Ash storage mechanism of mechanical dust removal system

A technology for mechanical dust removal and ash storage, which is used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. The effect of water shortage, sufficient water flow, and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

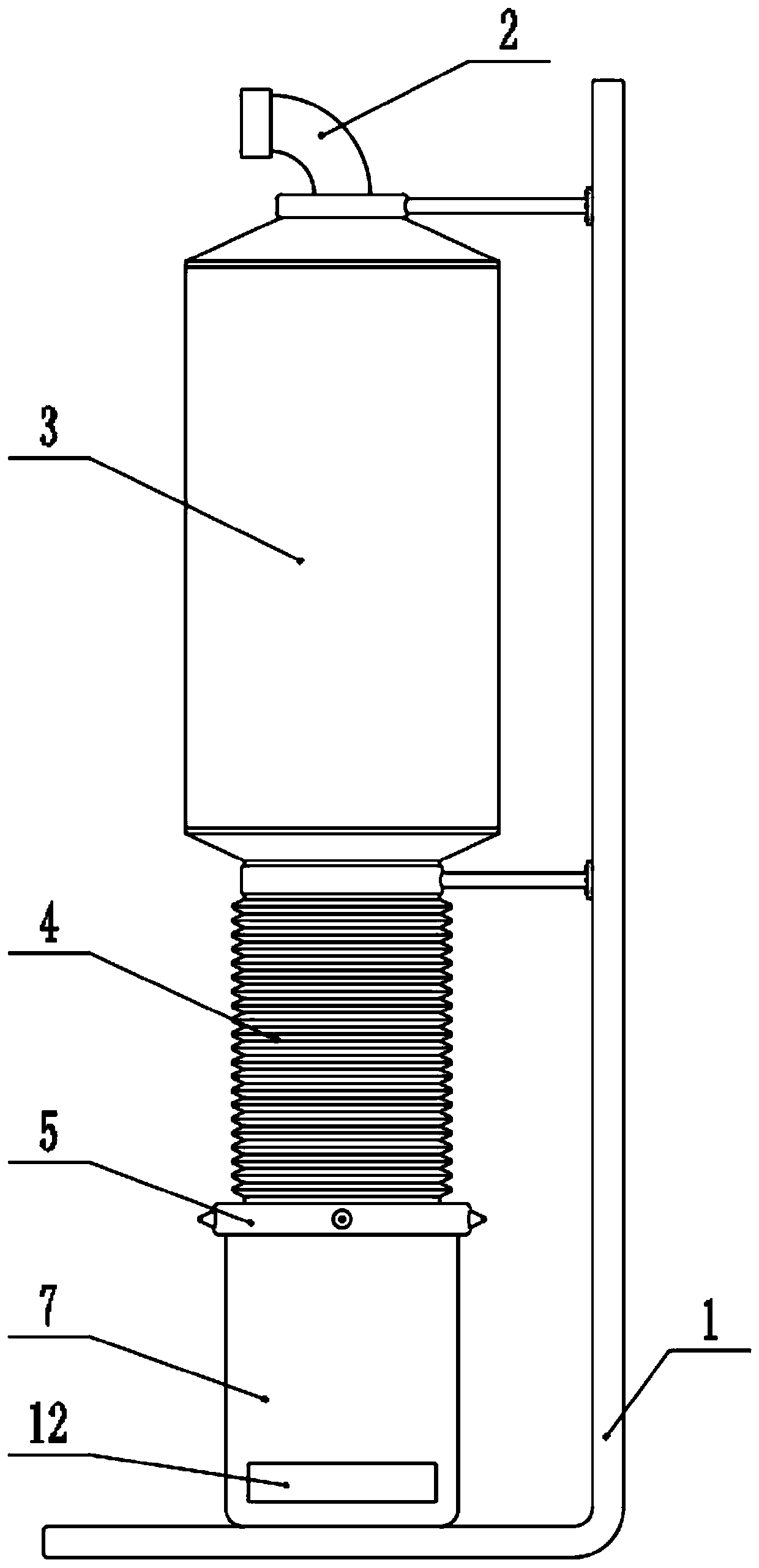

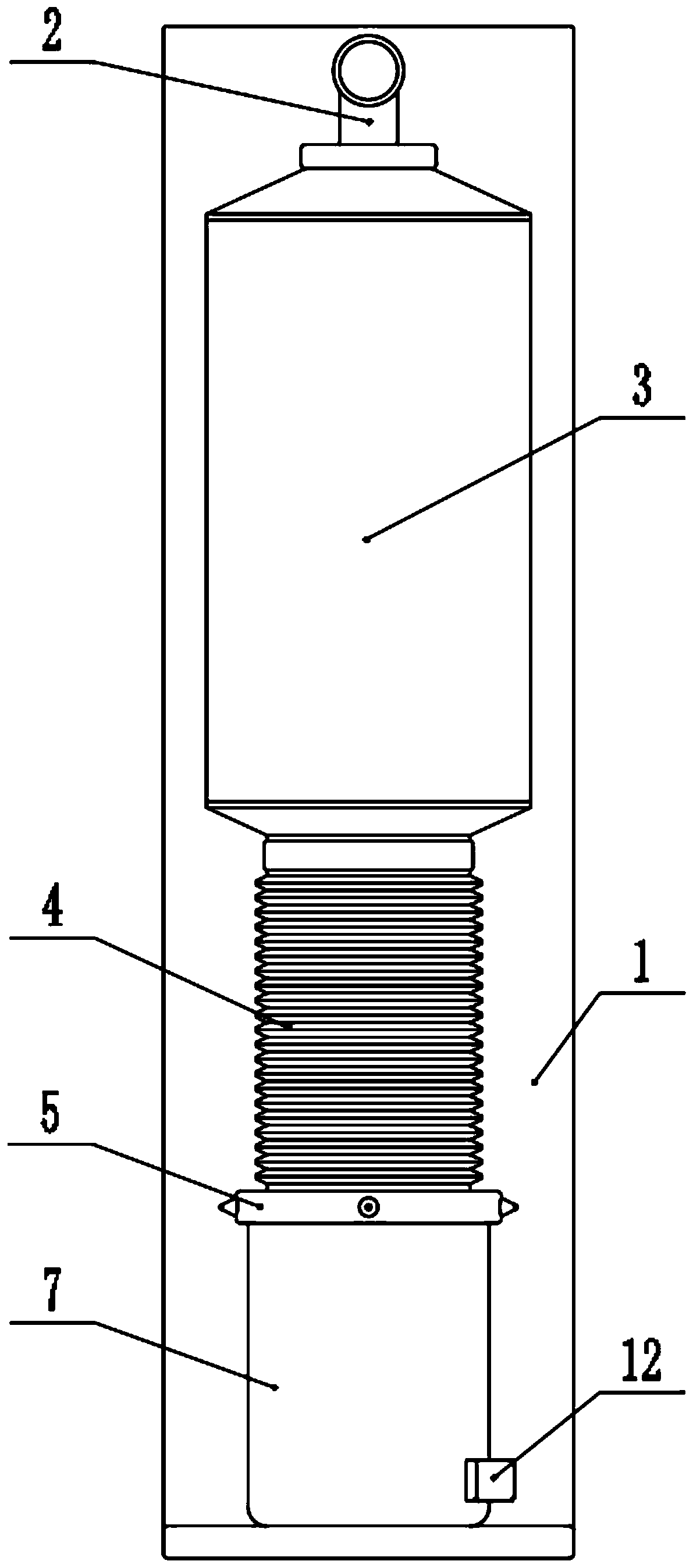

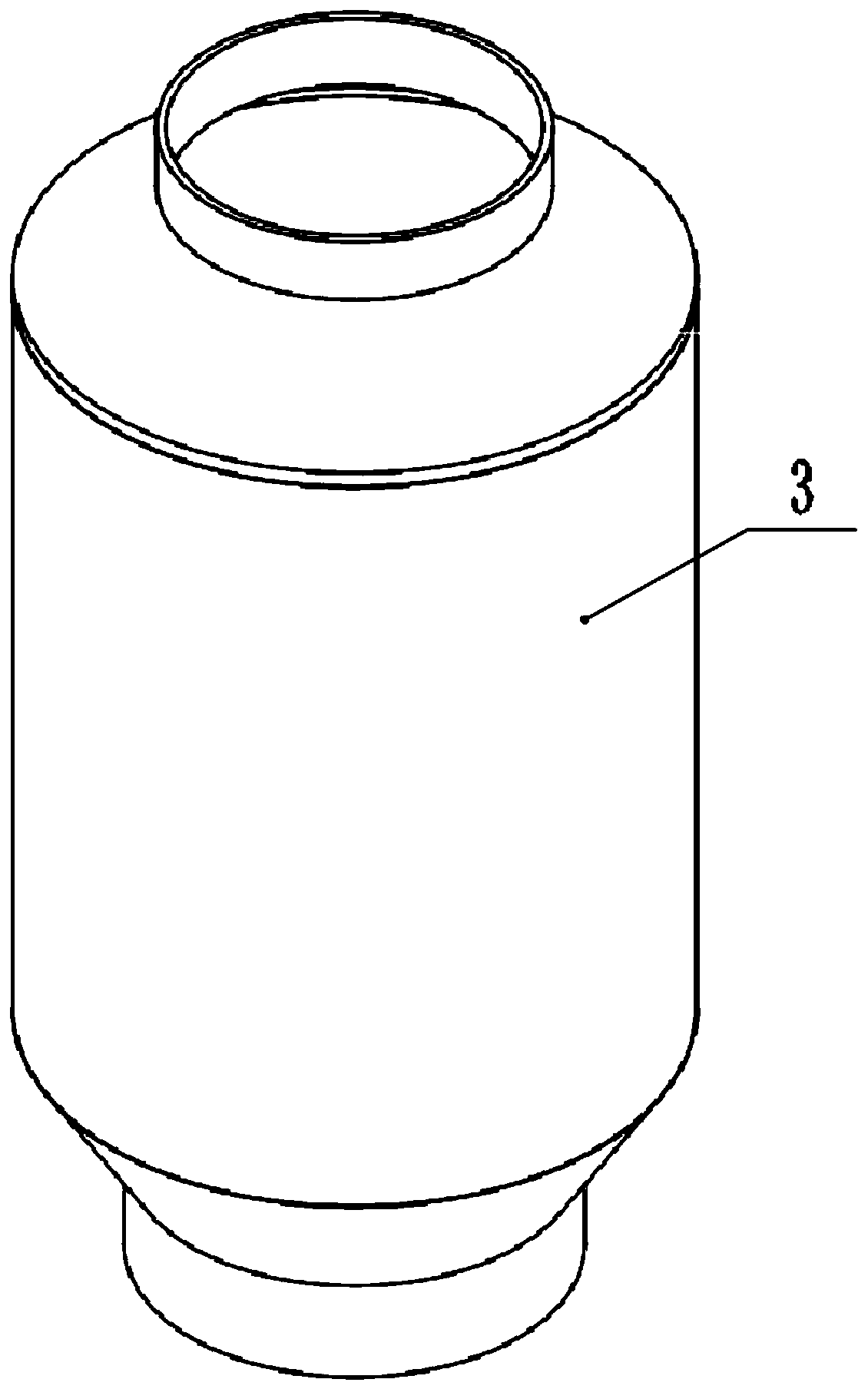

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The invention provides an ash storage mechanism of a mechanical dust removal system, which includes a base 1, a dust inlet pipe 2, a cloth filter cylinder 3, a telescopic cylinder 4, a threaded connection ring 5, a sealing rubber ring 6, an ash storage bucket 7, and an ash storage tank 701, water storage cavity 702, pipe column 8, water absorption rope 9, lifting plate 10, sliding hole 1001, pull rod 11 and water inlet tank 12; the inlet end of the dust inlet pipe 2 is connected with the dust removal system, and the dust inlet pipe 2 is installed On the top of the base 1; the cloth filter cartridge 3 is installed at the bottom of the dust inlet pipe 2, and the cloth filter cartridge 3 is located at the middle part of the top of the base 1, and the telescopic cartridge 4 is installed at the bottom of the cloth filter cartridge 3; the thread The inside of the connecting ring 5 is provided with an internal thread, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com