Patents

Literature

32results about How to "Easy draft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

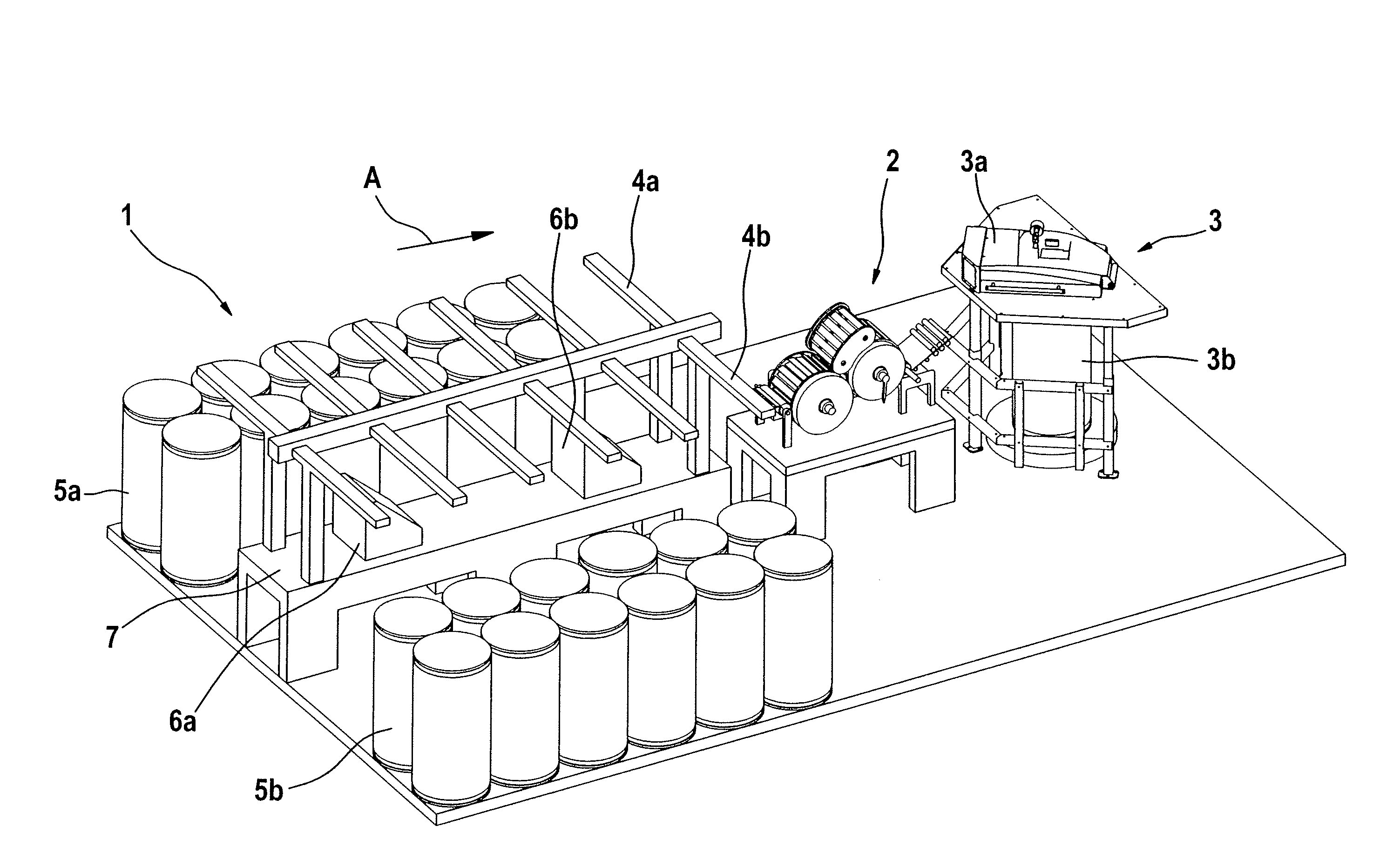

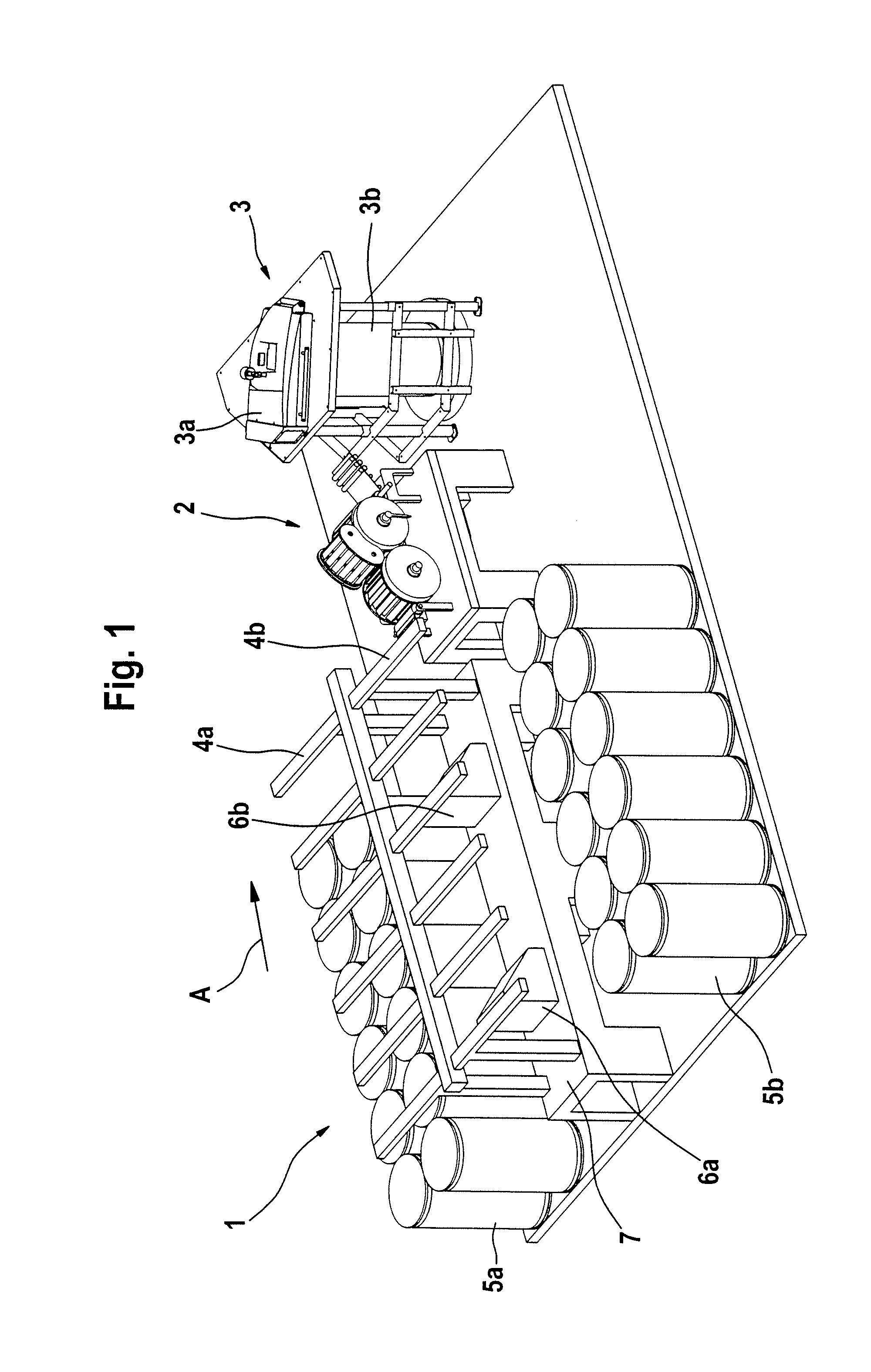

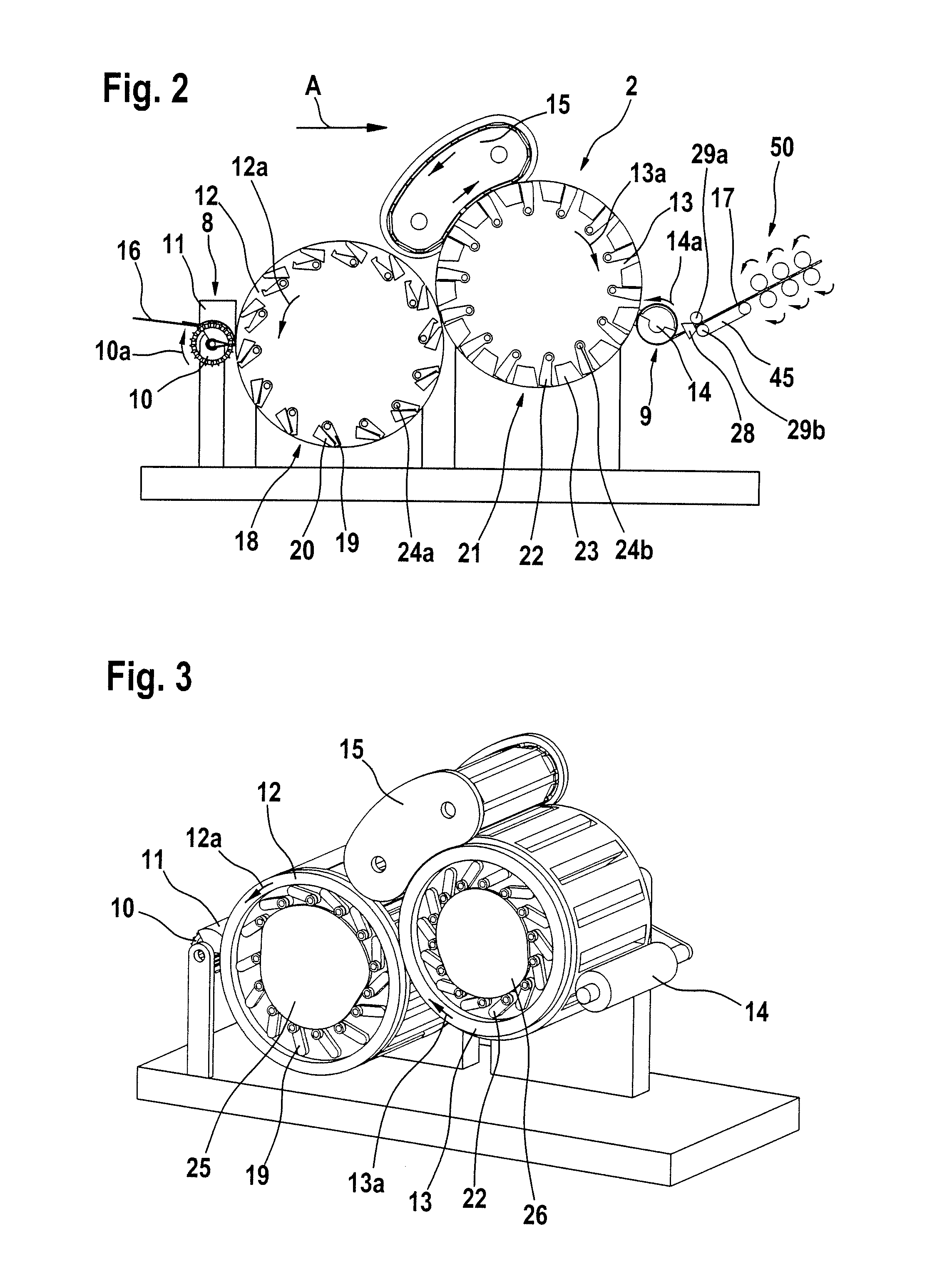

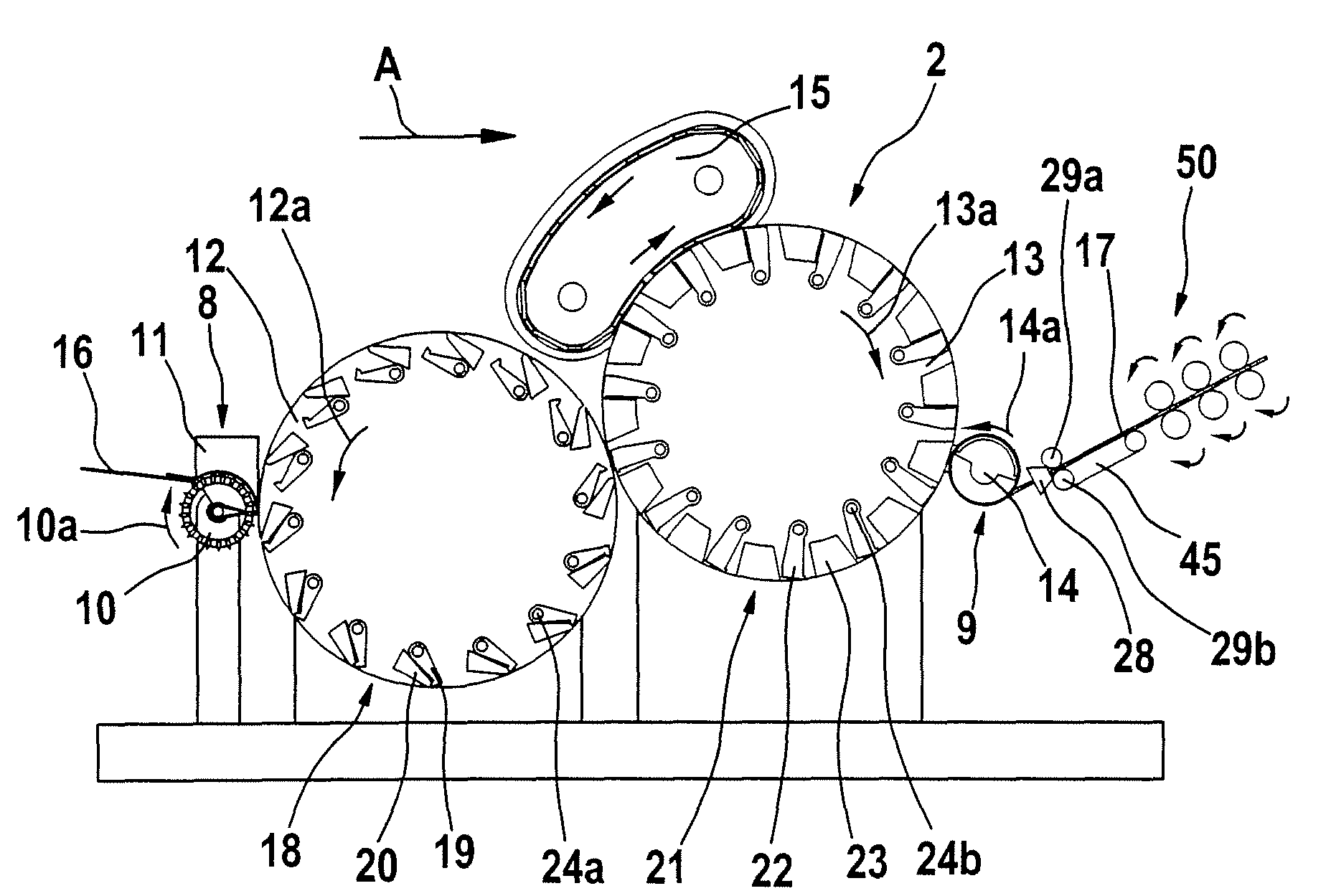

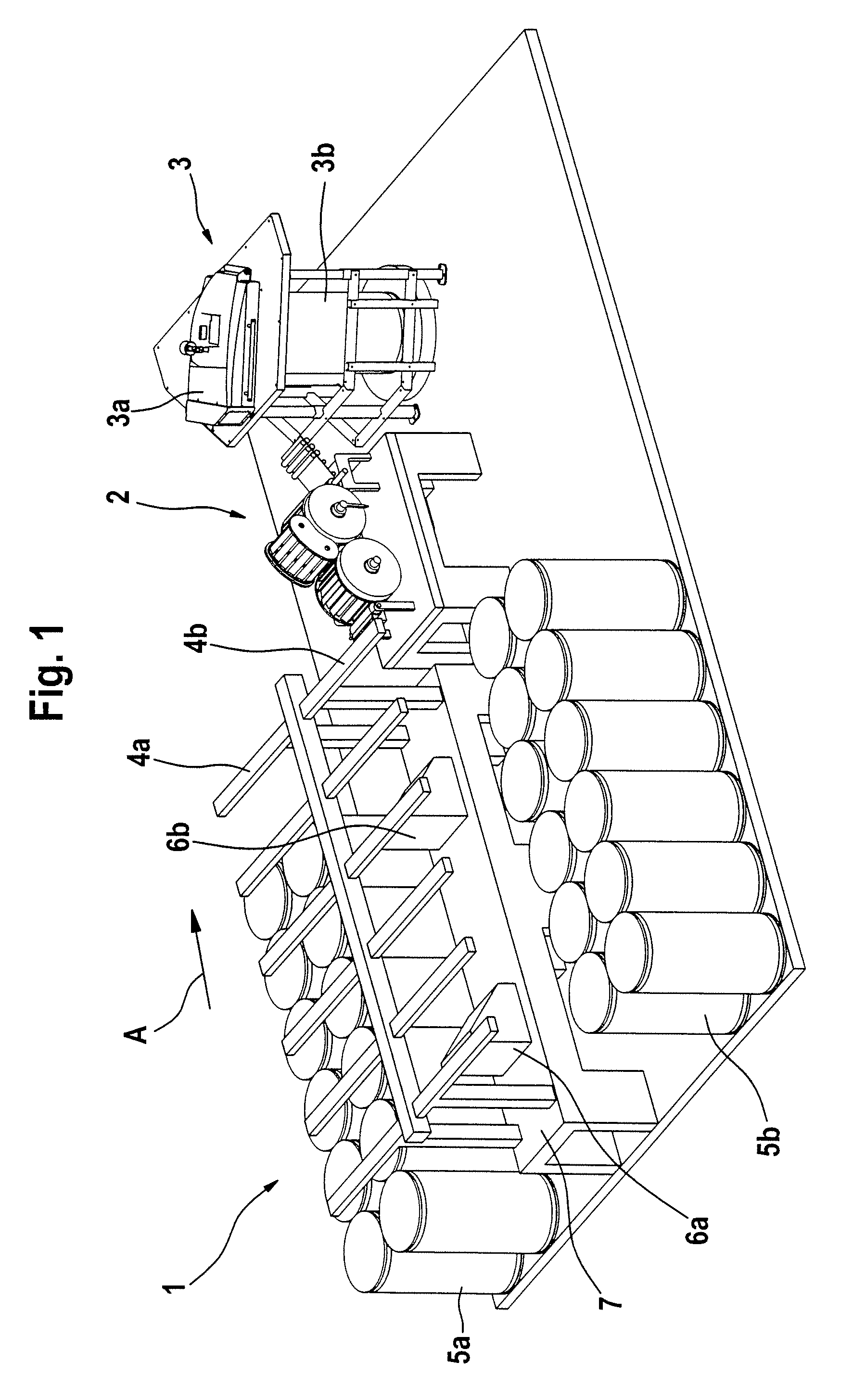

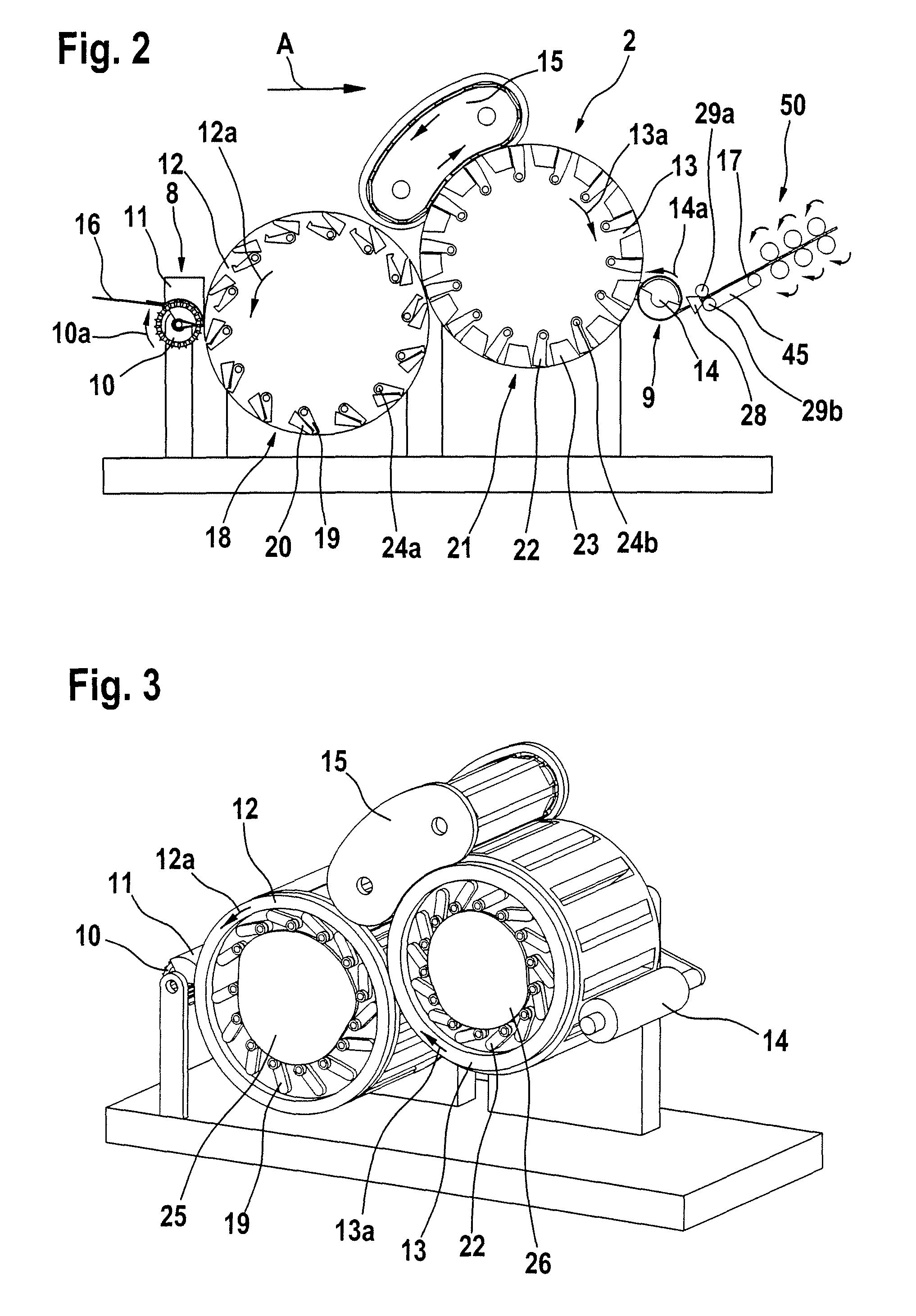

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000075A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

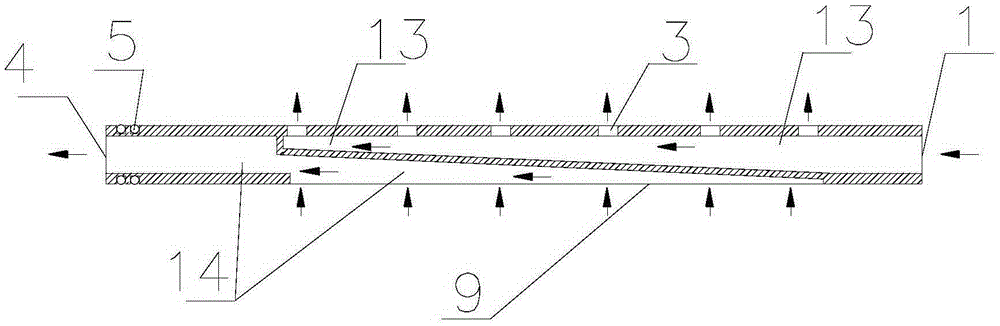

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by a supply device to a fibre-sorting device, especially a combing device, having clamping devices, which clamp the fibre bundle at a distance from its free end, for combing to remove non-clamped constituents, at least one take-off device 14 with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and improve the combed sliver, the fibre-sorting device has at least two rotatably mounted rollers rotating rapidly without interruption, having the clamping devices and between the sliver-forming element and the drafting system the at least one fibre sliver is present in the form of a fibre structure having a width greater than its height, for example, following spreading by a web-spreader.

Owner:TRUETZSCHLER GMBH & CO KG

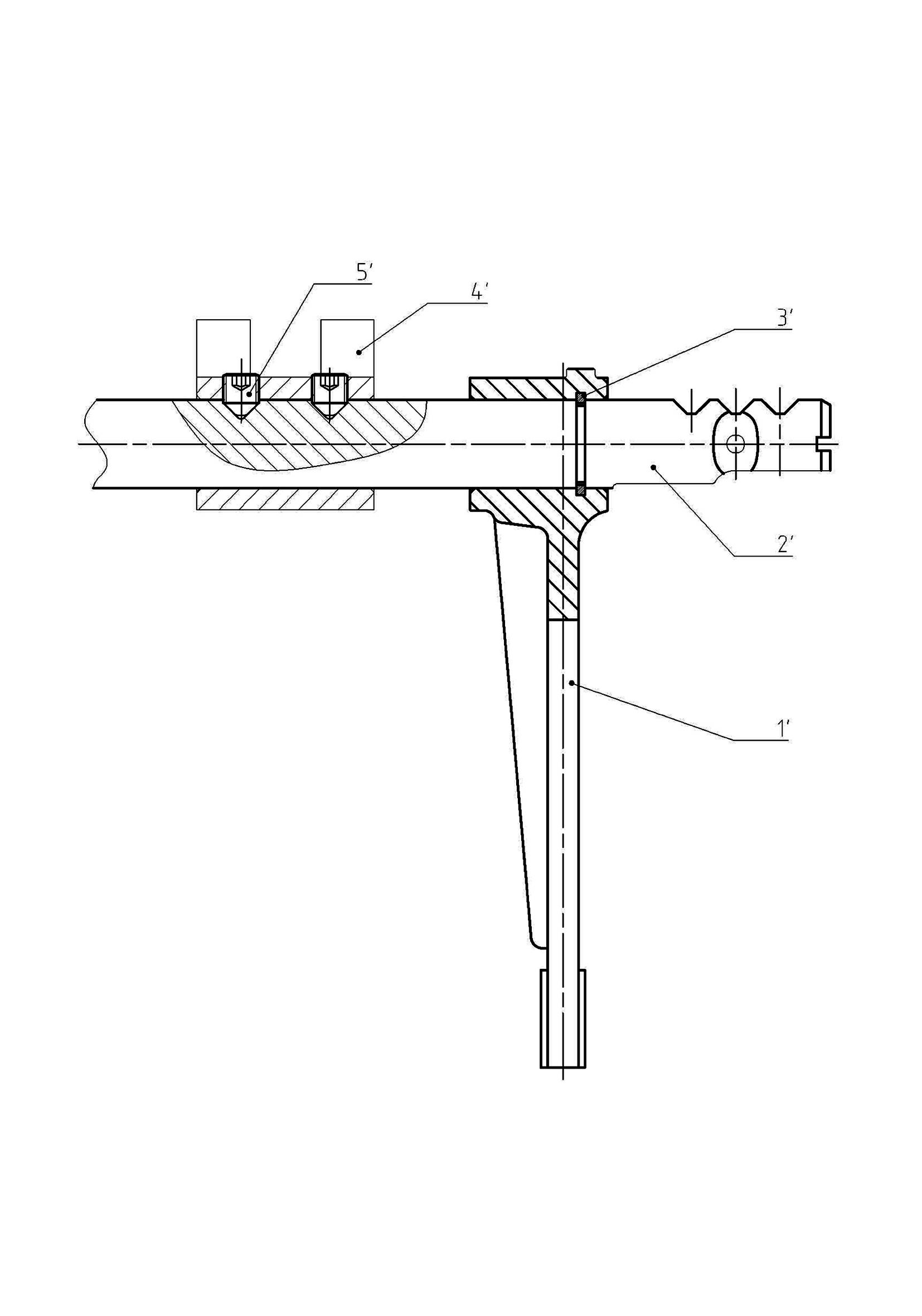

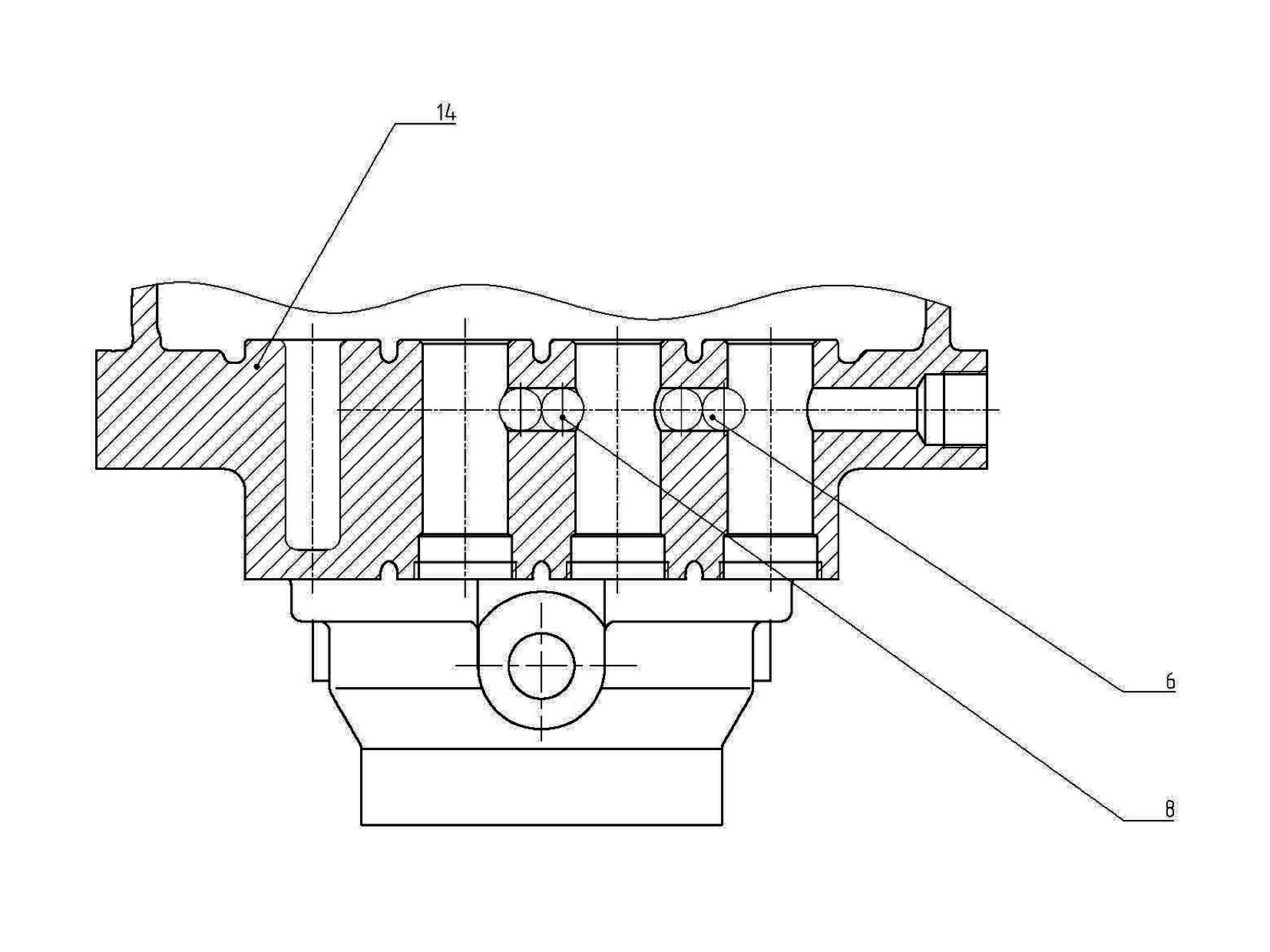

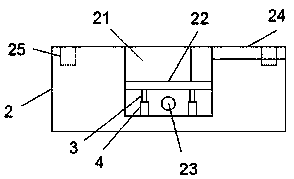

Self-locking and interlocking mechanism for cylindrical shell speed changer

InactiveCN102494129AGuaranteed performanceEasy to produceGearing controlGearing detailsBatch productionSelf locking

The invention relates to a self-locking and interlocking mechanism for a cylindrical shell speed changer. The self-locking and interlocking mechanism comprises a shifting fork (1'), a shifting fork shaft (2'), a guide block (4'), a cylindrical pin (5'), a pressurizer, steel balls and a signal switch (10), wherein the guide block (4') acts on a cylindrical shell to limit the rotation of the cylindrical shell, and is fixed to the shifting fork shaft (2') by the cylindrical pin (5') to prevent the shifting fork shaft (2') from rotating; a tangent plane is positioned on the surface of the shifting fork shaft (2'), so that the shifting fork shaft is convenient to install; the shifting fork is connected with the shifting fork shaft by an elastic retainer ring (3'), so that the shifting fork shaft can rotate after being installed; the shifting fork shaft comprises a plurality of locking grooves and movable pins; and the movable pins are used for pushing the steel balls accommodated in the locking grooves out of the grooves to lock or unlock the shifting fork shaft. The self-locking and interlocking mechanism can be convenient to produce while the using performance is ensured by combining the advantage of a classical simple and reliable self-locking and interlocking mechanism for the steel balls and the advantages of light quality and convenience for batch production of aluminum alloy cylindrical shells.

