Porcelain plate and stone dry hanging hardware component

A stone dry-hanging and porcelain plate technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of poor adaptability, large distance from the wall, etc., and achieve the effect of easy splicing and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

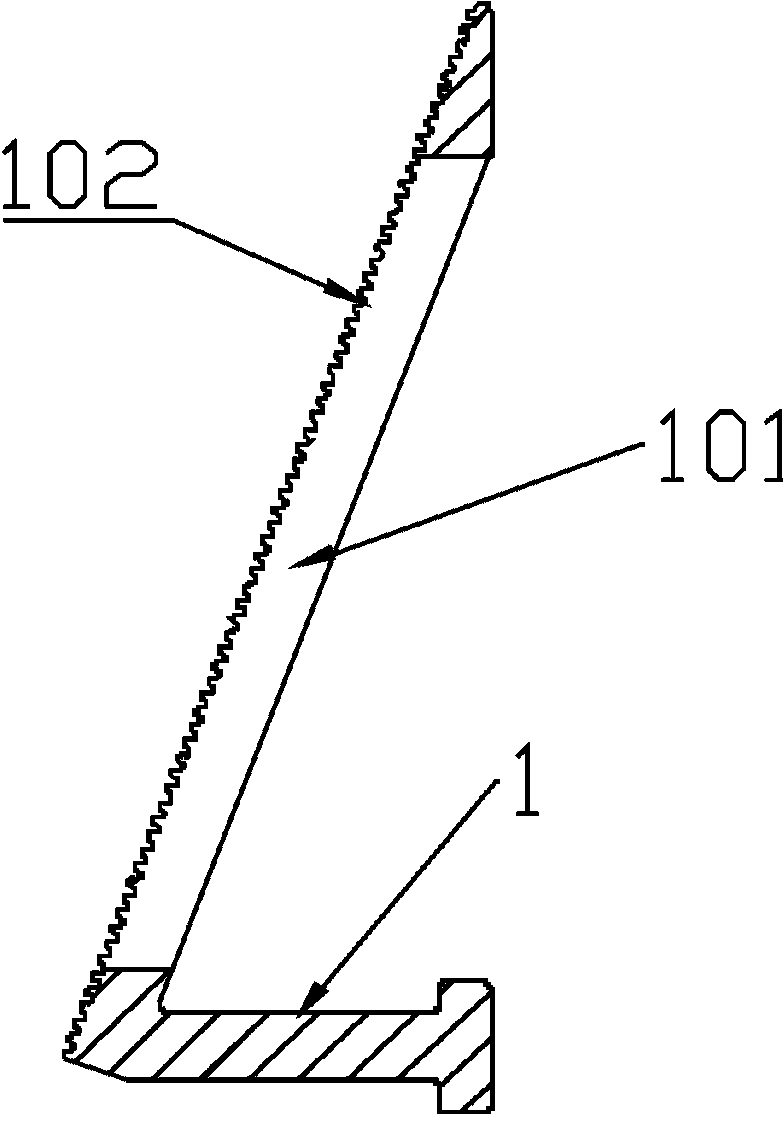

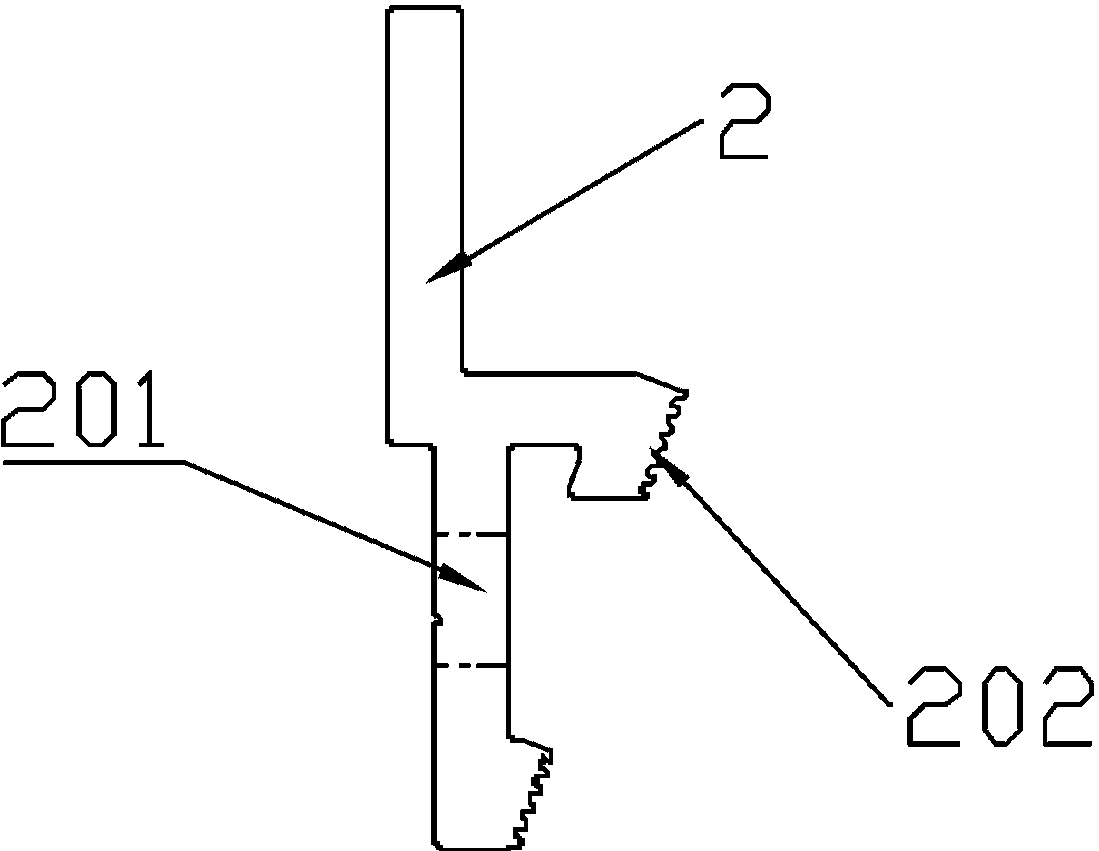

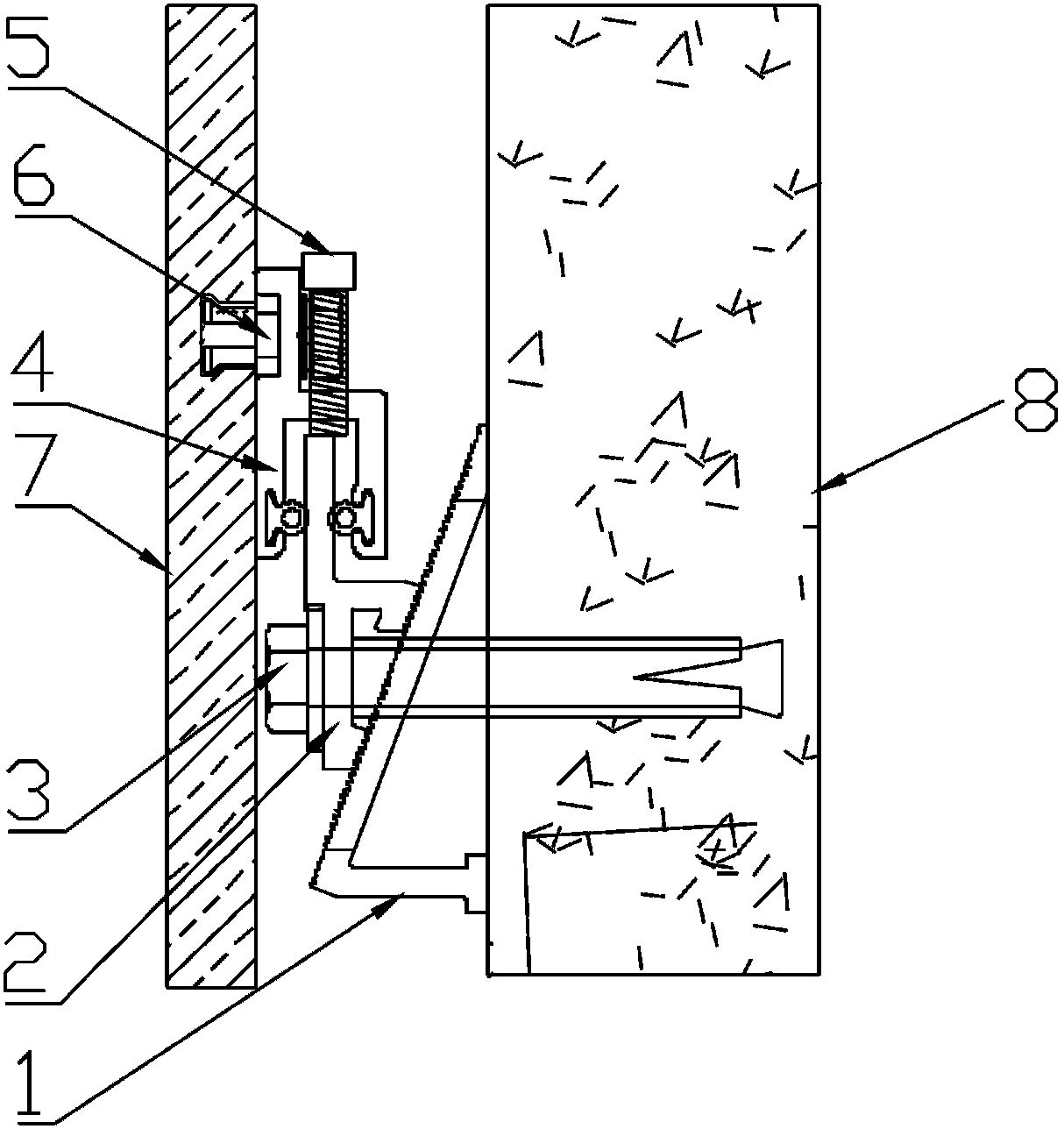

[0020] see Figure 1-3 , in an embodiment of the present invention, a porcelain plate and a stone dry-hanging hardware component include a bearing 2; a wedge-shaped spacer 1 abuts against the lower part of the bearing 2, and the wedge-shaped spacer 1 and the bearing 2 are connected in series through