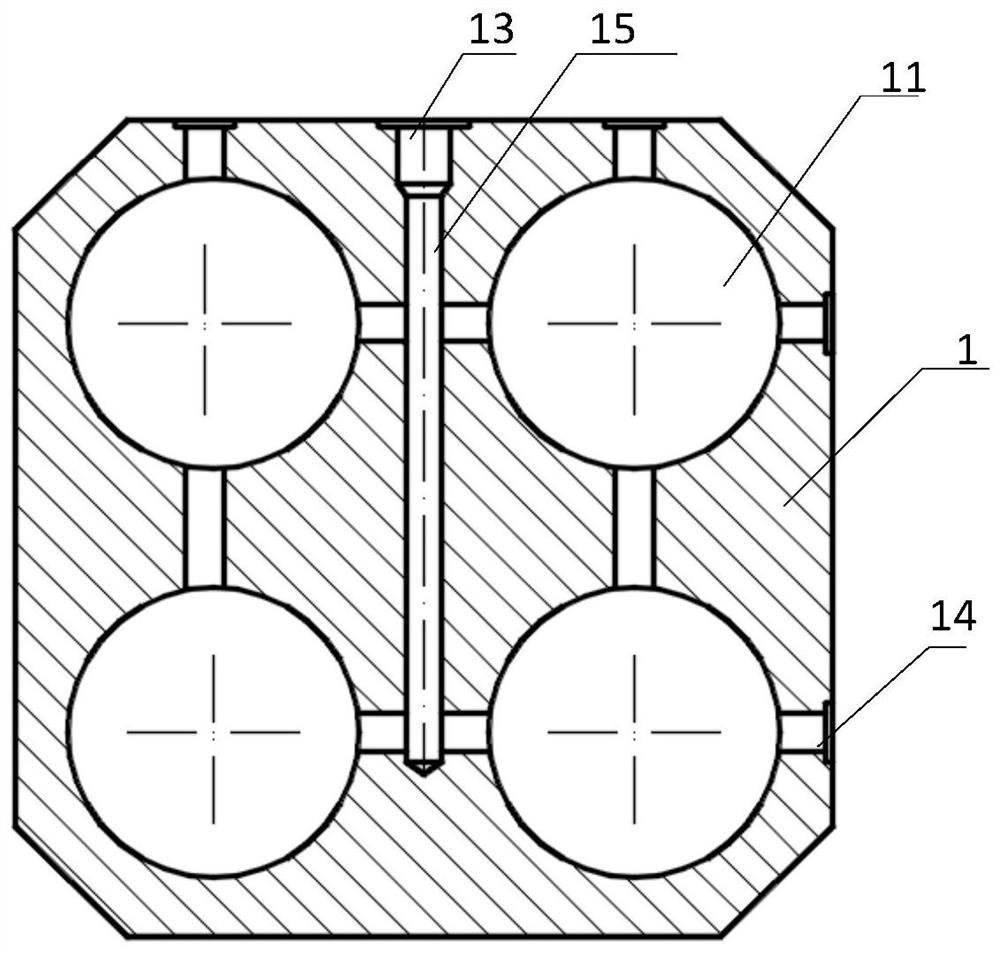

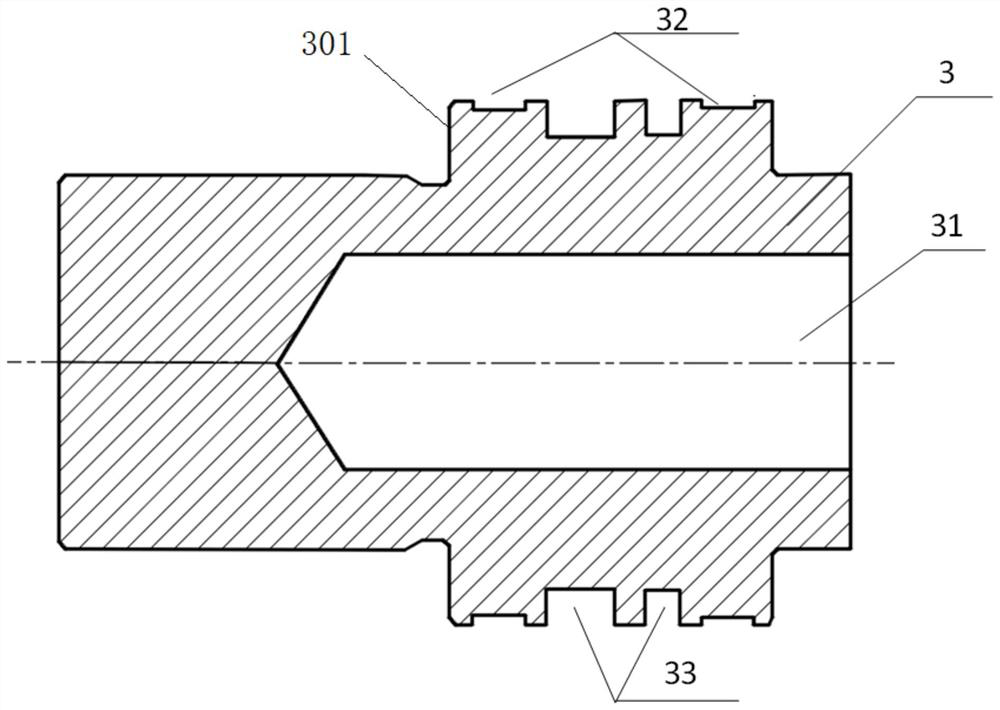

[0025] A multi-channel self-adaptive pressure-balanced ammunition press molding tool is installed between the upper slider of the press and the mold, including a cylinder 1, a plurality of plungers 3 and a plurality of end caps 2, such as figure 1 As shown, in this embodiment, four plungers 3 and four end caps 2 are specifically included, as figure 2 As shown, four plunger cavities 11 are arranged on the cylinder body 1, and an oil passage 15 is provided in the cylinder body 1, the plunger cavities 11 communicate with each other through the oil passages 15, the end cover 2 is installed on the cylinder body 1, and the column The plug 3 is installed in the plunger chamber 11 of the cylinder body 1 and is limited by the end cover 2, and the front end of the plunger 3 protrudes from the plunger chamber 11 to act on the mold, and the plunger 3 can be placed in the plunger chamber 11 Swipe freely.

[0026] When in use, the cylinder body 1 is connected with the upper slider of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com