Owner:QIJIANG GEAR TRANSMISSION

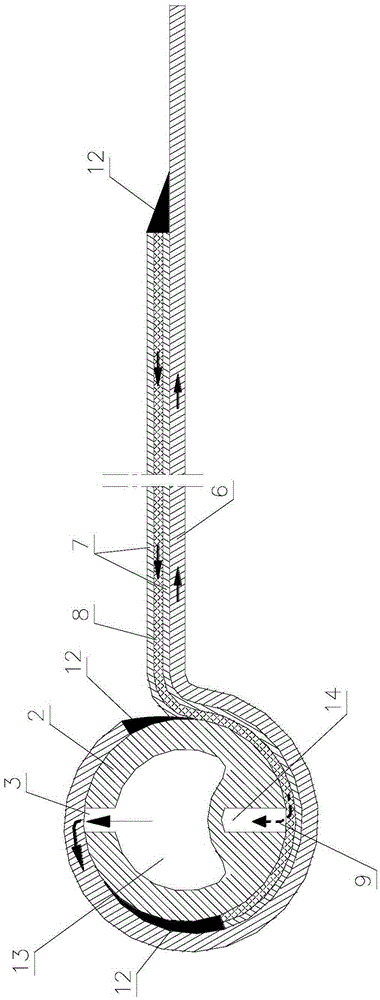

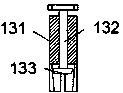

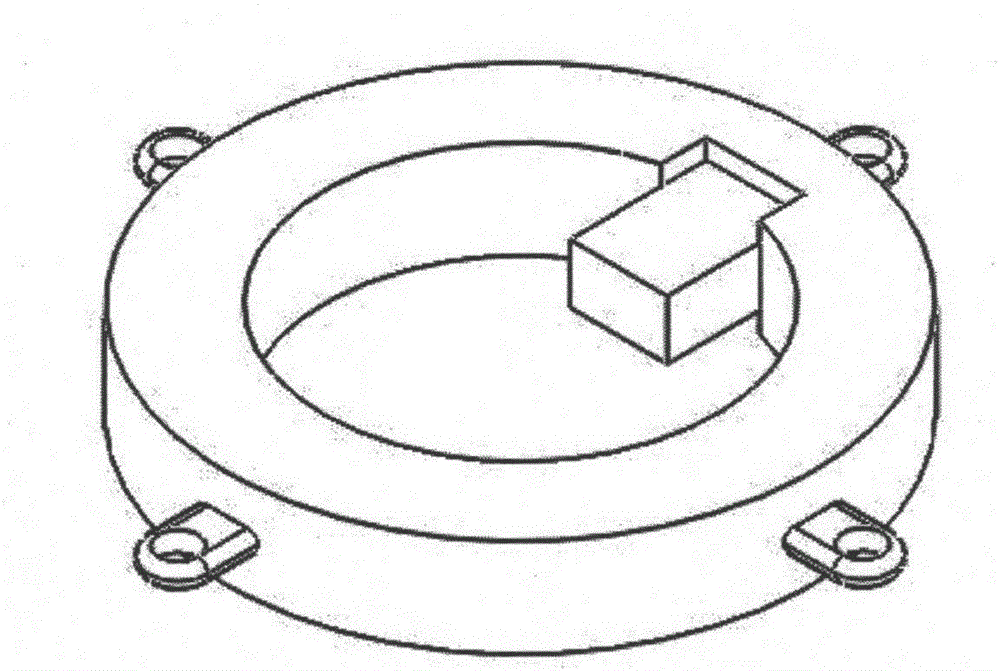

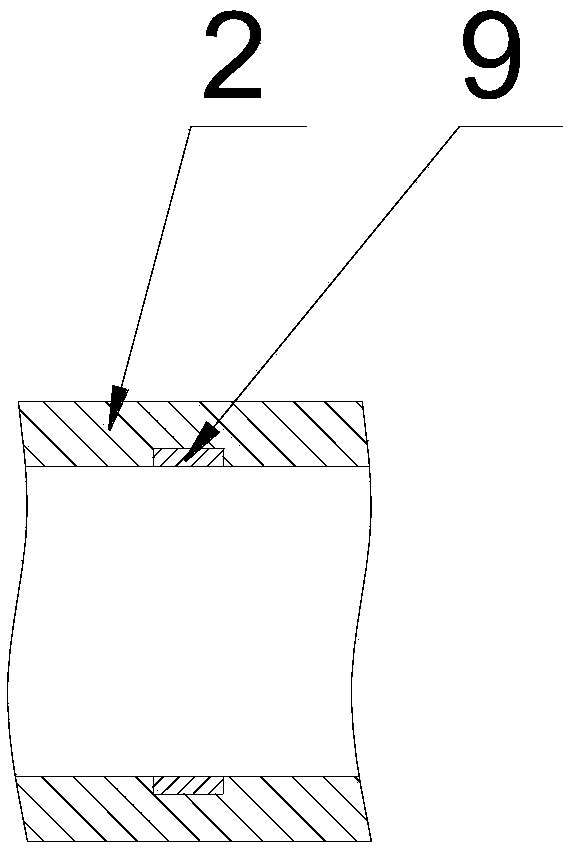

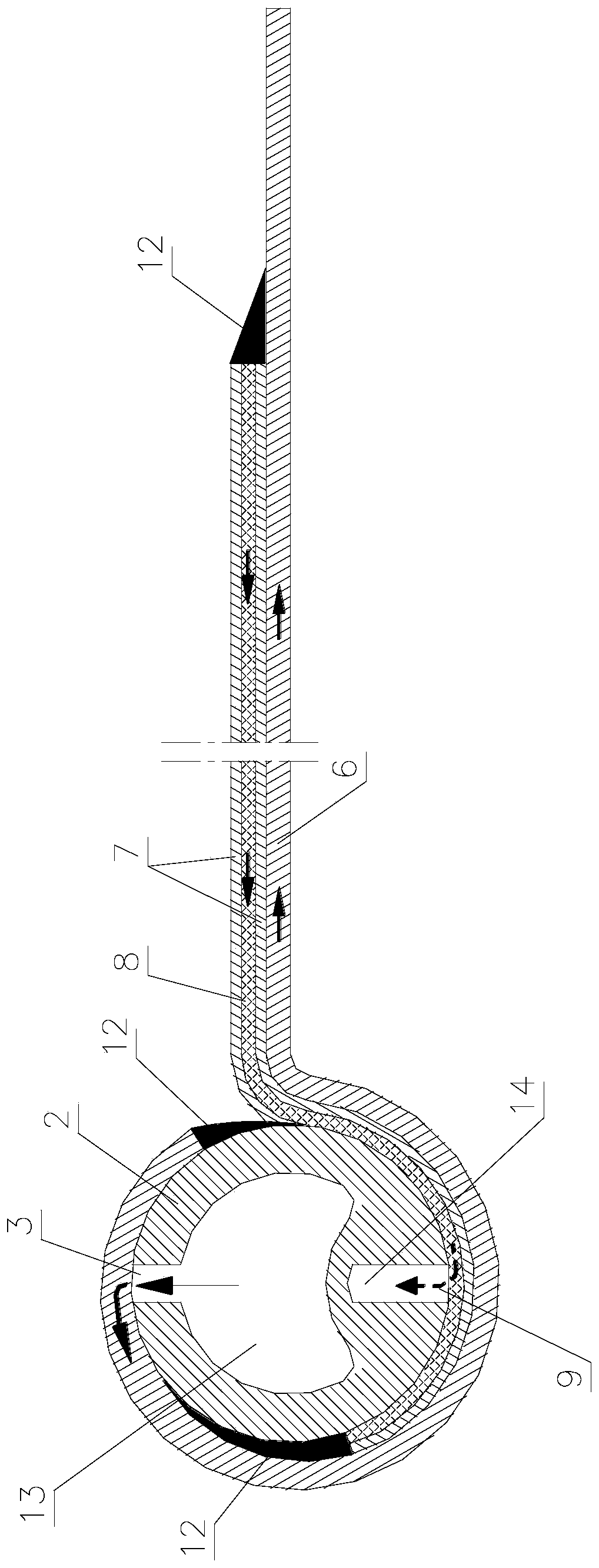

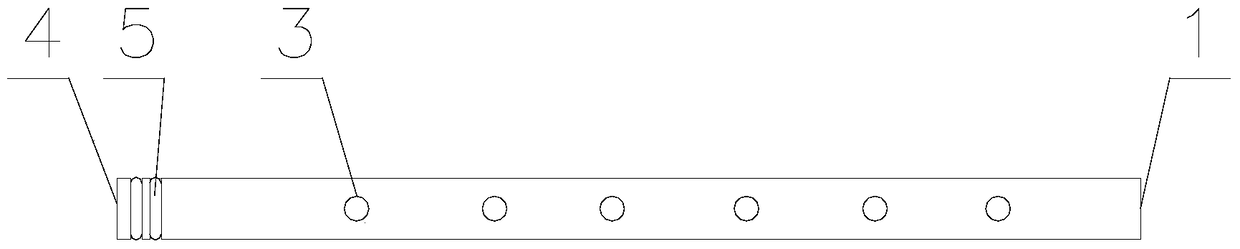

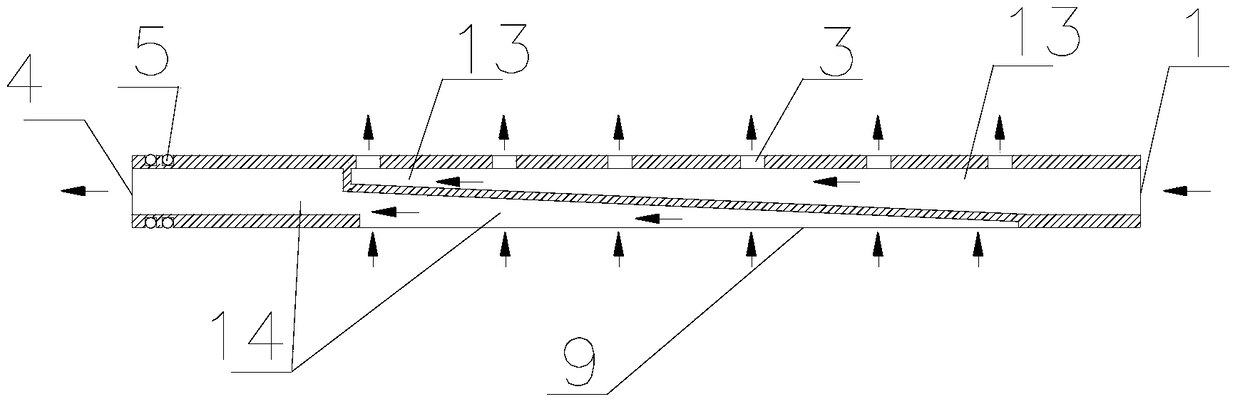

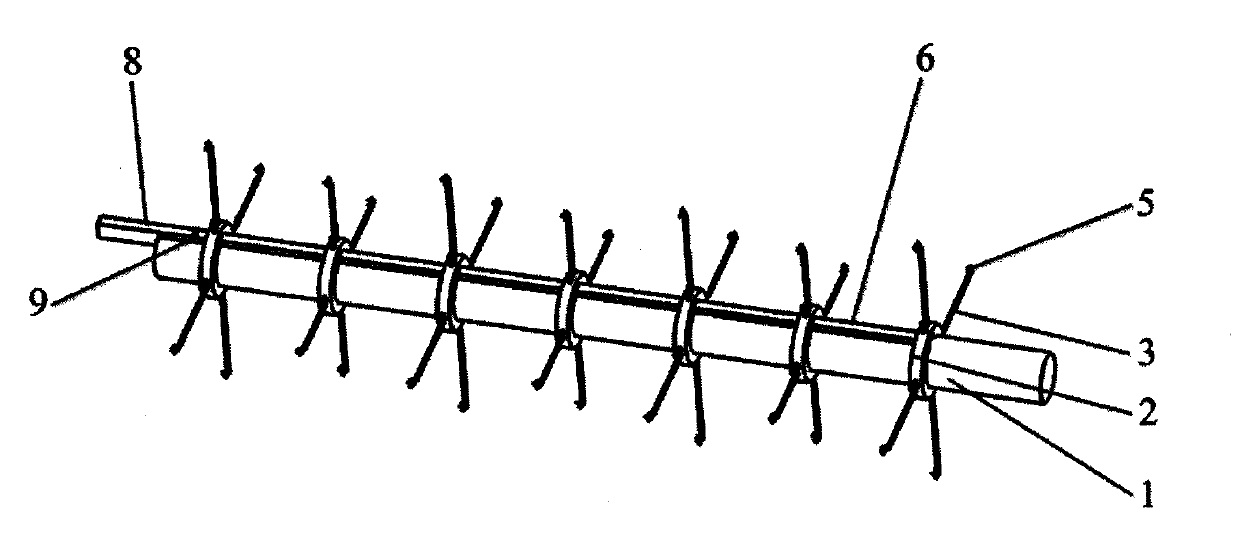

Spiral-wound membrane component and filter element employing same

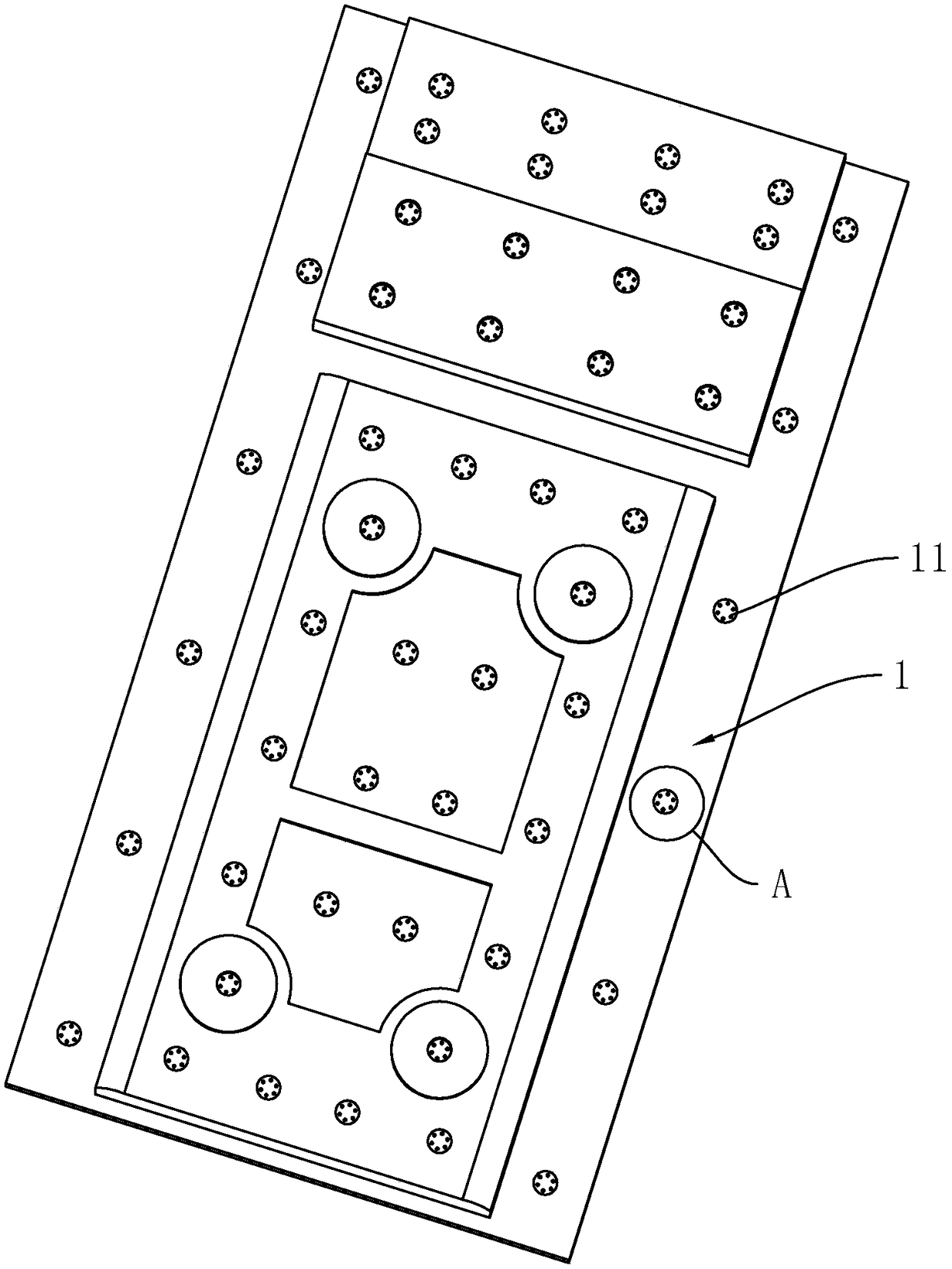

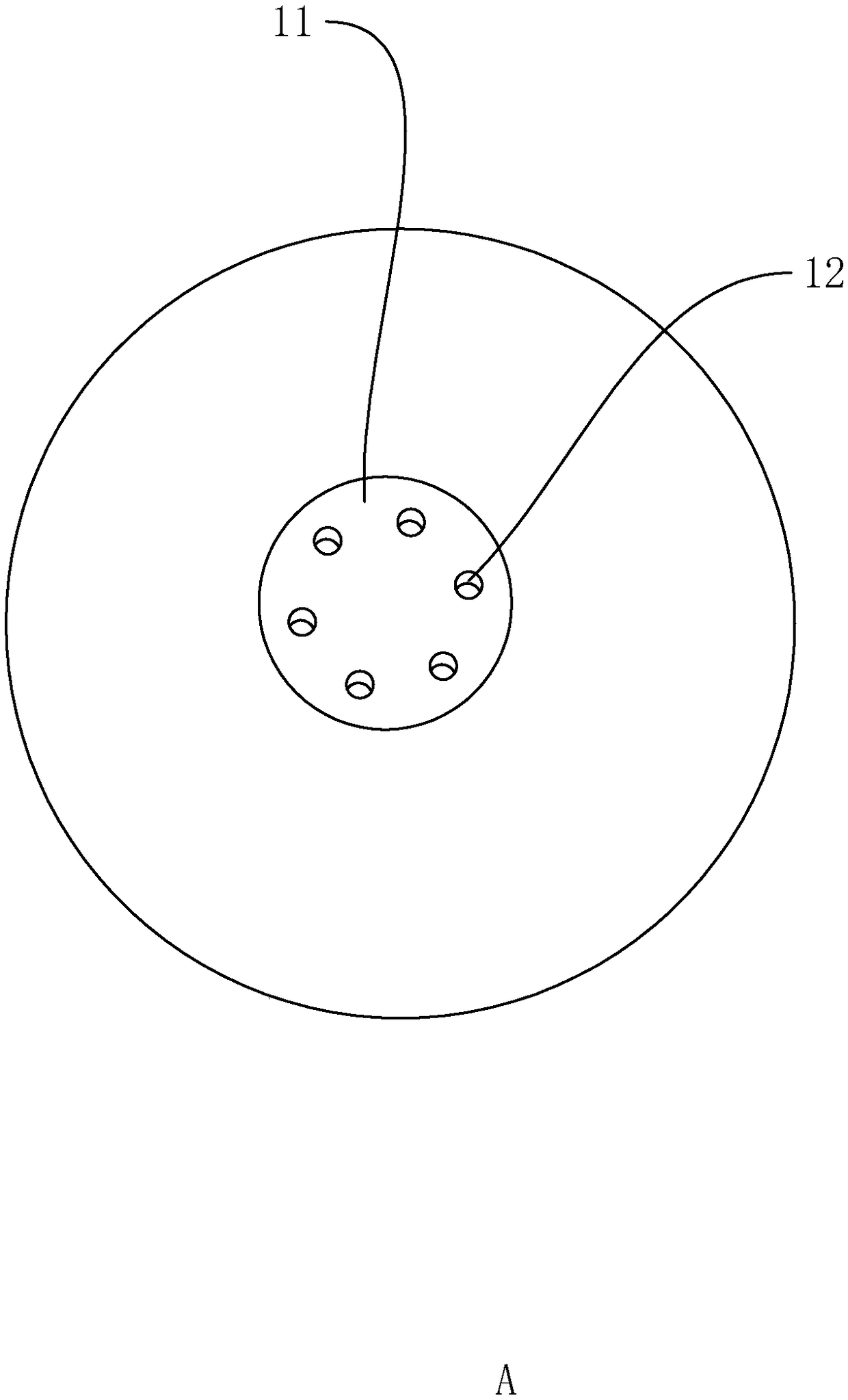

ActiveCN105344250ASmall concentrated water flowImprove water saving performanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater savingStreamflow

The invention relates to the field of water purifying equipment and provides a spiral-wound membrane component and a filter element employing the same. The spiral-wound membrane component comprises a core tube and a water purification membrane group, wherein the water purification membrane group is wound around the core tube; the width of the edge, adjacent to the core tube side, of the water purification membrane group is larger than that of the edge, far away from the core tube side. Compared with the prior art, the spiral-wound membrane component and the filter element employing the same have the following benefits: when the thickness of a raw water guide net is set, the sectional area of a raw water channel in the spiral-wound membrane component is smaller or obviously smaller than that of the raw water channel of a traditional spiral-wound membrane component; when the raw water flow rates, the filtering areas and the water pressures on the raw water side are the same, the flow rate of raw water in the spiral-wound membrane component is much smaller, so that the flow rate of discharged concentrated water is also much smaller, and accordingly, the water-saving effect can be remarkably improved.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

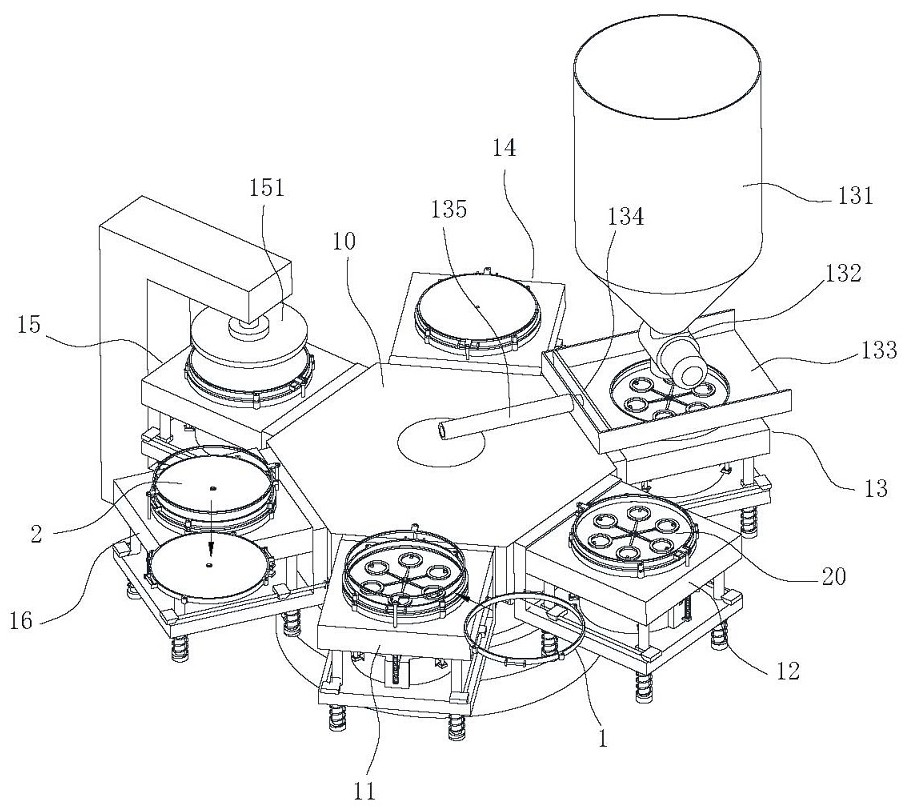

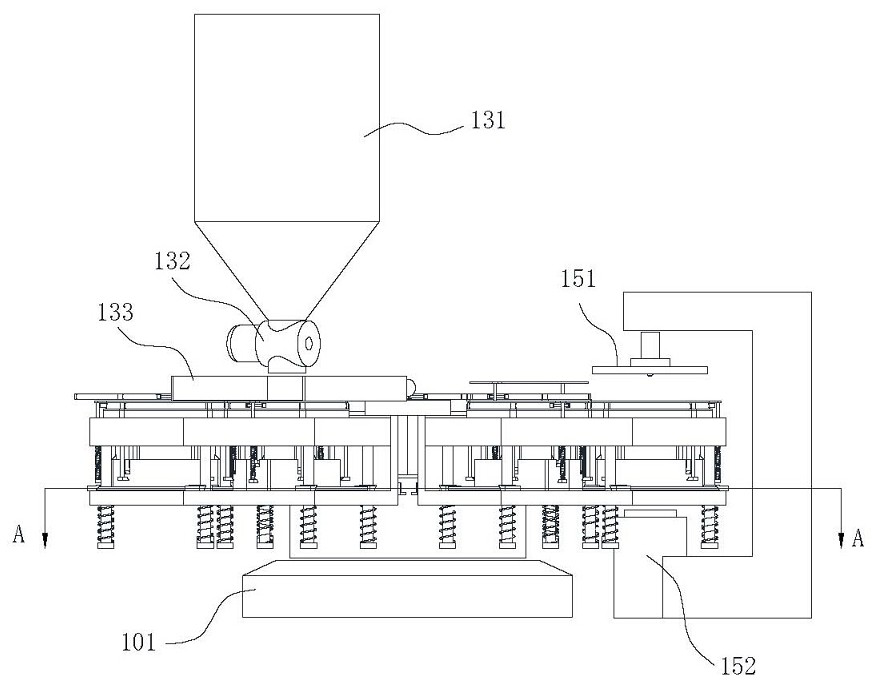

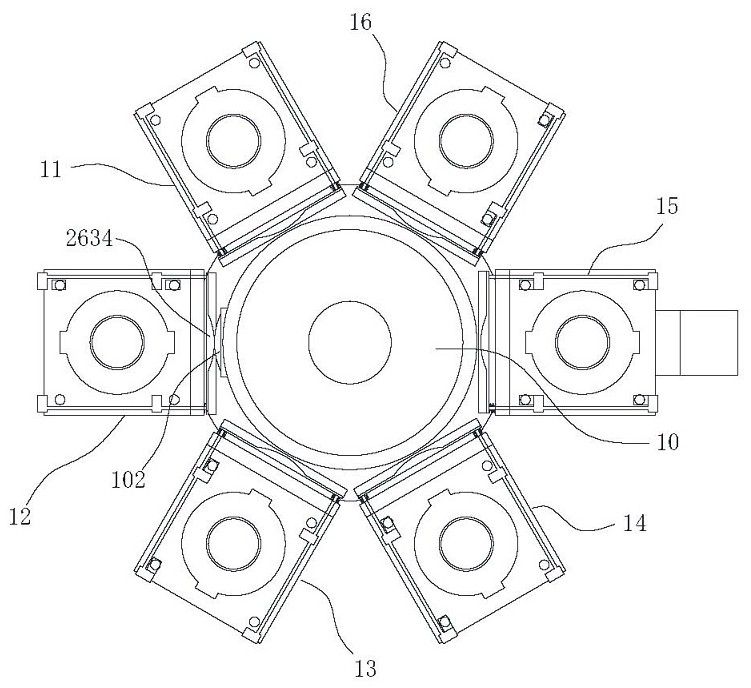

Anti-blocking type mould and production process for mould

InactiveCN108908836AIncrease the entry areaIncrease the areaMoulding machinesProduction rateUltimate tensile strength

