Diamond rope saw joint pressing clamp

A technology of diamond wire saw and die, applied in the field of crimping pliers, can solve the problems of damage, complicated operation of crimping device, extrusion deformation of die base, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

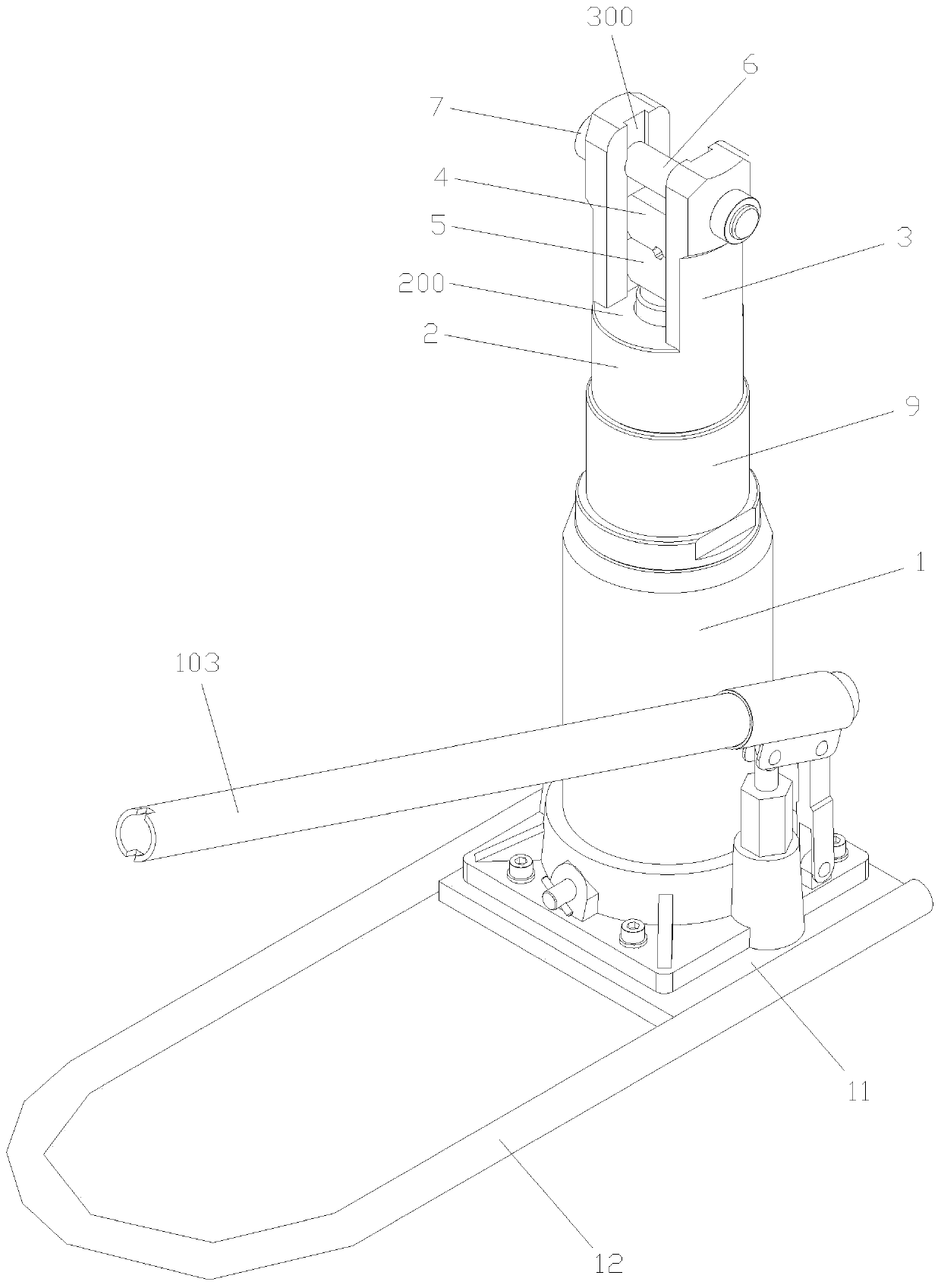

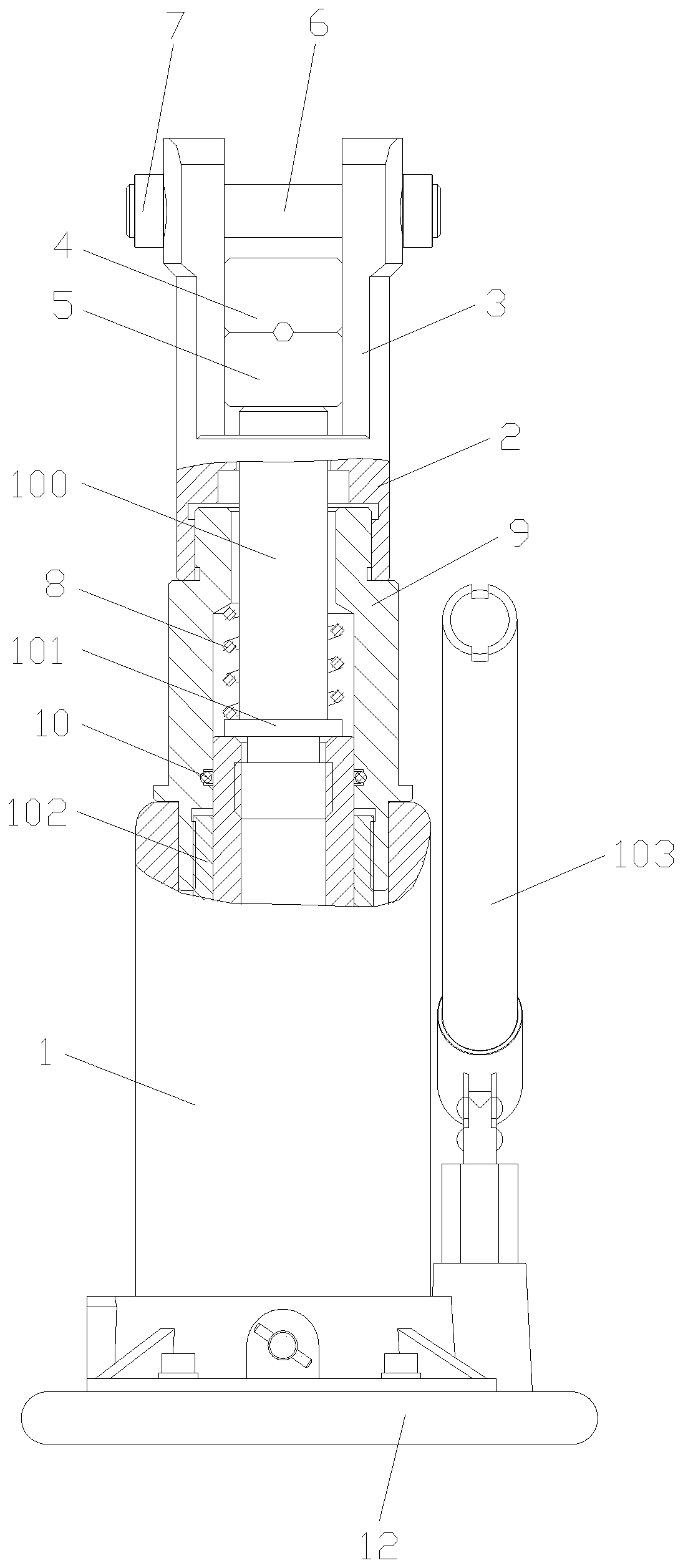

[0037] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0038] see figure 1 , the present invention provides a diamond wire saw joint press pliers, which is used for crimping the diamond wire saw terminal, so that the diamond wire saw forms a closed loop, especially the diamond wire saw can be crimped to the tension required for its work, In addition, there is no need to disassemble the entire device during use, only part of the device needs to be disassembled, the operation is simple and efficient, and the components will not be distorted and damaged during the operation.

[0039] In a specific embodiment, the diamond wire saw joint press pliers include a hydraulic jack 1, a clamp head seat, an upper die 4, a lower die 5 and a limiting member. The hydraulic jack 1 is used to provide extr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap