A sorting device for shredded stems

A sorting device and sorting technology, applied in the field of tobacco machinery, can solve the problems of uneven width direction of cut tobacco, uneven distribution of cut stems in the sorting channel, and influence on cigarette production speed, so as to improve uniformity and production speed , to ensure the effect of balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

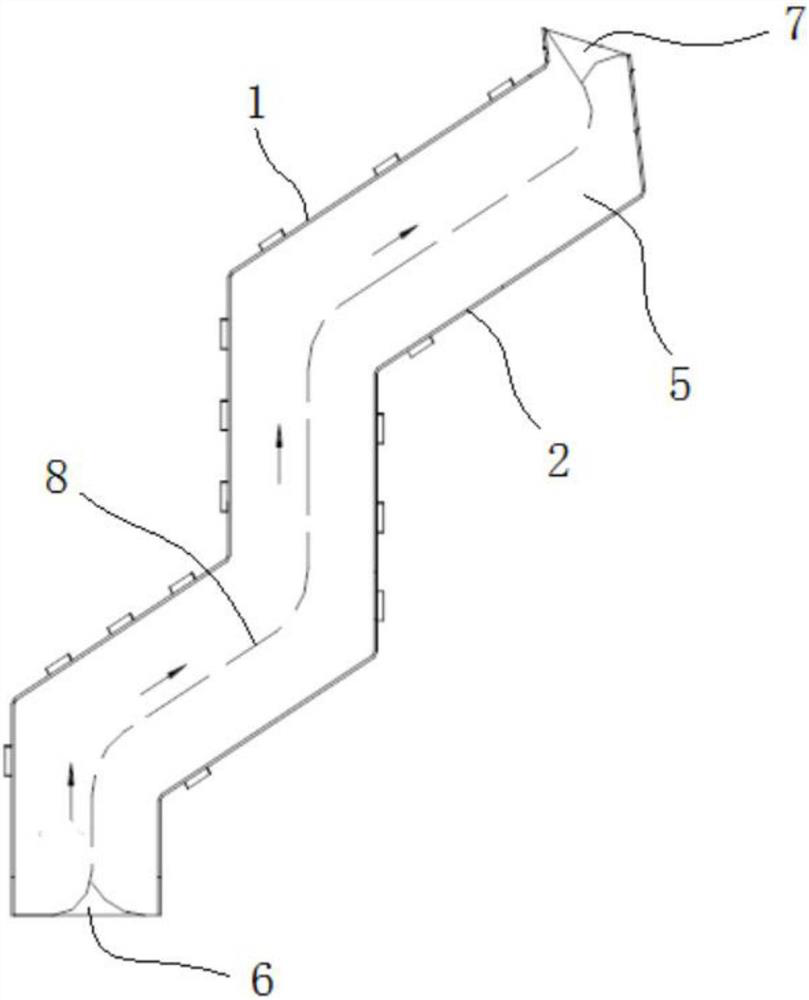

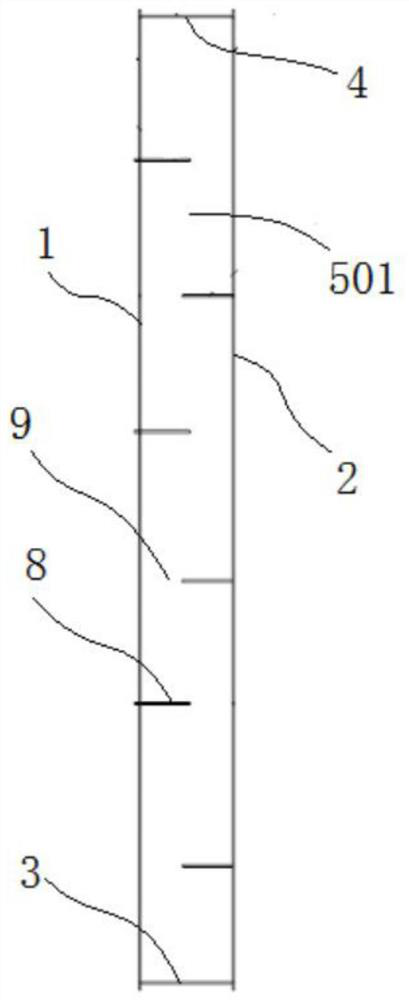

[0020] see figure 1 and figure 2 , figure 1 and figure 2 A specific embodiment of the cut stem sorting device is provided, wherein, figure 1 It is a schematic diagram of the overall structure of the cut stem sorting device provided in Example 1 of the present invention; figure 2 It is a top view of the cut stem sorting device provided in Example 1 of the present invention;

[0021] Such as figure 1 and figure 2 As shown, the present invention provides a specific embodiment of a cut stem sorting device, which can realize the sorting of shredded tobacco with high quality and high efficiency.

[0022] In this solution, the cut stem sorting device includes a front baffle 1 at the front, a rear baffle 2 at the rear, a left side 3 on the left and a right side 4 on the right, the front baffle 1. A sorting passage 5 is formed around the rear baffle 2, the left side plate 3, and the right side plate 4, and the sorting passage 5 is used to provide a working space for removing...

Embodiment 2

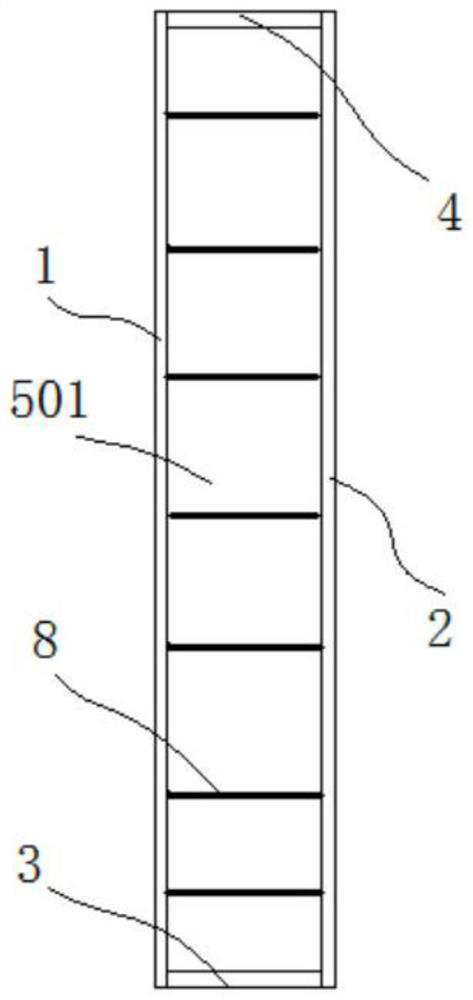

[0028] see image 3 and Figure 4 , image 3 and Figure 4 A specific embodiment of the cut stem sorting device is provided, wherein, image 3 It is a top view of the cut stem sorting device provided in Example 2 of the present invention; Figure 4 It is a schematic structural diagram of the separator provided in Example 2 of the present invention.

[0029] Other parts of this embodiment are the same as Embodiment 1, the difference is:

[0030] The front end surface of the partition 8 is connected to the front baffle 1, the rear end surface of the partition 8 is connected to the rear baffle 2, and the partition 8 is provided with air guide holes 10 for ventilation. .

[0031] In this way, the sorting passage 5 can be divided into a plurality of independent sorting chambers 501 through the partition plate 8 itself, and the air flow between the sorting chambers 501 can be realized through the air guide hole 10, so as to overcome the deflection characteristics of the cut st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com