Owner:칭다오탠윤헝왠폼플라스틱머쉬너리앤드이콰이먼트

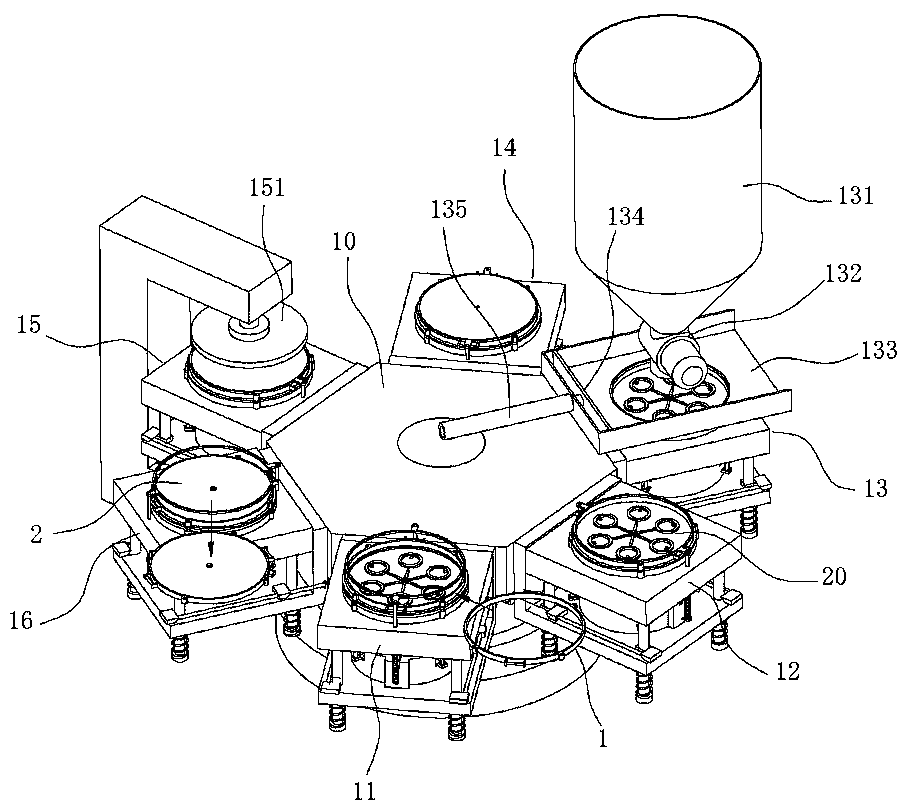

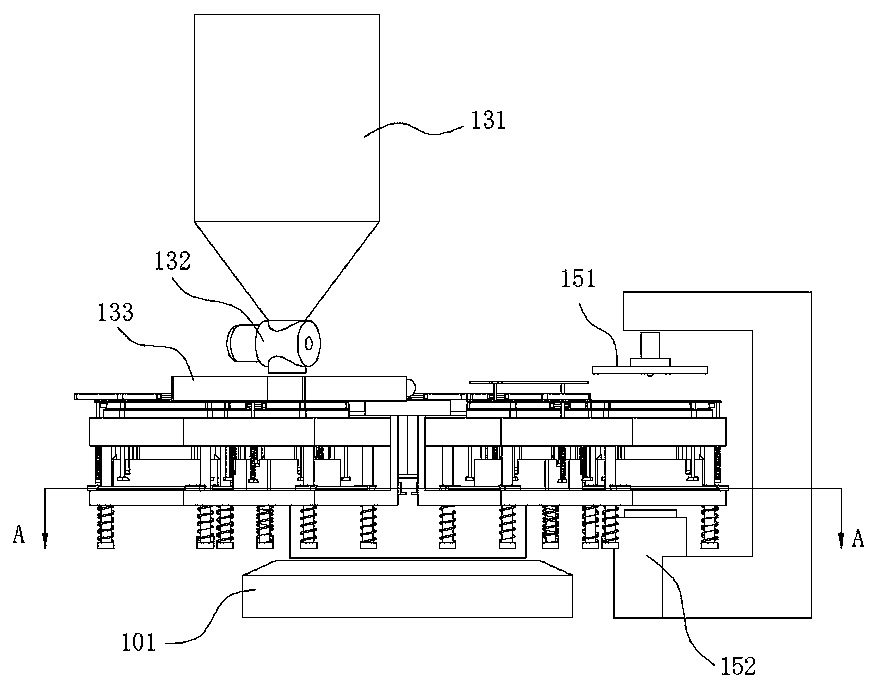

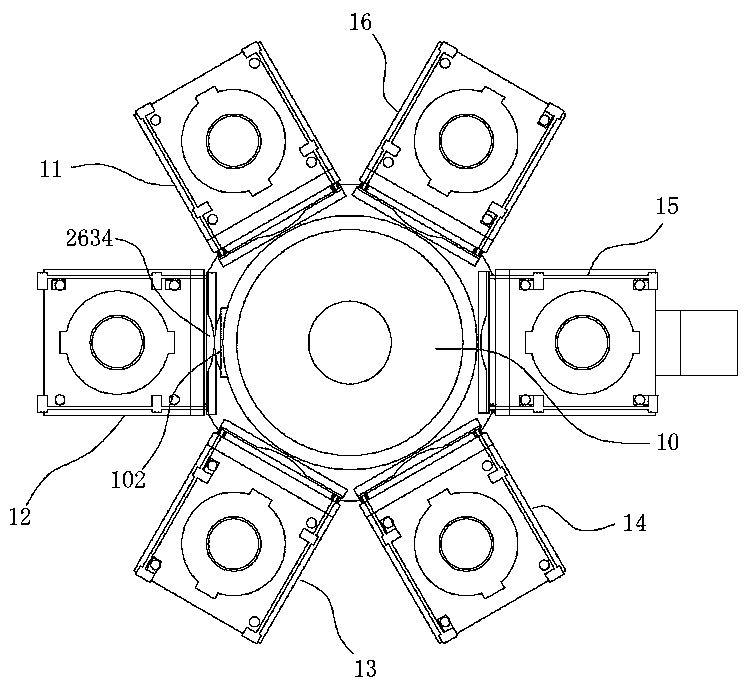

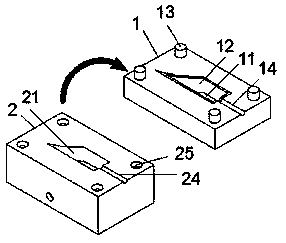

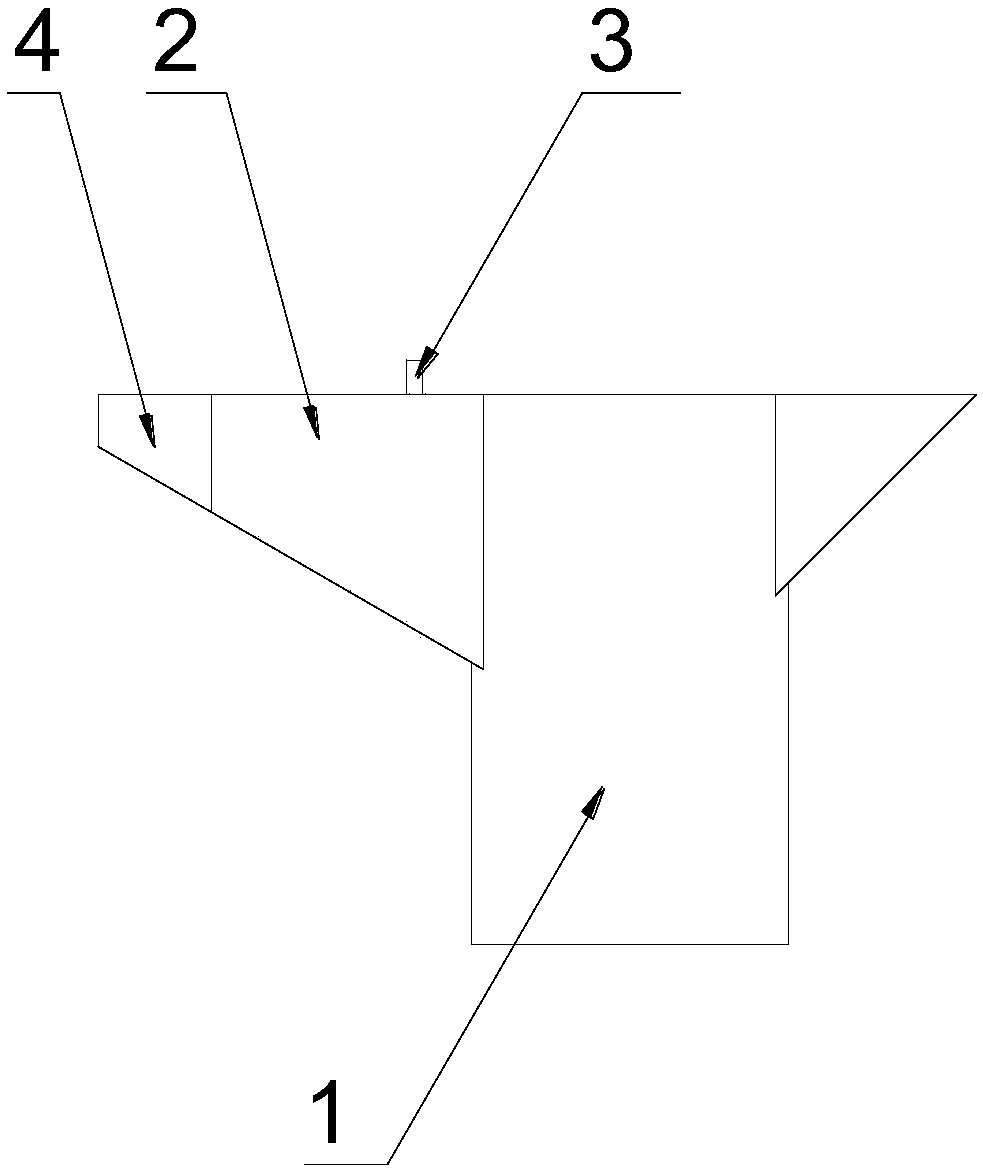

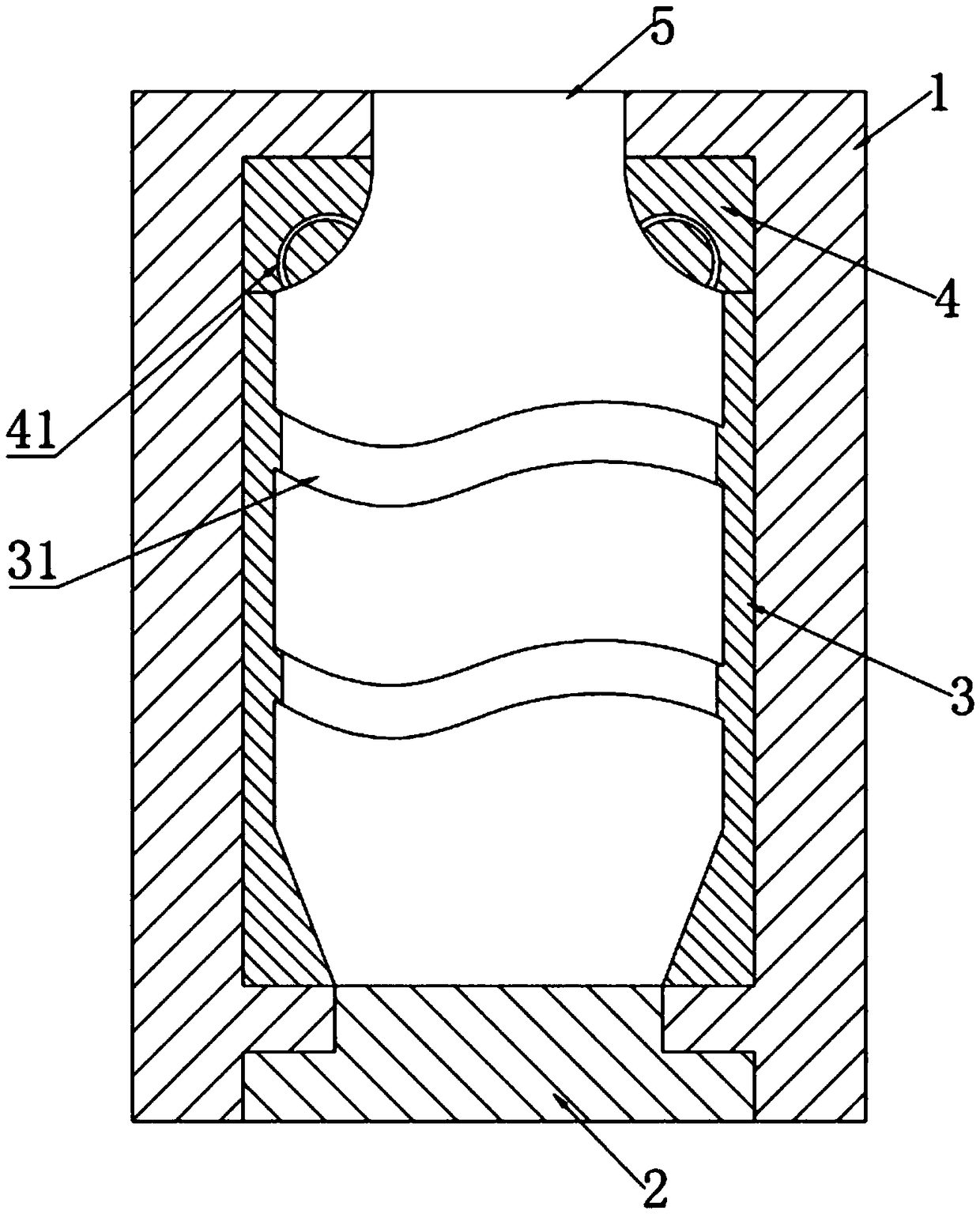

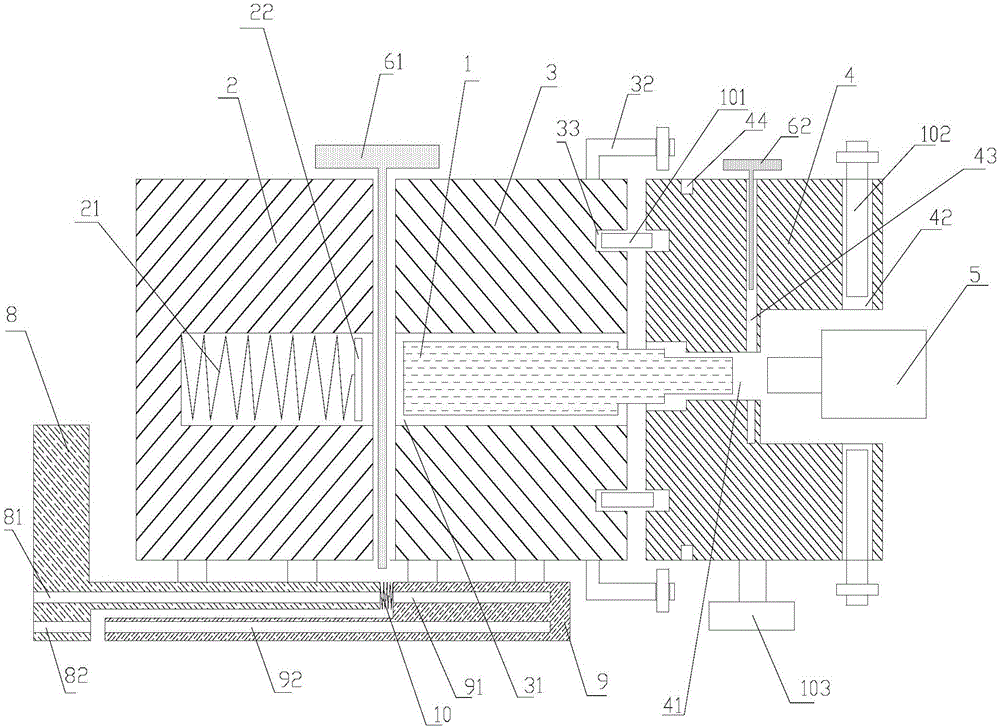

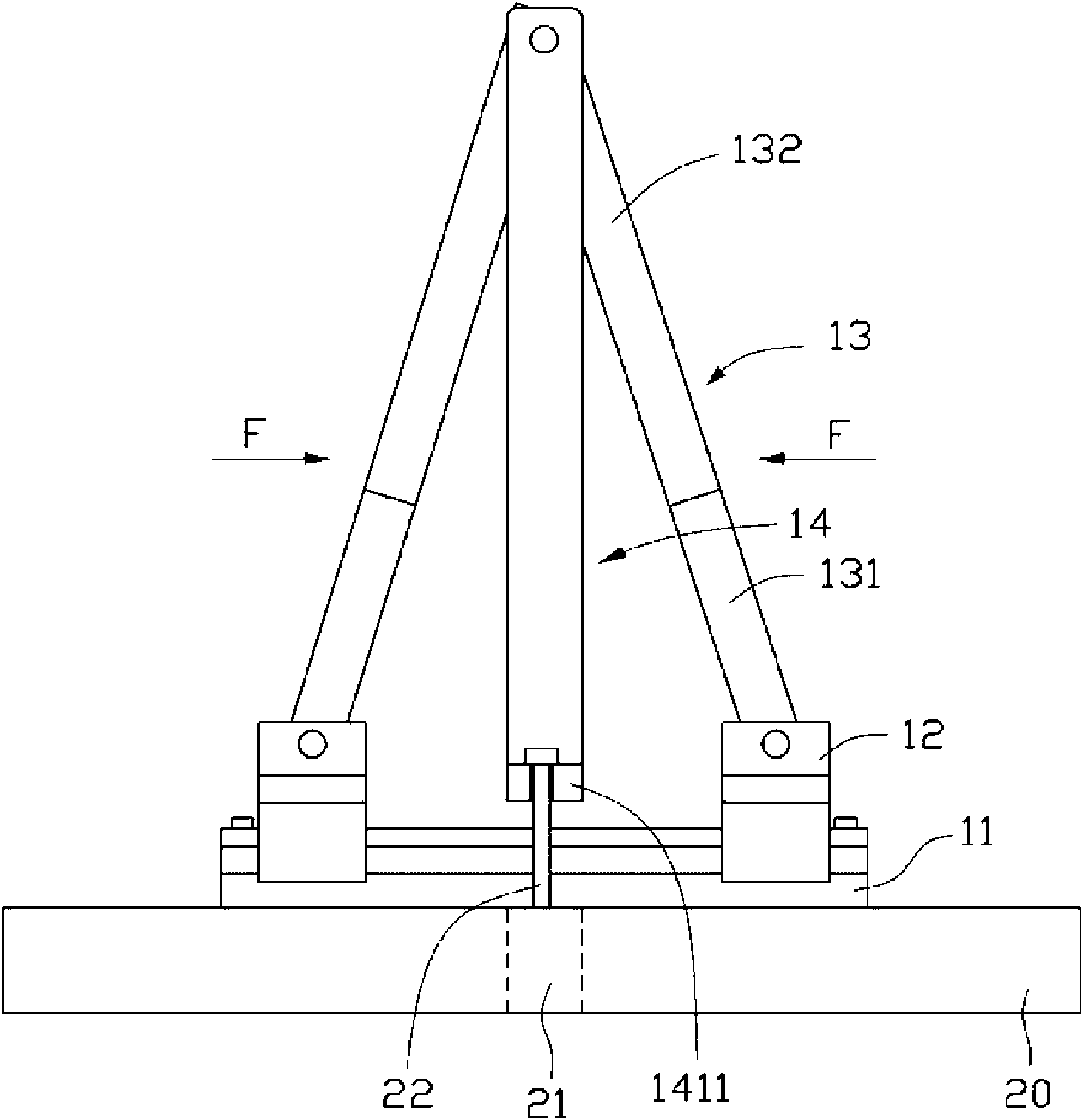

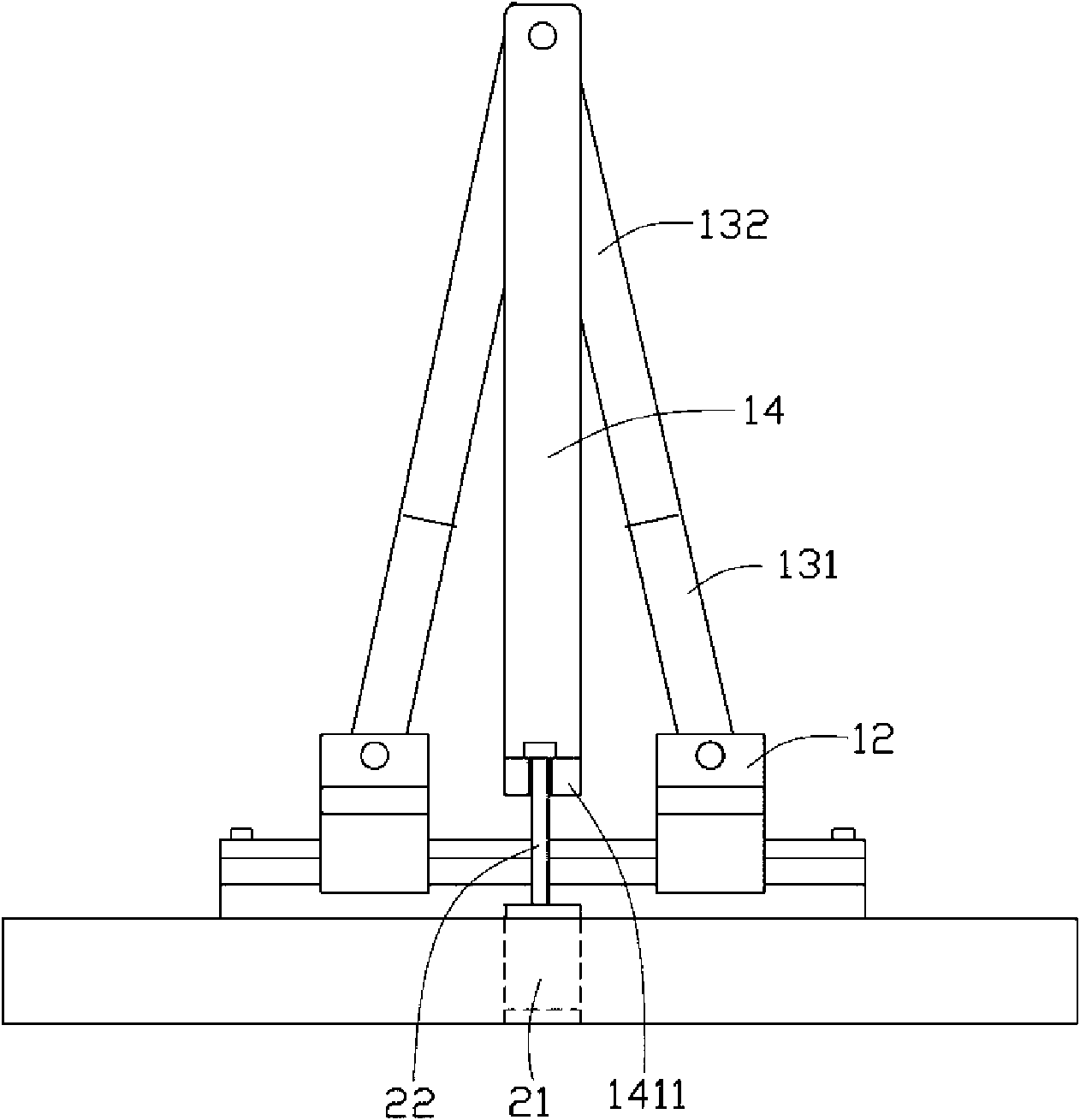

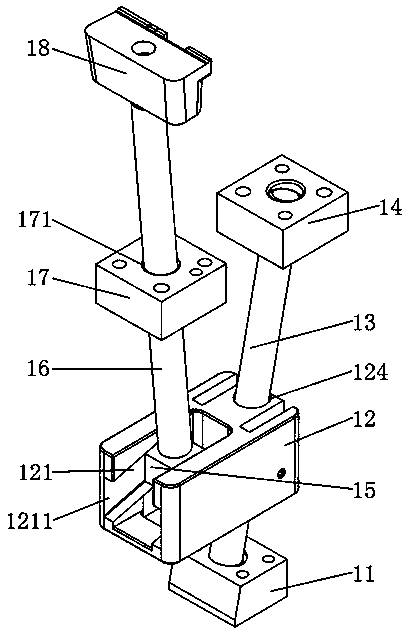

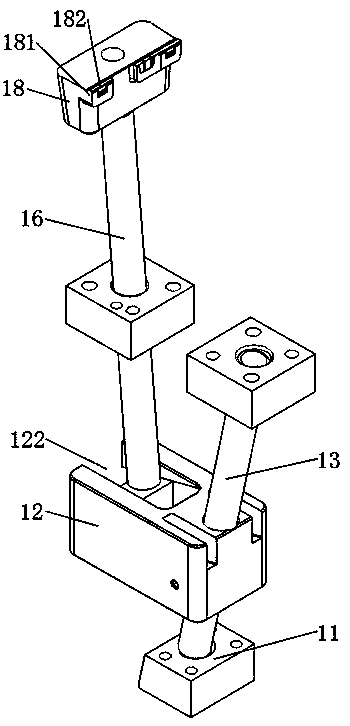

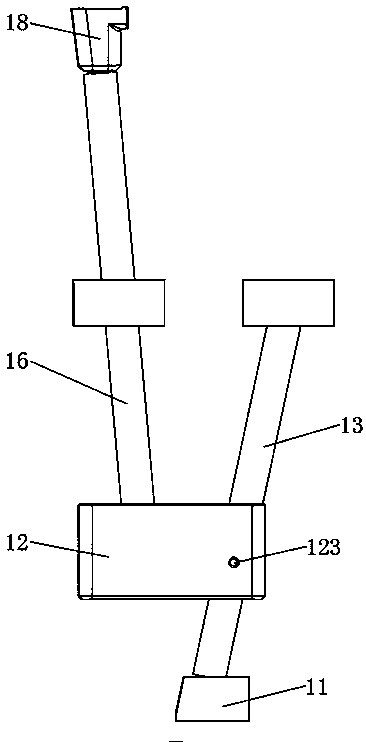

Demolding mechanism

ActiveCN110947919AShorten mold opening strokeGood for draftFoundry mouldsMoulding machine componentsPhysicsEngineering

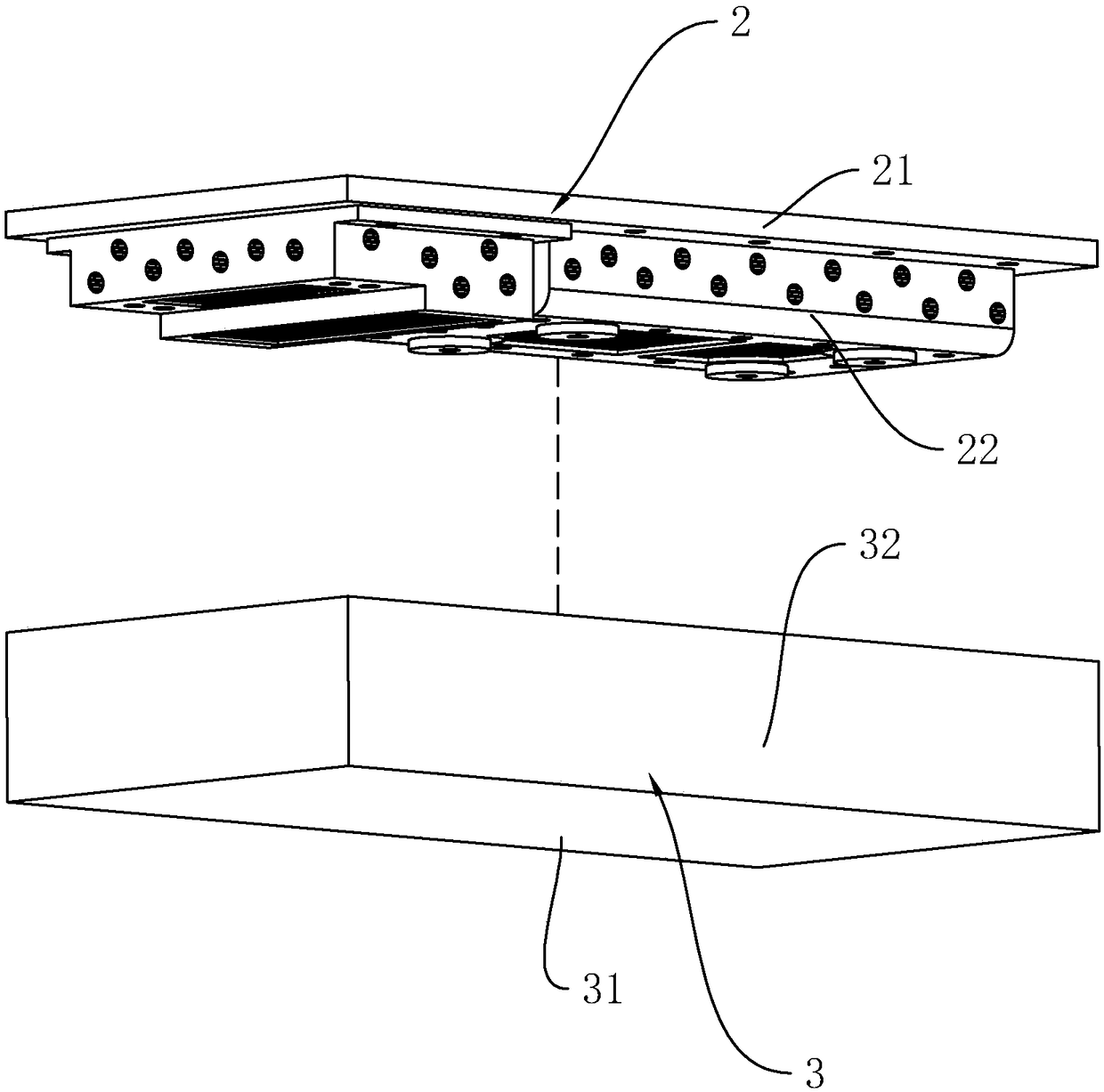

The invention belongs to the field of automobile part production and processing and particularly relates to a demolding mechanism comprising an upper mold plate and a lower mold plate which are arranged in the vertical direction in an open-close mode. A mandrel for forming a sand mold center runner is arranged in the center of the lower mold plate. The mandrel and a core hole formed in the centerof the lower mold plate are in sliding fit in the vertical direction, and a first elastic unit is arranged between the mandrel and the lower mold plate and is used for driving the mandrel to pop up relative to the lower mold plate. The side wall of the mandrel is further provided with an annular groove. A clamping plate arranged slidably in the radial direction of the mandrel is arranged in the lower mold plate. A second elastic unit is arranged between the clamping plate and the lower mold plate. A telescopic airbag is further arranged between the clamping plate and the lower mold plate. According to the demolding mechanism, the mandrel is of an elastic structure, the lower mandrel is flush with the surface of molding sand during sand spreading so as to ensure the pass-through longitudinal runner, in addition, in the extrusion forming process, the mandrel contracts downwards under extrusion of a pressing column, the mandrel and the pressing column achieve mold opening to the upper andlower sides correspondingly during mold opening, the mold opening stroke of the mandrel is reduced, and mold pulling is facilitated better.

