Support structure for vehicle and method of manufacturing same

A technology for structures and vehicles, which can be used in manufacturing tools, vehicle components, steering mechanisms, etc., and can solve problems such as hindering lightweighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described in detail.

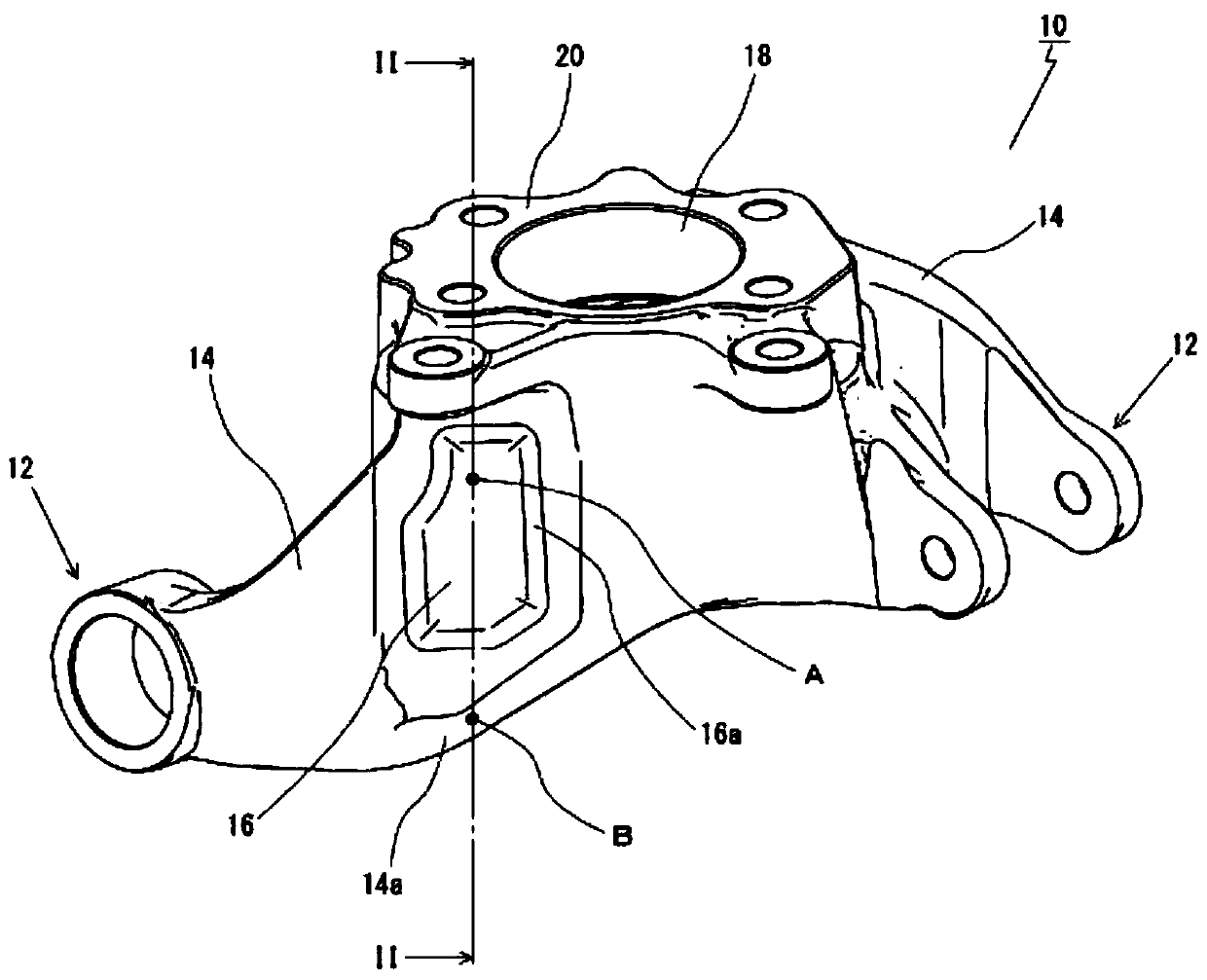

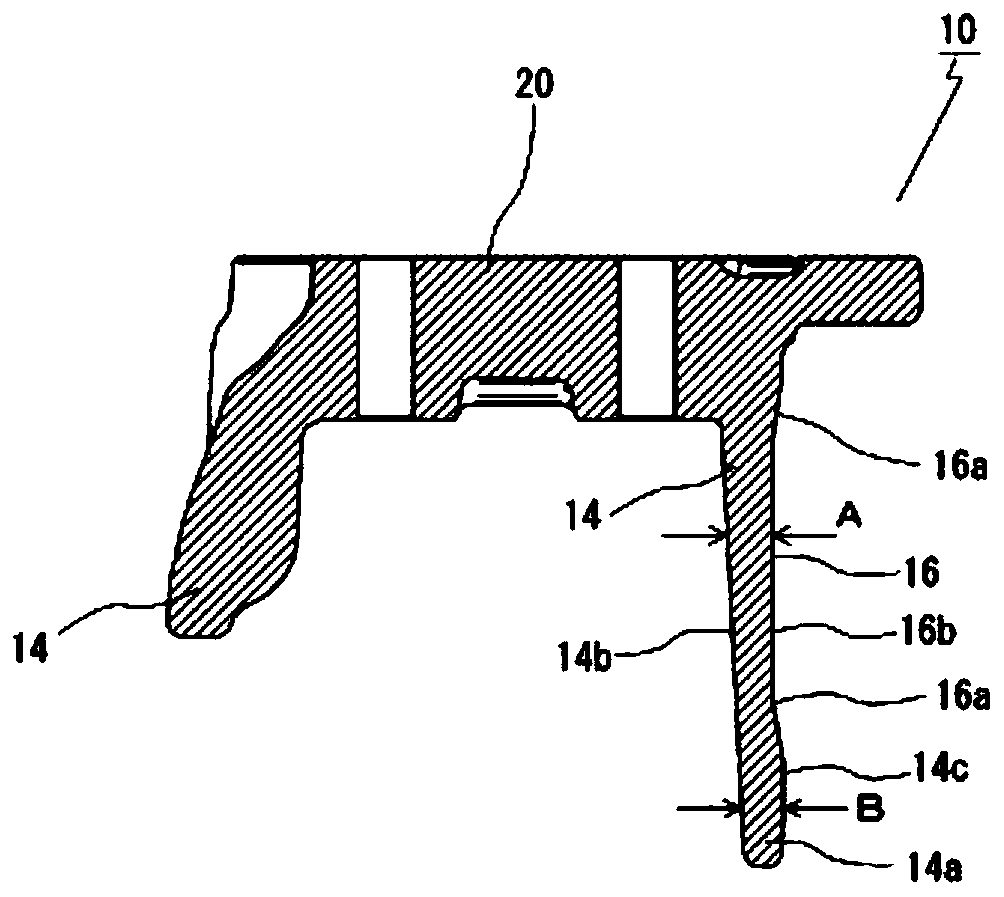

[0036] figure 1 is a perspective view showing a steering knuckle 10 as an example of a vehicle support structure, figure 2 yes figure 1 II-II sectional view.

