Quick tool pouring ladle

A casting ladle and tooling technology, which is applied in the direction of manufacturing tools, metal processing equipment, and casting molten material containers, etc., can solve the problems of reduced slag blocking effect, complicated ladle building process, and large manpower and material resources, so as to achieve smooth discharge and reduce production Cost, the effect of reducing the waste of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

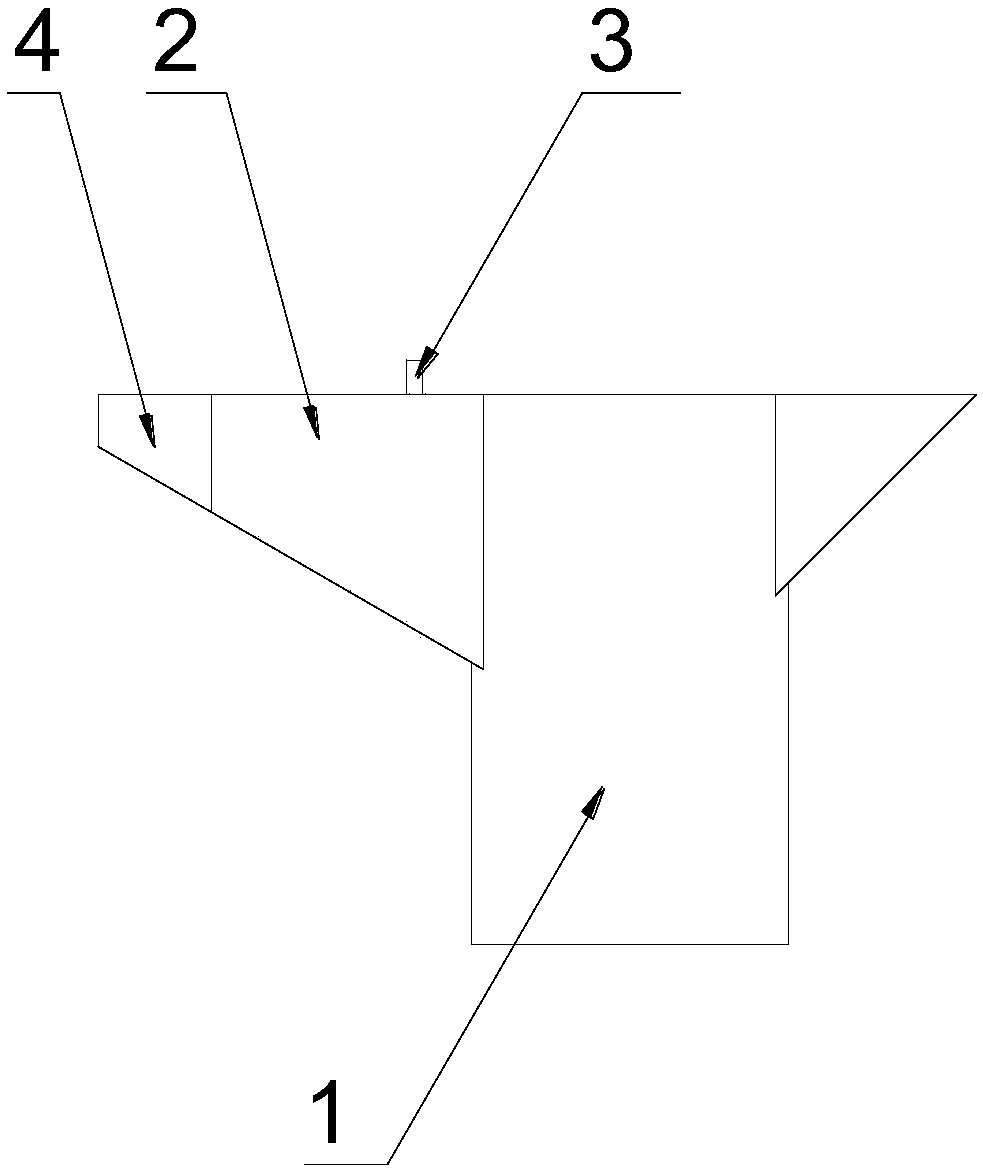

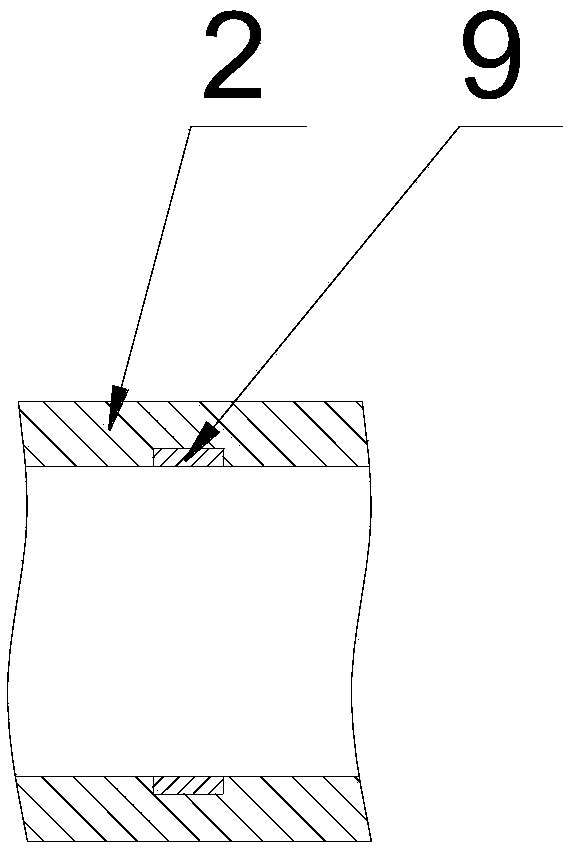

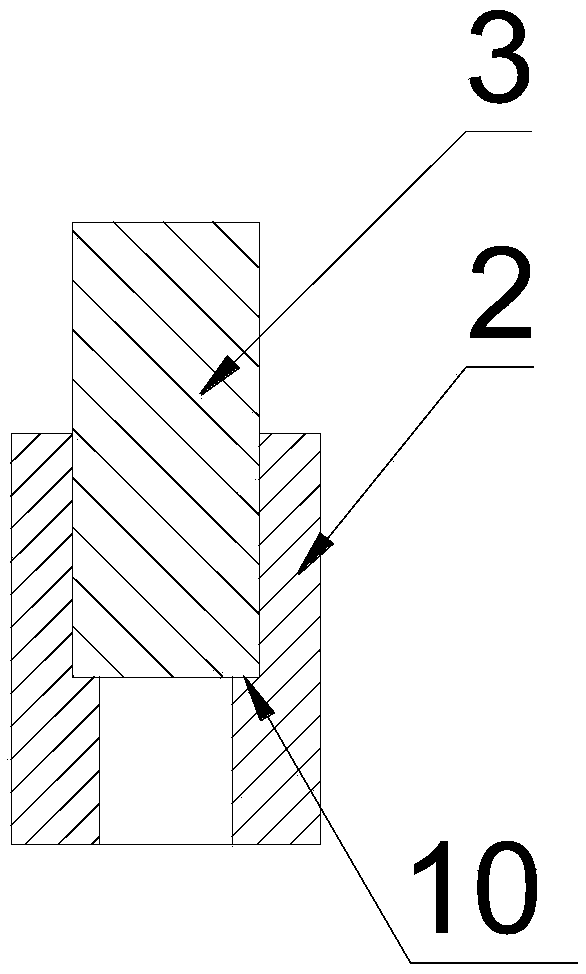

[0022] like Figure 1-6 as shown, figure 1 It is a structural schematic diagram of a quick tooling pouring ladle proposed by the present invention; figure 2 It is a top view of the end of the spout near the body of the quick tooling pouring bag proposed by the present invention; image 3 It is a schematic diagram of the connection structure between the spout and the slag retaining plate in the quick tooling pouring ladle proposed by the present invention; Figure 4 It is a top view of the discharge end of the spout in the quick tooling pouring bag proposed by the present invention; Figure 5 It is a top view of the connection structure between the spout and the movable spout in the quick tooling pouring ladle proposed by the present invention; Image 6 It is a front view of the connection structure between the spout and the movable spout in the rapid tooling pouring ladle proposed by the present invention.

[0023] refer to Figure 1-6 , a rapid tooling pouring ladle pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com