Owner:安庆海威尔机械有限公司

Mould capable of preventing cold shrinkage for excavator shovel head tip precision casting

The invention discloses a mould capable of preventing cold shrinkage for excavator shovel head tip precision casting. The mould comprises an upper mould body and a lower mould body; an upper mould groove is formed in the middle of the upper mould body, and a demoulding ring is sleeved with the inner side wall of the upper mould groove; a lower mould groove is formed in the middle of the lower mould body; a jacking plate is slidably connected to an inner cavity of the lower mould groove; a hydraulic oil inlet channel is formed in the front side wall of the inner cavity of the lower mould groovein a penetrating mode; and a lower wax channel and an upper wax channel are mutually buckled. Through using of the jacking plate and the hydraulic oil inlet channel, when external wax is led into thelower mould groove and the upper mould groove, the hydraulic oil inlet channel is connected with an external hydraulic pump, and thus hydraulic oil enters the bottom face of the jacking plate to prevent cold shrinkage deformation of a wax mould; and meanwhile, through using of the demoulding ring, the function of convenient mould drawing is achieved.

Owner:山东同其智能科技有限公司

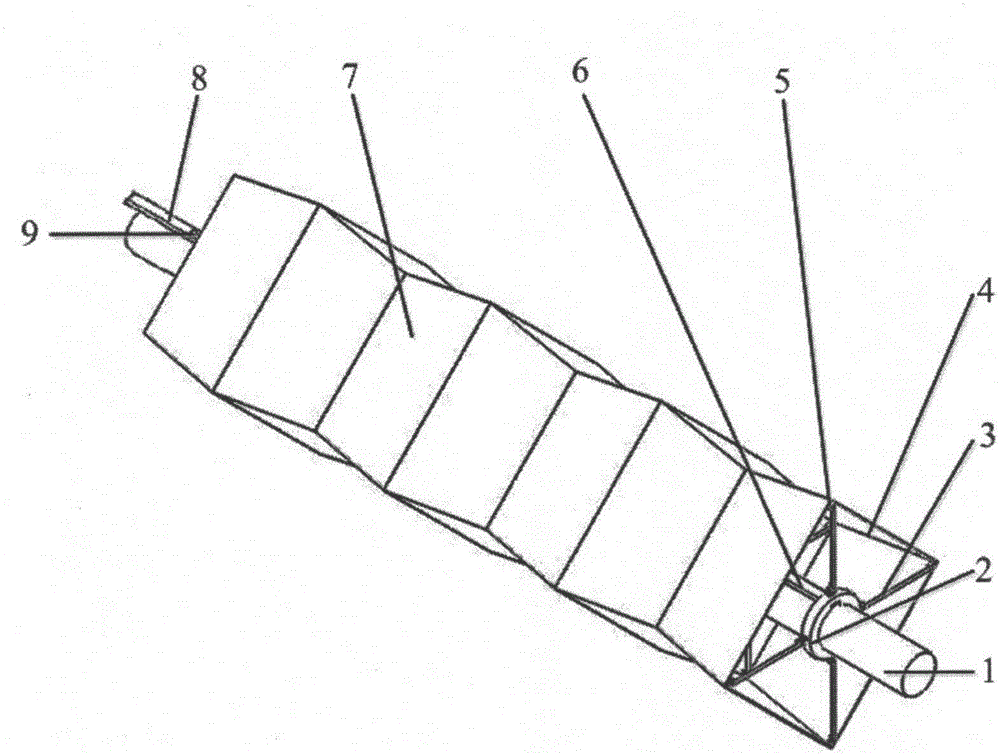

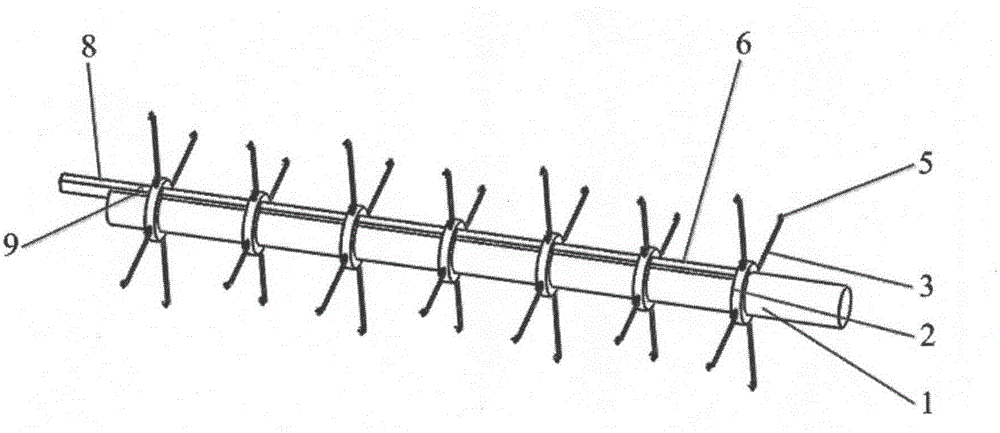

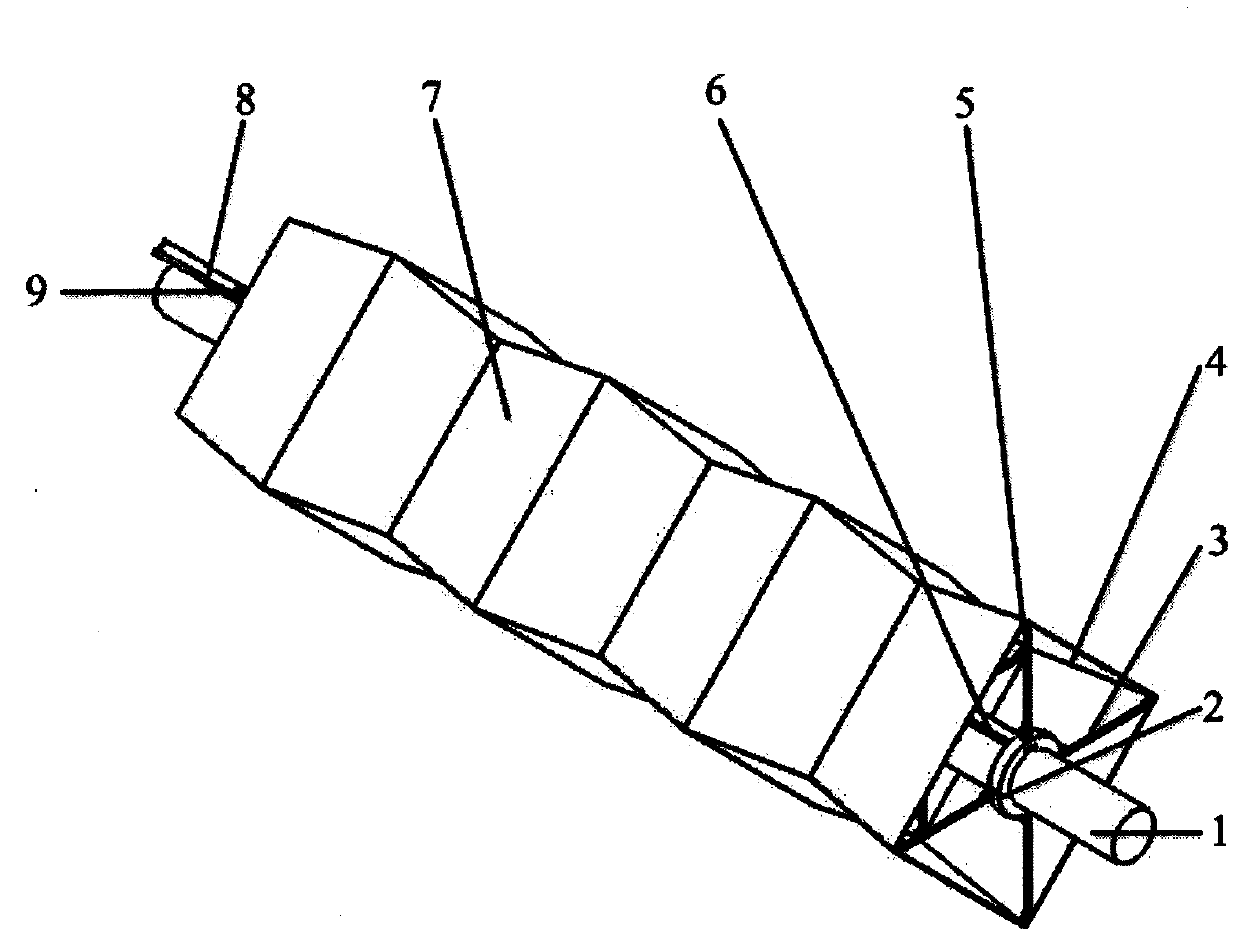

Variable-section polygonal woven mandrel and assembling method thereof

The invention relates to a variable-section polygonal woven mandrel which is characterized by comprising a mandrel shaft, wherein a long groove is formed in the mandrel shaft, the long groove extends to the bottom end surface of the mandrel shaft from the top of the mandrel shaft along with the length direction of the mandrel shaft, so as to form a through groove end, a plurality of mandrel rings are sheathed outside the mandrel shaft and are arranged along with the length direction of the mandrel shaft, bulges matched with the long groove are arranged on the inner ring surface of each mandrel ring, a catch lever matched with the long groove is arranged between the bulges of two adjacent mandrel rings, the locking catch lever and the mandrel shaft are fixedly connected, N positioning levers are evenly distributed on the outer peripheral surface of each mandrel ring circumferentially, N is more than or equal to 3, and a cover body component is supported by the positioning levers. According to another technical scheme, the invention provides an assembling method of the variable-section polygonal woven mandrel. By adopting the technical scheme, the advantages are as follows: 1. the structure is simple, the weight is light, and the universality is strong; and 2. the manufacturing is easy, and the mandrel withdrawal is convenient and consumes less time.

Owner:DONGHUA UNIV

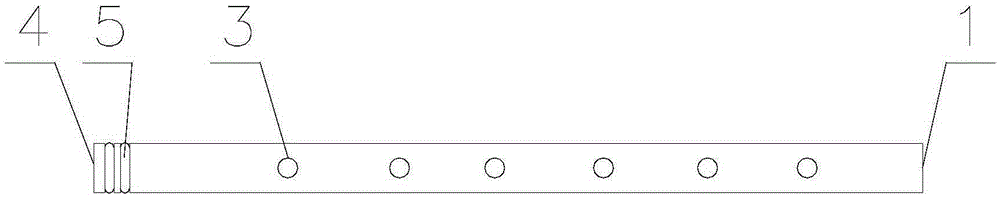

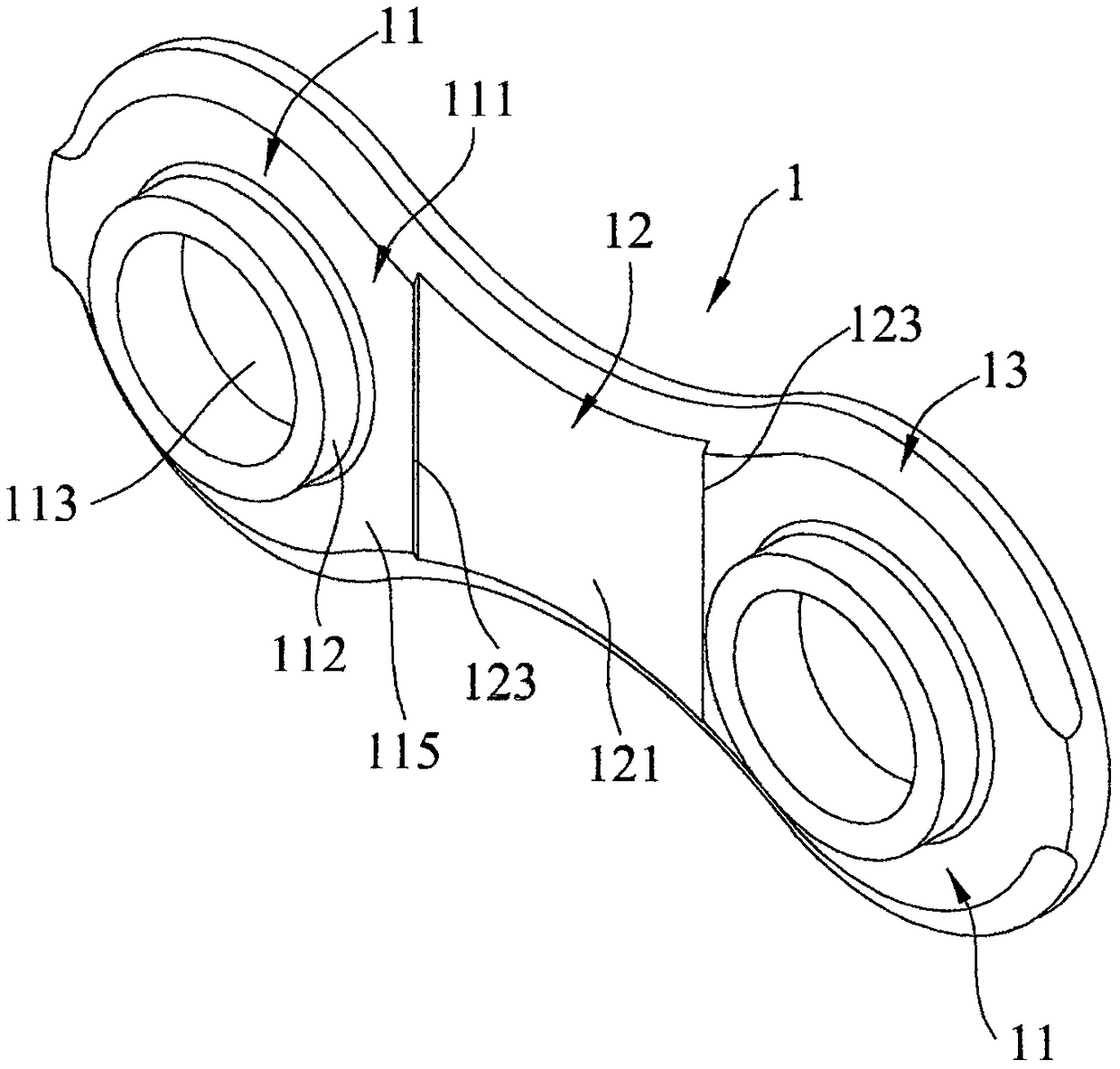

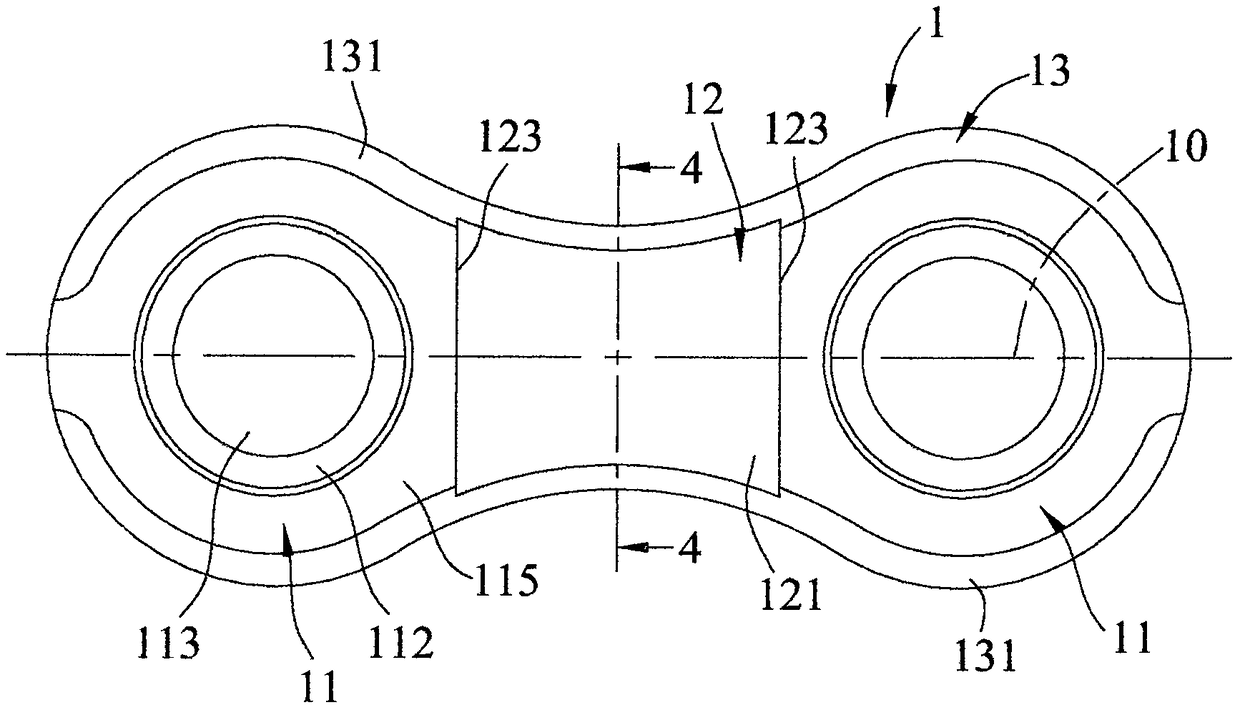

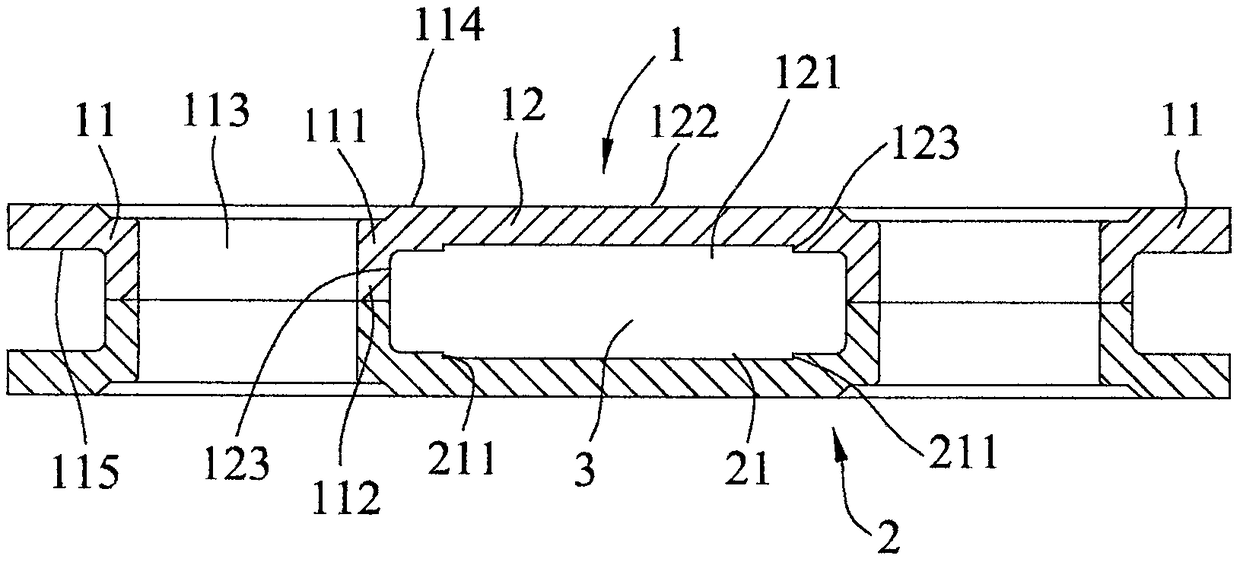

Chain and inner chain pieces

PendingCN108343708AIncrease widthEasy to snapChain linksDriving chainsEngineeringMechanical engineering

The invention discloses a chain and inner chain pieces thereof. Each inner chain piece and one opposite chain piece can jointly define a clamping space, each inner chain piece comprises two assembledconnection parts arranged at an interval along a longitudinal center line, and a connection part connected with the assembled connection parts, each assembled connection part is proved with an assembled connection hole, the connection part is provided with a groove which is sunk in the direction away from the clamping space and is provided with two parallel spaced groove sides, the chain comprisesthe multiple inner chain pieces, multiple outer chain pieces and multiple chain shafts in series connection with the inner chain pieces and the outer chain pieces and each provided with a center axis, an axis distance is achieved between two adjacent center axes, and the ratio of the axis distance to the total width of the chain is 2.39+ / -0.12. The chain can be more suitable for being used in thefield with the higher variable segment number and meanwhile, the speed changing smoothness is improved.

Owner:超汇桂盟传动(苏州)有限公司

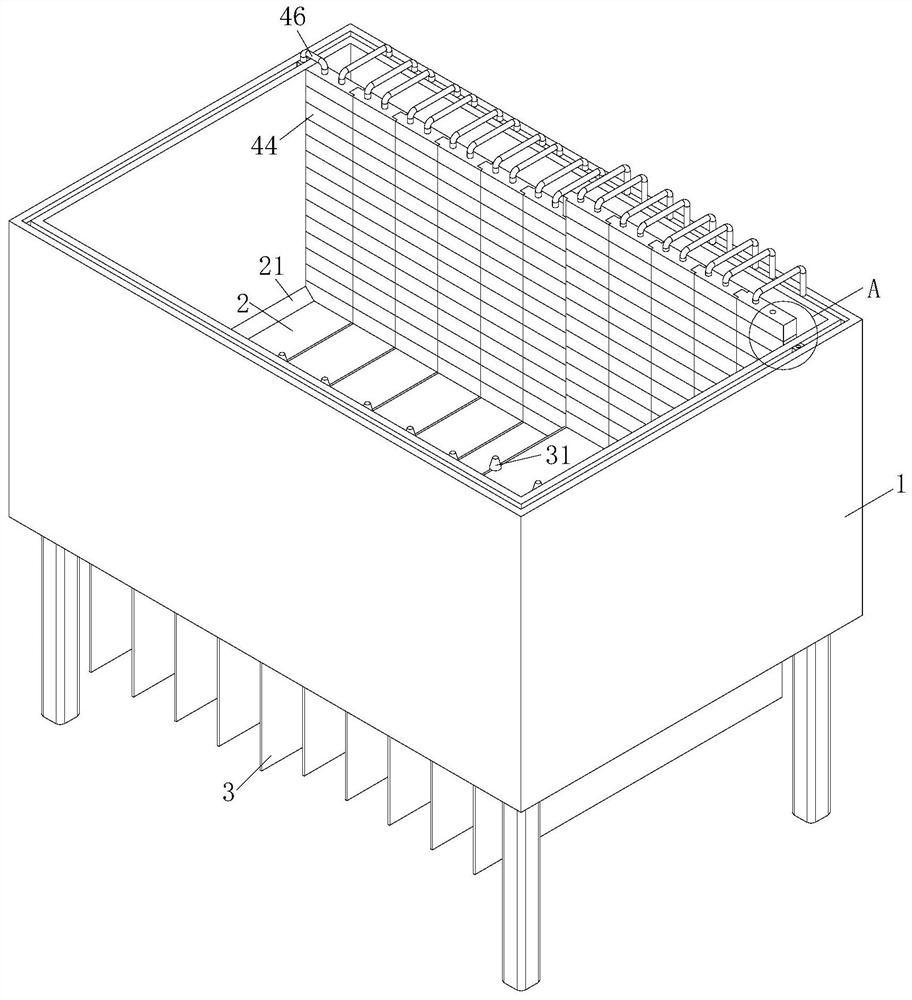

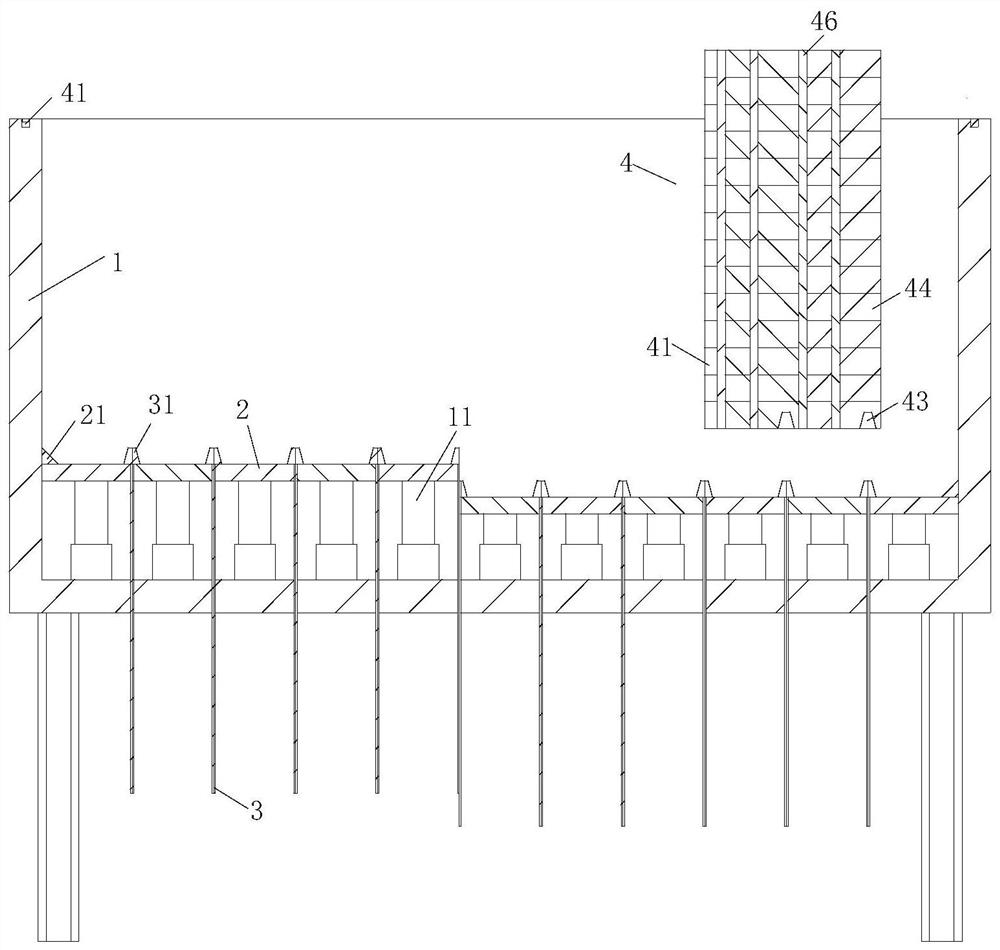

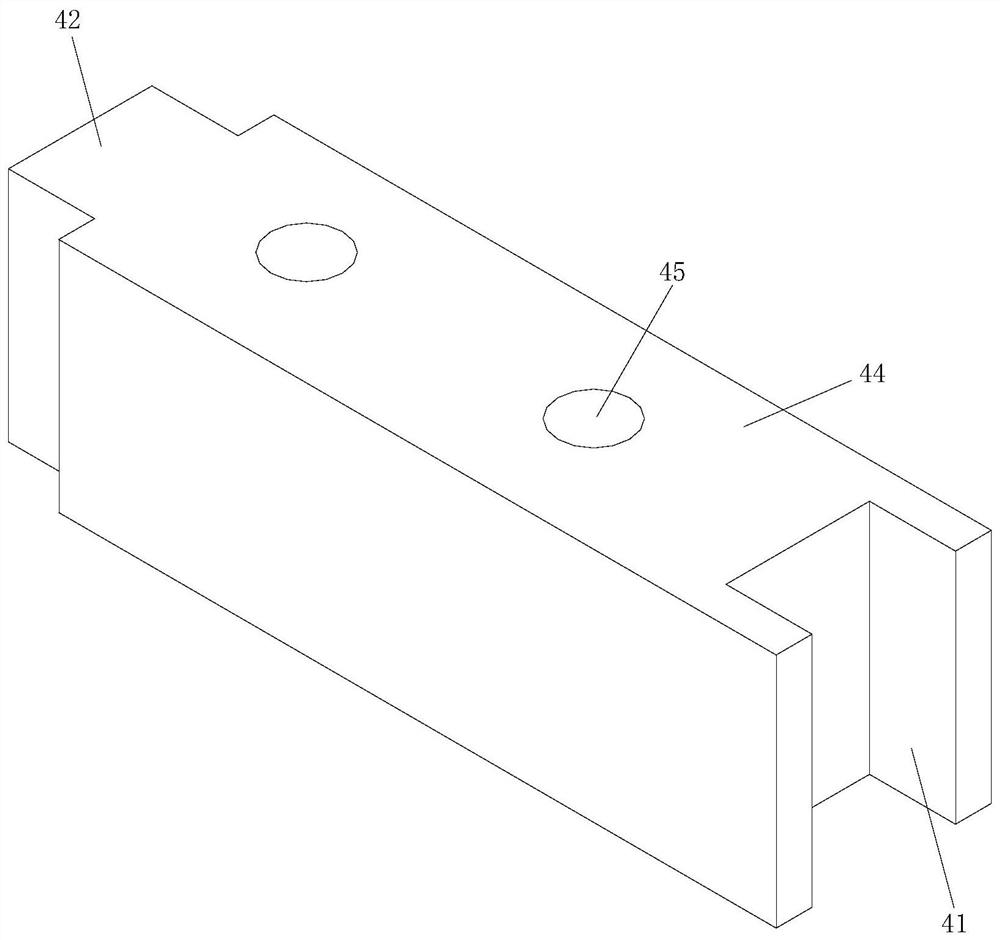

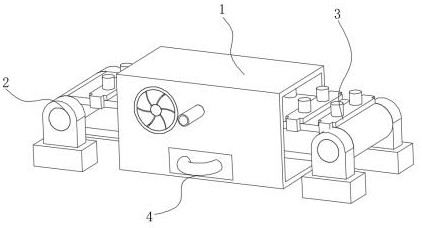

Building construction equipment and construction method based on BIM modeling

ActiveCN113618872AEasy to prefabImprove molding efficiencyMouldsCeramic shaping mandrelsBrickArchitectural engineering

The invention belongs to the technical field of building construction, and particularly relates to building construction equipment and a construction method based on BIM modeling. The building construction equipment comprises a box body and a controller; the bottom of the box body is fixedly connected with hydraulic push rods, the push rod tops of the hydraulic push rods are fixedly connected with bottom plates, baffles are arranged between the bottom plates and slidably connected with the box body, the tops of the baffles are slidably connected with limiting blocks, the limiting blocks are fixed to the baffles through screws, the bottoms of the limiting blocks make contact with the bottom plates, and side plates are arranged at the top of the bottom plates, and grooves are formed in one sides of the side plates. In the prior art, bricks of various models need to be used for building walls in the construction process, and the sizes of the bricks are often inappropriate for corners, so that the construction efficiency is low; and according to the building construction equipment, by arranging the box body, the brick size can be prefabricated conveniently, the cavity size of the box body can be adjusted conveniently according to the BIM modeling result, concrete block prefabrication is facilitated, the forming efficiency is high, and then the construction efficiency is improved.

