Easy snap-on and snap-off structure

A buckle structure and female buckle technology, applied in mechanical equipment, fixing devices, etc., can solve the problems of single appearance and inconvenient use, and achieve the effects of beautiful appearance, low cost and good market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

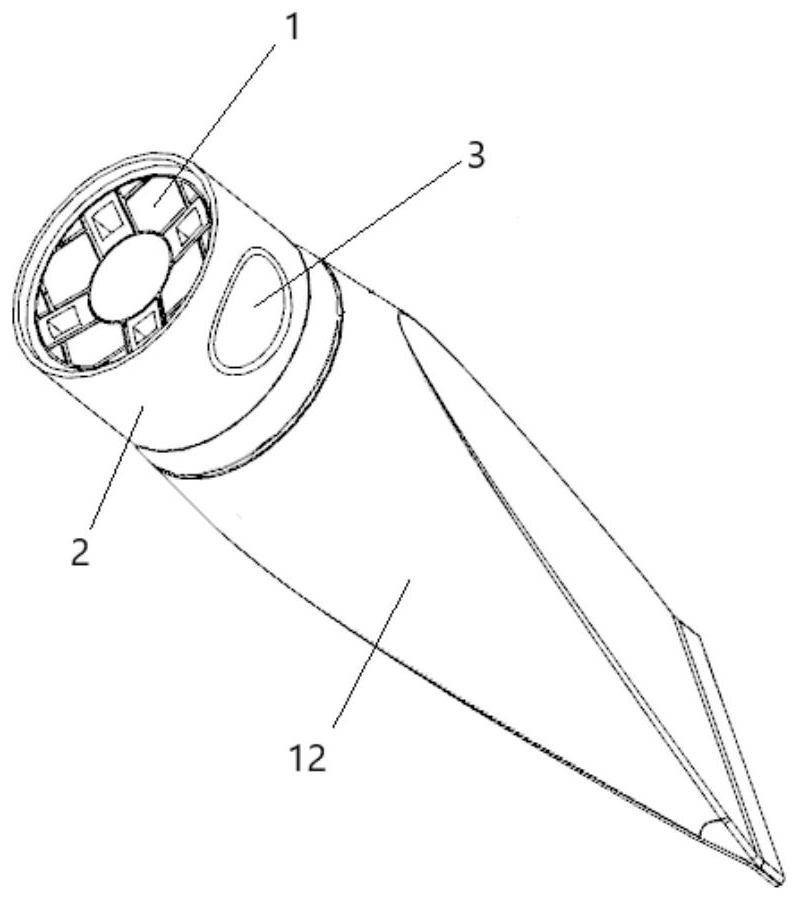

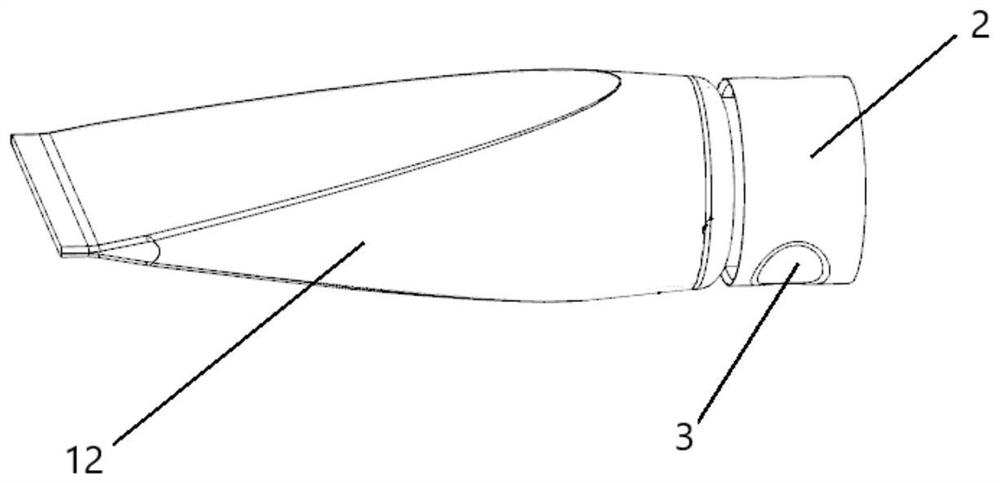

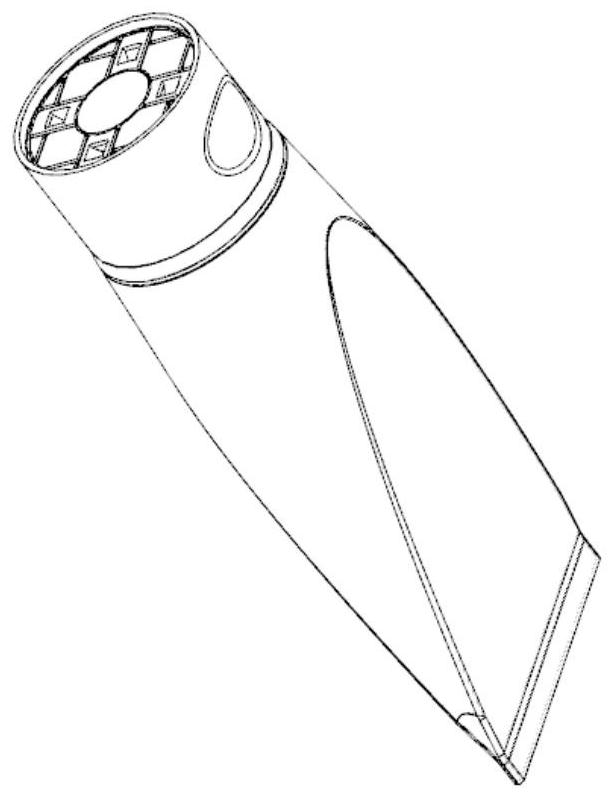

[0044] A buckle structure that is easy to buckle and separate according to the present invention, as a whole Figure 1~4 As shown, including elastic sheet 1, female buckle and male buckle;

[0045] The cover composed of the elastic piece and the female buckle is as follows: Figure 5-8 As shown, the elastic sheet 1 is a circular sheet, which is connected with a cylindrical cylinder 12 with openings at both ends, is positioned at the bottom of the cylinder 1, and protrudes to the outside of the cylinder 1, and the outer wall of the cylinder 1 is provided with There are two opposite circular pits 3, the cylinder body I is provided with a cylindrical cylinder body II 4 connected with the elastic sheet, the cylinder body II is coaxial with the cylinder body I, and the inner wall of the cylinder body II is provided with an annular protrusion 5;

[0046] There are 4 female buckles, all of which have the same shape and size and are uniformly distributed around the center of the elas...

Embodiment 2

[0053] A buckle structure that is easy to buckle and separate, including an elastic piece 1, a female buckle and a male buckle;

[0054] The elastic sheet 1 is bulged on one side, and the elastic sheet 1 has a circular structure, and can also be linear, Y-shaped, cross-shaped, or rice-shaped. The elastic sheet 1 is connected to the cylinder I 2 with both ends open, and is located Bottom, raised to the inner side of cylinder I 2;

[0055] The cylinder body I 2 is provided with a cylinder body II 4, both of which are cylindrical and coaxial, and the cylinder body II 4 is connected with the elastic sheet 1;

[0056] The whole connection of the elastic piece 1, the cylinder body I 2 and the female buckle is referred to as the cover body for short, and its structure is as follows Figures 14-19 As shown, the female buckle includes a support column 6 and a hook 7. The support column 6 is connected to the surface of the elastic sheet 1 located inside the cylinder 12, and is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com