Device for manufacturing multi-row core autoclaved aerated concrete block

A concrete block, autoclaved gas filling technology, applied in the direction of ceramic forming core, ceramic forming mandrel, etc., can solve the problems of poor heat insulation, block damage, high thermal conductivity, etc., and achieve the effect of ensuring integrity and avoiding adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

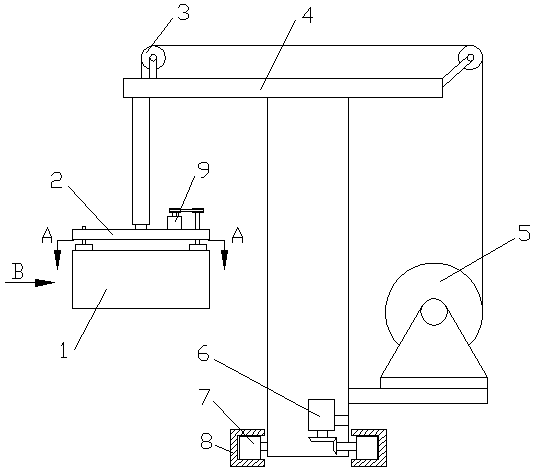

[0021] Such as figure 1 Shown is a device for making multi-row autoclaved aerated concrete blocks, including a frame 4 and a lifting frame 2 that is slid on the frame 4 in the vertical direction, and connected with the lifting frame The lifting device 5 is fixed with a vertical outer sleeve 10 on the frame.

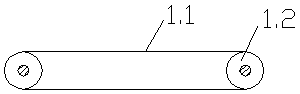

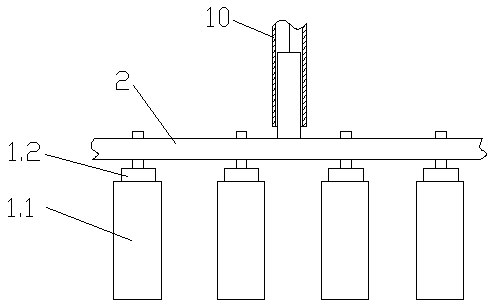

[0022] The mounting plate on the lifting frame 2 is provided with several endless belt type mandrels 1 and a motor 9 that drives the endless belt 1.1 to rotate. The belt surface of the said endless belt 1.1 is smooth and vertically arranged, and the material of the endless belt is an alkali-resistant rubber belt , and can withstand a temperature of not less than 60 ° C to ensure sufficient service life. Specifically, the mandrel 1 includes two rollers 1.2 arranged vertically and arranged in the horizontal direction, and the endless belt 1.1 connecting the two rollers, wherein the mandrel of one roller is affixed to the output shaft of the motor 9, The mandrels of the tw...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the mandrels are arranged staggeredly in the width direction, and the mold cavities formed during casting are also staggered. One or two gaps are formed on one side of the block, which can block the thermal bridge during building, thereby improving the thermal insulation performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Withstand temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com