Owner:蒋贤龙 +6

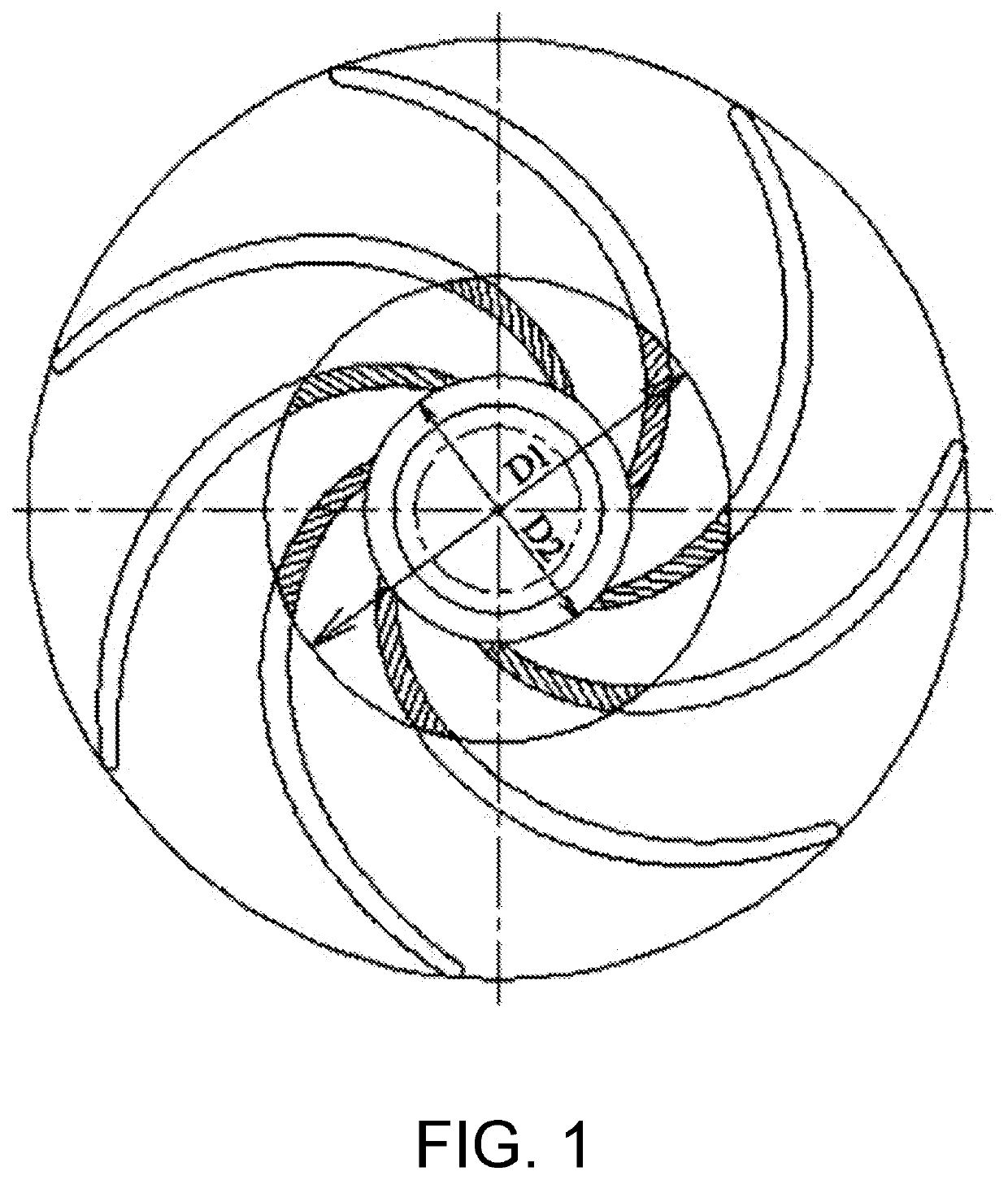

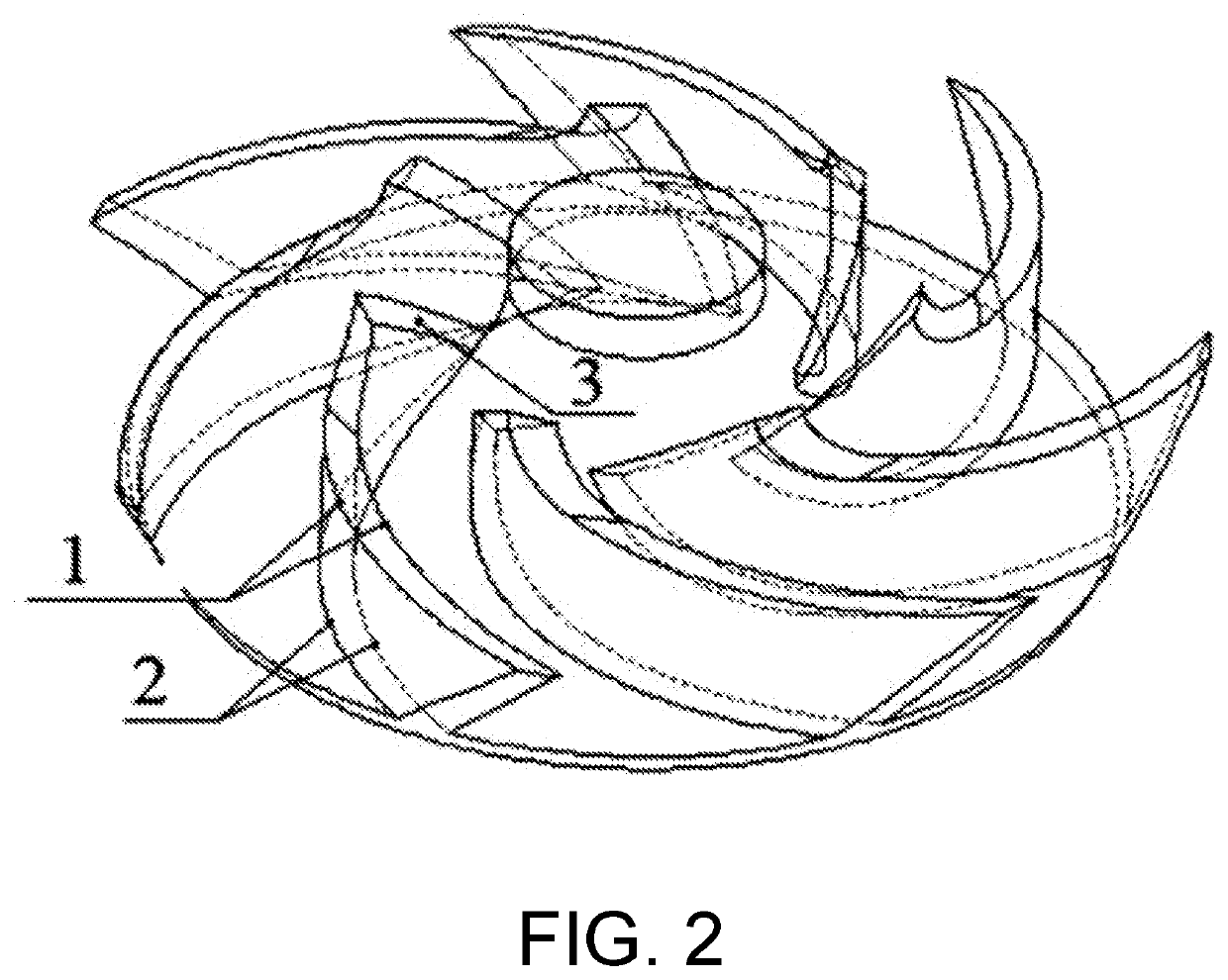

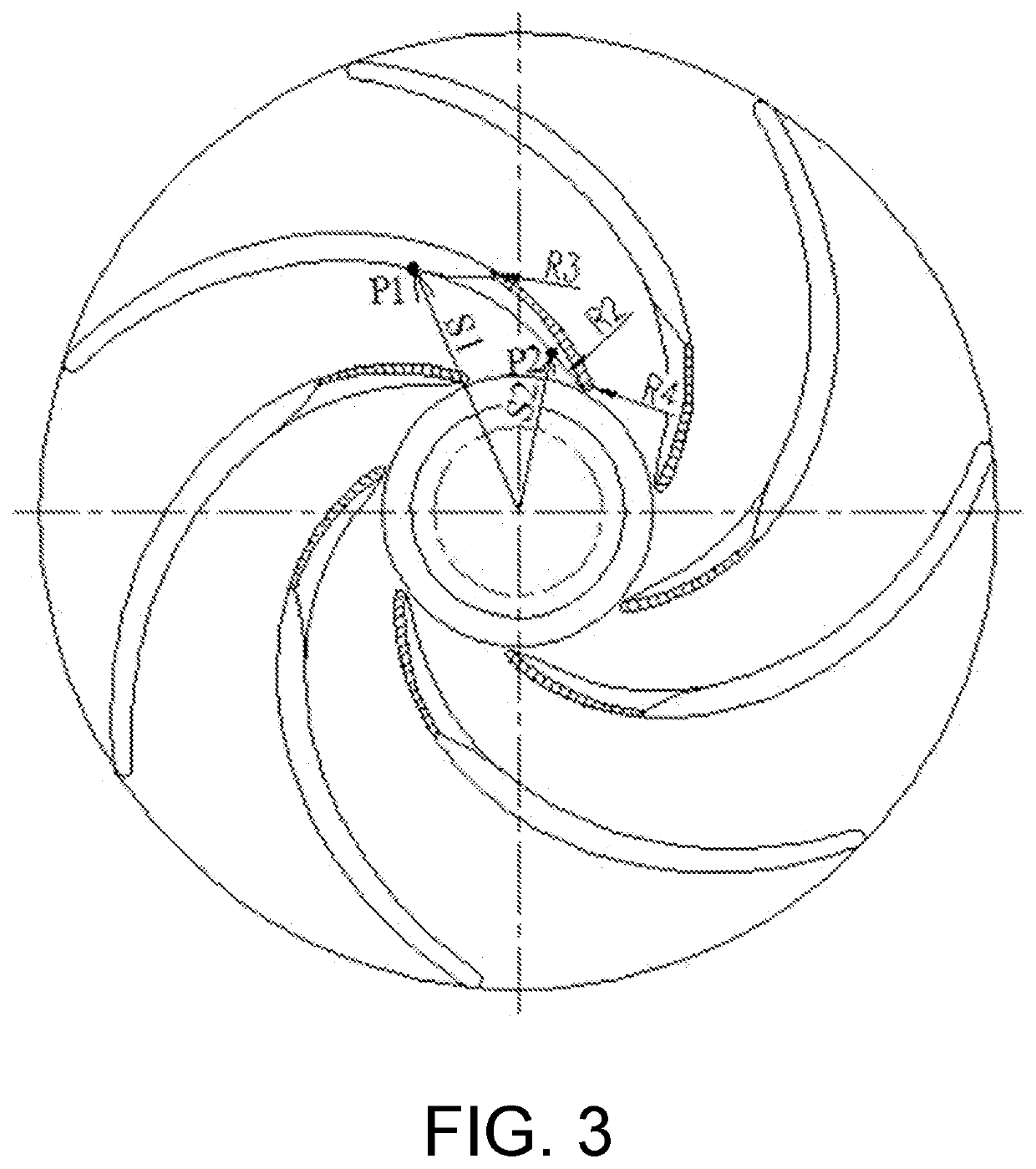

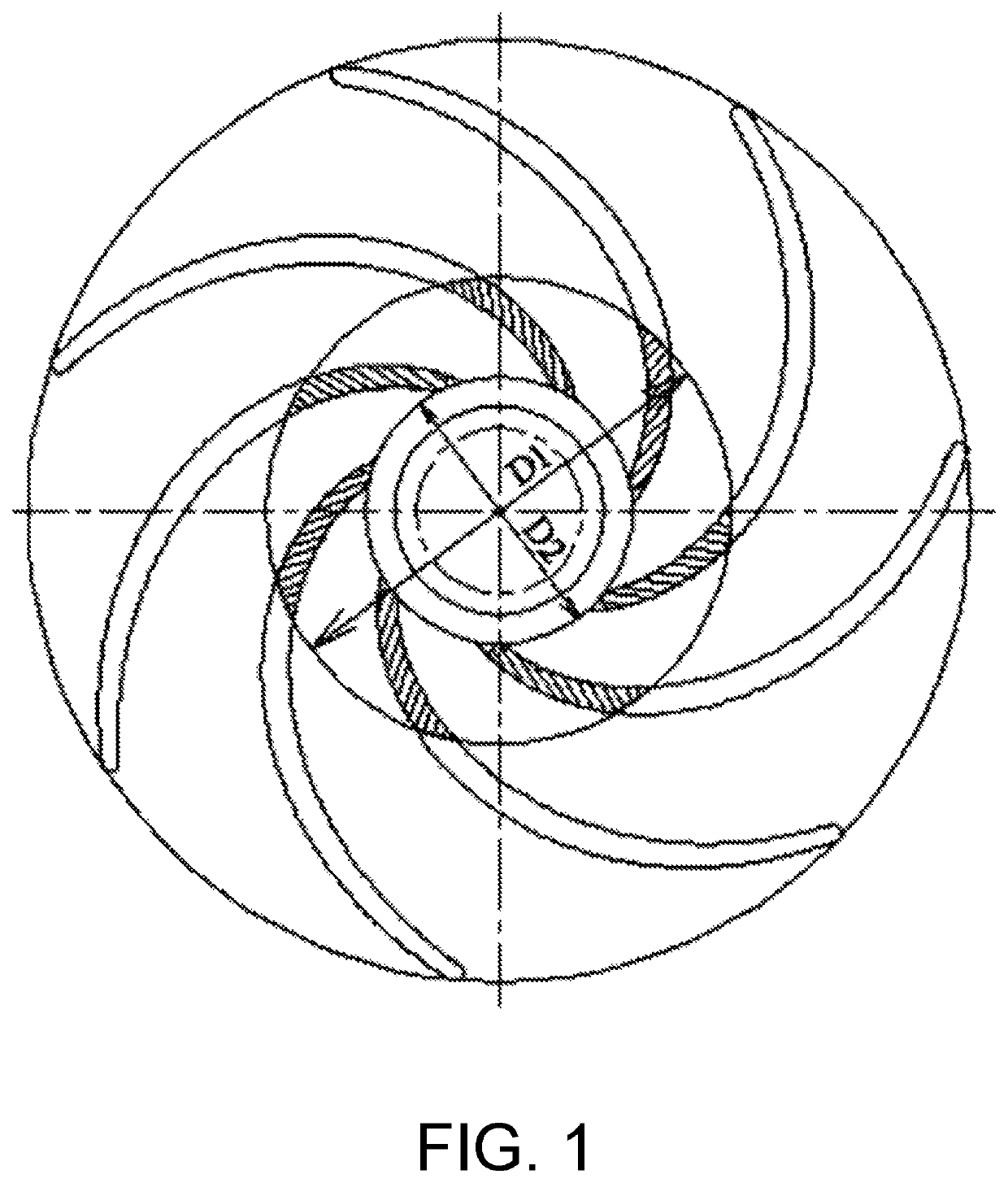

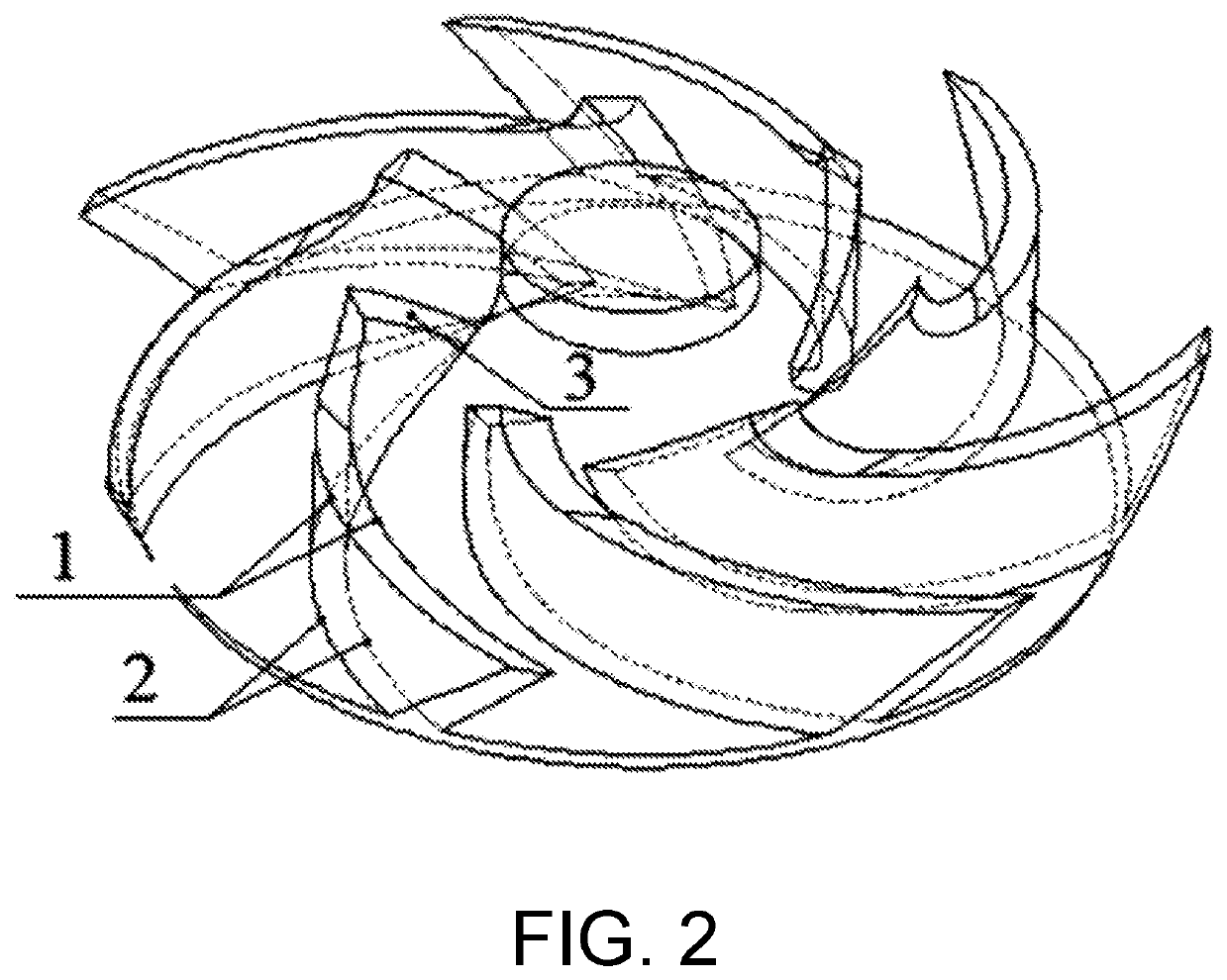

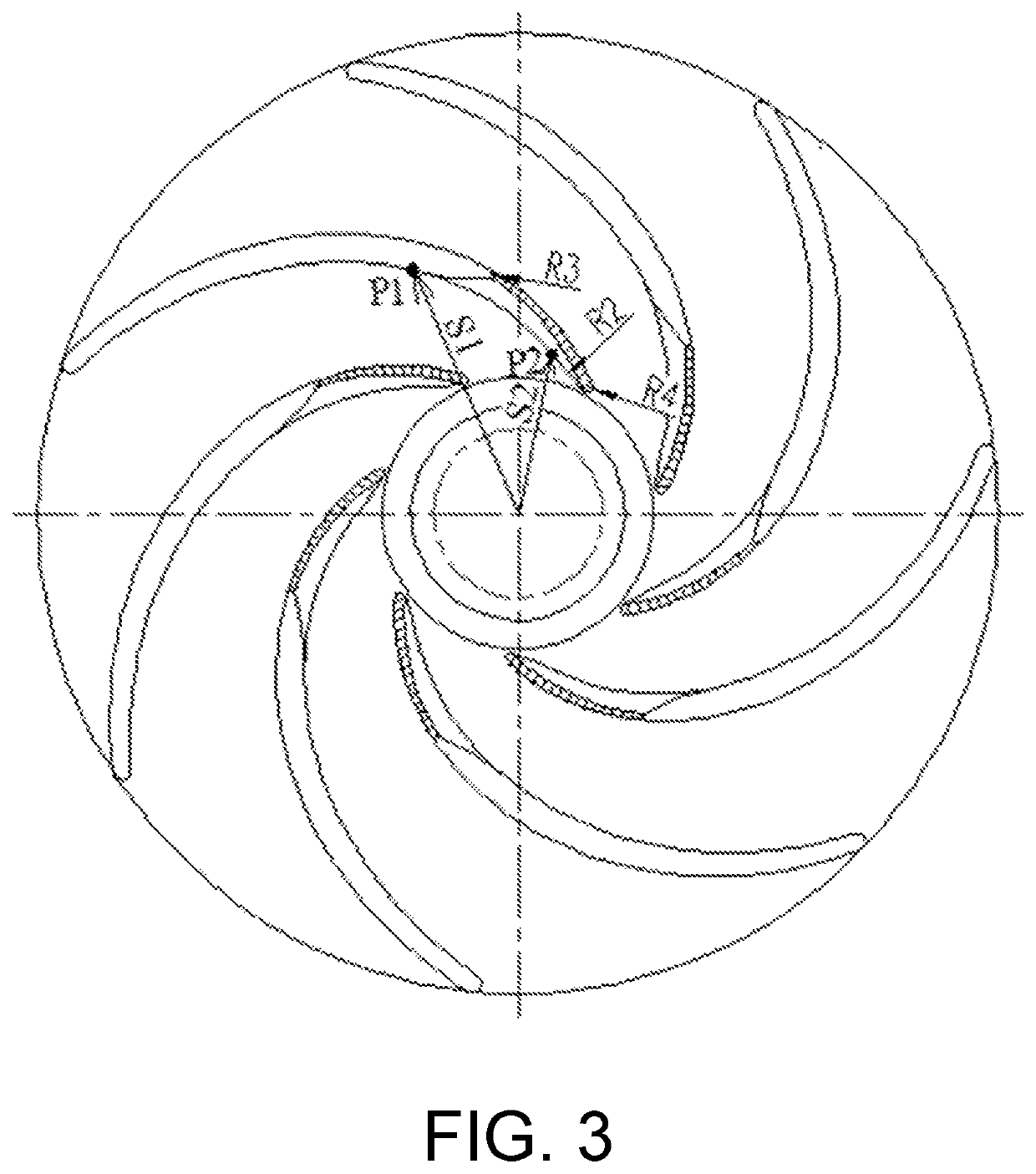

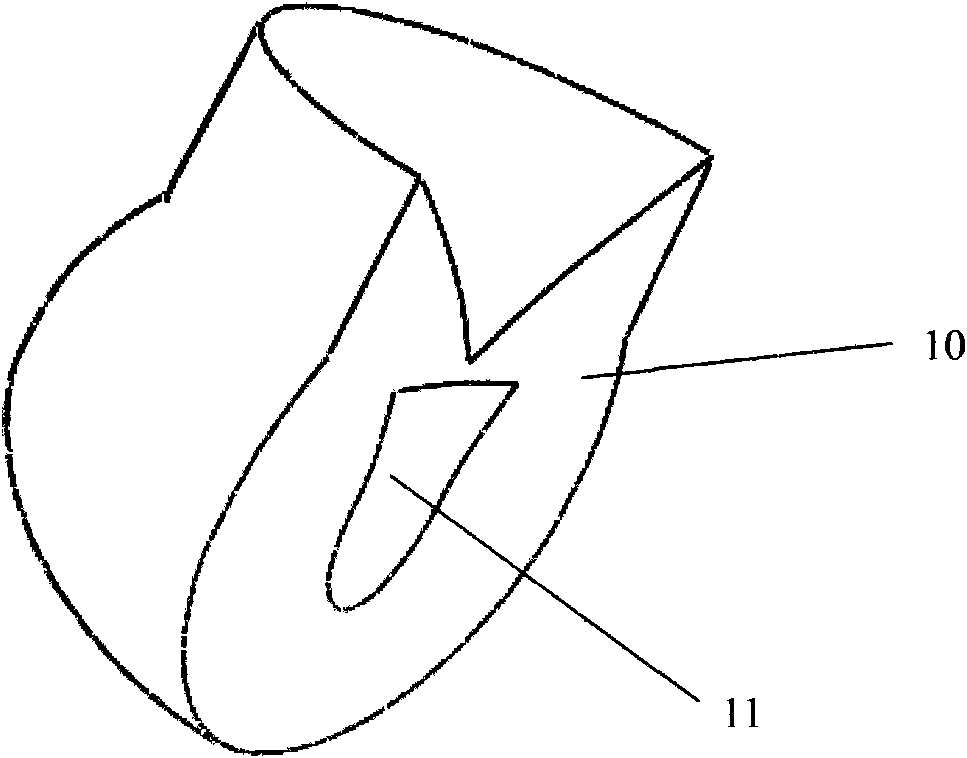

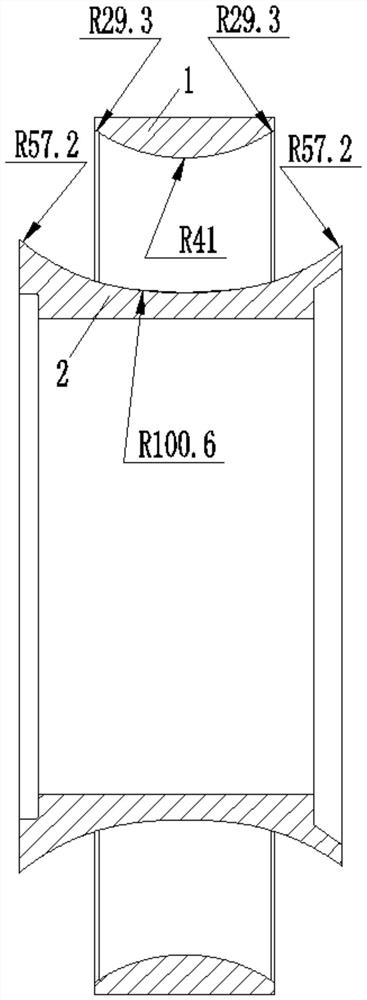

Curved surface processing method for inlet edge of cylindrical blade of centrifugal pump impeller

A curved surface processing method for an inlet edge of a cylindrical blade of a centrifugal pump impeller includes following steps. A center of an impeller is used as a center to draw circles having respective diameters. A first point having a first distance from the center is determined on a concave side curve at a top of the blade, and a second point having a second distance from the center is determined on a concave side curve at a bottom of the blade. By improving the shape of a blade in an impeller, the angle of an inlet edge at the top of the blade is more close to the tangent direction, and the inlet angle of the top blade is reduced. A twisted surface is formed between a first arc segment at the top and a second arc segment at the bottom.

