Quality management apparatus and quality management method

A quality management and quality technology, applied in the direction of comprehensive factory control, program control, instruments, etc., can solve the problems of unclear correlation, failure to consider management items, defects, etc., to achieve the effect of stable quality management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

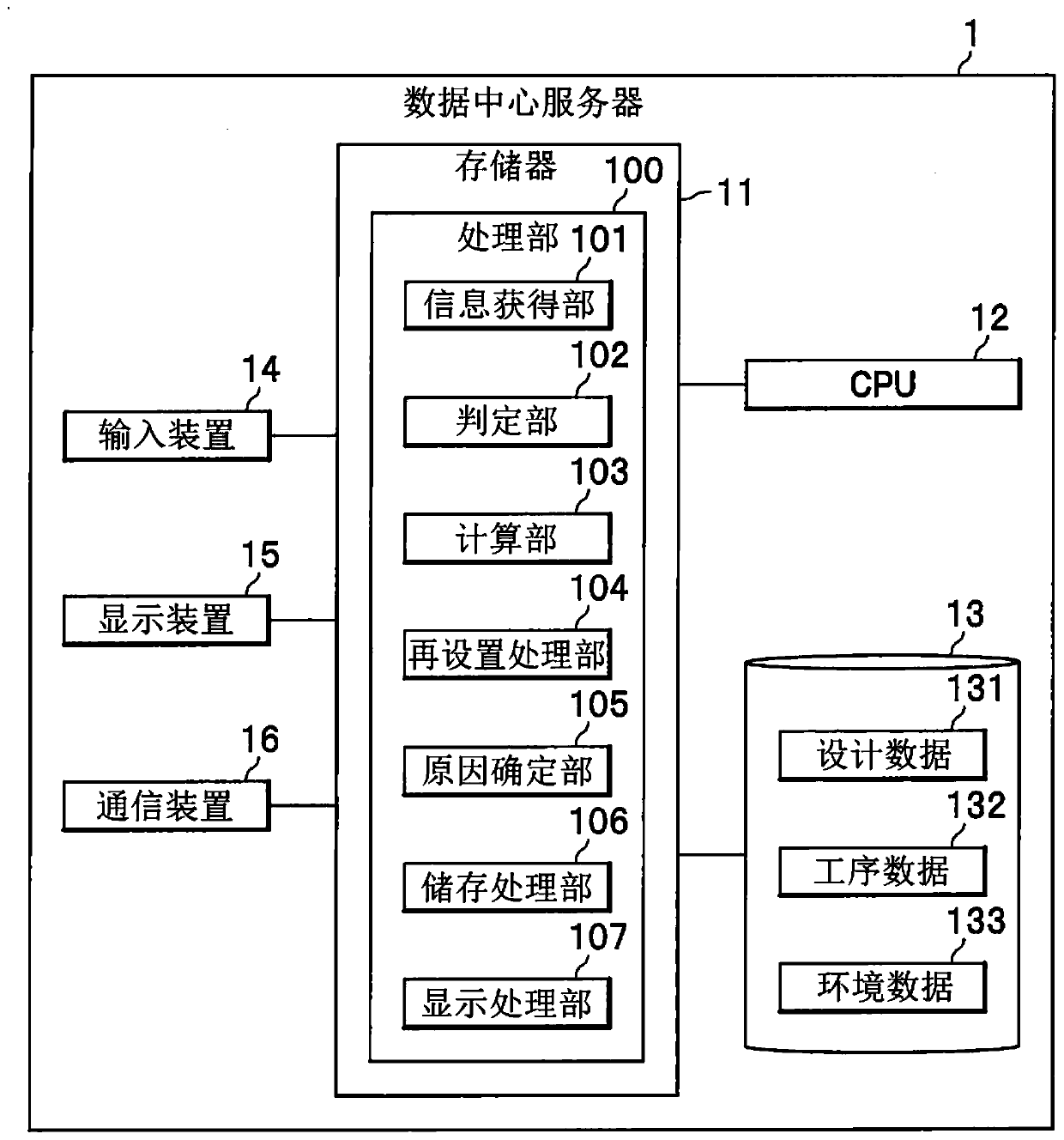

[0031] (System Components)