expansion bolts , the bearing part 2 is provided with a bolt hole 201, and the wedge-shaped pad 1 is provided with a waist hole 101 arranged along the slope of the wedge-shaped pad 1. During specific use, the expansion bolts pass through the bolt hole 201 of the bearing part 2 and the wedge-shaped pad in sequence. The waist hole 101 of 1 is embedded in the wall 8 to realize the abutment and fixation between the bearing part 2 and the wedge-shaped pad 1. The outer end surface of the wedge-shaped pad 1 is provided with a bearing anti-skid groove 102, and the lower end surface of the bearing part 2 is provided with a load-bearing anti-skid groove. 102 cooperates with the abutment anti...

Embodiment 2

[0022] The difference between this embodiment and Embodiment 1 is that a pendant 4 is clamped above the carrier 2, the pendant 4 is fixedly connected with a porcelain plate 7 through a fixing bolt 6, the pendant 4 runs through an adjusting screw 5, and the adjusting screw 5 and the pendant 4 Threaded connection, the lower end of the adjustment screw 5 abuts against the carrier 2, by turning the adjustment screw 5, the depth of the pendant 4 is changed, and then the fine adjustment of the height of the porcelain plate 7 can be realized, which is convenient for the entire surface to be mounted on each porcelain on the wall. Adjust the joint position of the board to improve the flatness of the mount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com