Owner:JIANGSU UNIV

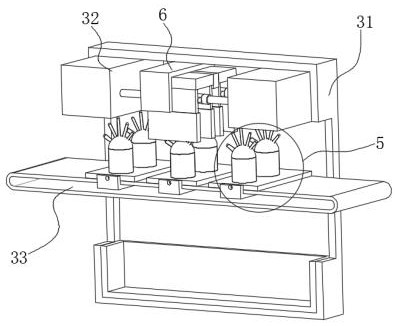

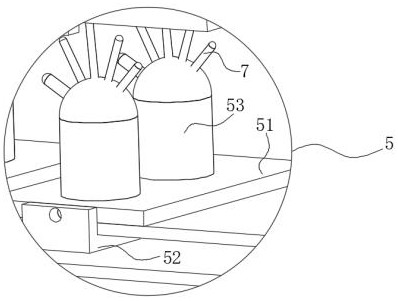

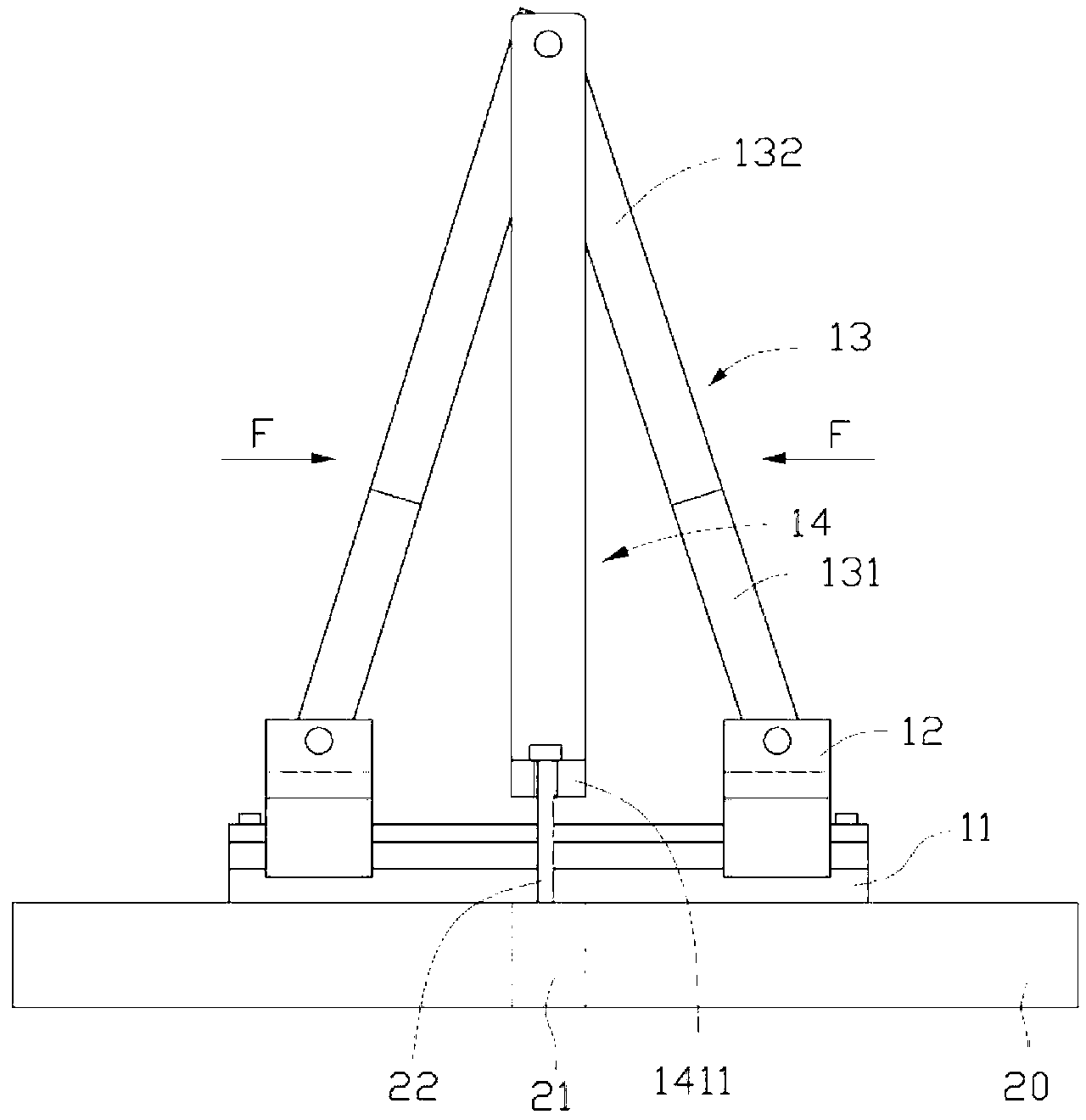

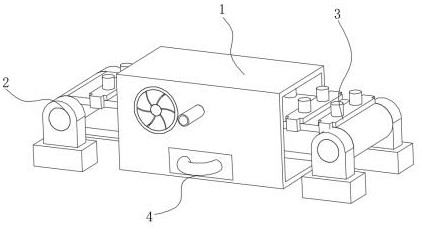

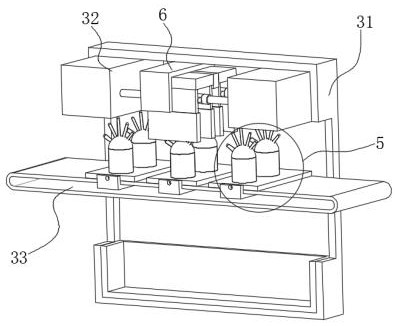

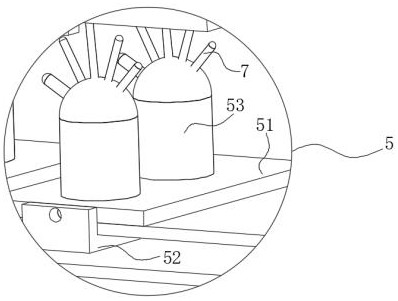

Labor protection glove demolding device

The invention belongs to the field of labor protection appliance manufacturing, and particularly relates to a labor protection glove demolding device, which comprises a mold drawing box, a demolding module is arranged in the mold drawing box, the upper surface of the demolding module is fixedly connected with the top of the inner wall of the mold drawing box, the two ends of the demolding module extend to the exterior of the mold drawing box, rotating motors are rotationally connected to the two ends of the inner wall of the demolding module correspondingly, a ventilation opening is formed in the middle of the front face of the mold drawing box, and an air inlet pipe is fixedly connected to the middle of an inner cavity of the mold drawing box. Compared with traditional manual mold drawing, the device is used for pulling the gloves in batches, the efficiency is obviously higher, in the working process of the device, only manual feeding and discharging work is needed, the glove mold pulling speed is effectively increased, manpower resources are saved, and compared with common devices, the device can be used for pulling the gloves in batches, is high in automation degree, is simple to operate, and has a better market prospect.

