Tool changing arm of automatic tool replacing mechanism

A technology of automatic tool changing and tool changing arm, applied in the field of tool changing arm, can solve the problems such as difficulty in reducing the total length of the rotating body 2, disadvantageous automatic tool changing mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

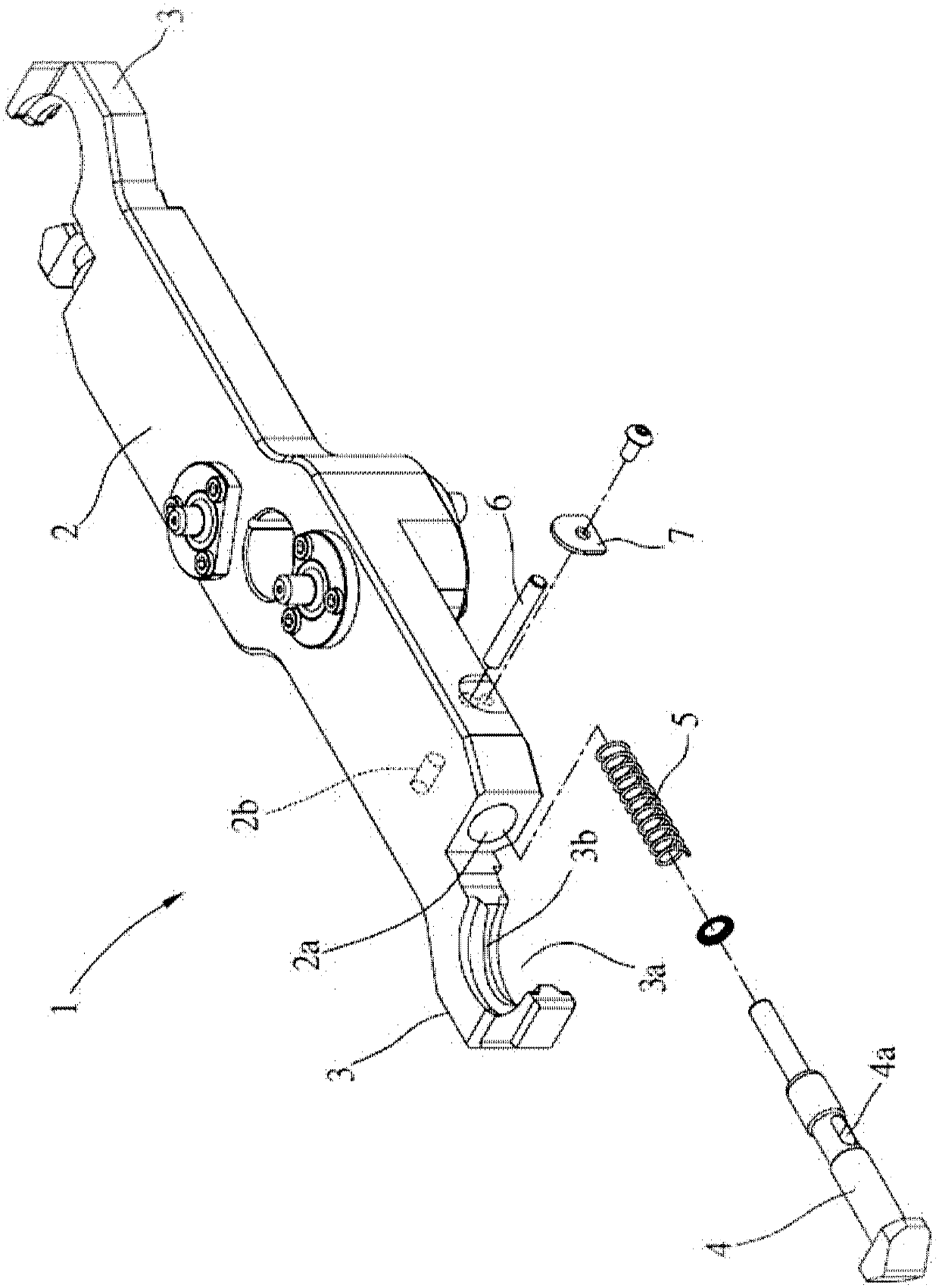

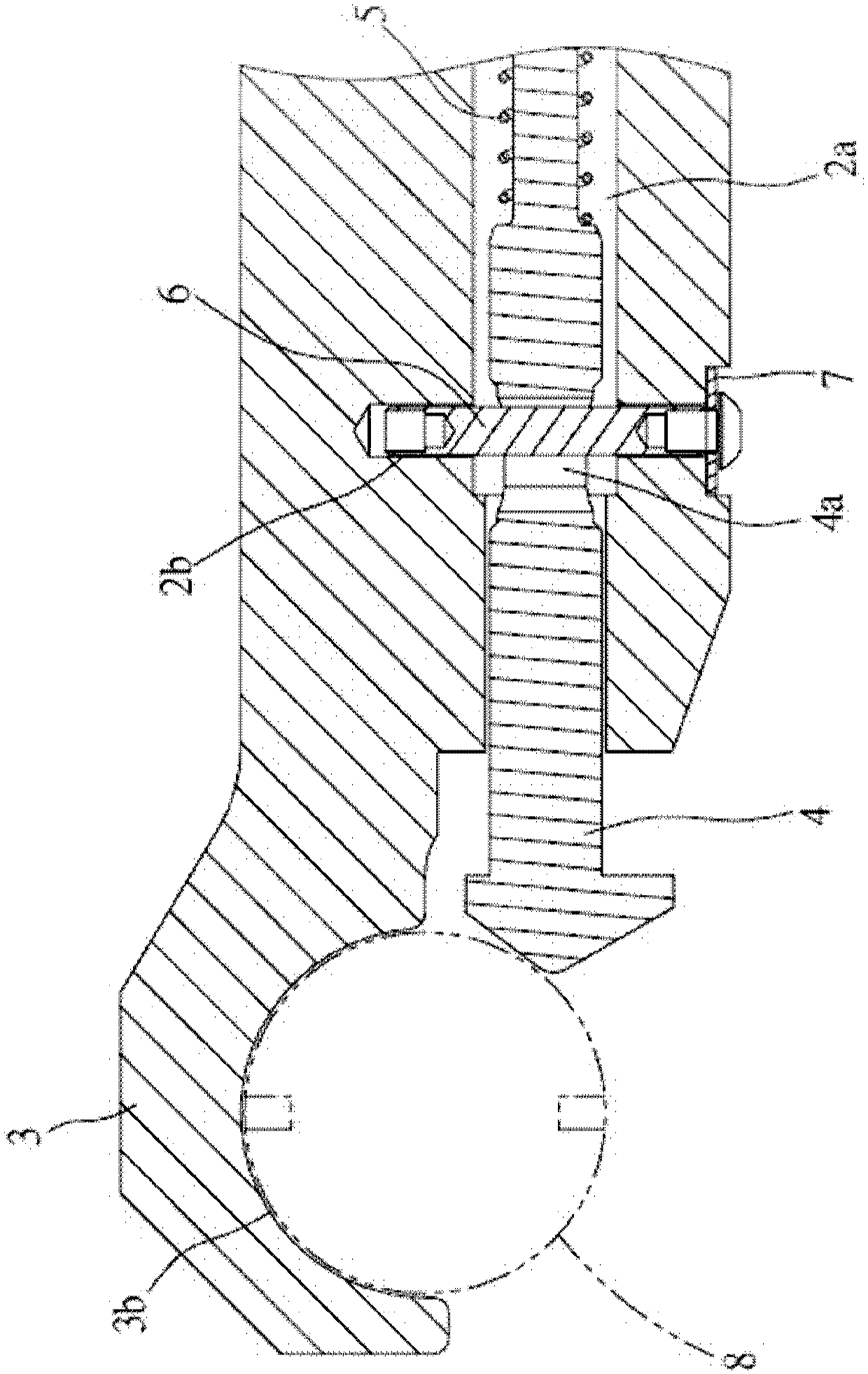

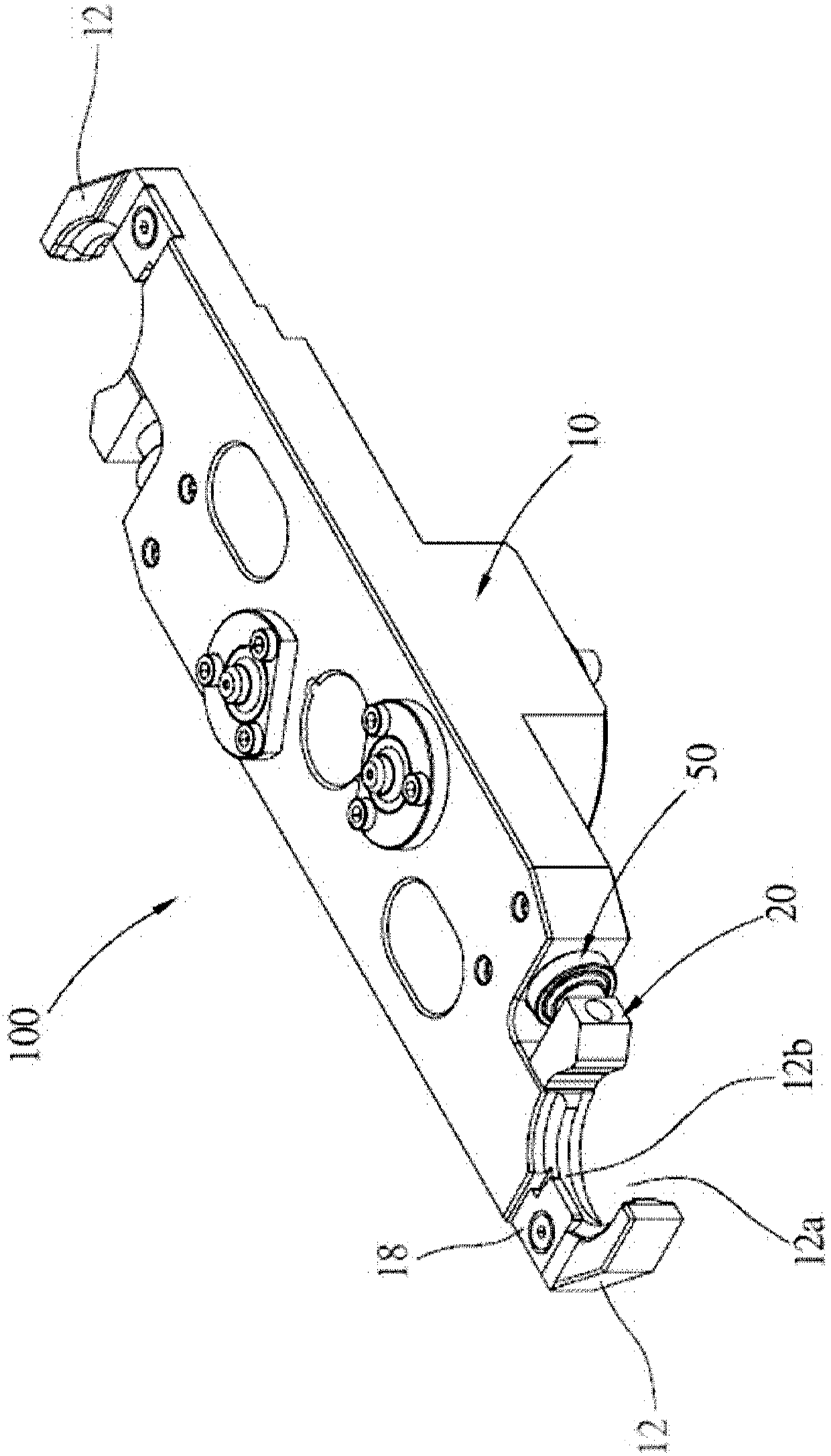

[0031] In order to illustrate the present invention more clearly, a preferred embodiment is given below and described in detail with accompanying drawings. Please refer to Figure 3 to Figure 5 Shown is a tool change arm 100 of an automatic tool change mechanism according to a preferred embodiment of the present invention, which includes a rotating body 10 , two abutting components 20 , two elastic components 30 and two limiting components 40 . The rotating body 10 is connected to the driving device through a rotating shaft (not shown in the figure) and is controlled to rotate. The driving device is a known technology and will not be repeated here. The rotating body 10 takes the connecting shaft as the center of rotation, which refers to the central part of the rotating body 10 in this embodiment.

[0032] The rotating body 10 has a tool buckle part 12 on both sides of the rotation center, which is respectively used to buckle the tool holders of the tool magazine and the mach...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap