Tapering component

A mold assembly and the same technology, applied in the field of draft assembly, can solve the problems of difficulty in demoulding, can not be demolded smoothly, etc., and achieve the effect of convenient mold assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

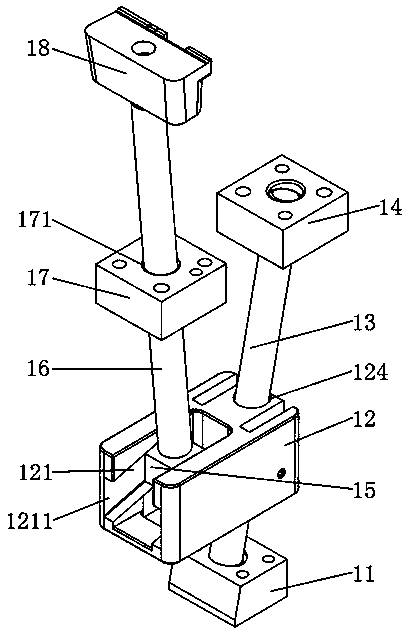

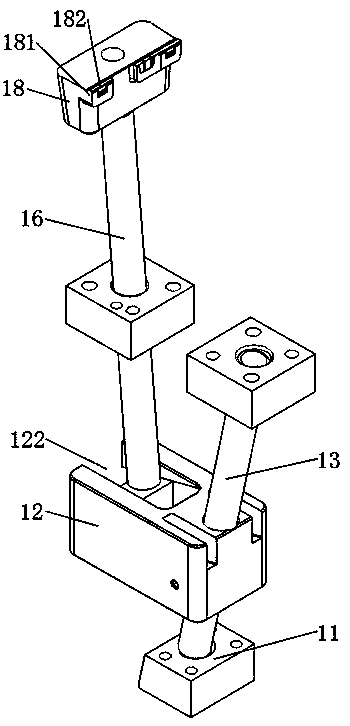

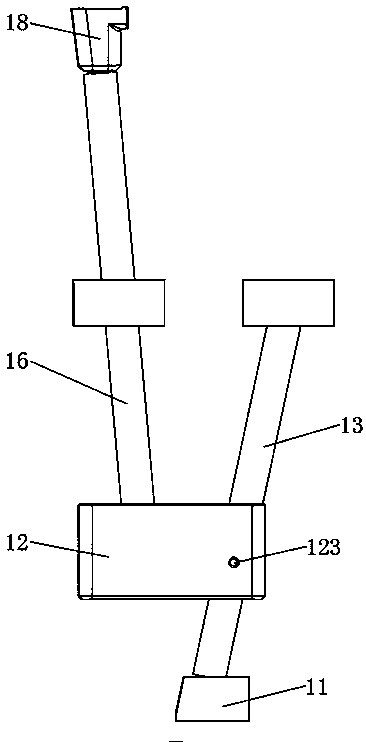

[0022] see Figure 1-4 , the present invention provides a technical solution: a draft assembly, including a first fixed block 11, a second fixed block 14 and a third fixed block 17, the top of the first fixed block 11 and the second fixed block 14 A guide rod 13 is installed between the bottoms, and the connecting block 12 for sliding connection is sleeved on the guide rod 13, and the inside of the connecting block 12 has a first through hole 124 matched with the guide rod 13 , the first fixing block 11 and the second fixing block 14 are not on the same vertical plane, the top of the connecting block 12 is provided with a gap 122, and the inside of the connecting block 12 is away from a part of the first through hole 124 The short side is provided with an inclined chute 121, the chute 121 has an opening 1211, a slider 15 is slid in the chute 121, an inclined connecting rod 16 is provided on the top of the slider 15, and the third fixed The top of the block 17 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com