Owner:江苏晟力捷安全用品科技有限公司

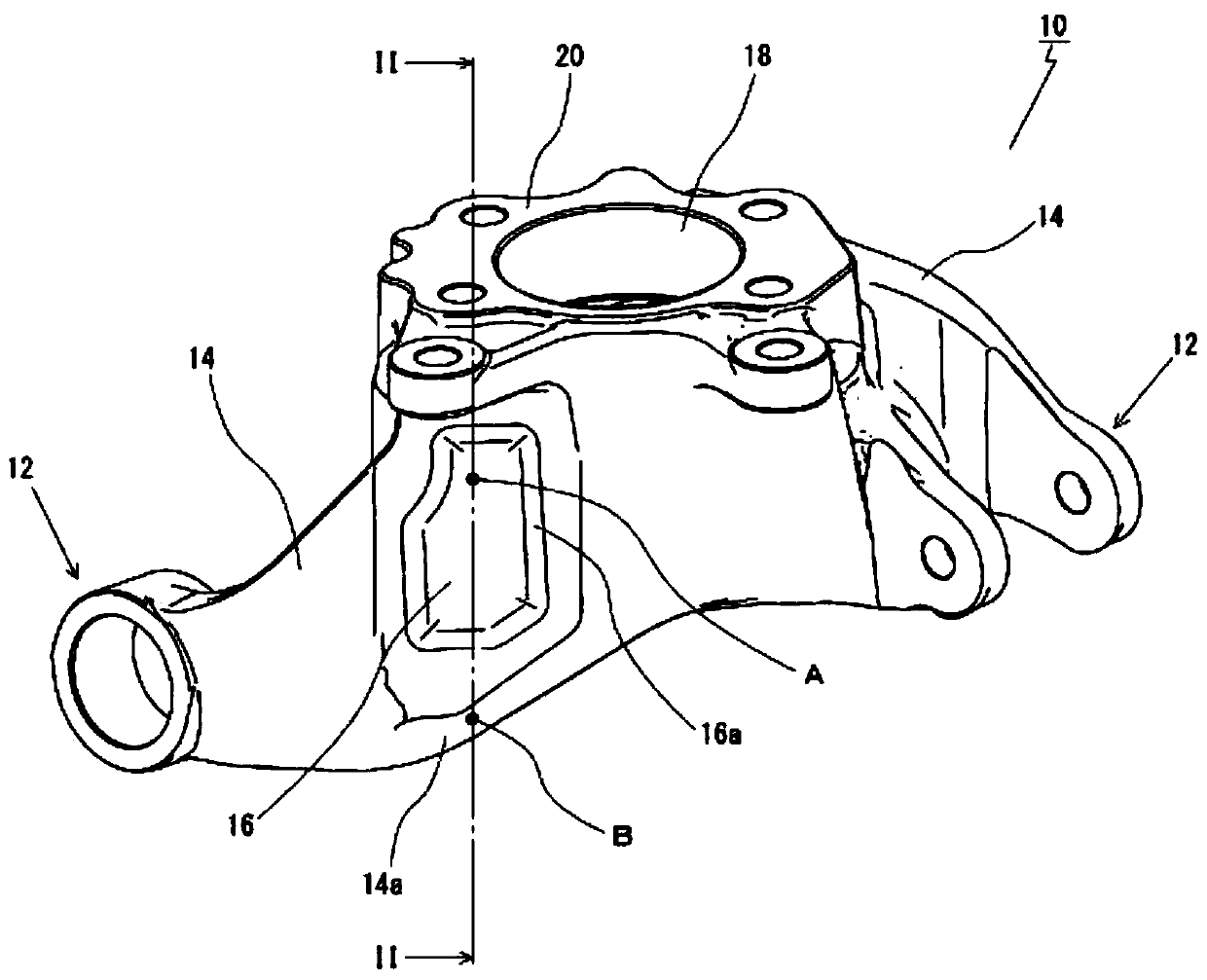

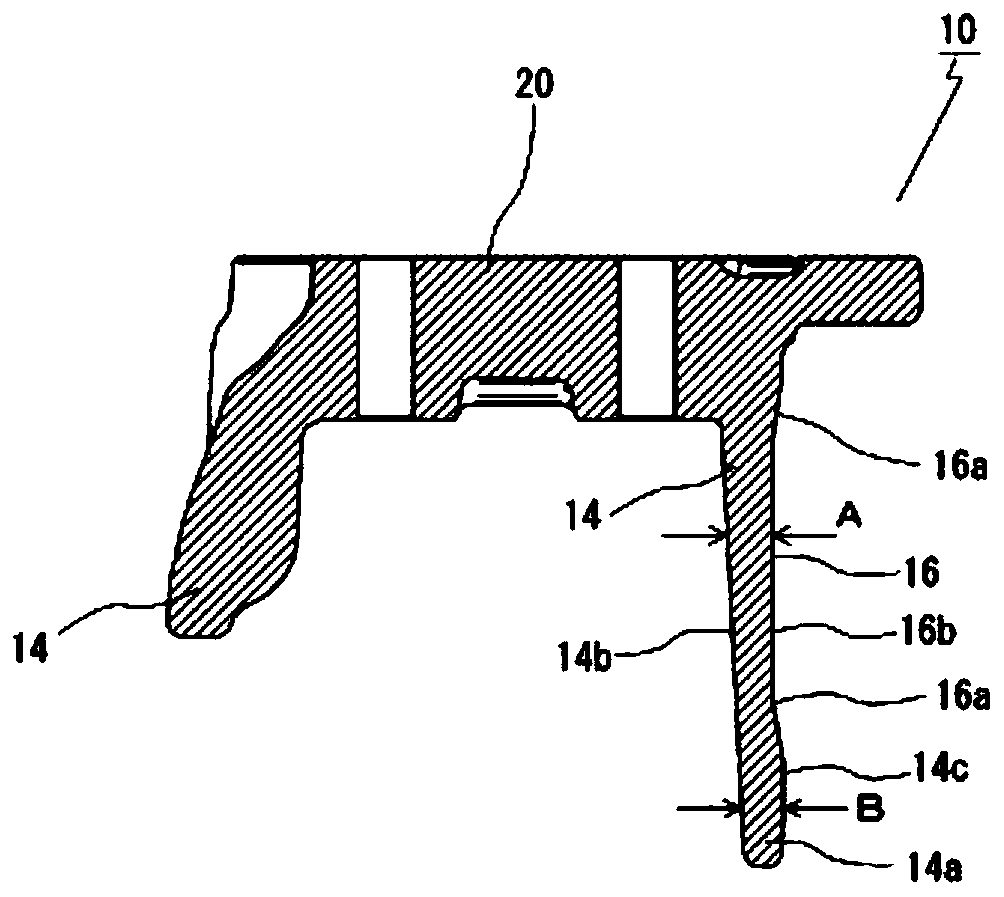

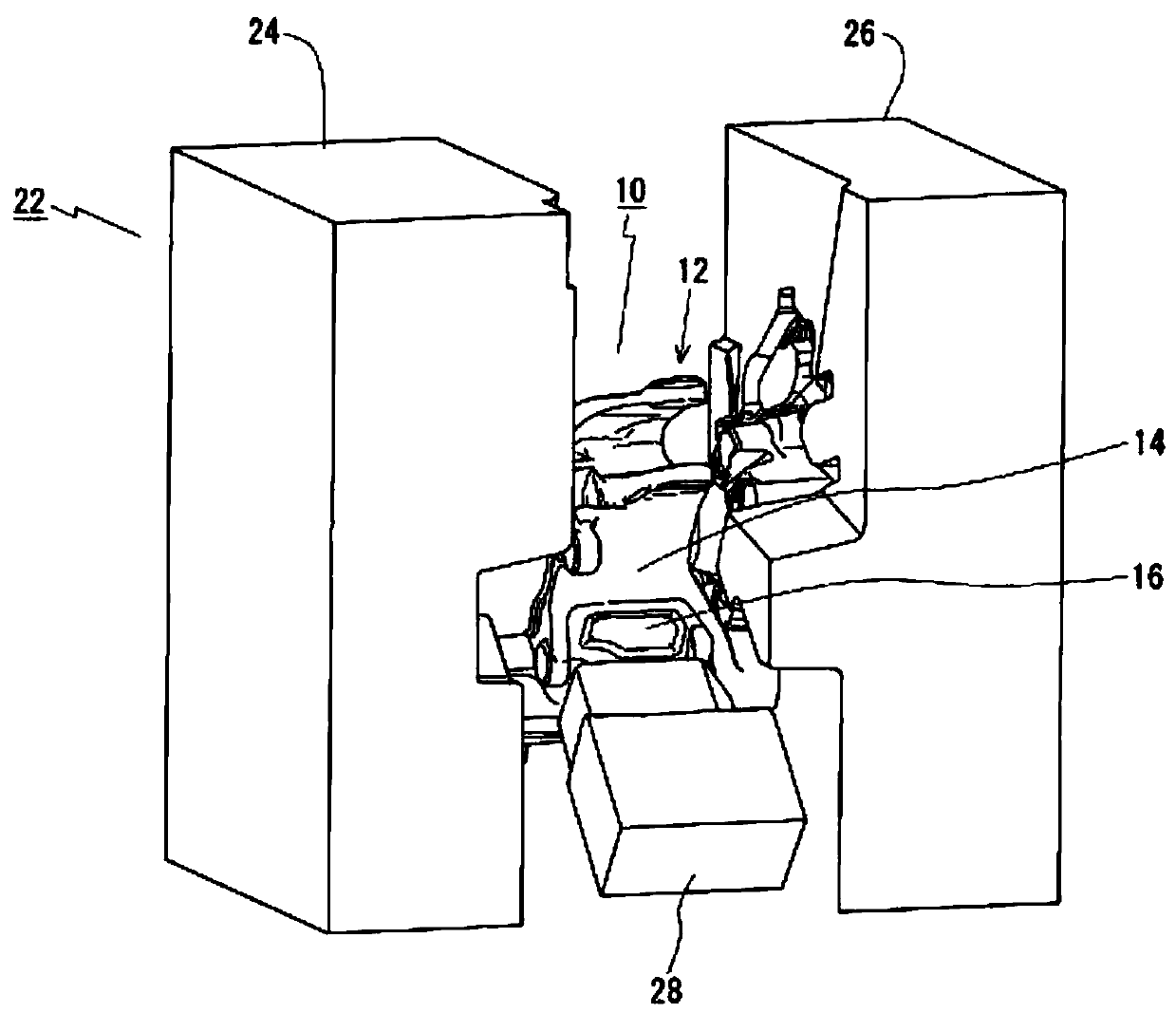

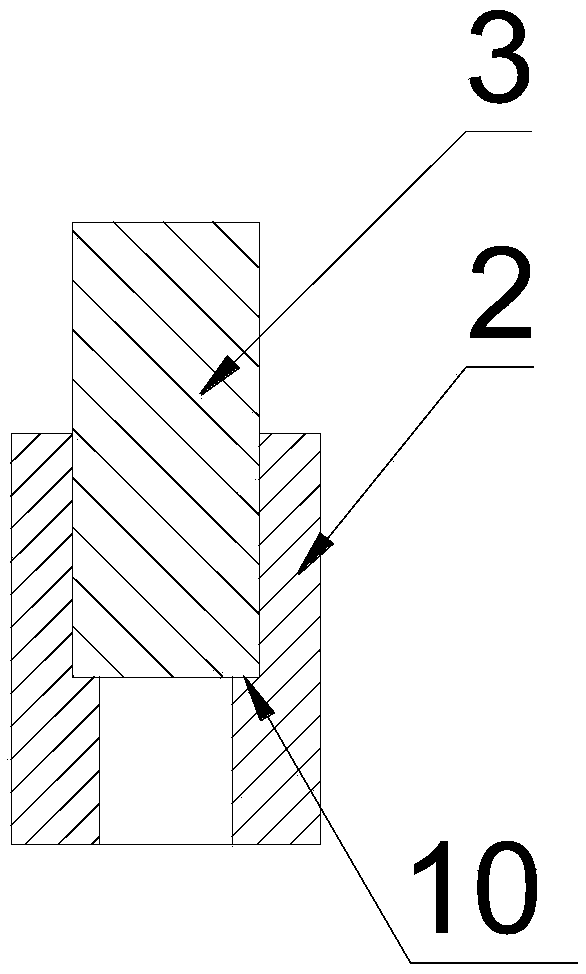

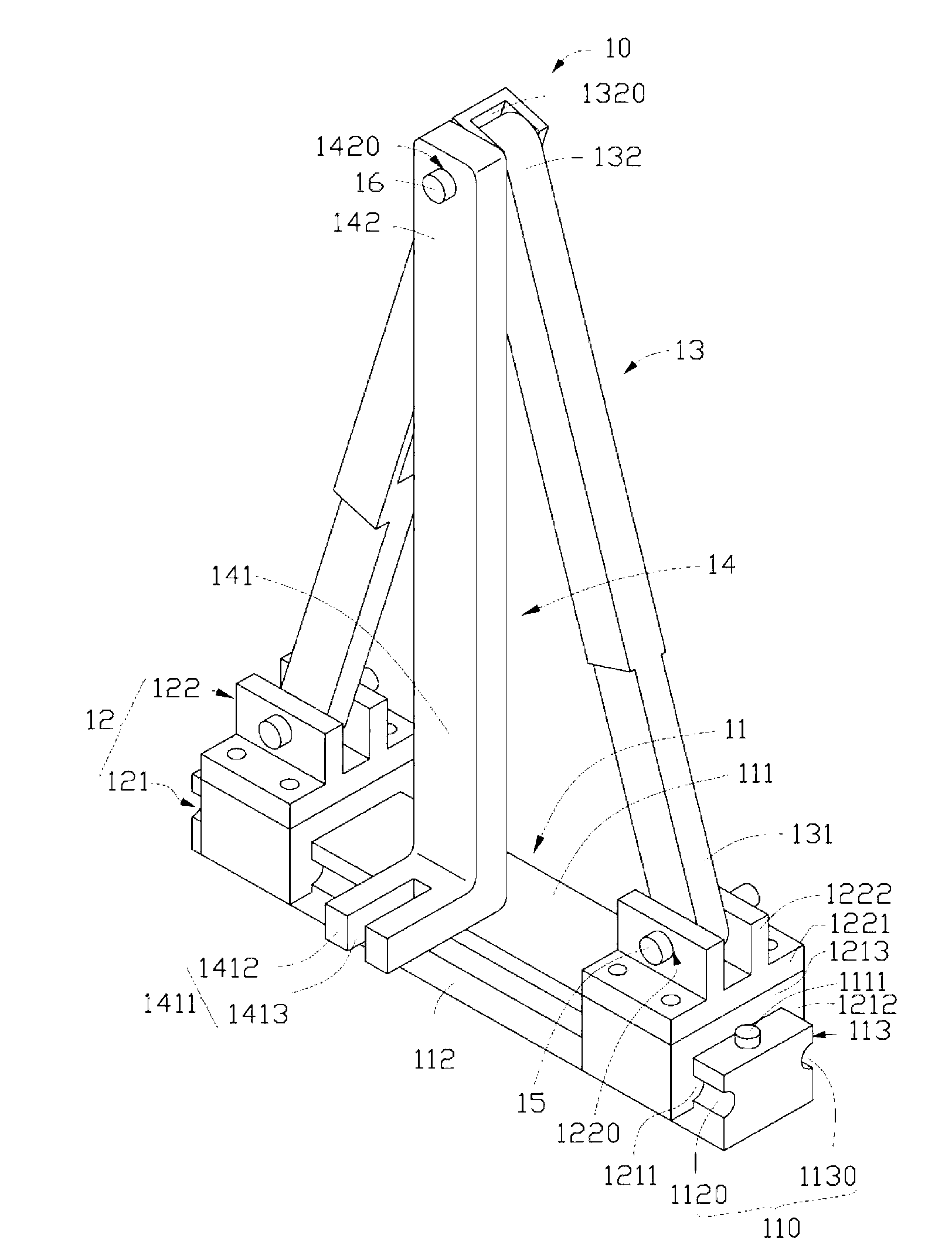

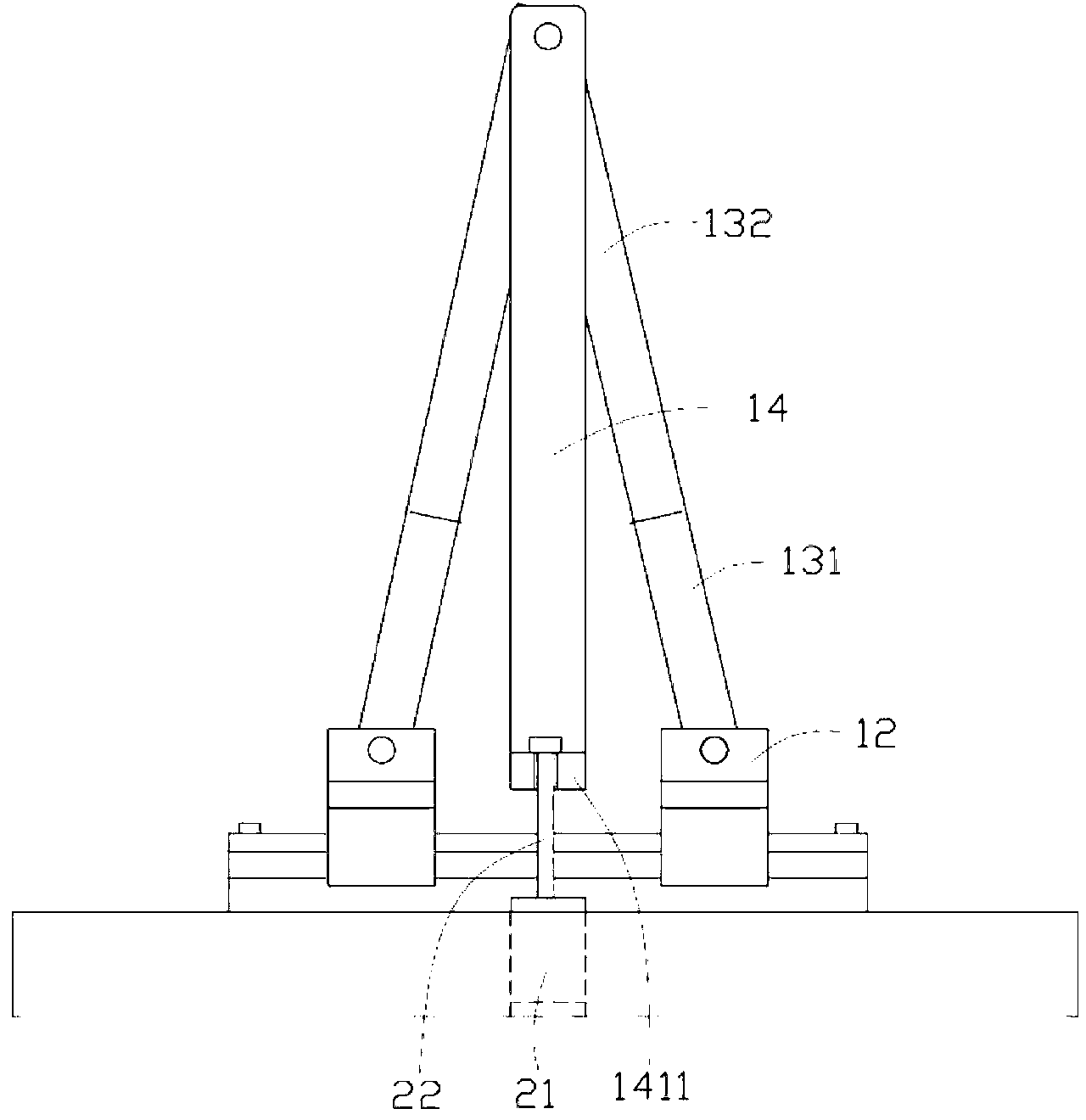

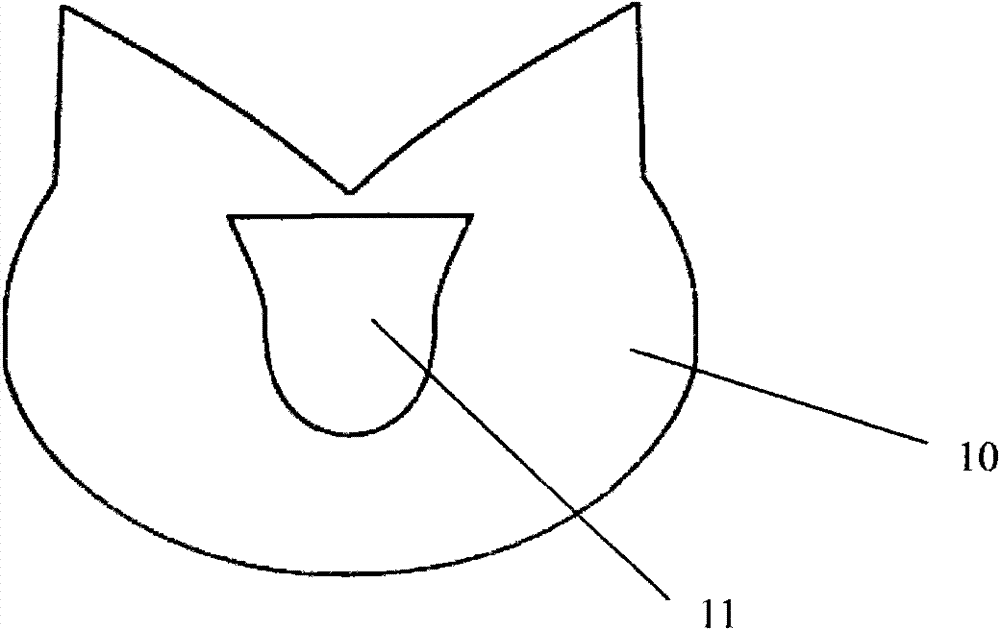

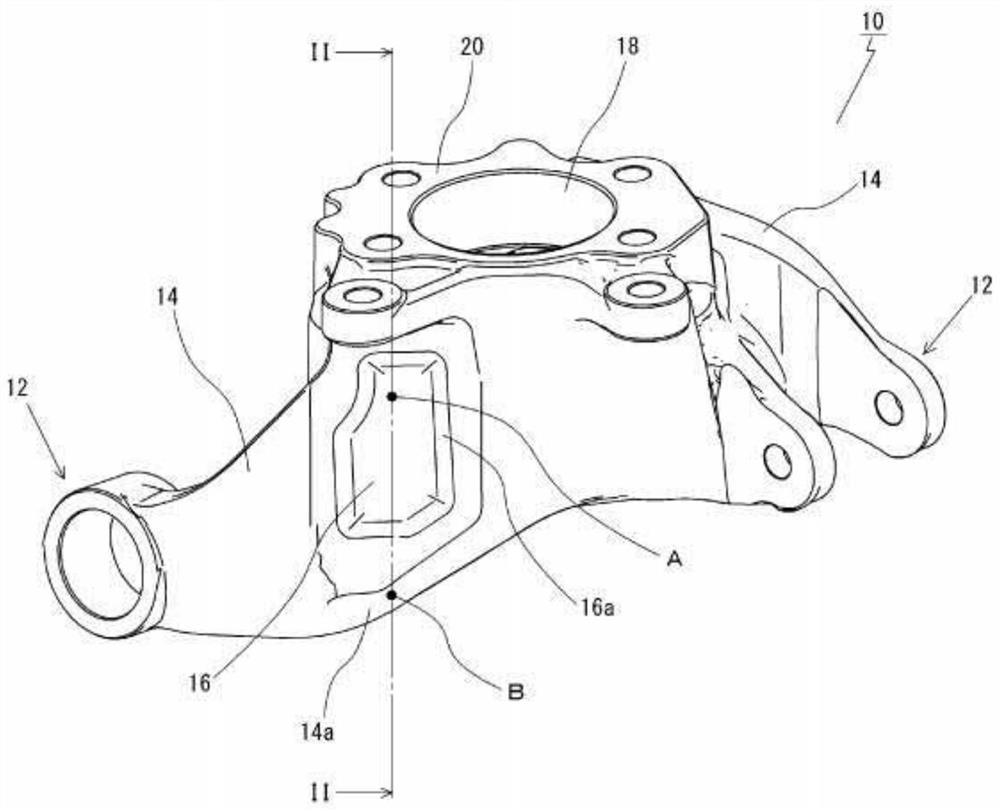

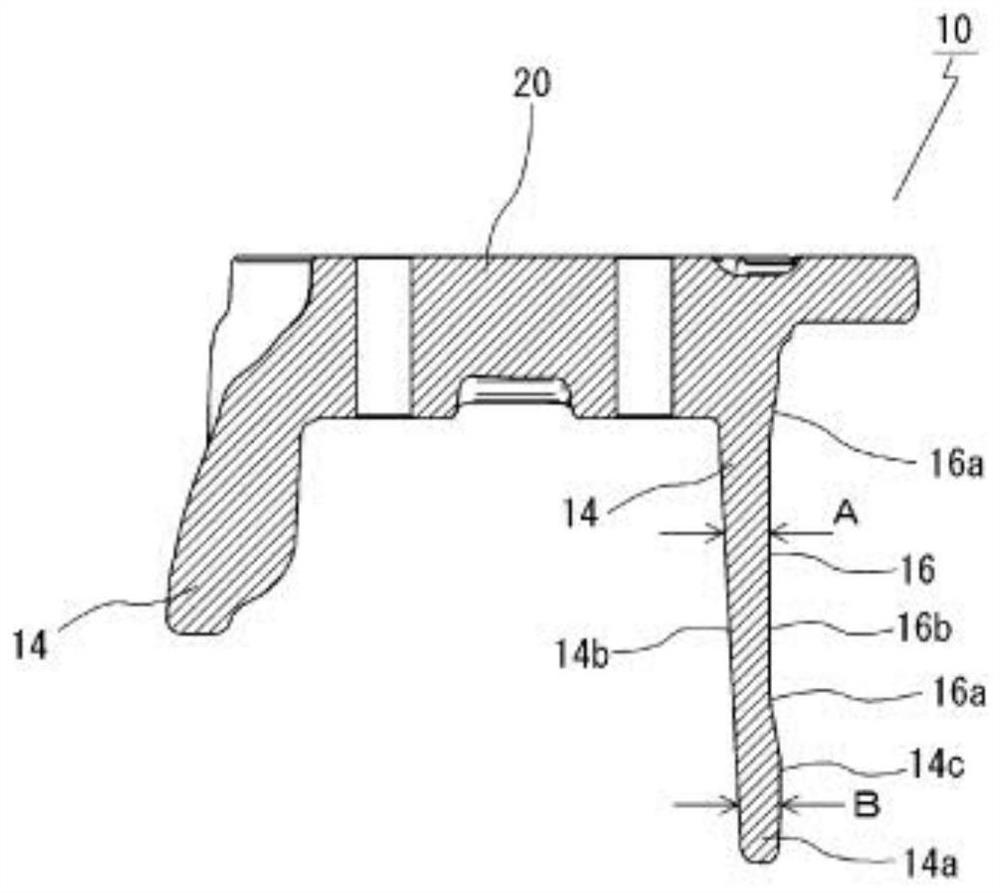

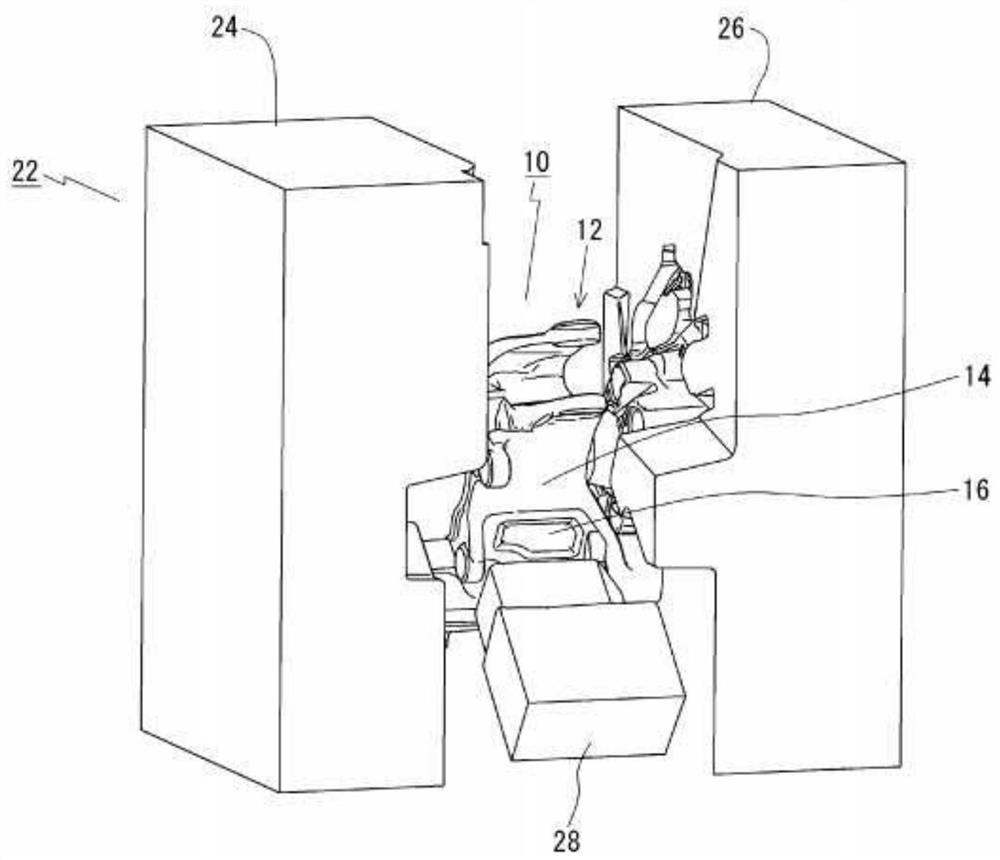

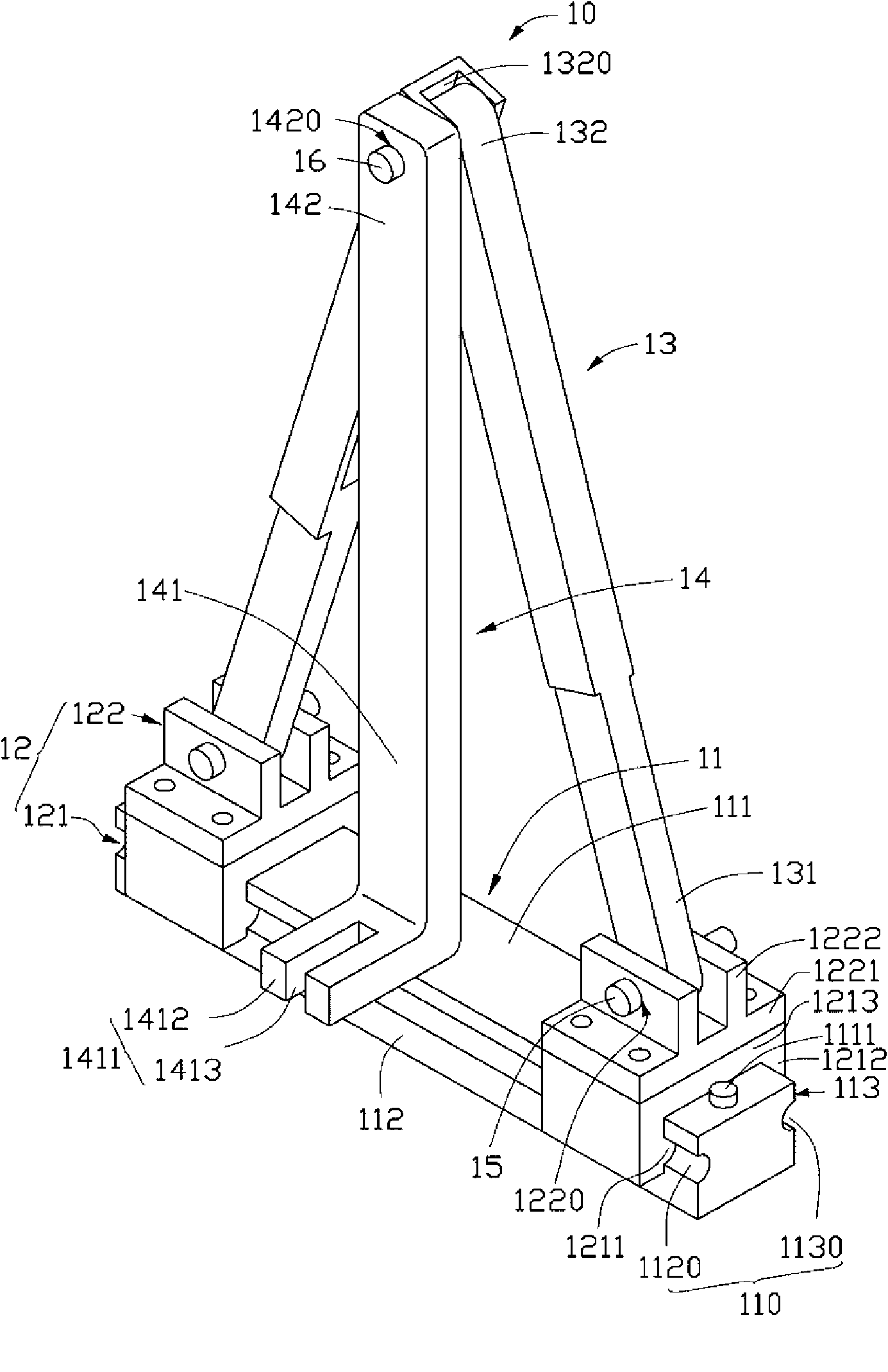

Support structure for vehicle and method of manufacturing same

ActiveCN110539797AEliminate redundant wallsAchieve lightweightSuspensionsSteering linkagesEngineeringCasting mold

The invention provides a support structure for a vehicle and a method of manufacturing the same. Weight reduction is realized. A support structure (10) for a vehicle is molded by a casting mold (22),provided between a vehicle body and a vehicle component, and including a support portion (12) which supports the vehicle component and a rib (14) which is continuously formed on the support portion (12). The support structure for a vehicle includes a core portion (16) recessed in a direction different from a mold split direction of the casting mold (22) on a side surface portion of the rib (14).

Owner:HITACHI ASTEMO LTD

Curved surface processing method for inlet edge of cylindrical blade of centrifugal pump impeller

A curved surface processing method for an inlet edge of a cylindrical blade of a centrifugal pump impeller includes following steps. A center of an impeller is used as a center to draw circles having respective diameters. A first point having a first distance from the center is determined on a concave side curve at a top of the blade, and a second point having a second distance from the center is determined on a concave side curve at a bottom of the blade. By improving the shape of a blade in an impeller, the angle of an inlet edge at the top of the blade is more close to the tangent direction, and the inlet angle of the top blade is reduced. A twisted surface is formed between a first arc segment at the top and a second arc segment at the bottom.

Owner:JIANGSU UNIV

Quick tool pouring ladle

InactiveCN108817367AImprove discharge efficiencyEasy to disassembleMelt-holding vesselsSlagLiquid iron

The invention discloses a quick tool pouring ladle. The quick tool pouring ladle comprises a body, a ladle mouth, a slag retaining plate and a movable ladle mouth, wherein the slag retaining plate andthe movable ladle mouth are detachably arranged on the ladle mouth; the ladle mouth comprises a base plate and a side plate; the ladle mouth is arranged at the front end of the body; one end, close to the body, of the ladle mouth is provided with a first accommodating groove; the slag retaining plate is inserted into the first accommodating groove in a matching manner; a discharging opening for discharging liquid iron is formed between the bottom of the slag retaining plate and the base plate; one end, far away from the body, of the ladle mouth is a discharging end; the discharging end of theladle mouth is provided with a second accommodating groove; the movable ladle mouth comprises a first base plate and a first side plate; the movable ladle mouth is inserted into the second accommodating groove in a matching manner; and the movable ladle mouth and the ladle mouth are fixed by using a locating pin. According to the quick tool pouring ladle disclosed by the invention, the service life of the pouring ladle is prolonged and the pouring quality is stabilized by replacing a tool; a fetal membrane manufacturing process of the pouring ladle is simplified; and labor and materials are saved.

Owner:广德亚太汽车智能制动系统有限公司

Combined type PE plastic bottle mold

The invention discloses a combined type PE plastic bottle mold. The combined type PE plastic bottle mold comprises a mod body, wherein a mold cavity is arranged in the mold body and has a structure with an upper opening and a lower opening; a mold base matched with the mold cavity is arranged at the lower end of the mold body; a bottle body mold matched with the inner wall of the mold cavity is arranged in the mold cavity; and a handle mold matched with the inner wall of the mold cavity is arranged at the upper end of the bottle body mold. According to the invention, a PE plastic bottle mold is divided into a mold body, a mold base, a bottle body mold and a handle mold; plastic bottles with different shapes are combined according to different needs when in use; one set of molds is equivalent to the functions of common multiple sets of molds; and the PE plastic bottle mold has the advantages of simple structure, easy operation and cost saving.

Owner:江苏源铢塑业有限公司

Core insert drawing device

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

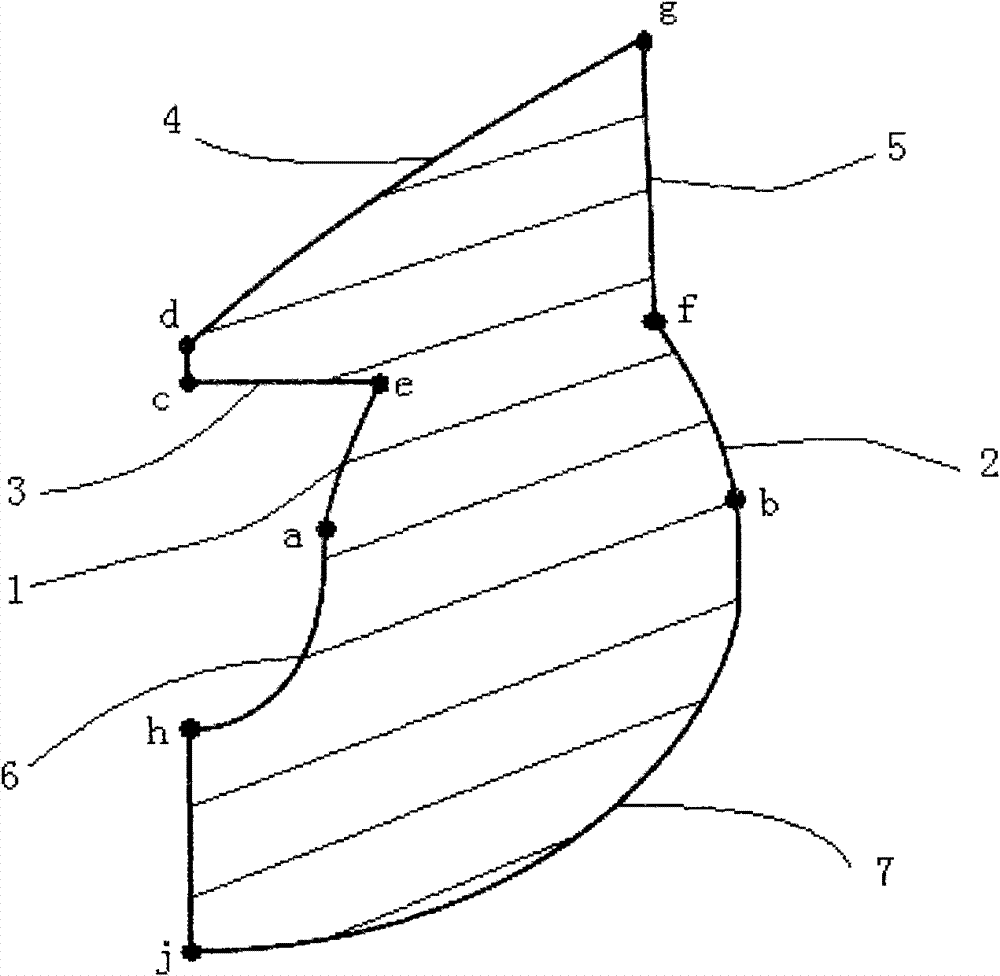

Lens for increasing spacing height ratio and improving illumination uniformity of light emitting diode (LED) lamp

ActiveCN102072460BImprove uniformity of illuminationHigh aspect ratioPoint-like light sourceSemiconductor devices for light sourcesIlluminanceLED lamp

The invention discloses a lens for increasing a spacing height ratio and improving the illumination uniformity of a light emitting diode (LED) lamp, which consists of seven transmission surfaces. The first, third and sixth refracting surfaces form the incident surface of the lens, and the second, fifth and seventh refracting surfaces form the emergent surface of the lens. Parallel light rays emitted from the second and fifth refracting surfaces are used for far-field small-angle illumination, and nonparallel light rays emitted from the seventh refracting surfaces are used for near-field wide-angle illumination. The lens provided by the invention can combine rear-field and near-field illumination and achieve high illumination uniformity, so that the lamp can be used at a high spacing height ratio without producing glare.

Owner:SHANGHAI SANSI ELECTRONICS ENG +3

A kind of labor protection glove demoulding device

Owner:江苏晟力捷安全用品科技有限公司

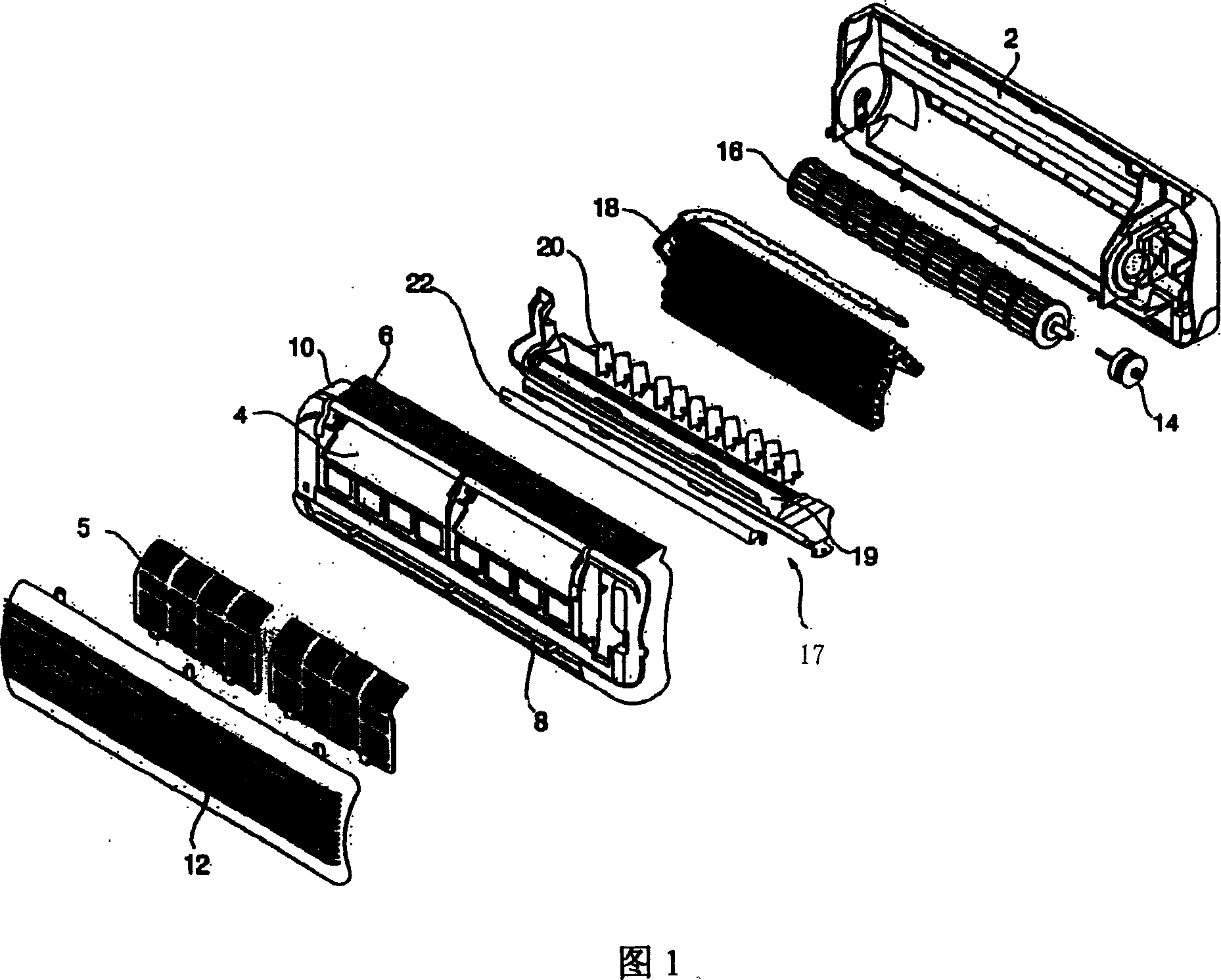

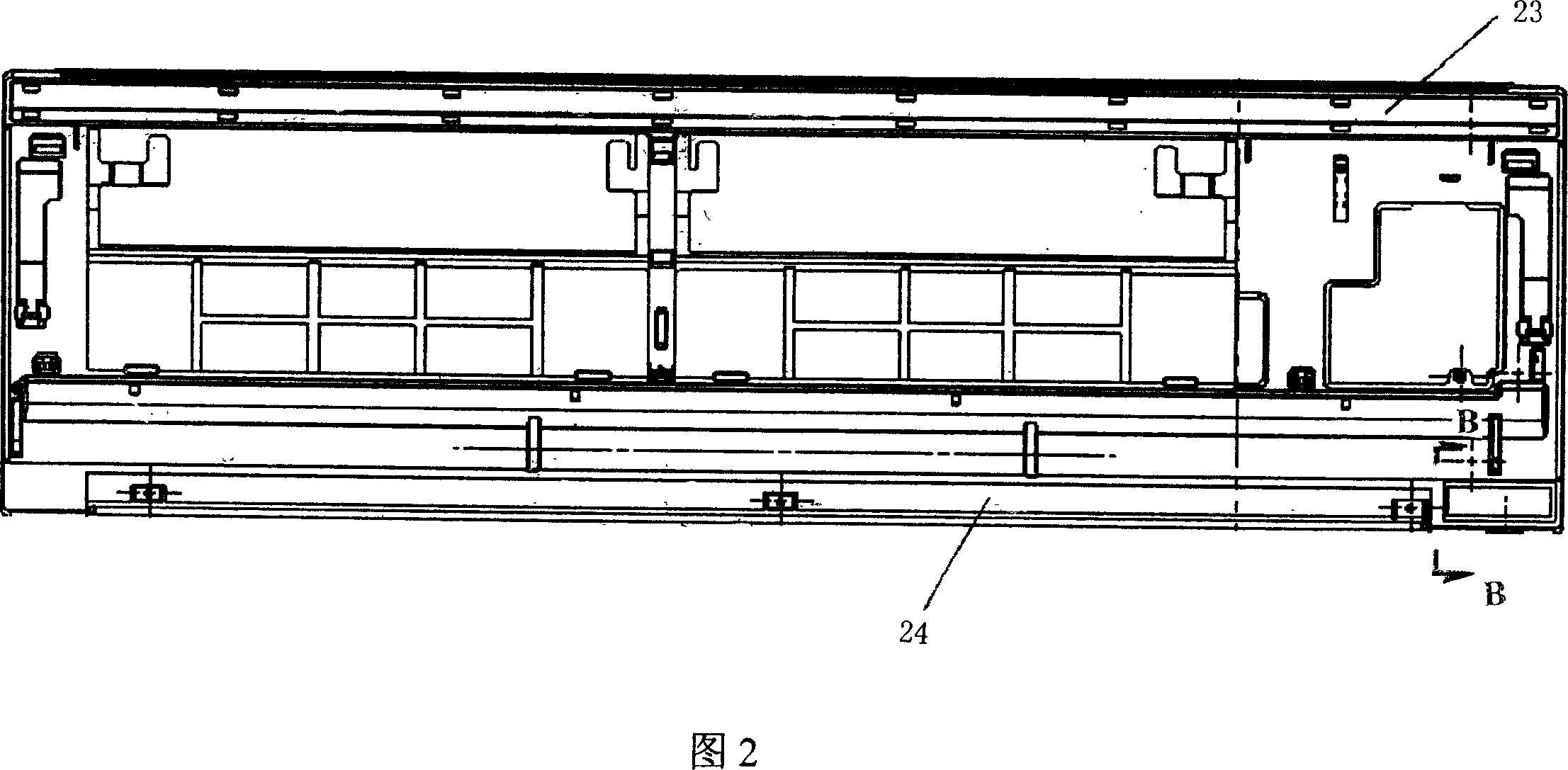

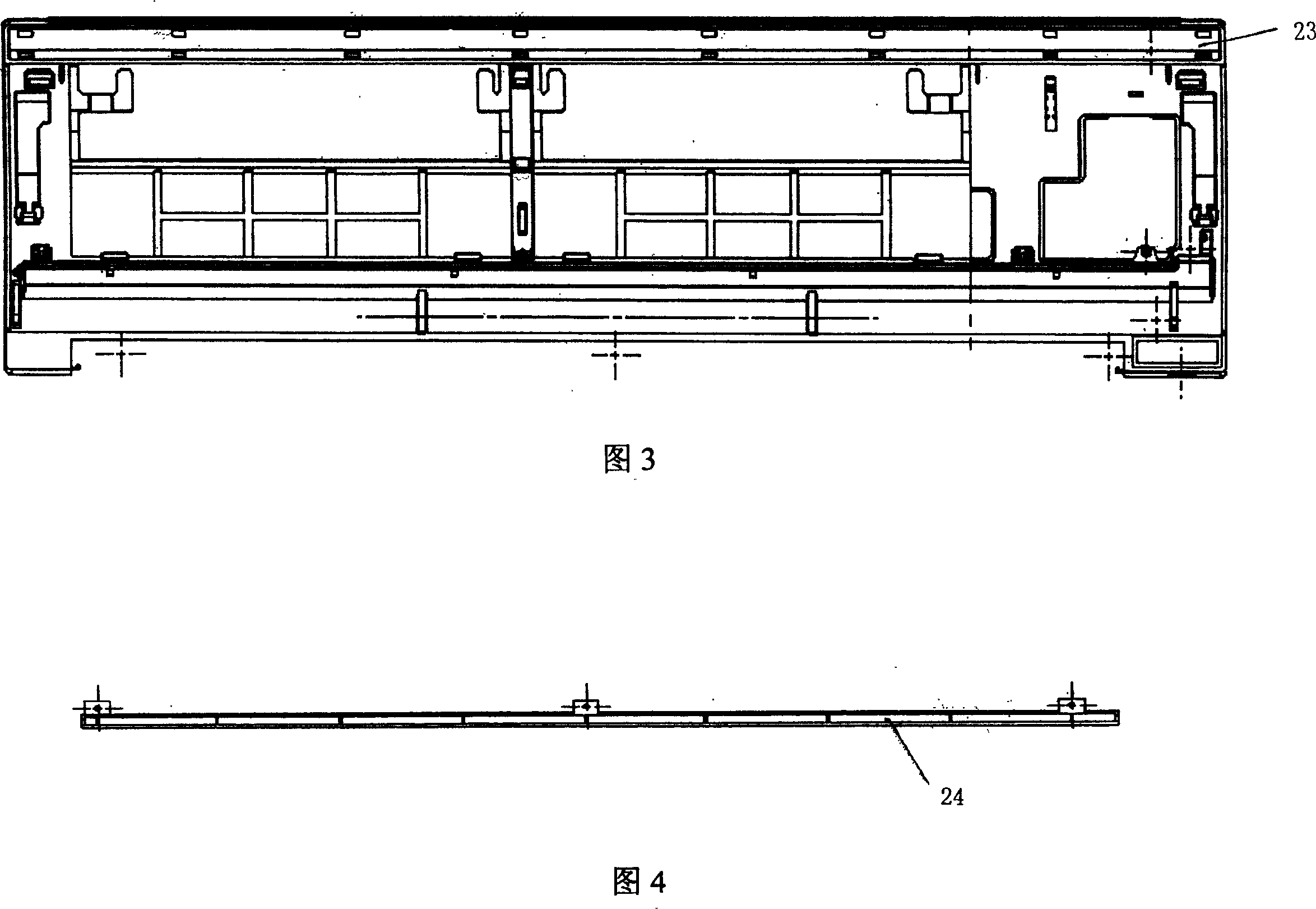

Front-panel structure of indoor unit of air conditioner

InactiveCN1979020AEasy to installIncrease productivityLighting and heating apparatusHeating and ventilation casings/coversDisplay devicePulp and paper industry

The invention relates to a front panel structure of air condition indoor machine that includes bottom, motor, air supply fan, and indoor heat exchanger, front panel, air intake grid, and display. Front panel is made up of identity and supporting under identity. Two ends under identity have hook snug, and a hook is set corresponding to snug at two ends of frame. The supporting is connected to identity through hook. The invention has the advantages of easy to install, and working efficiency is improved. The producing cost is lowered.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

A roll-type membrane module and a filter element having the roll-type membrane module

ActiveCN105344250BSmall concentrated water flowImprove water saving performanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater savingPore water pressure

The invention relates to the field of water purifying equipment and provides a spiral-wound membrane component and a filter element employing the same. The spiral-wound membrane component comprises a core tube and a water purification membrane group, wherein the water purification membrane group is wound around the core tube; the width of the edge, adjacent to the core tube side, of the water purification membrane group is larger than that of the edge, far away from the core tube side. Compared with the prior art, the spiral-wound membrane component and the filter element employing the same have the following benefits: when the thickness of a raw water guide net is set, the sectional area of a raw water channel in the spiral-wound membrane component is smaller or obviously smaller than that of the raw water channel of a traditional spiral-wound membrane component; when the raw water flow rates, the filtering areas and the water pressures on the raw water side are the same, the flow rate of raw water in the spiral-wound membrane component is much smaller, so that the flow rate of discharged concentrated water is also much smaller, and accordingly, the water-saving effect can be remarkably improved.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