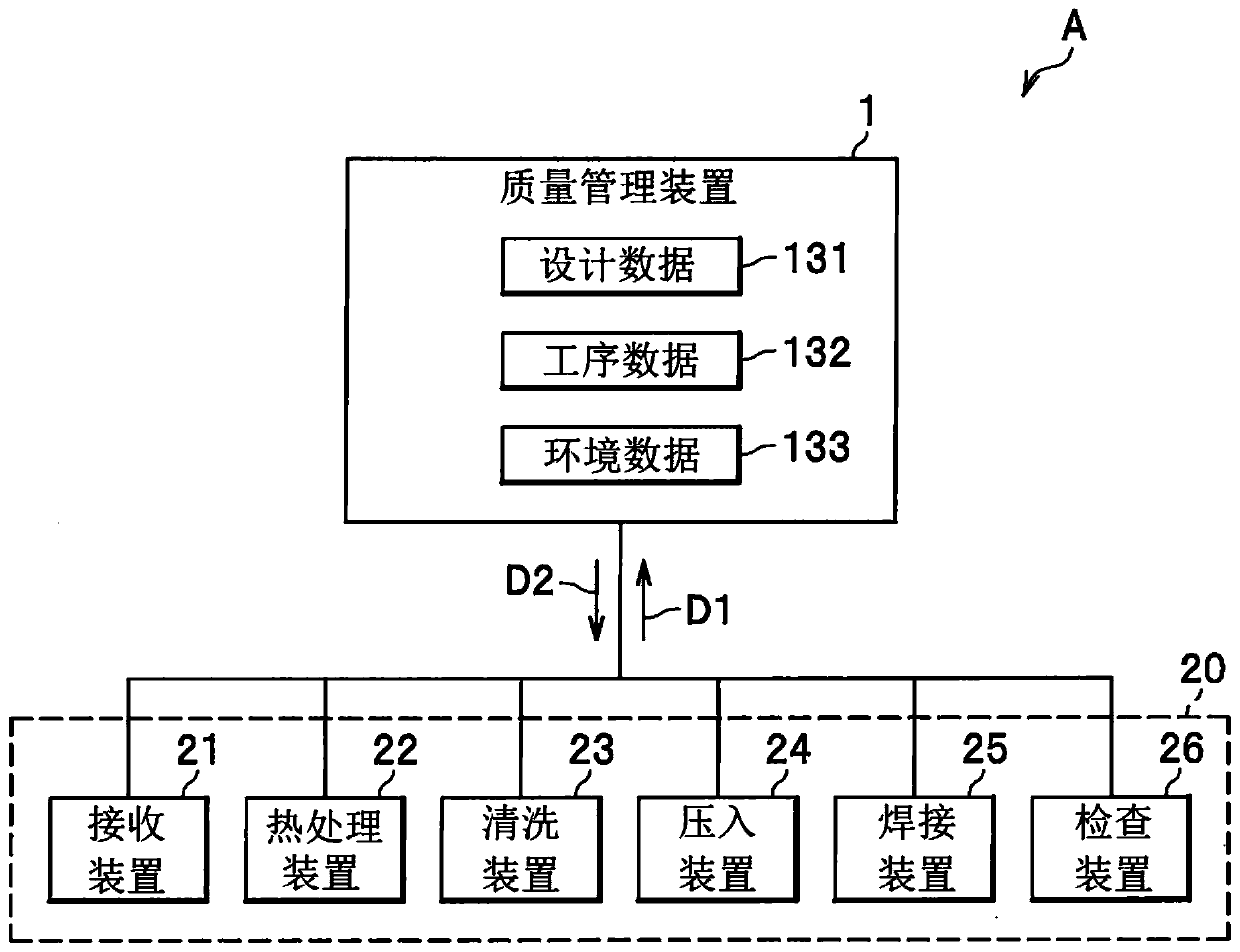

[0032] figure 1 It is a diagram showing an example of the overall configuration of the quality control system used in this embodiment.

