Conductive assembly and connection structure between conductive members

A technology of conductive components and connection structures, applied in the direction of connection where permanent deformation plays a role, can solve problems such as uneven electric field and uneven connection, and achieve the effect of avoiding electric field changes and improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

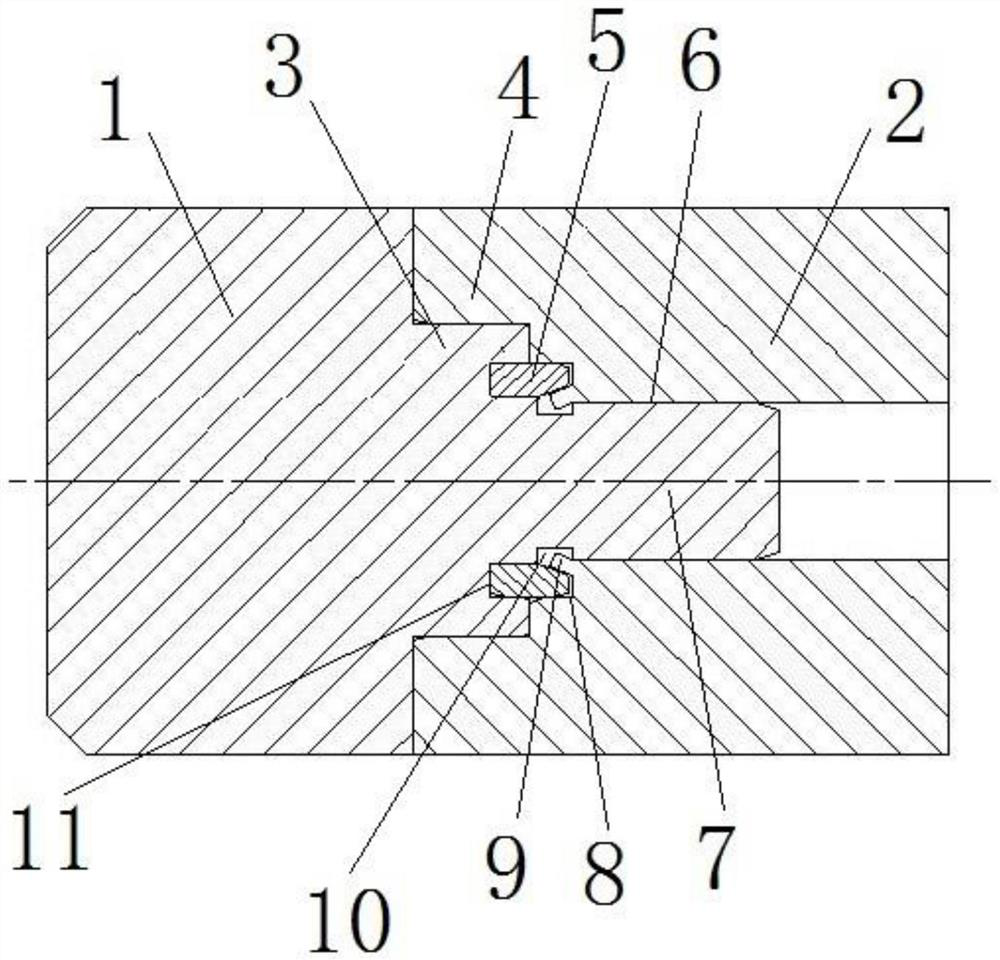

[0058] Such as figure 1 As shown, the connection structure between the conductive parts is formed by assembling the conductive components, and the conductive components include the second conductive part 2 and the first conductive part 1 . In this embodiment, the first conductive member 1 is the joint of the conductive rod, and the second conductive member 2 is the body of the conductive rod.

