Splicing type cable pre-wiring device adopting two-way magnetic force principle

A cable arrangement and splicing technology, which is applied in the field of spliced cable and wire pre-arrangement devices, can solve the problems of the influence of the inner core of the cable, increase the gravity of the cable, and stretch the cable, so as to improve the service life, avoid the load, and prevent the elongation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

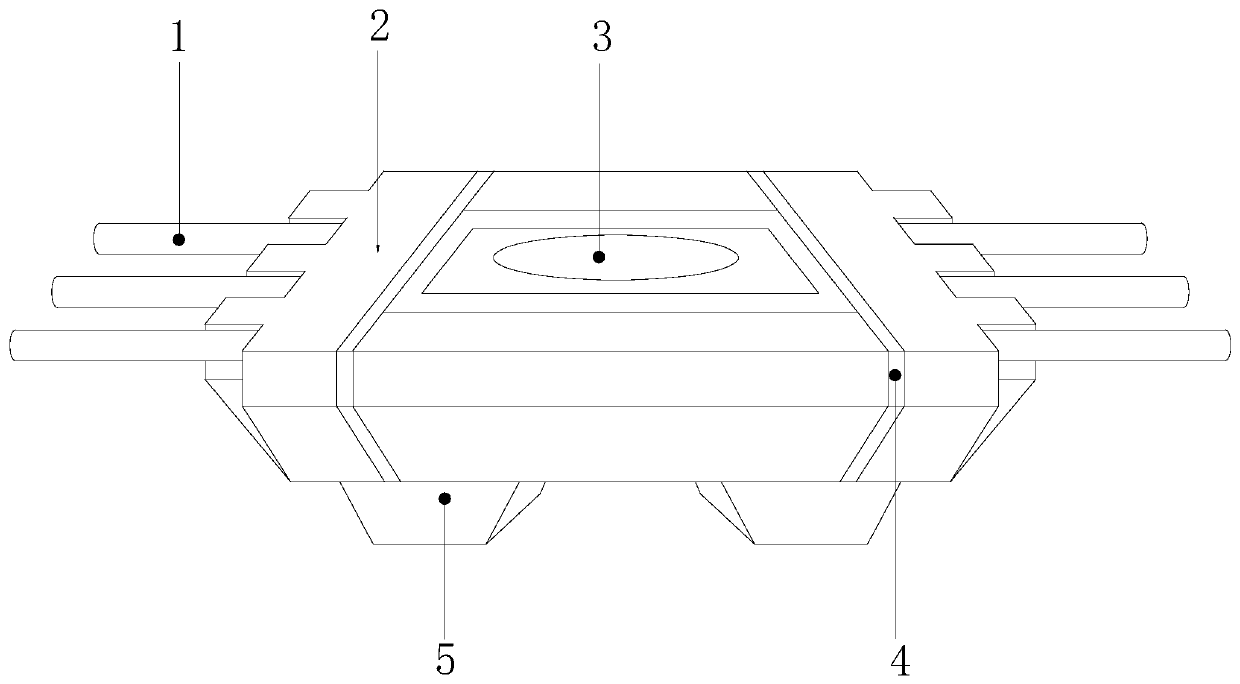

[0027] see Figure 1-Figure 6 , the present invention provides a splicing cable and wire pre-arrangement device adopting the principle of bidirectional magnetic force. There are four of them, and they are installed on the bottom of the main body 2 by buckling. The cables 1 run through the middle of both sides of the main body 2. The splicing box 3 has a rectangular structure and is installed in the middle of the main body 2 by embedding. The sealing line 4 is installed on both ends of the surface of the main body 2 by fitting, the cable 1 is inserted into the interior of the main body 2, and then the splicing box 3 is opened for splicing and fixing, the temporary hanging seat 5 is used for temporary support at the bottom, and the inside of the main body 2 is sealed Line 4 is disassembled.

