Double-body combined wire drawing die with replaceable die holes and using method thereof

A combination of wire drawing die technology, applied in the direction of wire drawing dies, etc., can solve problems such as reducing wire drawing efficiency, delaying working hours, and reducing factory benefits, and achieves the effects of increasing factory revenue, improving production efficiency, and realizing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

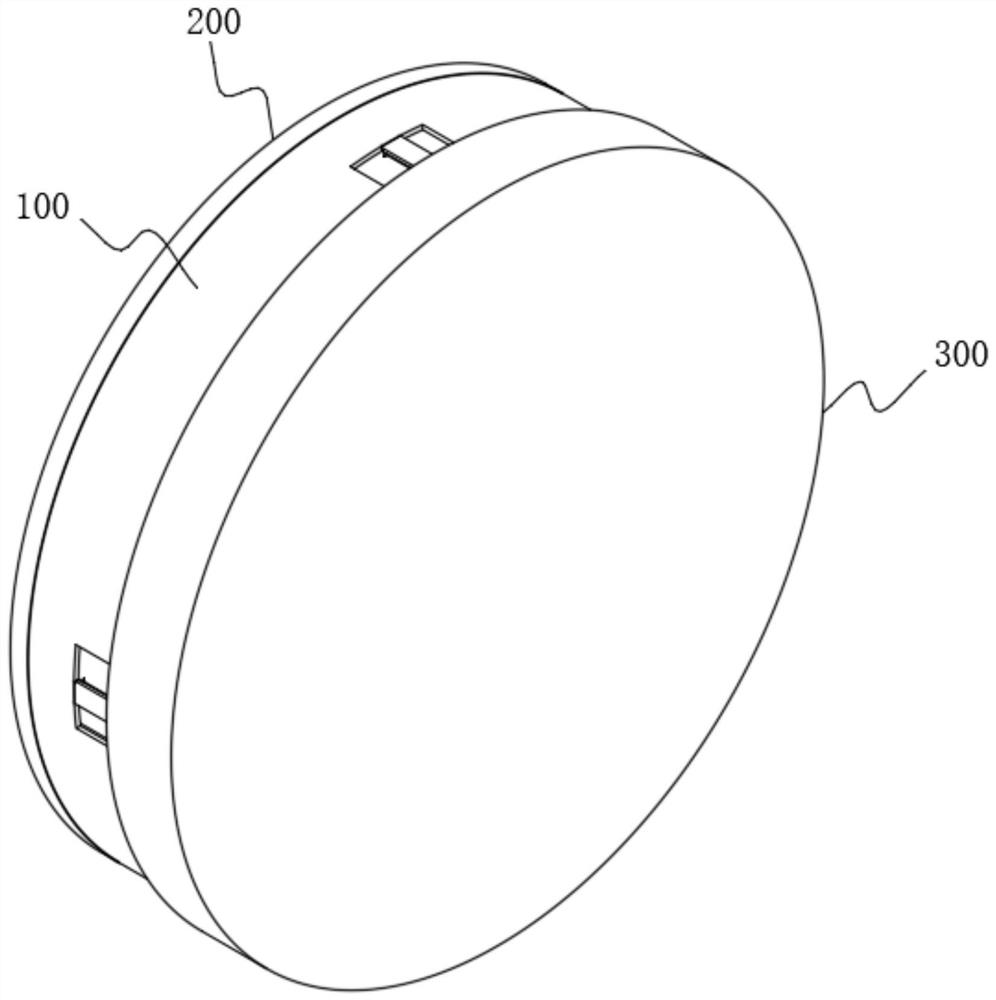

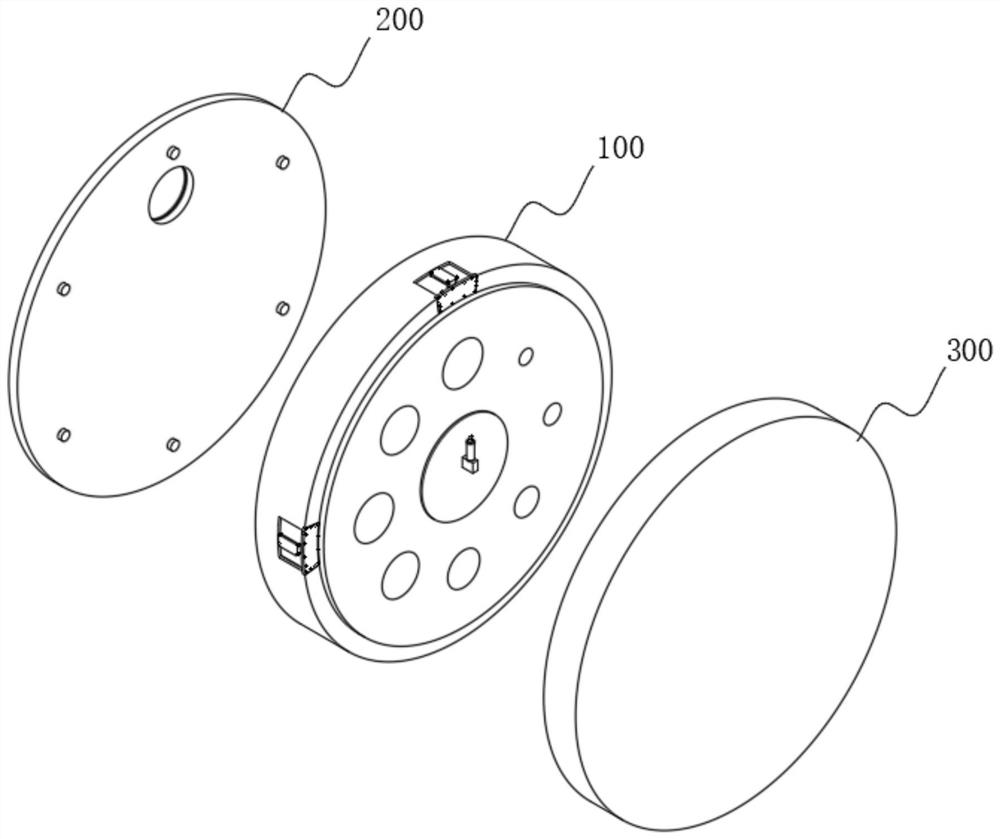

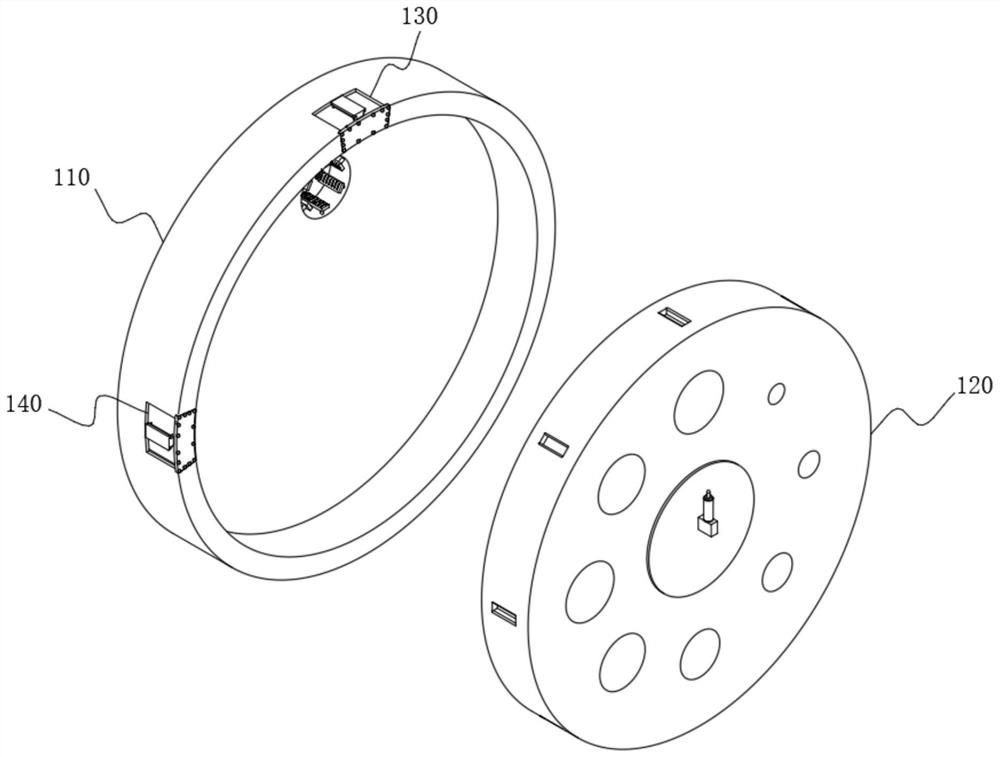

[0083] see Figure 1-Figure 13 As shown, one of the purposes of this embodiment is to provide a two-body combined wire drawing die with replaceable die holes, including a film changing hole mechanism 100, and the film changing hole mechanism 100 includes a back cover 110, and the inside of the back cover 110 is opened There is a "circular" groove opening forward, and a positioning hole 111 is opened on the rear side of the rear cover 110 near the top. The front cover 120 is arranged on the front side of the rear cover 110. The front cover 120 includes a front cover body 121, The front cover body 121 is rotationally connected with the "circular" groove of the back cover 110, and a plurality of die holes 1211 are ring-shaped around the front side wall of the front cover body 121. The inner wall of the die hole 1211 adopts natural diamond as a raw material. It has strong wear resistance, thereby prolonging the service life of the die hole 1211. The radius of the die hole 1211 gra...

Embodiment 2

[0105] In order to control the two-way rotation of 121 so that it can rotate clockwise in both directions and improve the rotation selectivity of the front cover body 121, please refer to image 3 , Figure 4 , Figure 8 , Figure 14 , Figure 15 with Figure 16 As shown, the right side of the rear cover 110 is provided with a unidirectional and bidirectional control device 140, the unidirectional and bidirectional control device 140 includes a control connection block 141, the control connection block 141 is fixedly connected with the rear cover 110, and the right side of the control connection block 141 is movably connected with a control Plate 143, so the bottom surface of the control plate 143 is an inclined surface, and the bottom surface of the control plate 143 is engaged with the insertion groove 1212. The right end of the control plate 143 is fixedly connected with a control plate 144, and the left side of the control plate 144 is provided with a control plate 143....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com