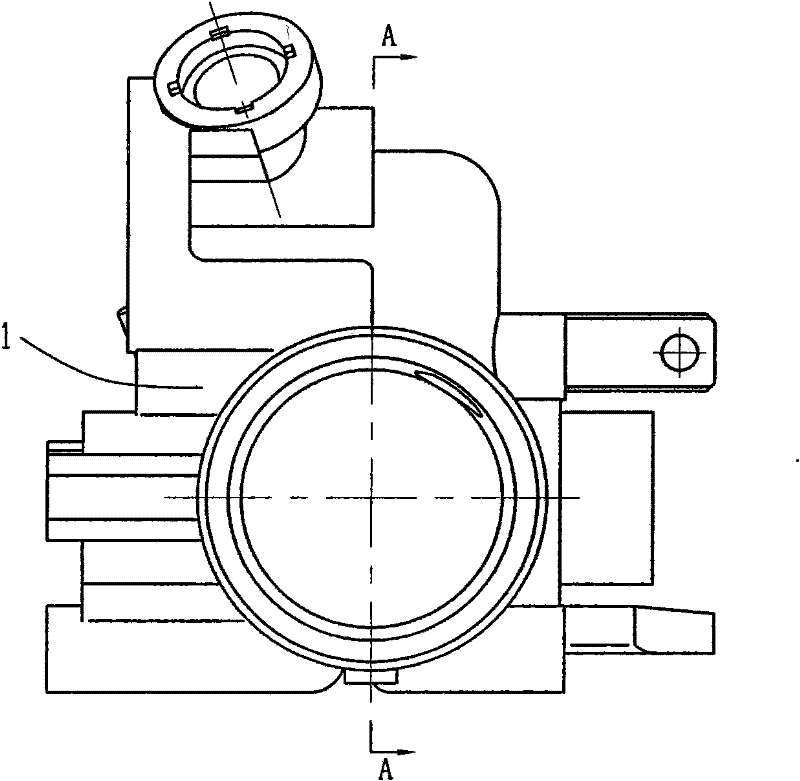

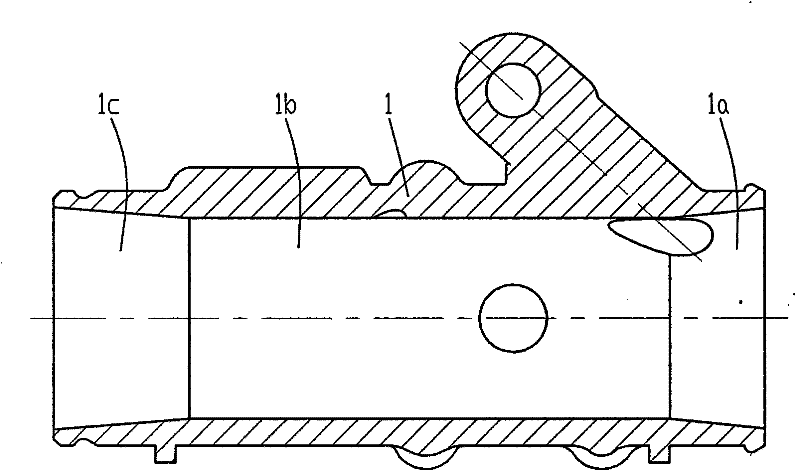

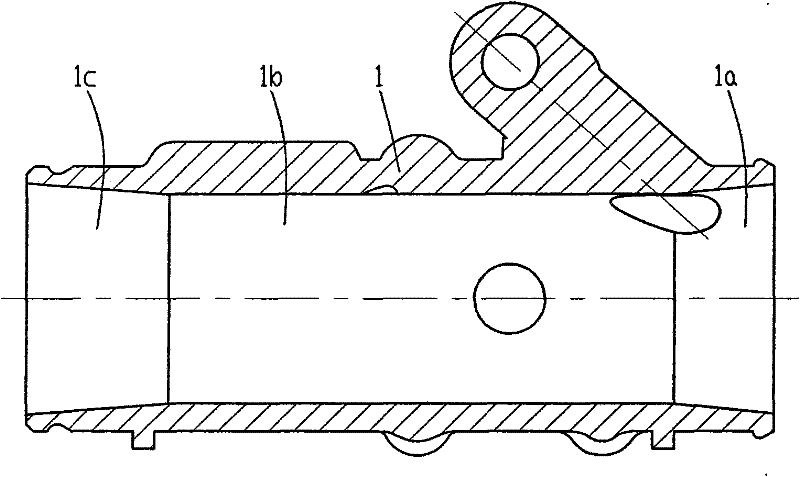

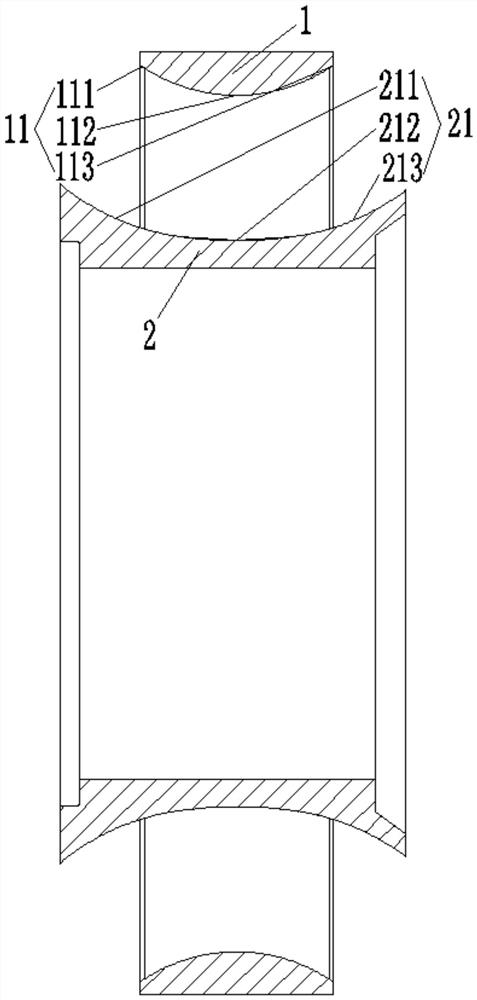

Throttle valve structure

InactiveCN101761397BConvenient lengthMeet the requirements of rapid air intakeEngine controllersMachines/enginesEngineeringMachining

The invention discloses a throttle valve structure, which comprises a valve body (1). A central hole of the valve body (1) consists of an inlet cone section (1a), a transition section (1b) and an outlet cone section (1c), wherein the transition section (1b) is a unidiameter straight section and is positioned between the inlet cone section (1a) and the outlet cone section (1c); the inlet cone section (1a) and the outlet cone section (1c) both have a bell-mouth structure; the length of the inlet cone section (1a) is between 11 and 17 millimeters, and the conical degree is between 5 and 8 degrees; and the length of the outlet cone section (1c) is between 17 and 23 millimeters, and the taper is between 3 and 6 degrees. The throttle valve structure meets the requirements of the air inlet speedand air inflow of small-displacement engines by changing a structure of the central hole of the valve body, and has the characteristics of ingenious design, simple structure, easy machining, strong generality and the like.

Owner:力帆科技(集团)股份有限公司

a demoulding mechanism

ActiveCN110947919BShorten mold opening strokeEasy draftFoundry mouldsMoulding machine componentsAirbagMold removal

The invention belongs to the field of automobile part production and processing and particularly relates to a demolding mechanism comprising an upper mold plate and a lower mold plate which are arranged in the vertical direction in an open-close mode. A mandrel for forming a sand mold center runner is arranged in the center of the lower mold plate. The mandrel and a core hole formed in the centerof the lower mold plate are in sliding fit in the vertical direction, and a first elastic unit is arranged between the mandrel and the lower mold plate and is used for driving the mandrel to pop up relative to the lower mold plate. The side wall of the mandrel is further provided with an annular groove. A clamping plate arranged slidably in the radial direction of the mandrel is arranged in the lower mold plate. A second elastic unit is arranged between the clamping plate and the lower mold plate. A telescopic airbag is further arranged between the clamping plate and the lower mold plate. According to the demolding mechanism, the mandrel is of an elastic structure, the lower mandrel is flush with the surface of molding sand during sand spreading so as to ensure the pass-through longitudinal runner, in addition, in the extrusion forming process, the mandrel contracts downwards under extrusion of a pressing column, the mandrel and the pressing column achieve mold opening to the upper andlower sides correspondingly during mold opening, the mold opening stroke of the mandrel is reduced, and mold pulling is facilitated better.

Owner:安庆海威尔机械有限公司

Variable-section polygonal braided mandrel and its assembly method

The invention relates to a variable-section polygonal woven mandrel which is characterized by comprising a mandrel shaft, wherein a long groove is formed in the mandrel shaft, the long groove extends to the bottom end surface of the mandrel shaft from the top of the mandrel shaft along with the length direction of the mandrel shaft, so as to form a through groove end, a plurality of mandrel rings are sheathed outside the mandrel shaft and are arranged along with the length direction of the mandrel shaft, bulges matched with the long groove are arranged on the inner ring surface of each mandrel ring, a catch lever matched with the long groove is arranged between the bulges of two adjacent mandrel rings, the locking catch lever and the mandrel shaft are fixedly connected, N positioning levers are evenly distributed on the outer peripheral surface of each mandrel ring circumferentially, N is more than or equal to 3, and a cover body component is supported by the positioning levers. According to another technical scheme, the invention provides an assembling method of the variable-section polygonal woven mandrel. By adopting the technical scheme, the advantages are as follows: 1. the structure is simple, the weight is light, and the universality is strong; and 2. the manufacturing is easy, and the mandrel withdrawal is convenient and consumes less time.

Owner:DONGHUA UNIV

Quick withdrawing mold

Owner:CHONGQING DEYUN MOLD MFG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS7913362B2Increase volumeImproved combed sliverCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fiber-sorting or fiber-selection of a fiber bundle comprising textile fibers, especially for combing, which is supplied by a supply device to a fiber-sorting device, especially a combing device, having clamping devices, which clamp the fiber bundle at a distance from its free end, for combing to remove non-clamped constituents, at least one take-off device with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and improve the combed sliver, the fiber-sorting device has at least two rotatably mounted rollers rotating rapidly without interruption, having the clamping devices and between the sliver-forming element and the drafting system the at least one fiber sliver is present in the form of a fiber structure having a width greater than its height, for example, following spreading by a web-spreader.

Owner:TRUETZSCHLER GMBH & CO KG

Support structure for vehicle and manufacturing method thereof

ActiveCN110539797BEliminate redundant wallsAchieve lightweightSuspensionsSteering linkagesCasting moldMechanical engineering

The present invention provides a supporting structure for a vehicle and a manufacturing method thereof, which can achieve weight reduction. The vehicle support structure (10) is formed by a casting mold (22) and is arranged between the vehicle body and the vehicle parts, and has a support part (12) supporting the vehicle part and a rib formed continuously with the support part 12 ( 14) A casting punch (16) recessed in a direction different from the parting direction of the casting mold (22) is provided on the side surface of the rib (14).

Owner:HITACHI ASTEMO LTD

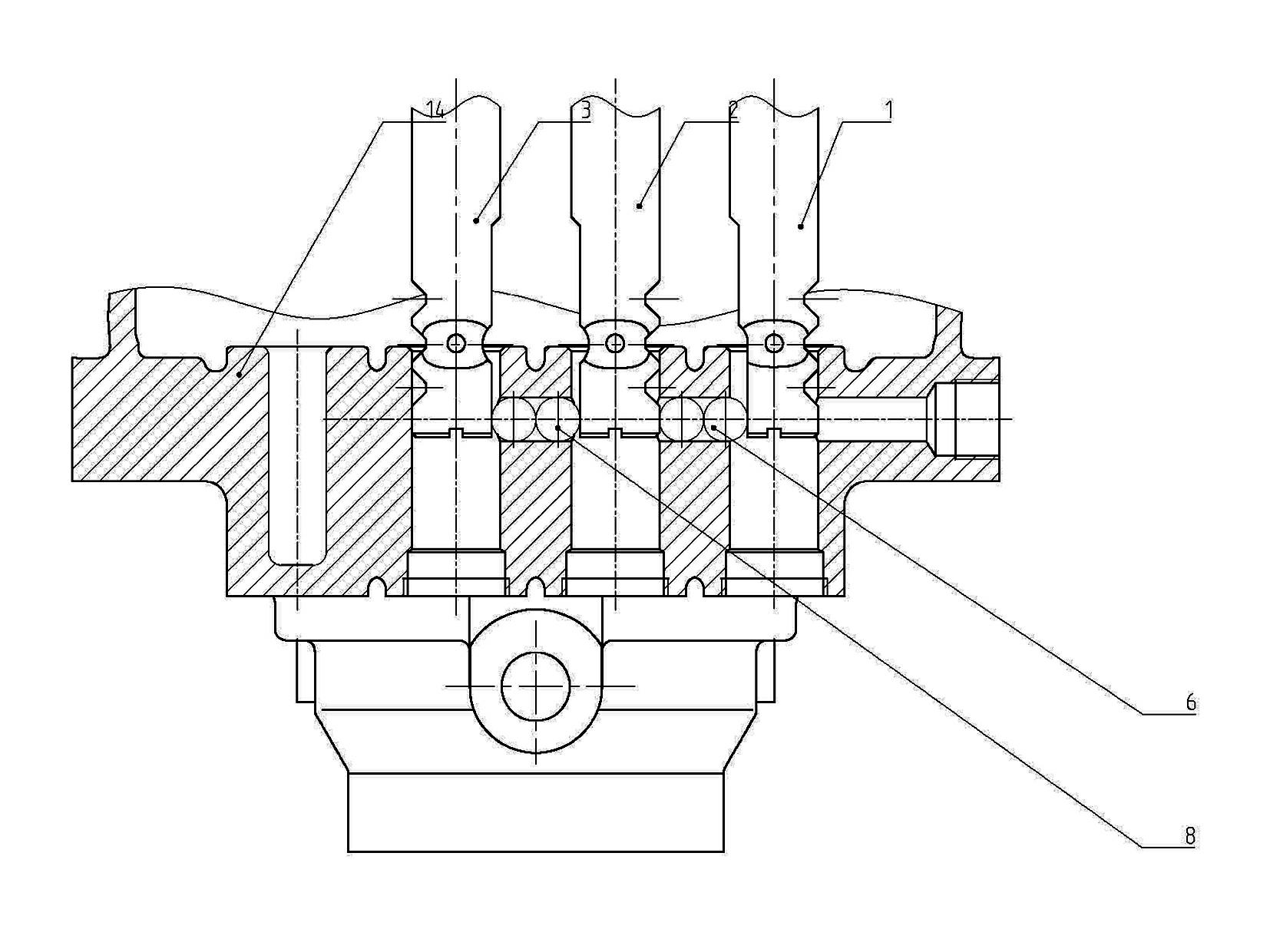

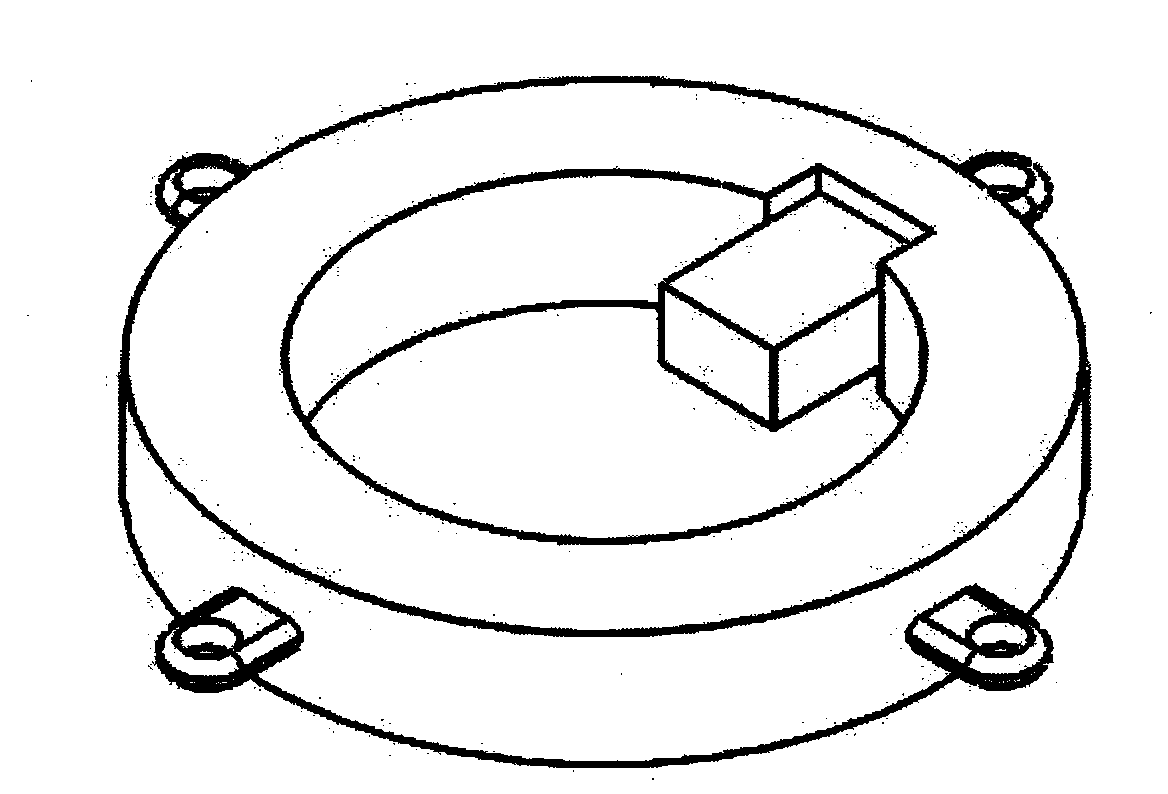

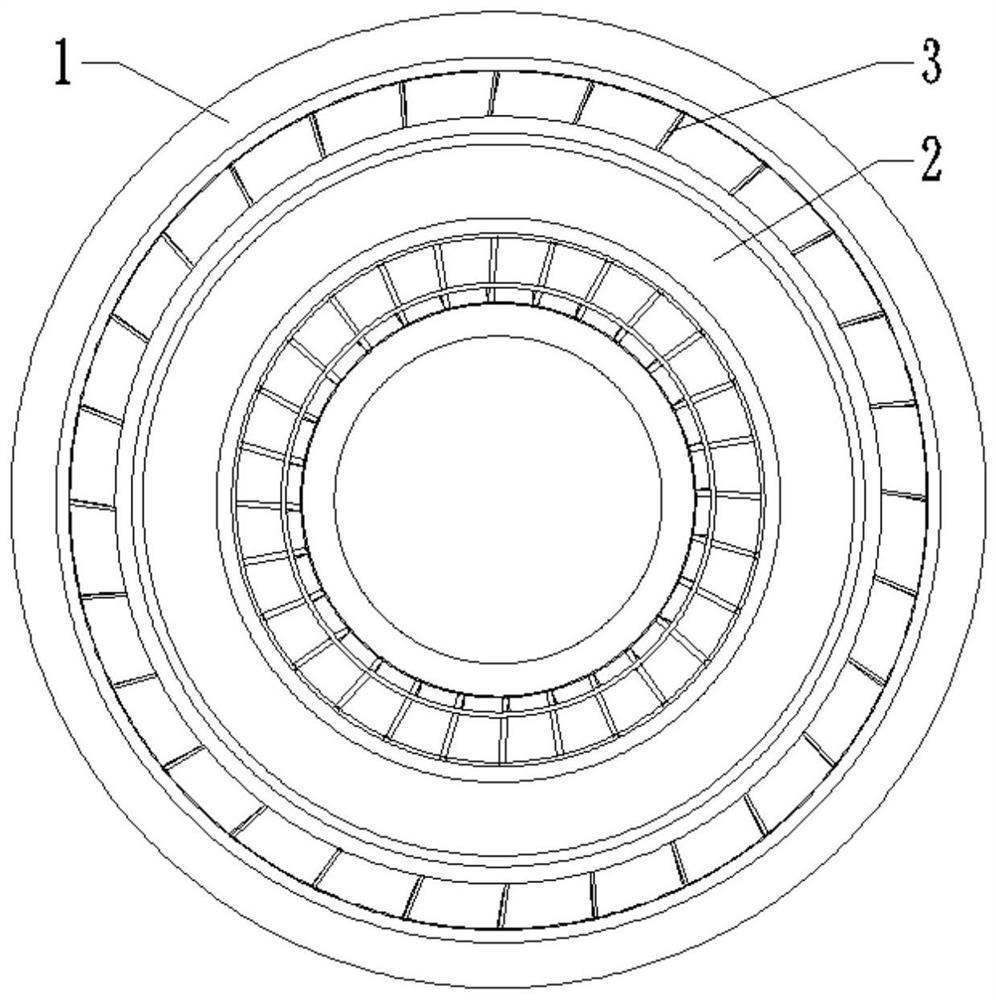

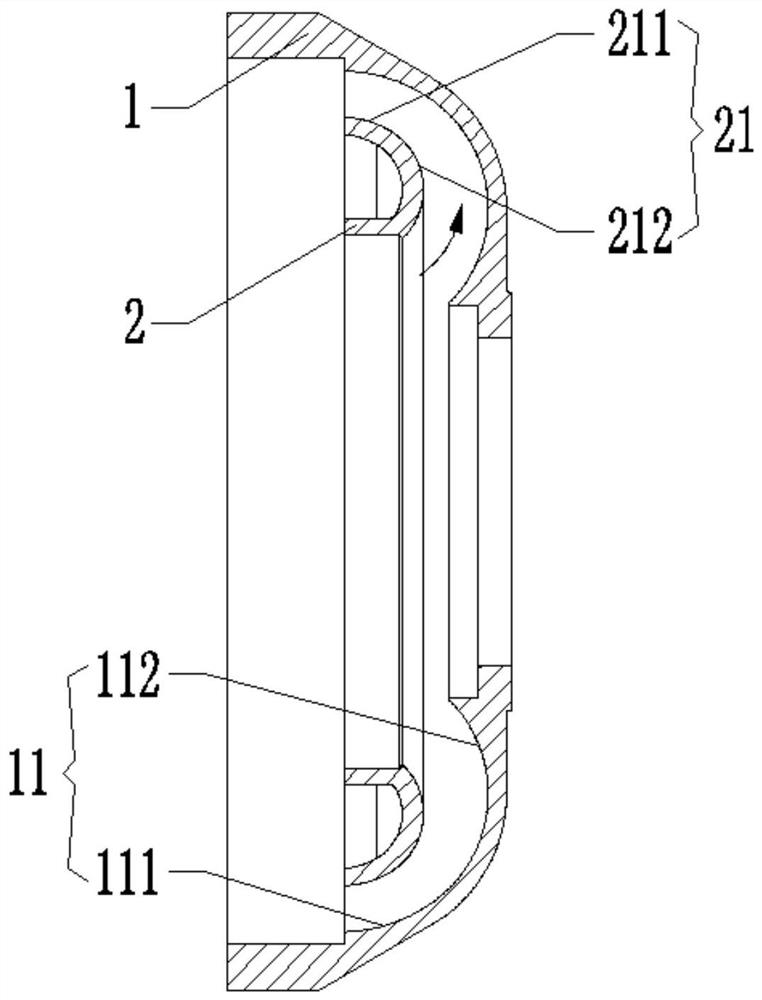

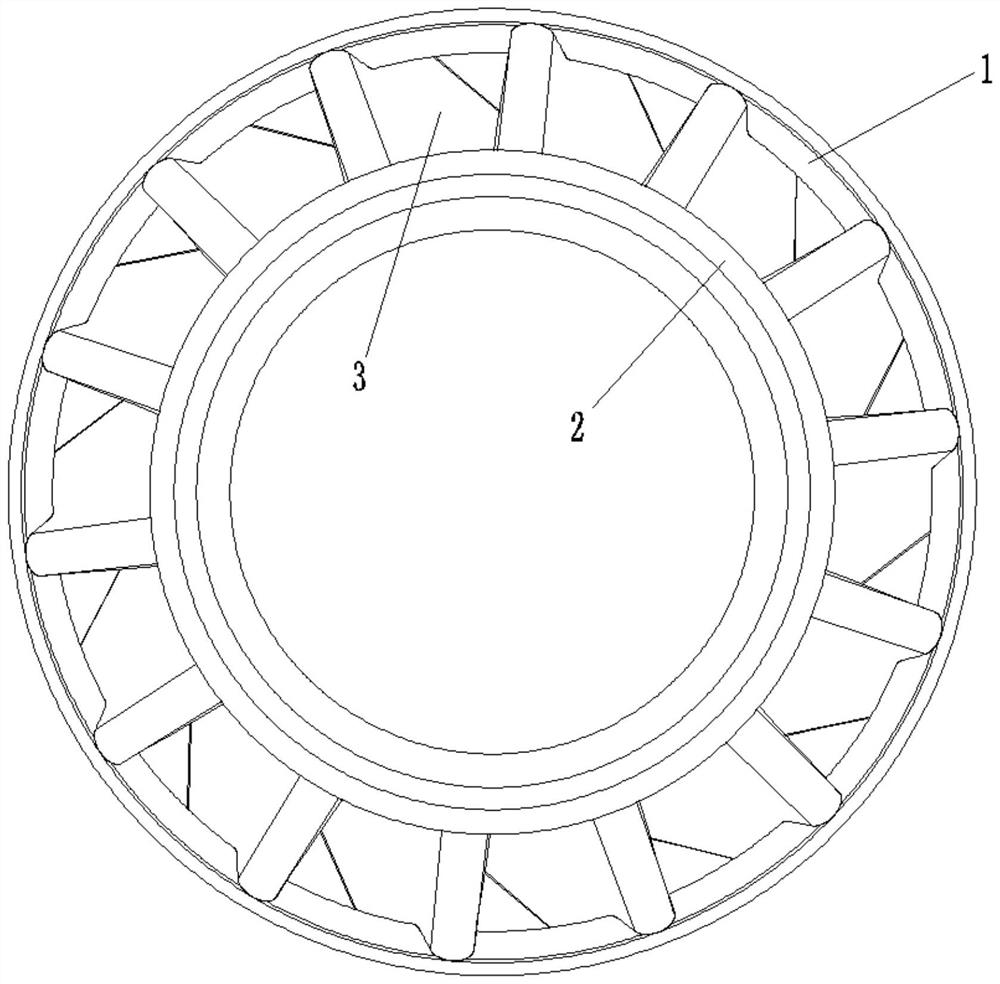

Engineering machinery hydraulic torque converter pump impeller structure

PendingCN113503352AImprove manufacturing precisionHigh degree of generalizationFluid gearingsImpellerEngineering

The invention relates to an engineering machinery hydraulic torque converter pump impeller structure. The structure comprises an inner ring, an outer ring and a blade grid connected between the inner ring and the outer ring, the inner ring and the outer ring are concentrically arranged, a circulating circular cavity is formed between the inner ring and the outer ring, the blade grid comprises n blades which are evenly arranged in the circumferential direction, n is larger than or equal to 26 and smaller than or equal to 30, n is an integer, a liquid flow channel with an inlet and an outlet is formed between every two adjacent blades, and the section, obtained by cutting any radial surface, of the circulating circular cavity is roughly in a sector ring shape. Parameters of the blades are redesigned, so that the whole circulating circular cavity is roughly in a basin shape, a space streamline structure is adopted, and the impact loss is reduced; the projection of the whole blade falls in the end surface of the outer ring end of each blade, so that mold drawing is facilitated, and the blade manufacturing precision is improved; compared with an existing mature product, a hydraulic torque converter can meet the requirement of the whole machine by just modifying the impeller blade grid, the universalization degree of parts is high, and the mold investment is saved.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

Core insert drawing device

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

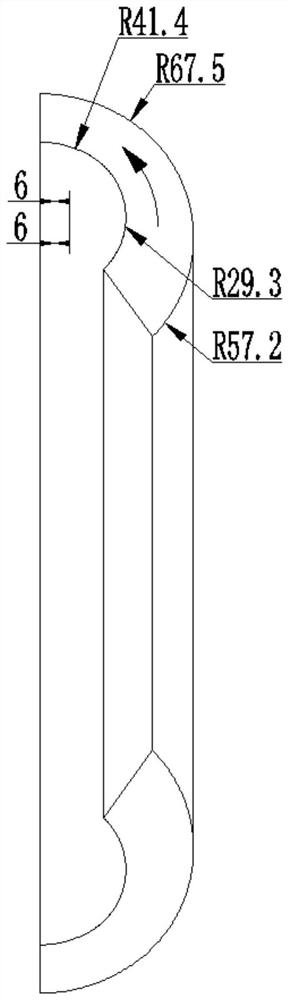

Guide wheel structure of hydraulic torque converter of engineering machinery

The invention relates to a guide wheel structure of a hydraulic torque converter of engineering machinery. The guide wheel structure comprises an outer ring, an inner ring and a blade grid connected between the outer ring and the inner ring. A circulating circular cavity is formed between the outer ring and the inner ring, the blade grid comprises n blades which are uniformly arranged in the circumferential direction, n is greater than or equal to 12 and less than or equal to 16, n is an integer, a liquid flow channel with an inlet and an outlet is formed between every two adjacent blades, the inner ring arc face of the outer ring is composed of three arcs, the outer ring arc face of the inner ring is composed of three arcs, and the width of the guide wheel is effectively shortened; the inlet angle, the outlet angle and the streamline length of the guide wheel are designed, the guide wheel blades are of a spatial streamline structure, internal impact loss is reduced, the projection of the end faces of the outer ring ends of the blades falls into the end faces of the inner ring ends of the blades, die drawing is easy, and the manufacturability of the blades is improved; and the capacity of a hydraulic torque converter adopting the guide wheel structure is improved, and therefore the performance of the hydraulic torque converter is improved.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

Tapering component

The invention discloses a tapering component. The tapering component comprises a first fixed block, a second fixed block and a third fixed block, wherein a guide rod is arranged between the top of thefirst fixed block and the bottom of the second fixed block and is in sleeve connection with a connecting block being in slip connection; a first through hole matched with the guide rod penetrates theinterior of the connecting block; the first fixed block and the second fixed block are not on the same vertical plane; an opening is formed in the top of the connecting block; when the mold release is required, the connecting block is controlled to slide on the guide rod toward the direction of the first fixed block; in the downward sliding process of the guide rod, a sliding block slides along asliding chute toward the direction far away from the opening, so that the connecting rod slides in a second through hole, at the moment a module also moves in succession, a boss of the module avoidstouching other components, and thus, the tapering is realized quickly and conveniently. When the mold needs to be spliced, a user controls the connecting block and the sliding block in the opposite direction, so that the mold splicing can be realized quickly and easily.

Owner:苏州市群友精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com