Hydraulic lash adjuster assembly sleeves

A technology of gap adjuster and casing, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

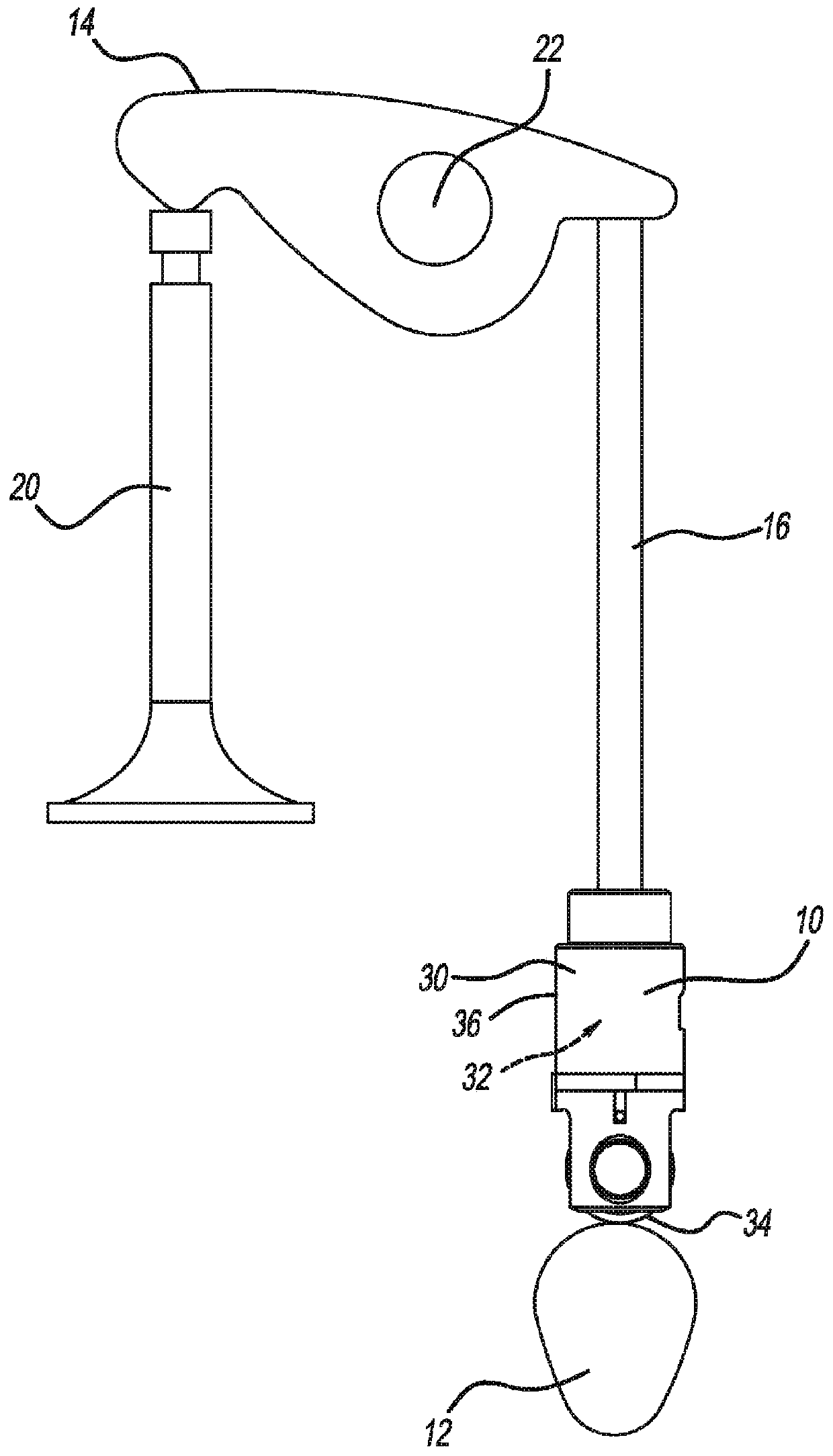

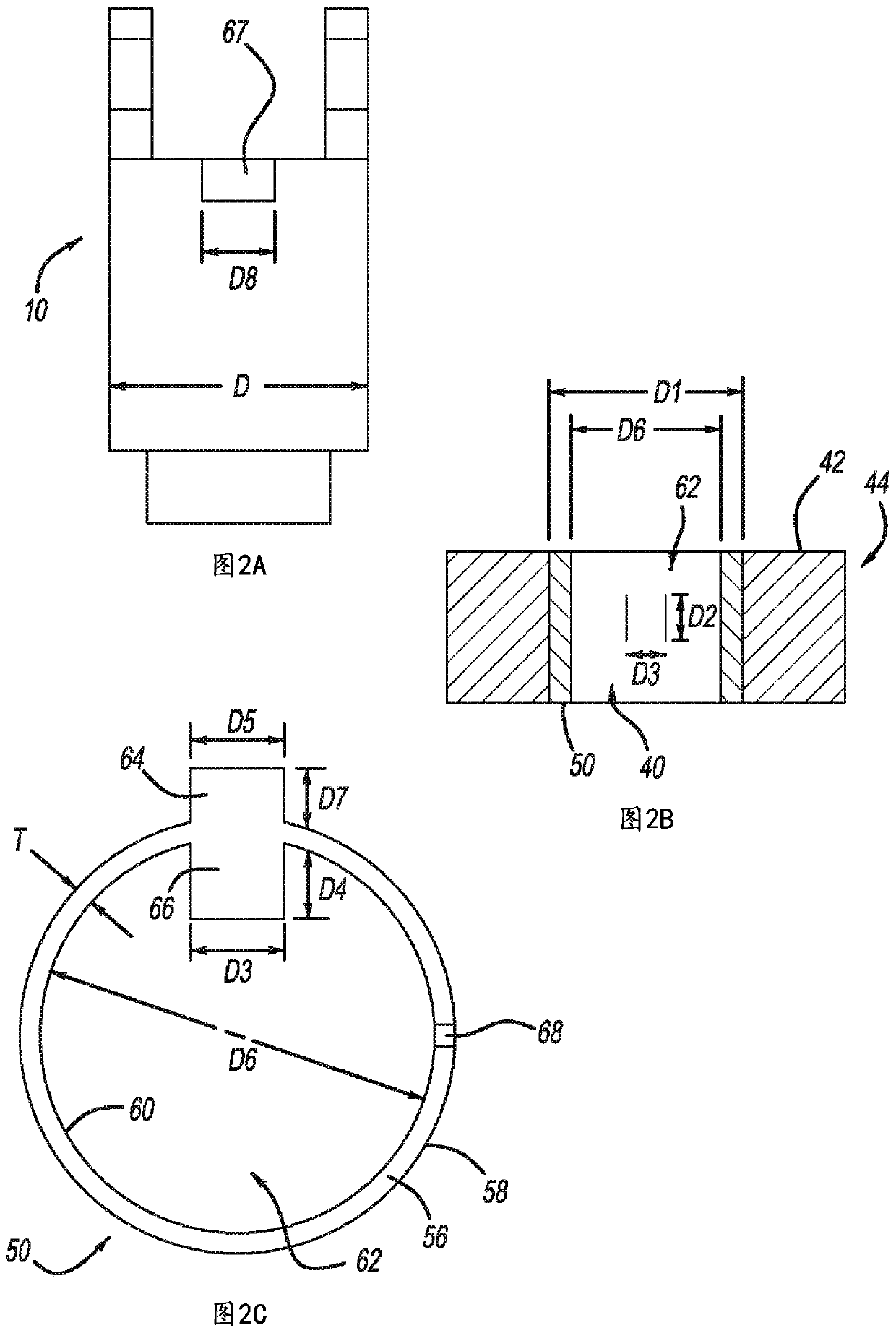

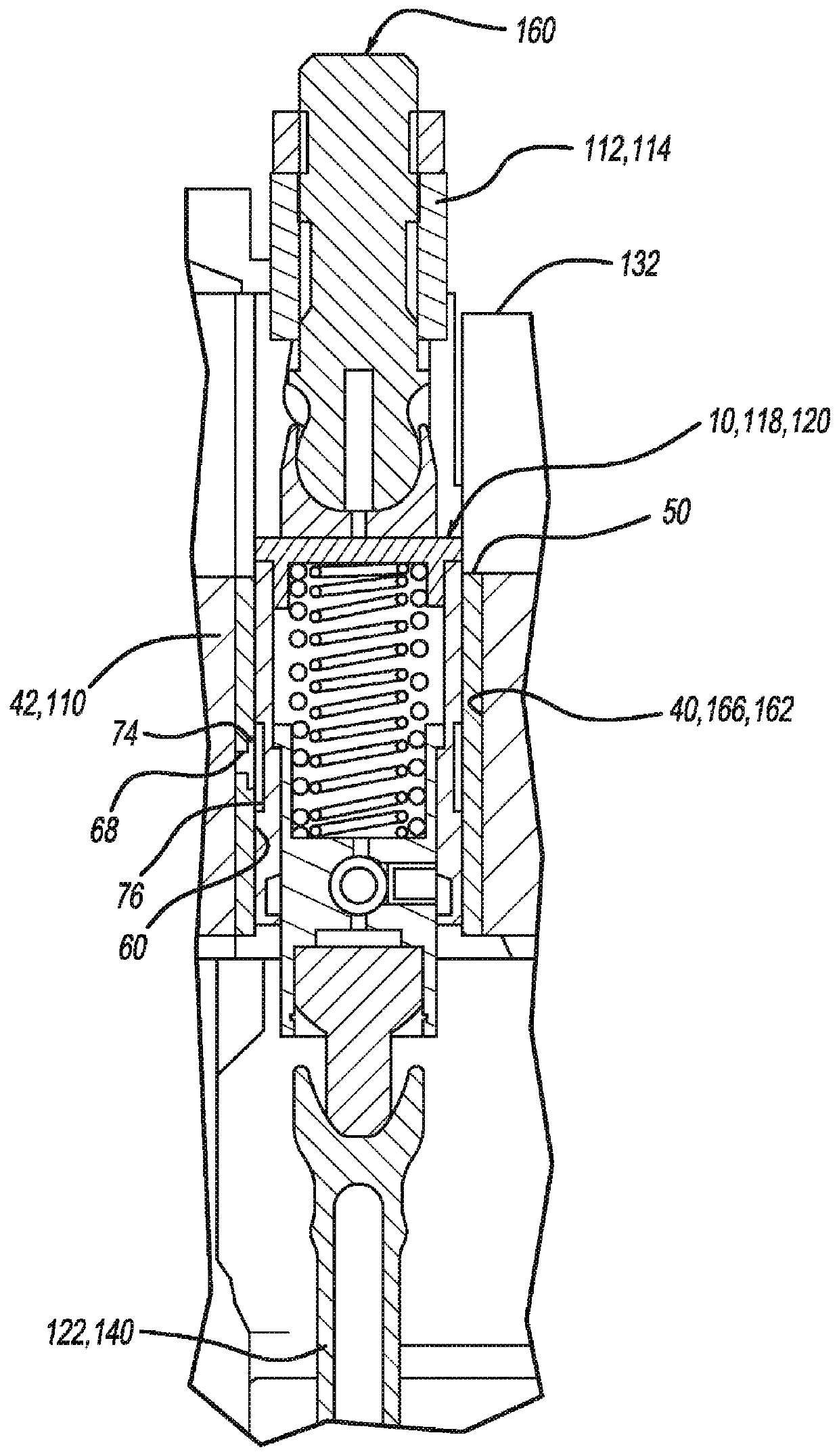

[0024] first reference figure 1 , shows a hydraulic lash adjuster (HLA) roll lifter constructed in accordance with one example of the present disclosure and is generally identified with reference numeral 10 . The roll lifter 10 is shown as part of a V-train arrangement. It should be understood, however, that although shown in a V-shaped arrangement, it is within the scope of the present disclosure that the various features described herein be used in other arrangements. In this regard, the features described herein associated with the valve train arrangement 10 may be suitable for a variety of applications. The cam lobe 12 indirectly drives the first end of the rocker arm 14 with a push rod 16 . It should be understood that in some configurations, such as an overhead cam, the roller lifter may be a direct connection between the cam lobe 12 and the rocker arm 14 . The second end of the rocker arm 14 actuates the valve 20 . As the cam lobe 12 rotates, the rocker arm 14 pivot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com