A yarn output device in a high-strength wear-resistant air-jet vortex spinning yarn processing device

A technology of vortex spinning and thread processing, which is applied to spinning machines, open-end spinning machines, continuous winding spinning machines, etc. Single problem, to achieve the effect of small footprint and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below by means of the accompanying drawings and examples.

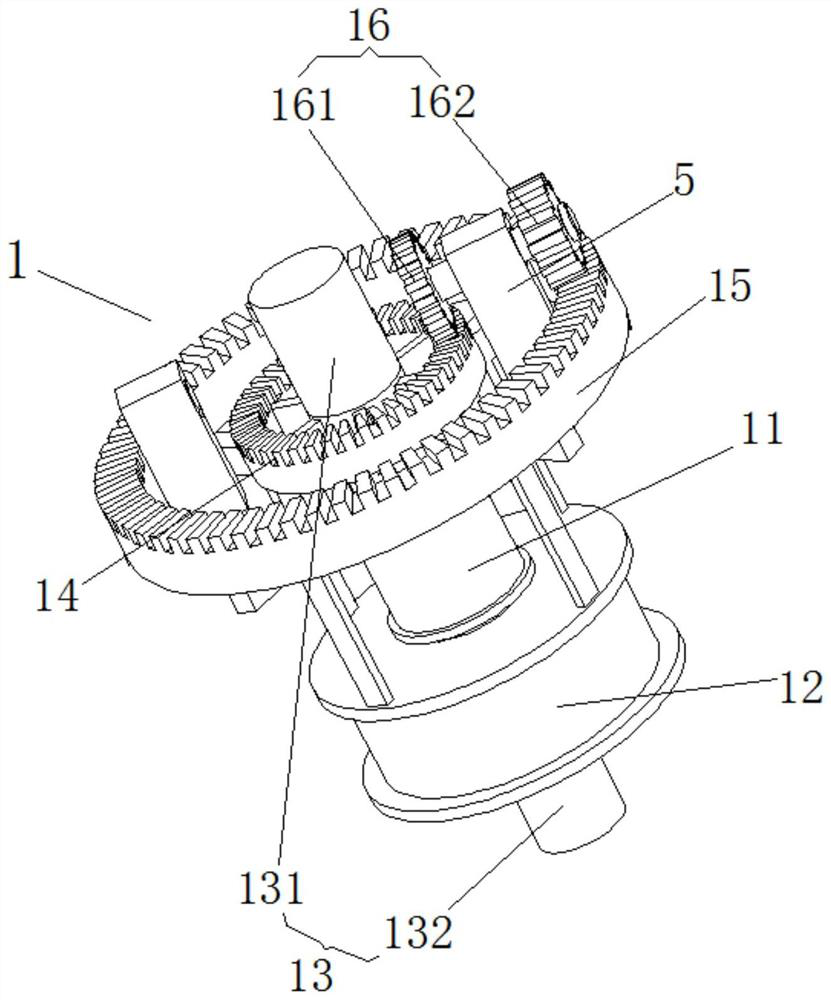

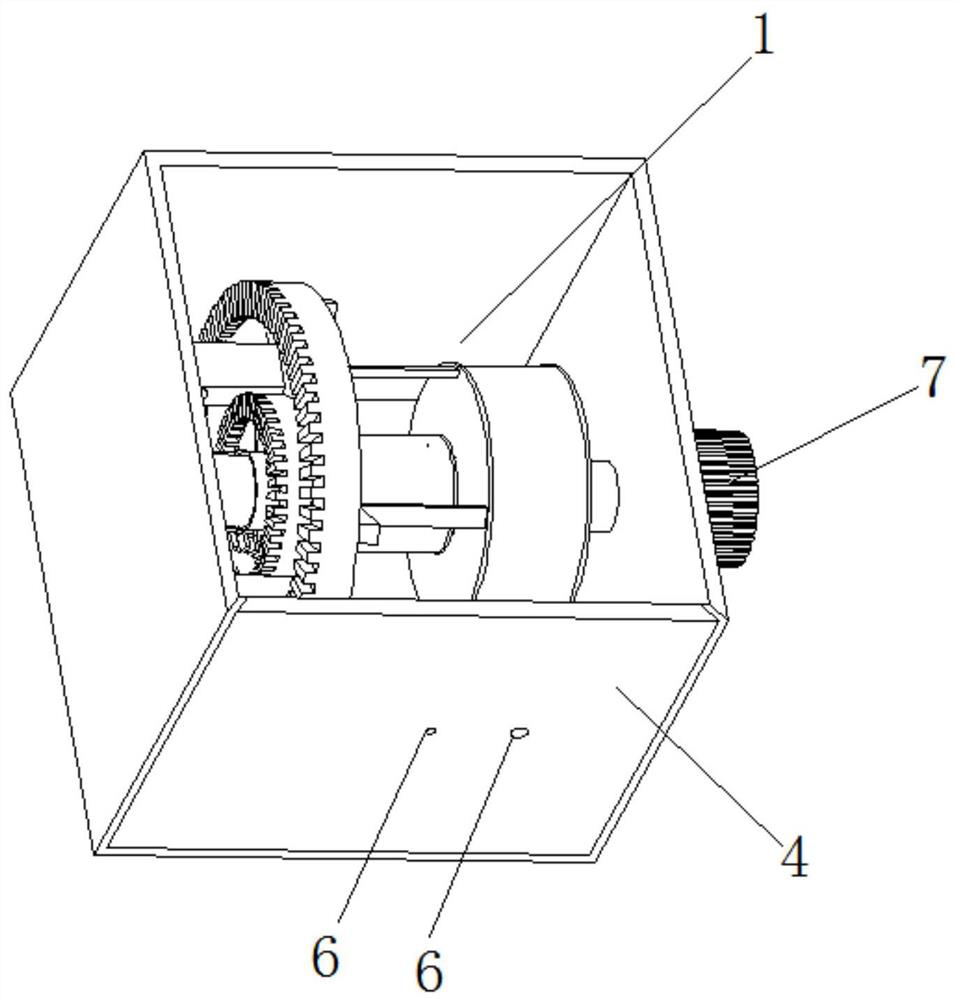

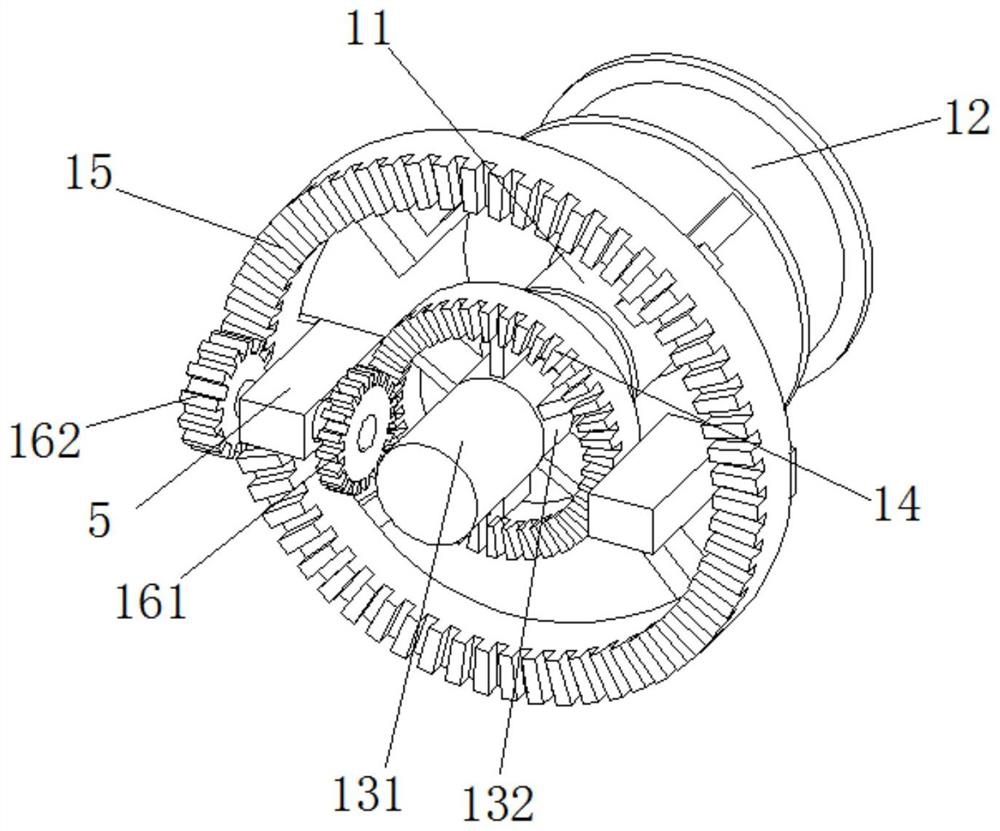

[0024] Such as Figure 1-5 Shown: a yarn output device in a high-strength wear-resistant air-jet vortex spinning yarn processing device, including a yarn output frame 11 for low-melting fiber 2, a yarn output frame 2 12 for ordinary fibers 3, a transmission rod 13, and an output frame Creel one 11 links to each other interlocking gear seat one 14, the interlocking gear seat two 15 that links to each other with creel two 12, transmission gear 16. Transmission bar 13 runs through interlocking gear seat one 14 and interlocking gear seat two 15, and its one side links to each other with motor 7, and the other side links to each other with interlocking gear seat one 14 by connecting rod. The transmission gear 16 can drive the linkage gear seat one 14 and the linkage gear seat two 15 simultaneously.

[0025] The transmission rod 13 includes a connected telescopic rod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap