Robot and material grabbing device thereof

A technology for grabbing devices and materials, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., and can solve the problems of tilting and sliding of materials, easy sliding of upper materials outside the compartment, waste of compartment space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The utility model will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the utility model. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

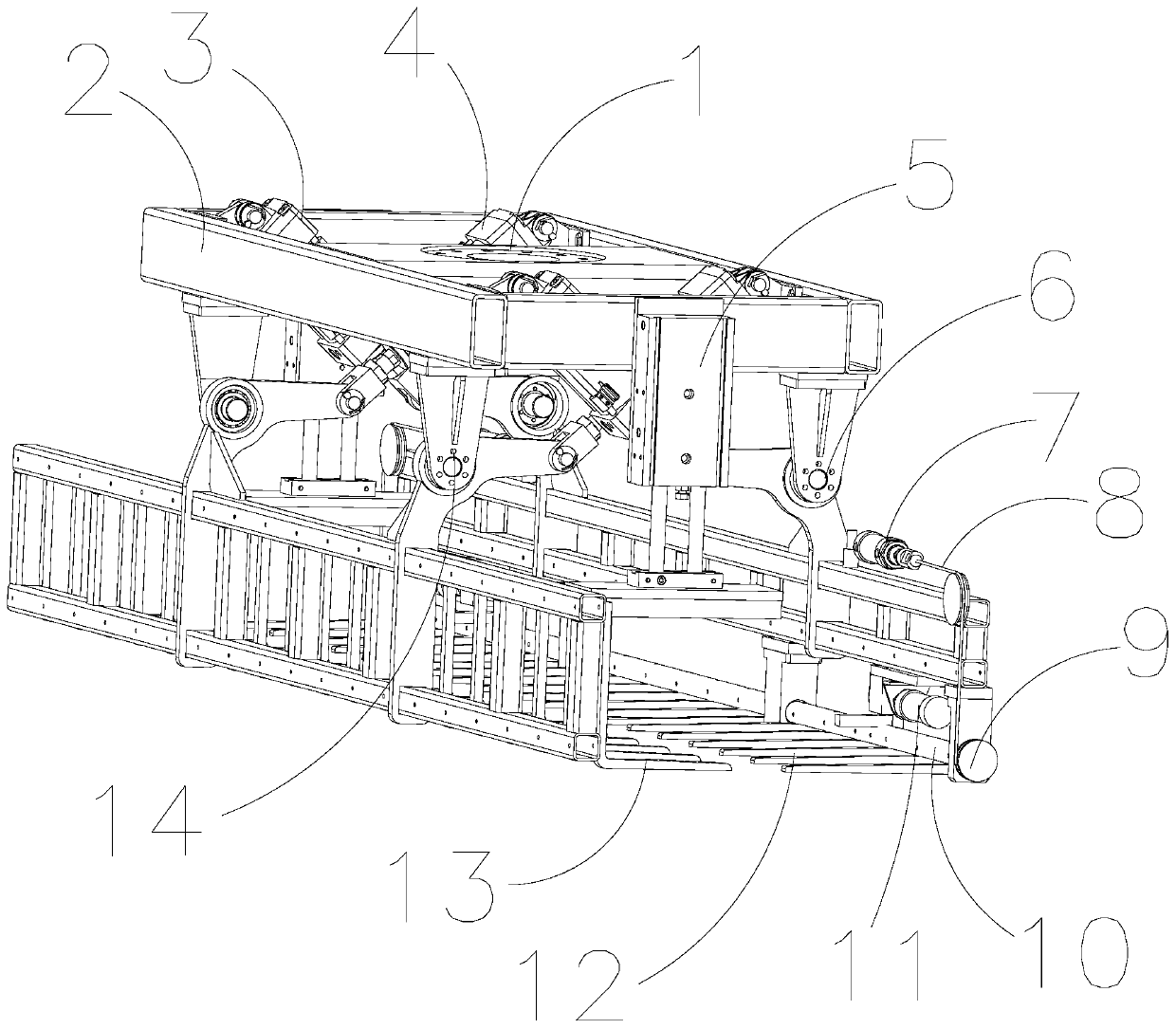

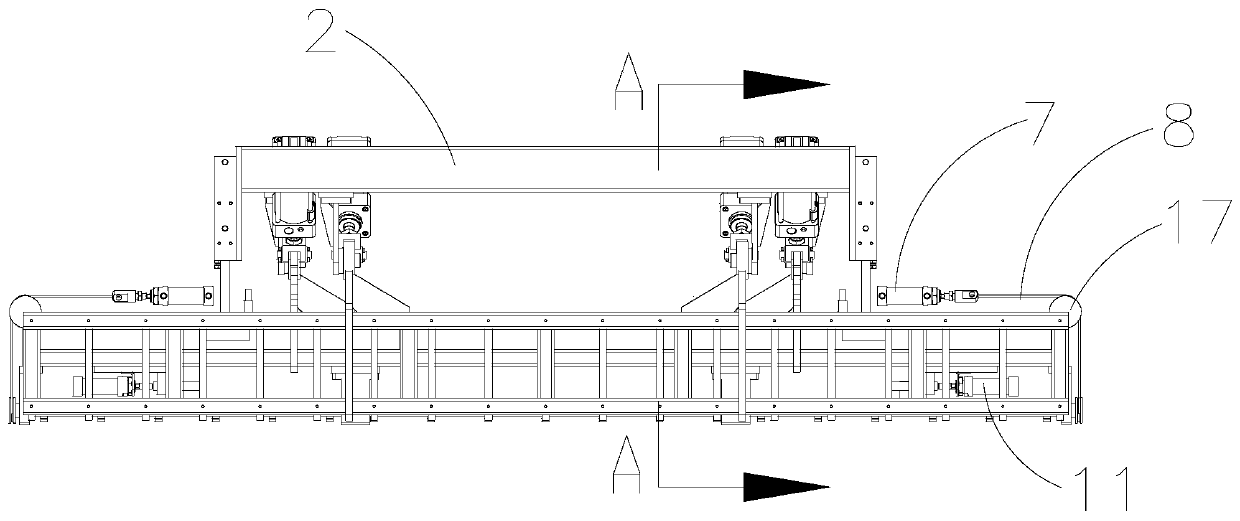

