Support structure for vehicle and manufacturing method thereof

A technology for structures and vehicles, which is applied in the direction of manufacturing tools, vehicle parts, steering mechanisms, etc., can solve problems such as hindering weight reduction, and achieve the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described in detail.

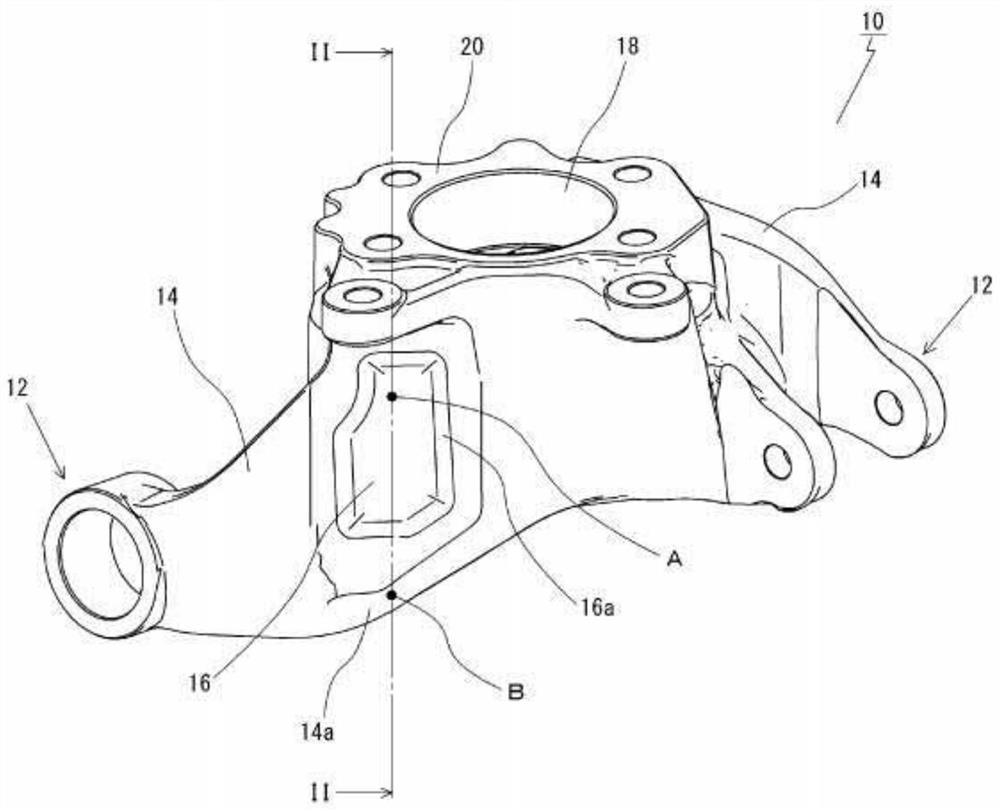

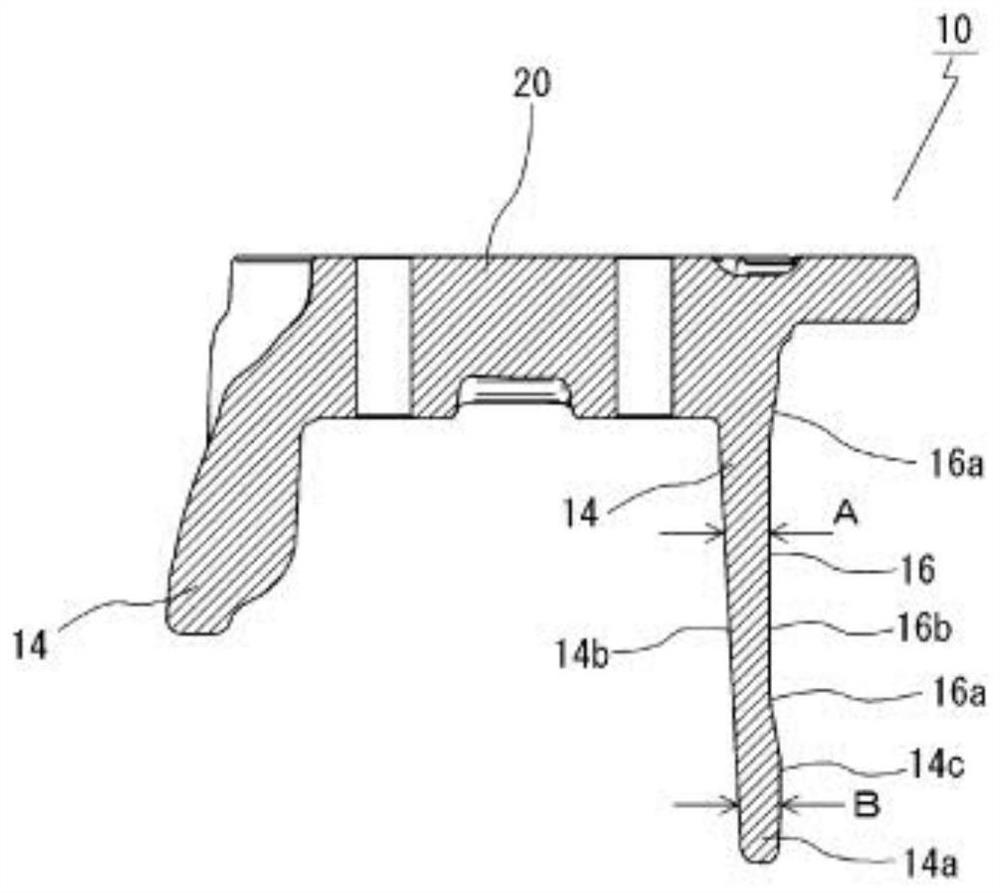

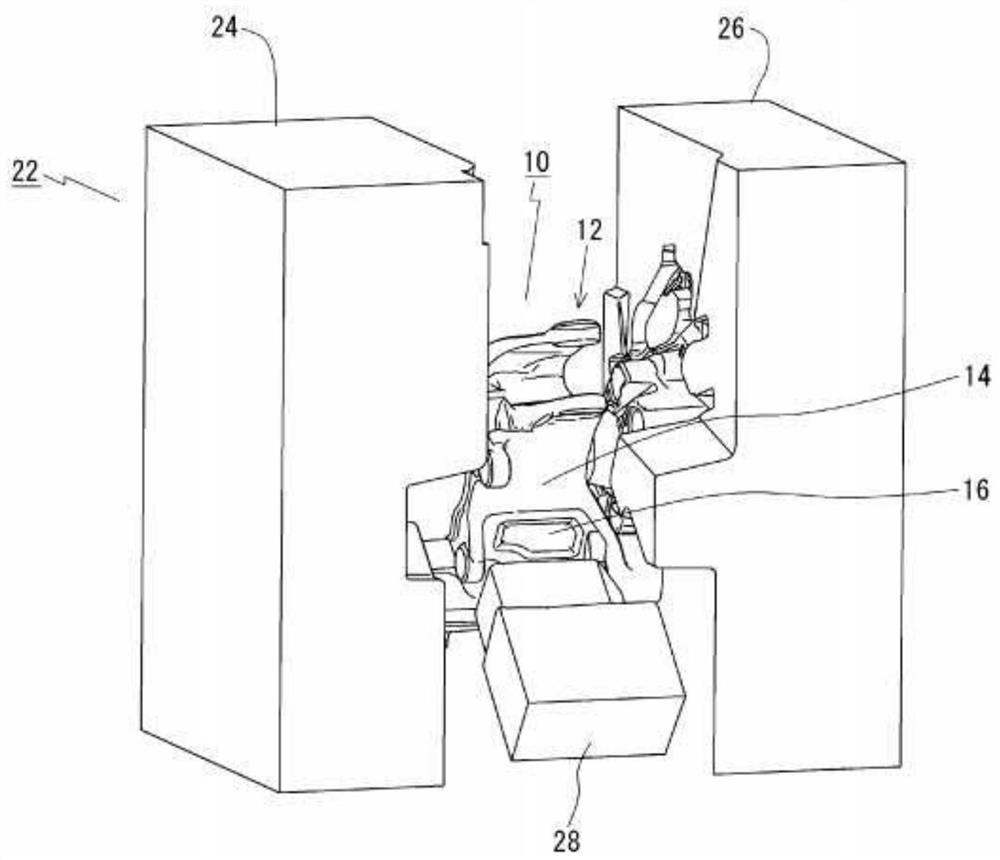

[0036] figure 1 is a perspective view of a steering knuckle 10 showing an example of a vehicle support structure, figure 2 Yes figure 1 Section II-II.

[0037] The steering knuckle 10 according to the embodiment of the present invention is formed by a casting mold as described above, is provided between the vehicle body and the vehicle component, and has the support portion 12 that supports the vehicle component, and the rib formed continuously with the support portion 12 . 14 is characterized in that the side surface portion of the rib 14 has a punch portion 16 recessed in a direction different from the parting direction of the casting mold.

[0038] The steering knuckle 10 is a member that transmits the transmission force from the steering device to the wheels. More specifically, the steering knuckle 10 has a complex deformed shape having a main body 20 and the support portion 12, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com