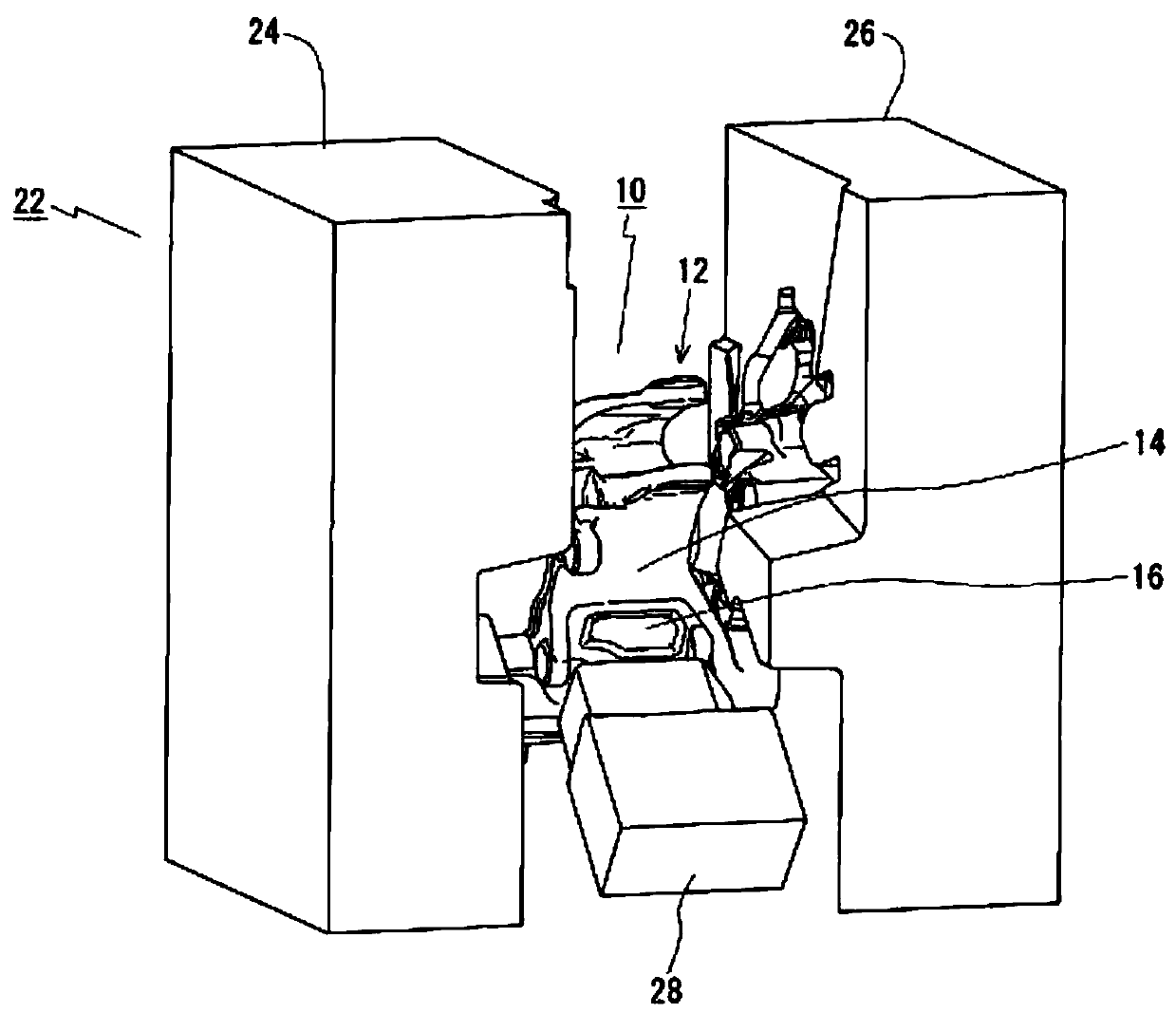

[0037] The steering knuckle 10 according to the embodiment of the present invention is formed by a casting mold and provided between the vehicle body and the vehicle component as described above, and has a support portion 12 supporting the vehicle component and a rib formed continuously with the support portion 12. 14. It is characterized in that, on the side surface of the rib 14, there is a casting punch portion 16 that is recessed in a direction different from the parting direction of the casting mold.

[0038] The steering knuckle 10 is a component that transmits the transmission force from the steering device to the wheels. More specifically, the steering knuckle 10 has a complex special-shaped shape with a body 20 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com