Pipe connector for connecting two pipe sections

A technology of connectors and pipe sections, applied in the field of heat exchangers, can solve problems such as incorrect assembly of pipe connectors, and achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

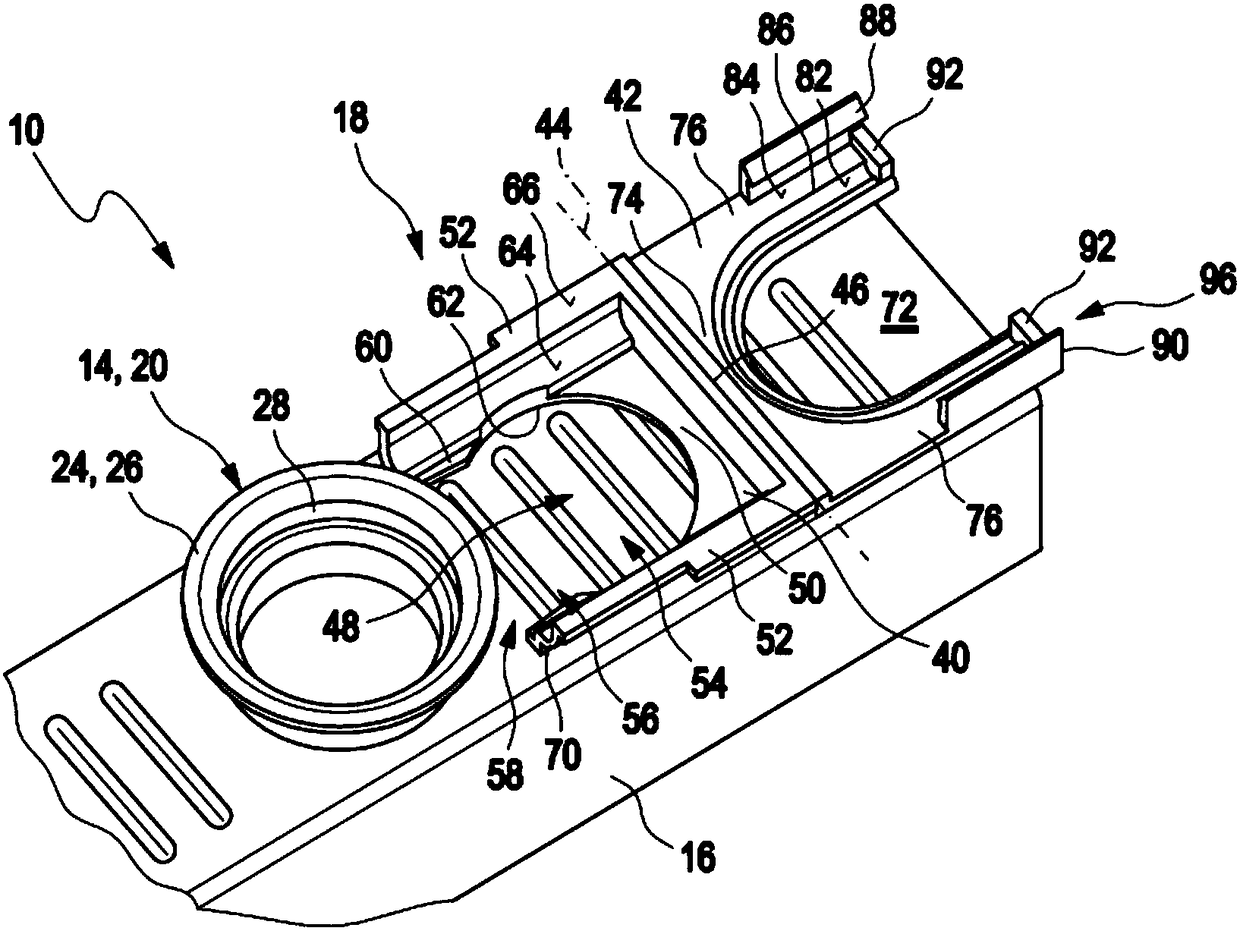

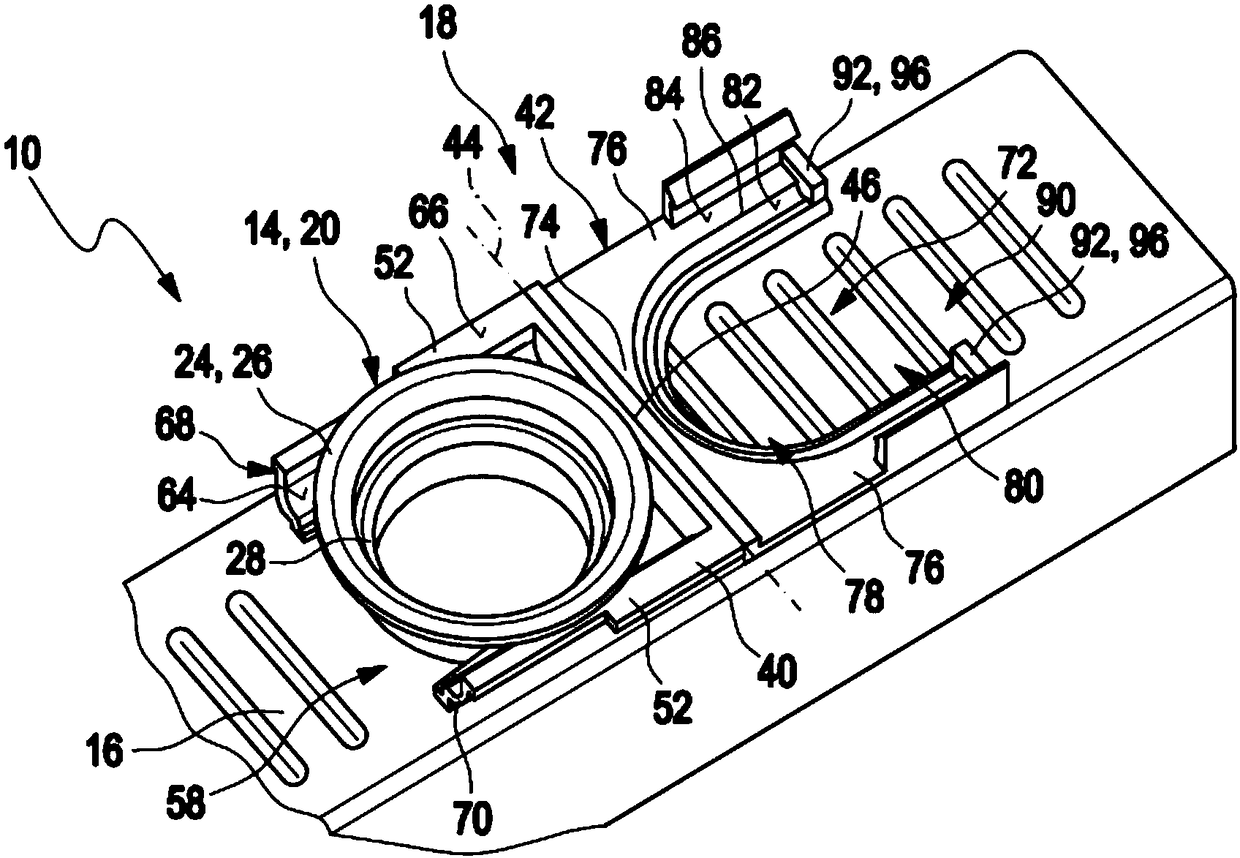

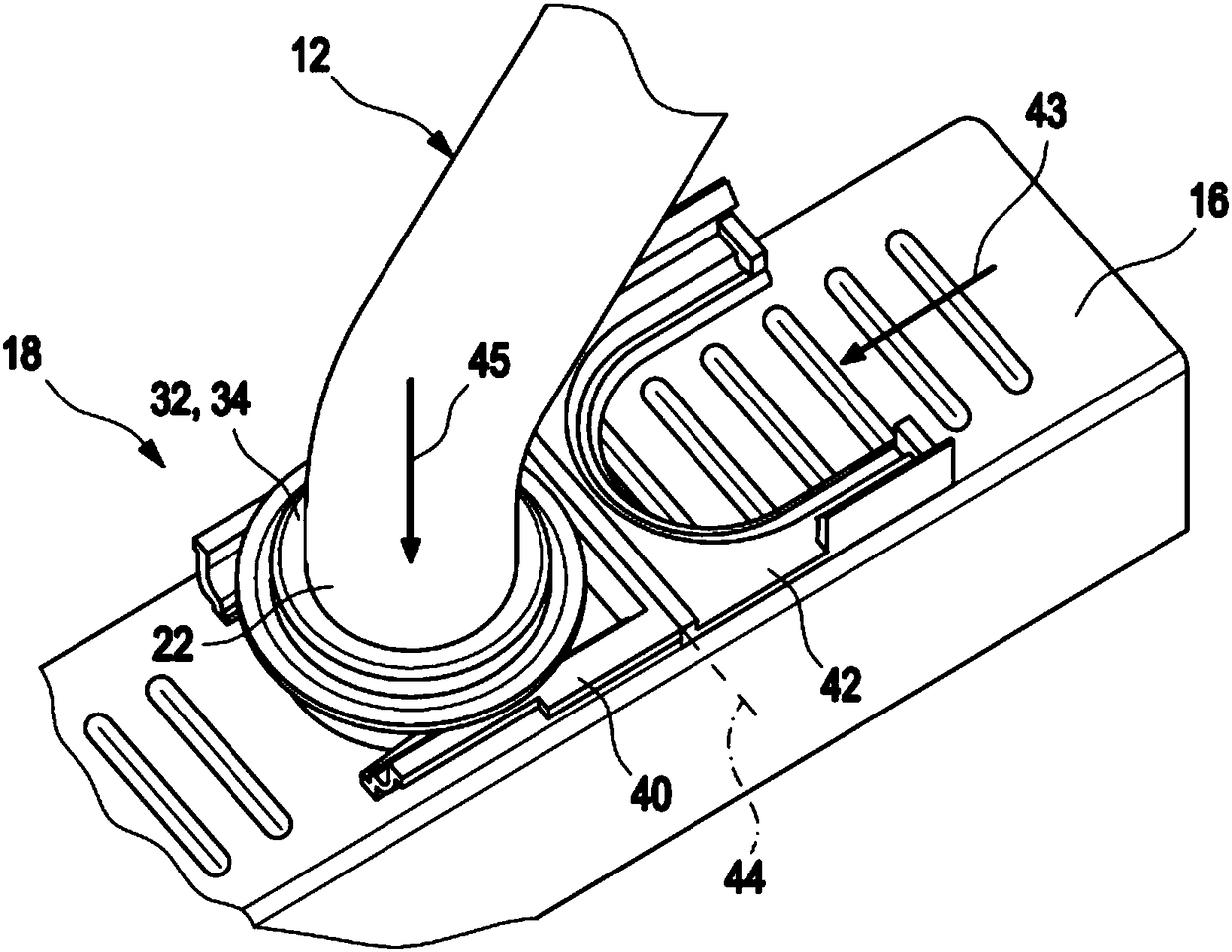

[0035] exist Figure 1 to Figure 5The embodiment of the tube connection 10 shown in can be used, for example, to connect a tube 12 , such as a feed tube, to a tube assembly 14 of a heat exchanger 16 . The pipe connection 10 has a pipe connector 18 which connects a first pipe section 20 with a second pipe section 22 . The first pipe section 20 corresponds to the tube assembly 14 of the heat exchanger 16 and the second pipe section 22 corresponds to the tubes 12 .

[0036] The first pipe section 20 has a connecting flange 24 which preferably has a connection 26 extending in its circumferential direction. A ring joint 26 is arranged at the free end of the pipe section 20 . A radially flared area 28 extending outwardly from the annular joint 26 is designed to receive a sealing element 30 .

[0037] The second pipe section 22 has a connecting flange 32 which preferably has the form of a collar 34 and is located at a distance from an end 36 of the second pipe section 22 . This f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com