Anti-blocking type mould and production process for mould

A mold and anti-blocking technology, which is applied in the field of foam molding, can solve the problems of affecting the surface quality of plastic parts, slow molding speed of plastic parts, and uneven heating of foamed plastics, so as to save steam costs, shorten foaming molding time, increase large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

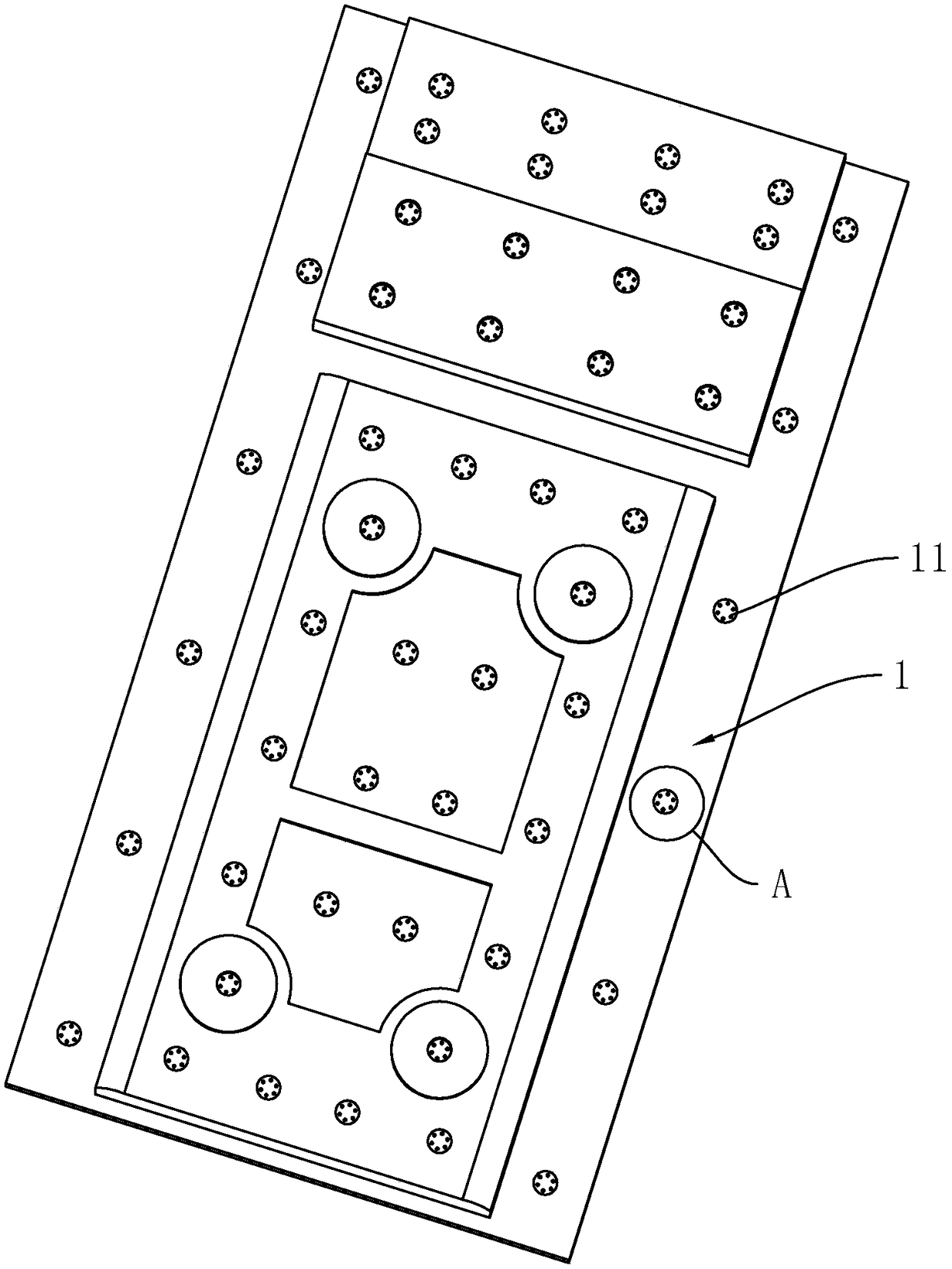

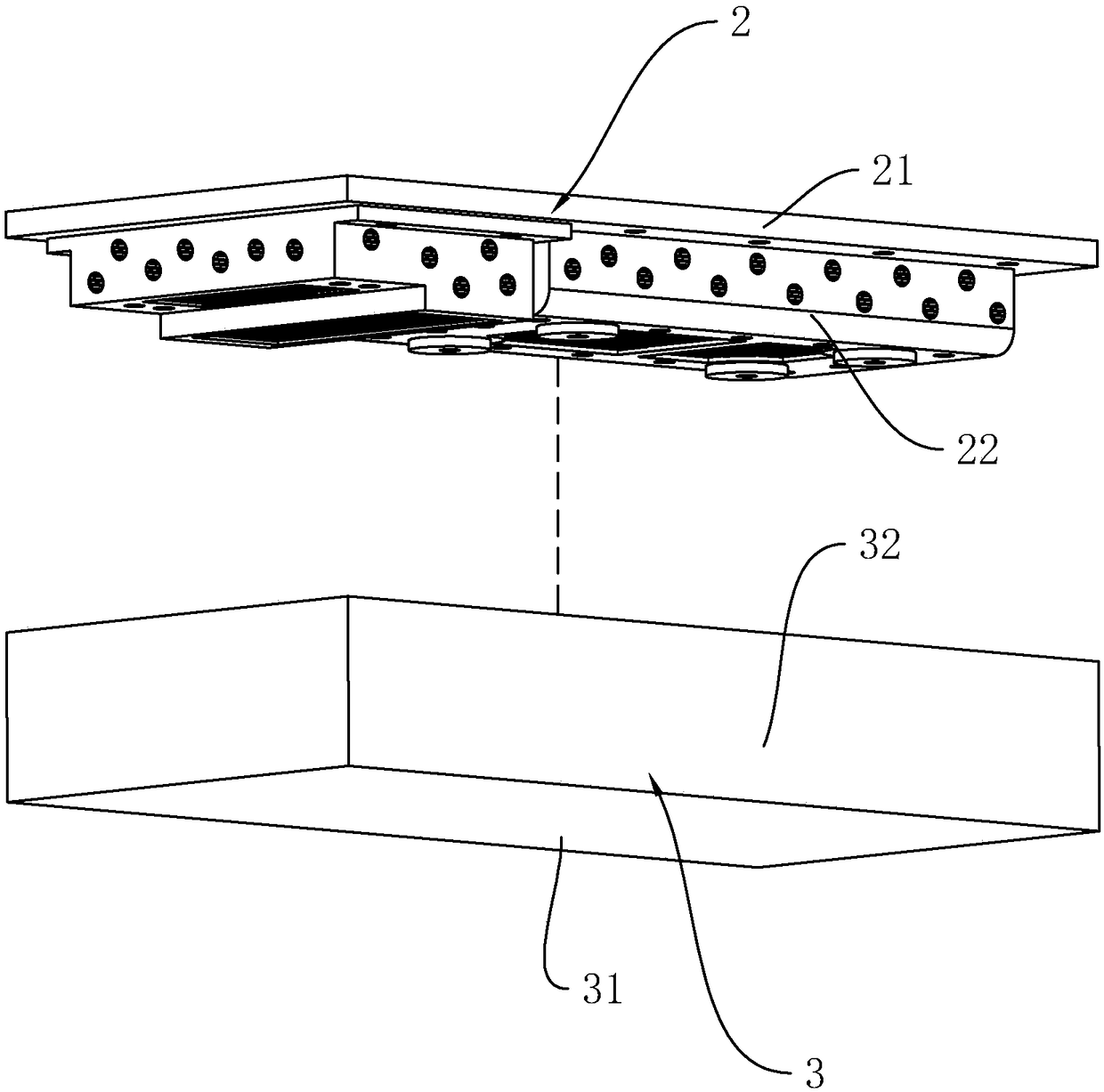

[0062] Embodiment 1: A kind of anti-blocking mold, combined with image 3 , including an upper mold 2 and a lower mold 3 used in conjunction with the upper mold 2 .

[0063] The upper mold 2 includes a horizontally arranged upper support plate 21 and two punches 22 arranged on the lower surface of the upper support plate 21 . The lower mold 3 includes a lower bottom plate 41 and a frame body 32 vertically and fixedly connected to the upper surface of the lower supporting plate 31 . During work, the two punches 22 of the upper die 2 are placed in the frame body 32, and the upper end of the frame body 32 of the lower die 3 abuts against the lower surface of the upper support plate 21 of the upper die 2, so that the upper die 2 and the upper die 2 are in contact with each other. A molding cavity for molding foamed plastics is formed between the lower molds 3 .