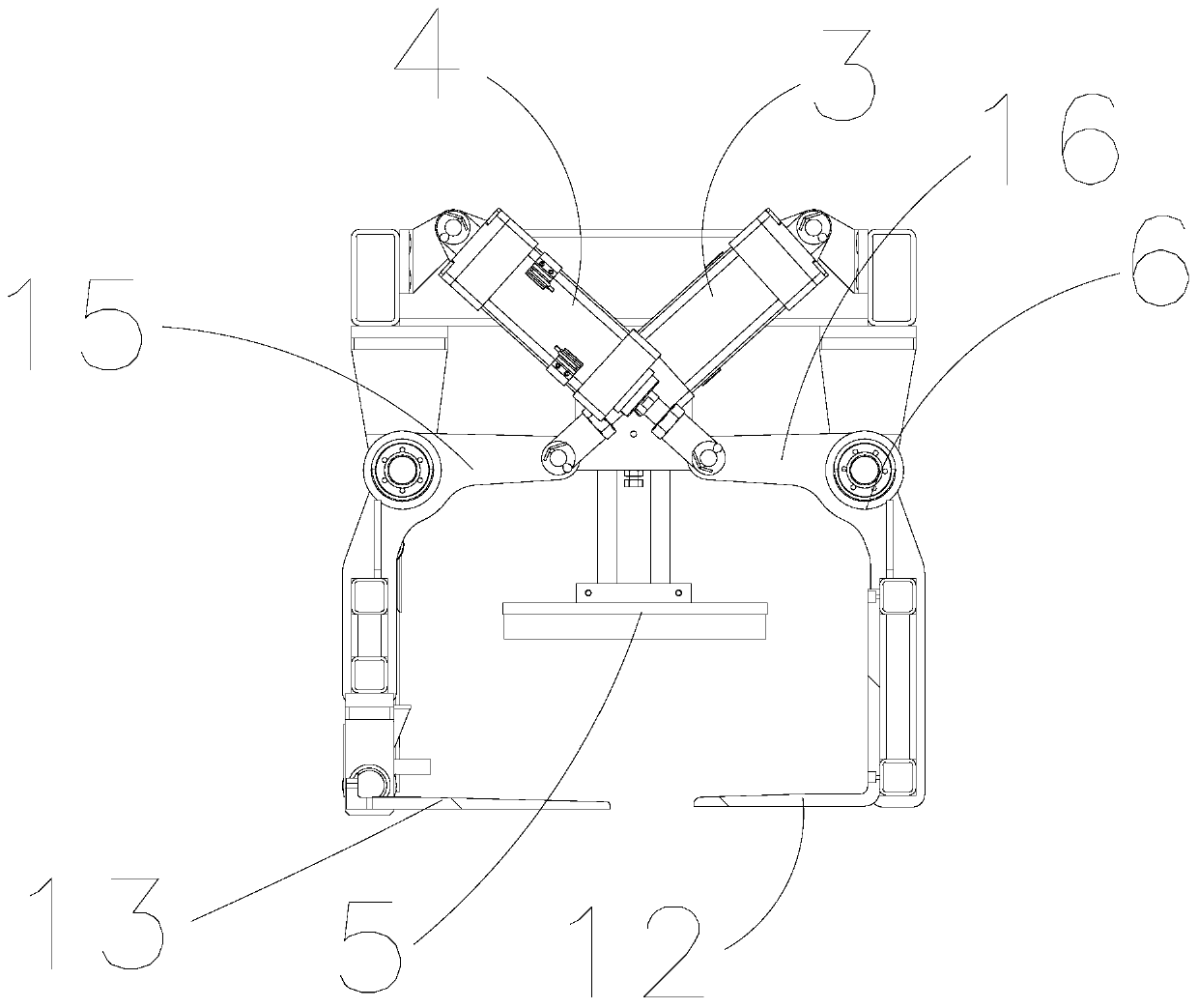

[0031] The utility model embodiment is as follows, please refer to Figure 1 to Figure 5 The material grabbing device shown is used to grab bagged objects, and specifically includes a frame 2, which is provided with a first gripper 12 and a second gripper 13 oppositely arranged on the frame 2, and the first gripper 12 includes a first gripper 12 A link frame 15 and a plurality of first grasping teeth detachably arranged on the first link frame 15, the second gripper 13 includes a second link frame 16 and detachably arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com