A method for adjusting and controlling the roll gap of a roller press

A control method and technology of a roller press, which are used in the adjustment and control of the roller gap of a roller press for cement production, and the field of grinding production systems, which can solve the problem of not being able to adjust and control the roller gap, the roller gap deviation of the roller press, etc. problems, to achieve a more controlled effect of the production state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The present invention will be further described in detail through the embodiments below in conjunction with the accompanying drawings.

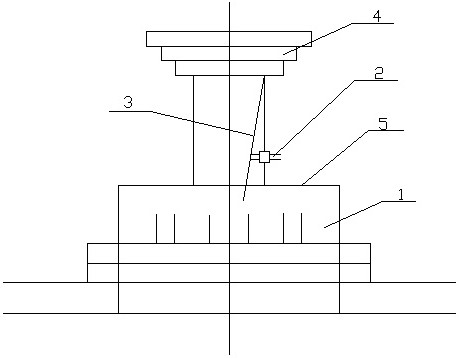

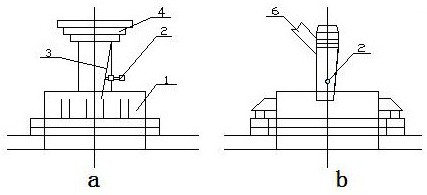

[0065] as attached figure 2 As shown, the specification and model of the roller press in this embodiment is HFCG160×140, the maximum design throughput is 900 tons, the weighing bin 1 is a round bin with a diameter of 2.2 meters, the actual production capacity is 180 tons / hour, and the cycle load rate is 350%. It is known that the bulk density of materials used in this embodiment is 1.35 tons / meter 3 , Weighing bin 1 feeding chute 4 is the case where the feeding direction of the mixed material in the batching station intersects obliquely with the direction of the roll gap.

[0066] Firstly, check the position of the blanking point and the segregation situation in different positions of the weighing bin 1. The deviation between the blanking point and the center of the bin is large, and sometimes the material rushes to the side wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com