Negative pressure self-suction type fluid dead cavity destruction device

A self-priming, negative pressure technology, used in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problem of bypass dead space, which cannot be solved well, the fluid resistance of the main pipeline increases, and the fluid flow rate changes. Slow and other problems, to achieve the effect of consistent temperature change, large fluid suction, and fast flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

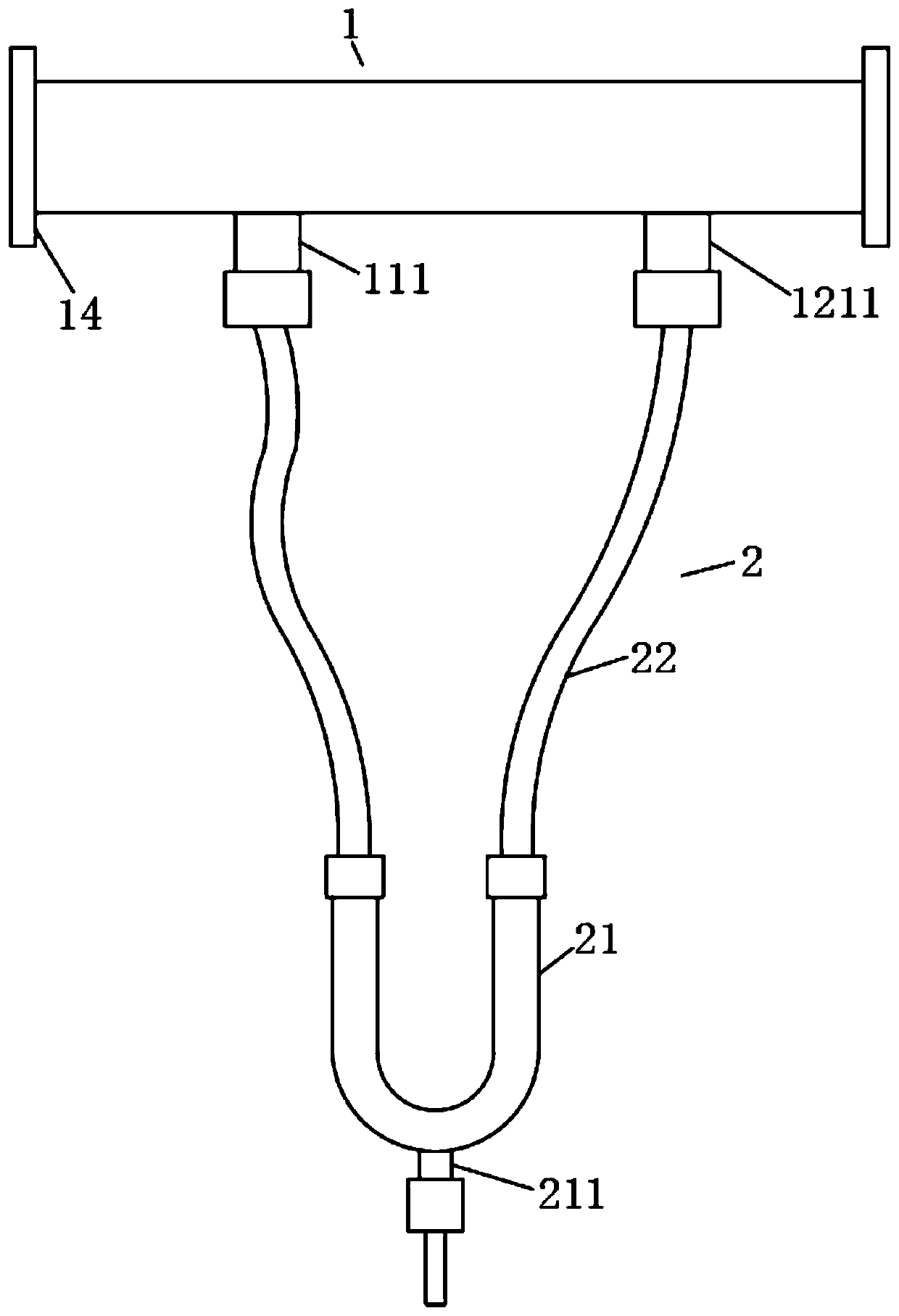

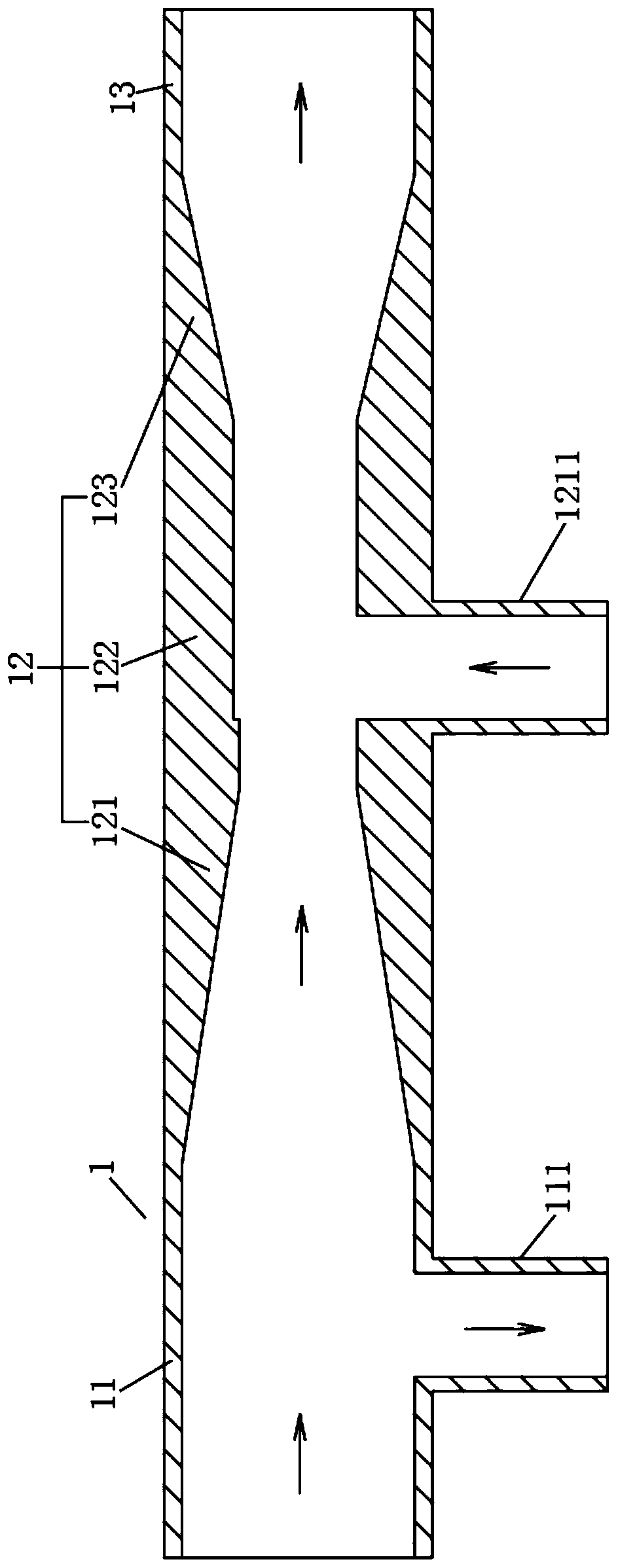

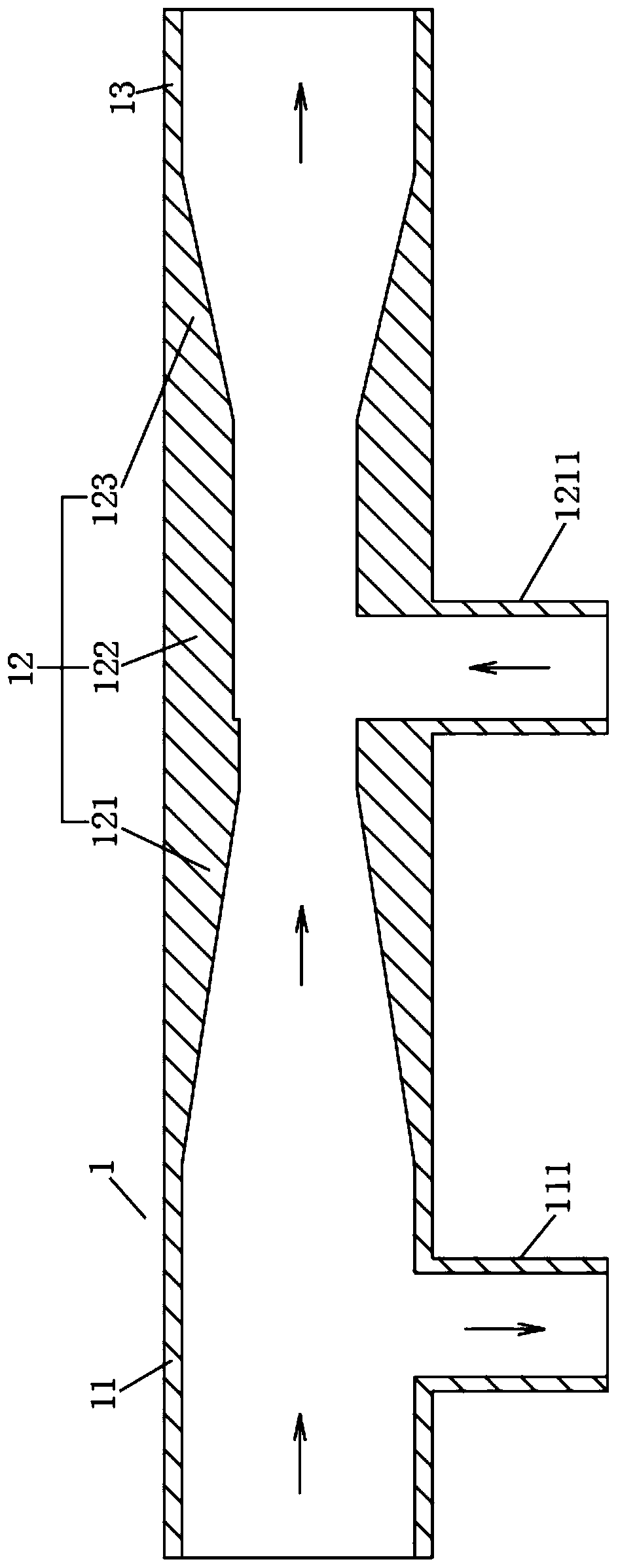

[0022] Example: such as figure 1 and 2 As shown, the negative pressure self-priming fluid dead space breaking device of this embodiment includes a main pipeline 1 and a bypass pipeline 2. The above-mentioned main pipeline 1 includes an advection inlet section 11 that is continuously arranged and communicated from front to back along its fluid flow direction. , the jet section 12 and the flat outlet section 13, the above-mentioned advection inlet section 11 is communicated with a bypass outlet nozzle 111, and the above-mentioned jet section 12 is communicated with a bypass suction nozzle 1211, and the above-mentioned jet section 12 is used to increase fluid flow velocity and pressure, and form a negative pressure at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com