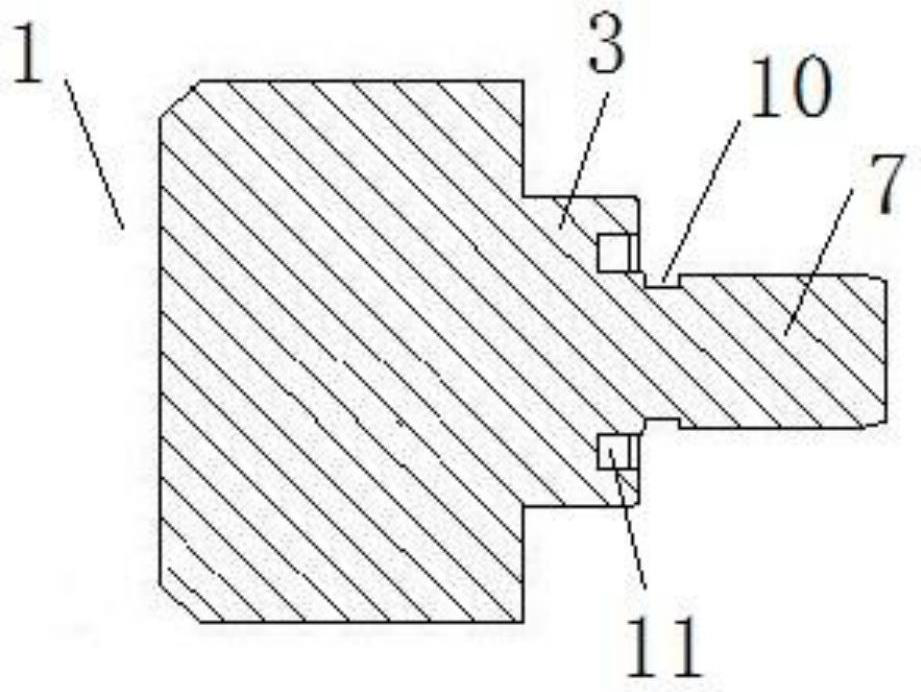

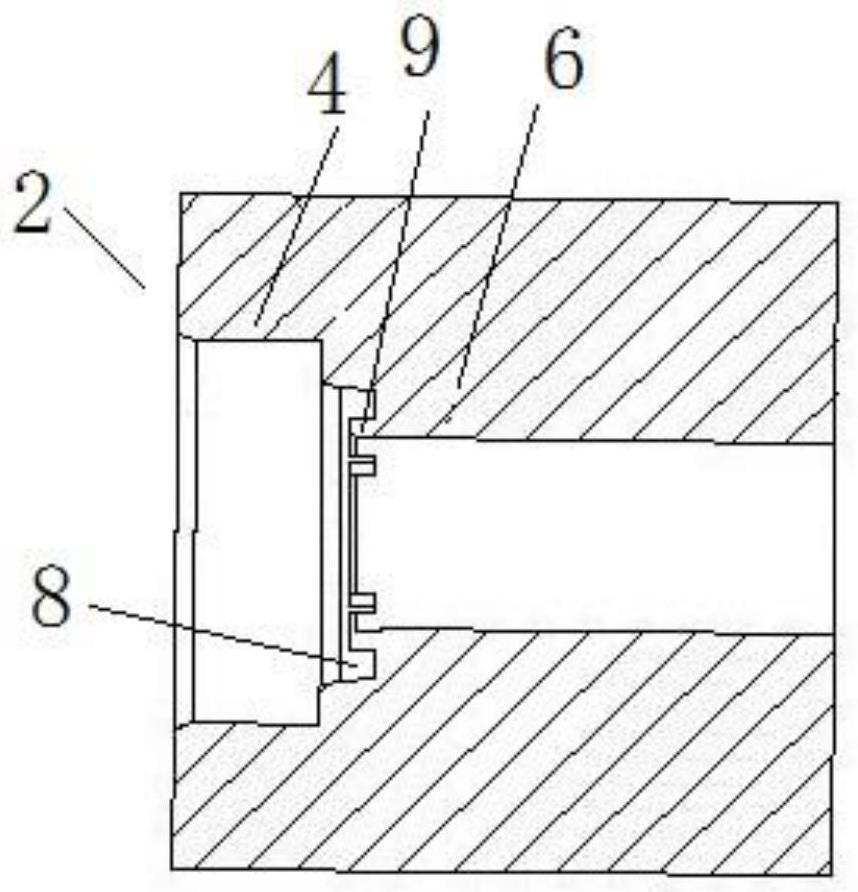

[0059] The second conductive part 2 and the first conductive part 1 are plugged together in an interference fit, specifically, as figure 2 As shown, the first conductive member 1 sequentially includes a large-diameter section, a middle-diameter section and a small-diameter section from left to right; image 3 As shown, the second conductive member 2 is a tubular structure as a whole, and it includes a large aperture section and a small aperture section from left to right. The inner diameter of the large aperture section is adapted to the outer diameter of the middle diameter section o...

Embodiment 2

[0064] The difference between this embodiment and Embodiment 1 lies in that: in Embodiment 1, a jack segment 6 is provided on the second conductive member 2 , and a plug segment 7 is provided on the first conductive member 1 . And in this embodiment, if Figure 6 As shown, the second conductive member 2 is provided with a plug segment 7, the first conductive member 1 is provided with a socket segment 6, and the end of the second conductive member 2 plug segment 7 is provided with a bending piece 9, and the bending piece 9 An annular groove is provided on the radial inner side of the inner wall to form a fitting space 8 for the wedge block 5 to be installed. An annular slot 10 is provided on the inner wall surface of the insertion hole section 6 of the first conductive member 1. The first conductive member 1 is inserted into the An annular wedge mounting groove 11 is provided on the end surface of the hole segment 6 opposite to the plug segment 7 .

Embodiment 3

[0066] The difference between this embodiment and Embodiment 2 is that in Embodiment 2, a ring is provided on the end surface of the first conductive member 1 section of the first conductive member 1 opposite to the ring-shaped fitting space 8 on the second conductive member 2. The wedge mounting groove 11 is inserted for the rear side of the wedge block 5 when installed. And in this embodiment, if Figure 7 As shown, no wedge installation groove 11 is provided on the end surface of the first conductive part 1 section of the first conductive part 1 opposite to the annular fitting space 8 on the second conductive part 2. When connecting, the orientation of the first conductive part 1 The end surface of one side of the second conductive member 2 pushes the wedge block 5 into the fitting space 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com