A self-cleaning dust collector

A dust collector and dust filtering technology, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of poor dust removal effect and frequent cleaning of dust collectors, so as to improve the scope of application, improve thrust, and improve cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

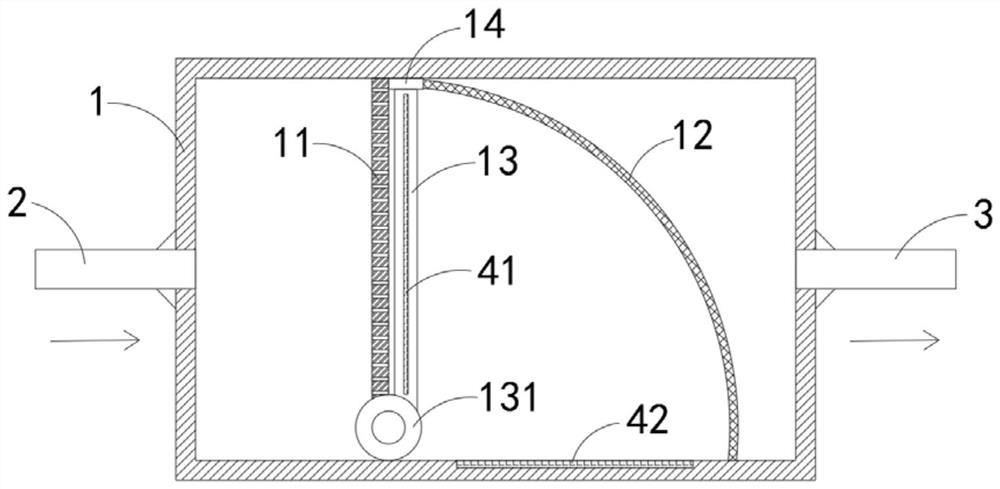

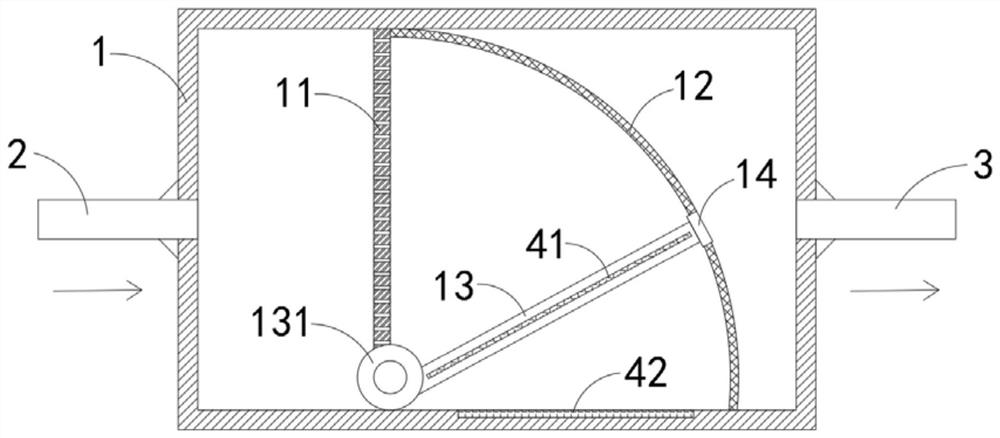

[0032] Such as Figure 1-3 As shown, a self-cleaning dust collector includes a housing 1, an air intake pipe 2 and an exhaust pipe 3, and the air intake pipe 2 and the exhaust pipe 3 are respectively fixedly installed at both ends of the housing 1, and the housing 1 is provided with:

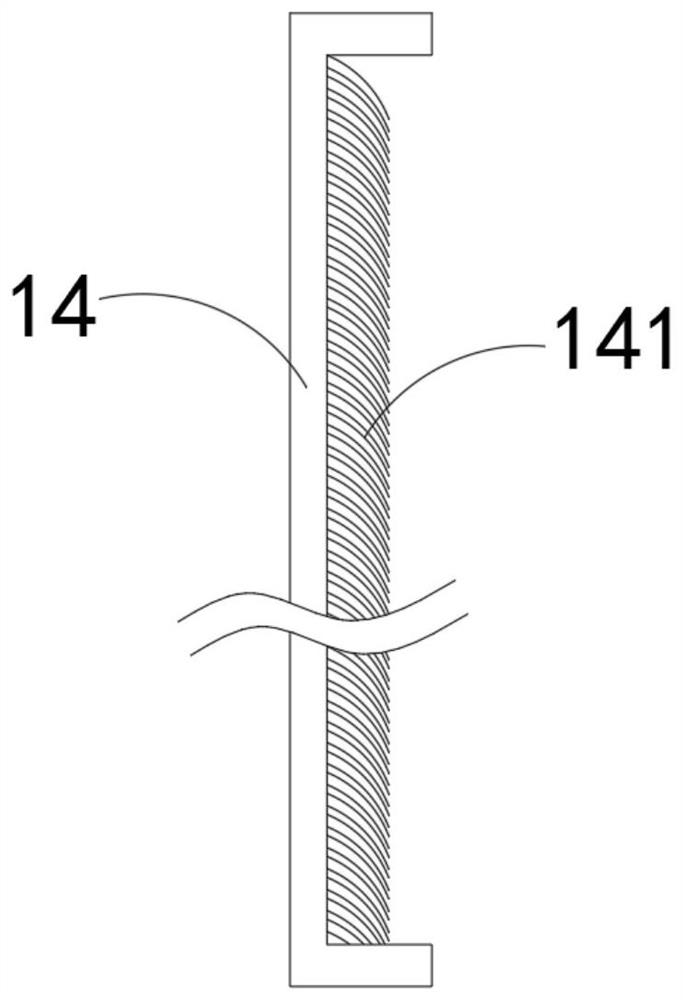

[0033] The first dust filter plate 11, the first dust filter plate 11 is fixedly connected on the inner side wall of the housing 1, the first dust filter plate 11 is vertically arranged, and the two ends of the first dust filter plate 11 are respectively connected to the two side walls of the housing 1 Fixed and sealed connection, the first dust filter plate 11 separates the housing 1 into a settling area and a filtering area, the side of the first dust filter plate 11 close to the intake pipe 2 is a settling area, which is used to collect large particles of settled smoke particles, the first dust filter plate 11 The side close to the exhaust pipe 3 is a filtering area, which is used for seconda...

Embodiment 2

[0043] Such as Figure 4-5As shown, the difference between this embodiment and Embodiment 1 is that a liquid storage box 51 is provided on the side of the first dust filter plate 11 close to the intake pipe 2, the liquid storage box 51 is filled with cleaning agent, and the liquid storage box 51 is fixedly connected On the inner side wall of the housing 1, a windshield 52 is rotatably connected to the inner sidewall of the housing 1, and a liquid spray pipe 521 is installed through the windshield 52, and the windshield 52 and the liquid storage box 51 are fixedly connected. There is an elastic liquid storage bag 53, and the liquid storage box 51 and the liquid spray pipe 521 are all connected with the elastic liquid storage bag 53. The direction of drainage is as Figure 5 Shown by the arrow in) is connected with the elastic liquid storage bag 53, and the liquid spray pipe 521 is a one-way liquid spray pipe (the liquid discharge direction of the one-way liquid spray pipe is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com