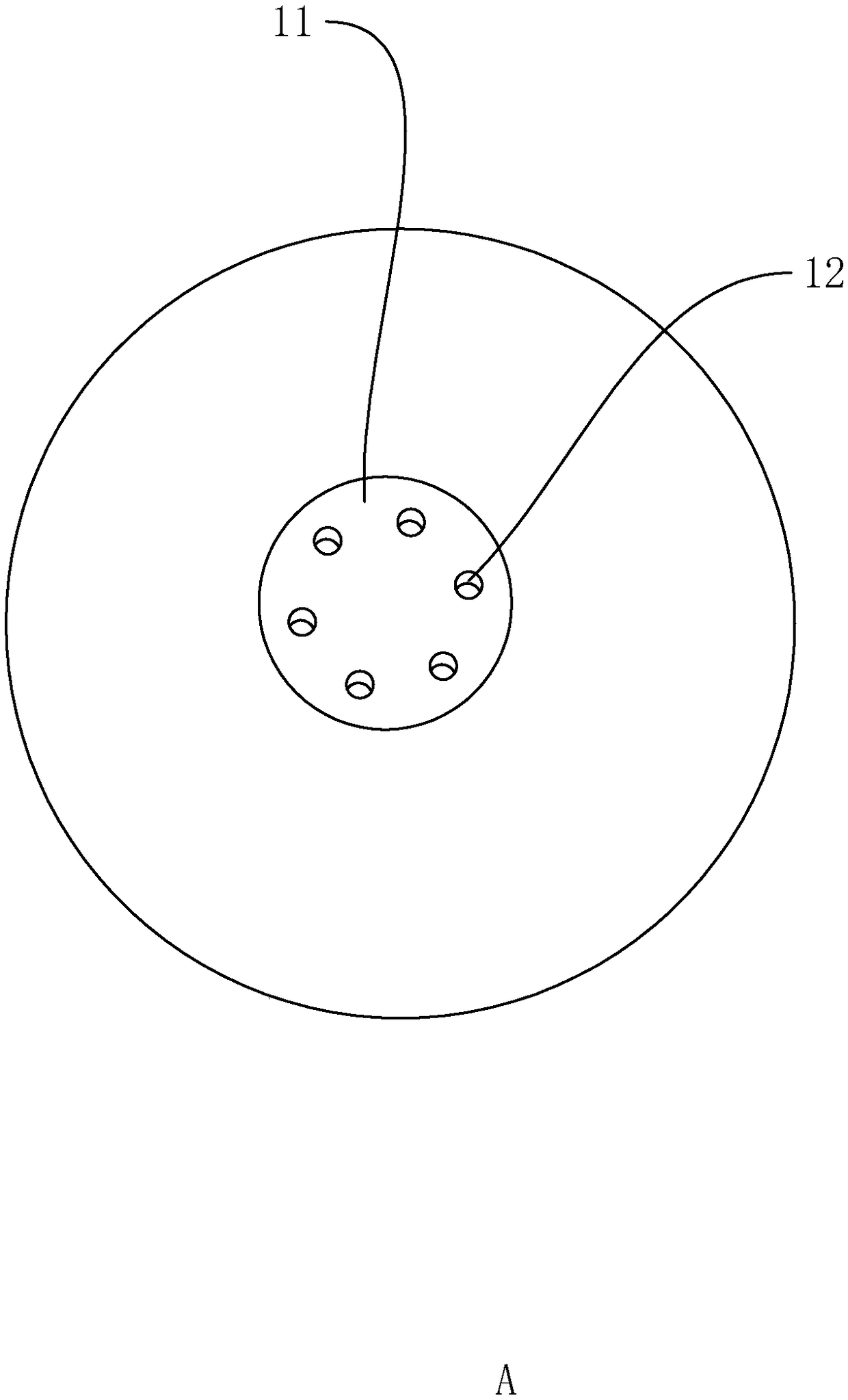

[0064] combine Figure 4 and Figure 5 , the upper support plate 21 and the punch 22 are respectively provided with...

Embodiment 2

[0067] Embodiment two: a kind of anti-clogging mold, combine Figure 7 , the difference from Embodiment 1 is that: the side wall of the punch 22 is also provided with a second through groove 222, and the second through groove 222 is also fixedly connected with a grid plate 24, and the grid plate in the second through groove 222 The length direction of the grid strips 241 of 24 is parallel to the lower surface of the upper support plate 21 .

[0068] Compared with Embodiment 1, the advantage is that: by opening the second through groove 222 on the side wall of the punch 22 and fixedly connecting the grid plate 24, the steam entering the molding cavity from the side wall of the punch 22 can be further increased. speed, so that the foamed plastic in the molding cavity is evenly heated, and then the foamed plastic on the side wall of the punch 22 and the foamed plastic on the bottom of the punch 22 are foamed and molded synchronously.

Embodiment 3

[0069] Embodiment three: a kind of anti-clogging mold, combined Figure 8 , and the difference from the second embodiment is that: the length direction of the grid bar 241 in the second through groove 222 is the same as the drawing direction of the punch 22 .

[0070] Compared with implementation one, the advantage is: the length direction of the grid bar 241 in the second through groove 222 is the same as the drawing direction of the punch 22, and when the convex film is pulled out, the amount of foaming plastic and the punch 22 can be reduced. The frictional force is convenient for the drafting of punch 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com