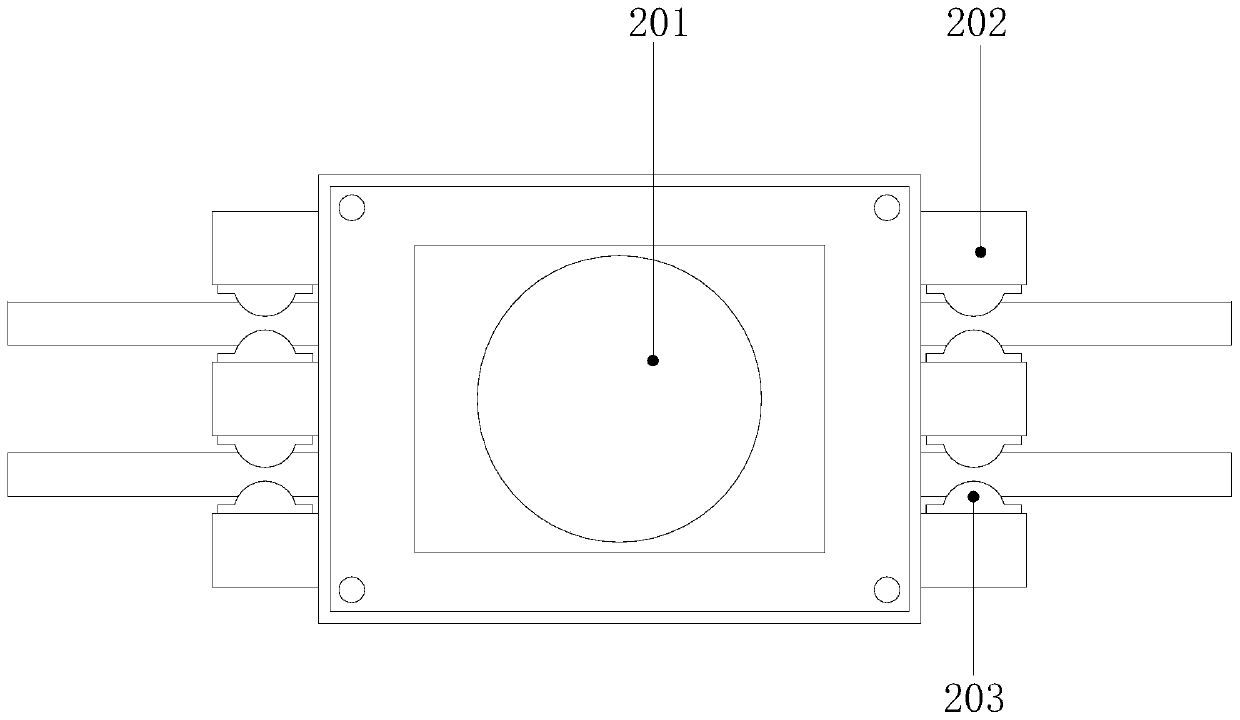

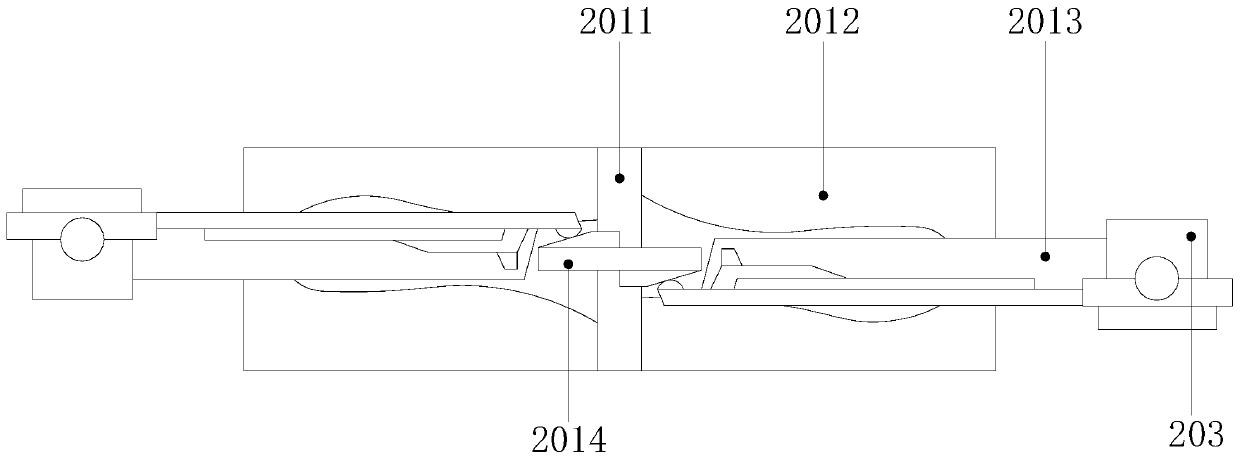

[0028] The main body 2 includes a flow diverter 201, an installation position 202, and an outsourcing device 203. There are more than two installation positions 202, which are installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com