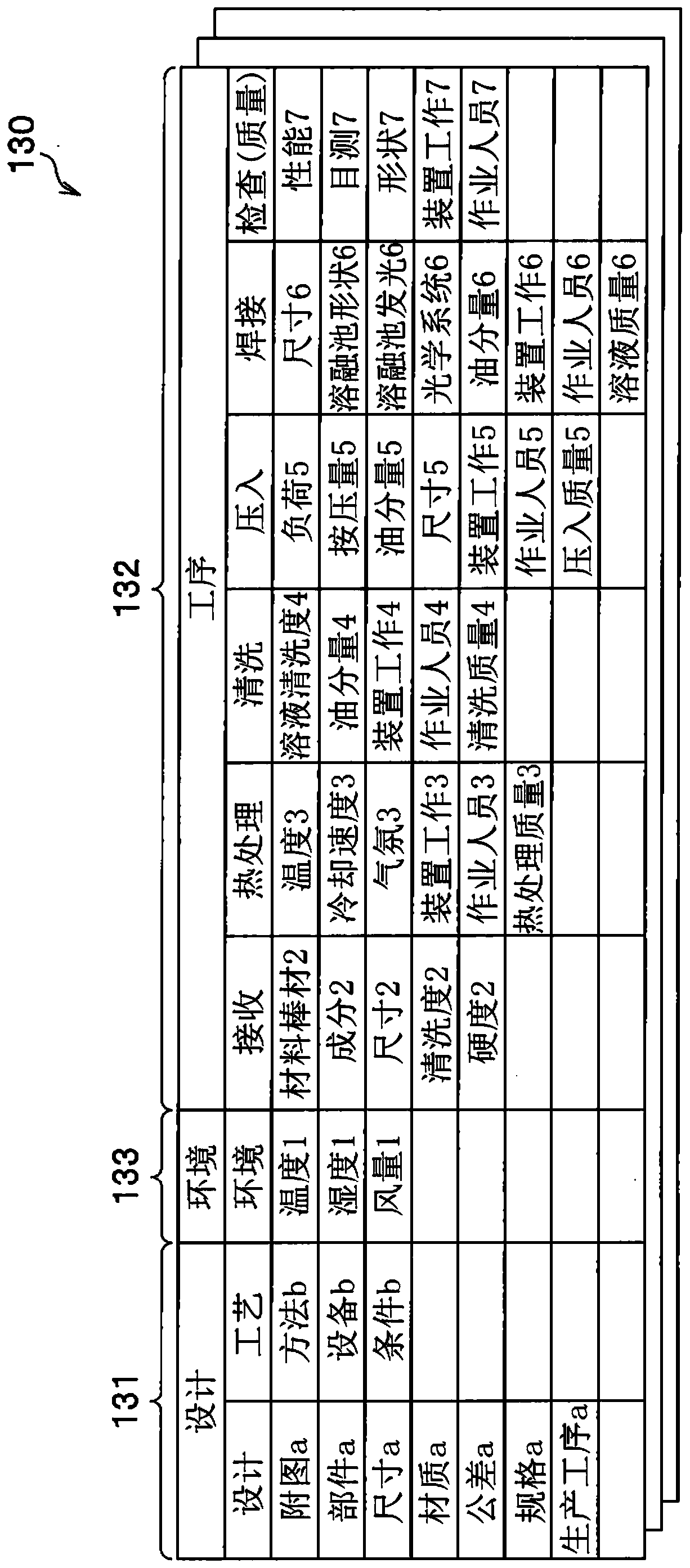

[0033] The quality control system A has a quality control device 1 and a production system 20 . The quality control device 1 is installed, for example, in a data center not shown.

[0034] The production system 20 has a receiving device 21 , a heat treatment device 22 , a cleaning device 23 , a pressing device 24 , a welding device 25 , and an inspection device 26 as devices for producing products.

[0035] That is, the production process carried out in the production system 20 begins with receiving, for example, two material rods by the receiving device 21 (receiving process), and after heat treatment by the heat treatment device 22 (heat treatment process), cleaning is performed by the cleaning device 23. process. Subsequently, the press-fitting device 24 presses the workpiece (press-fitting process), and th...

no. 2 approach

[0190] Next, refer to Figure 12 , the second embodiment of the present invention will be described.

[0191] Figure 12 It is a flowchart showing the procedure of the operating condition change process used in the second embodiment.

[0192] Figure 12 The processing of is performed offline, that is, when the production management system 20 is not working. and, Figure 12 The processing of steps S401 to S404 is the same as Figure 8 Since the processing in steps S212 to S215 is the same as that in Steps S212 to S215 , the description of the respective processing is omitted here.

[0193] According to the second embodiment, it is possible to reduce the influence on the production system 20 because it is the processing during the offline period.

[0194] In addition, in progress Figure 12 In the case of the processing shown, it may or may not be performed Figure 8 The processing of steps S212 to S215.

[0195] Moreover, in Figure 12 Before the processing of step S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com