Filter element waterway switching diverter structure

A waterway conversion and filter element technology, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of long manufacturing and assembly hours, high material consumption, and high cost, and achieve assembly and It is convenient to apply glue, the access area is enlarged, and the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solution and advantages of the present application clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. In the ensuing description some specific details are referred to for a thorough understanding of the present invention. While the present invention can be practiced without these specific details, the description and representations herein can be used by those skilled in the art to more effectively convey the substance of their work to others skilled in the art.

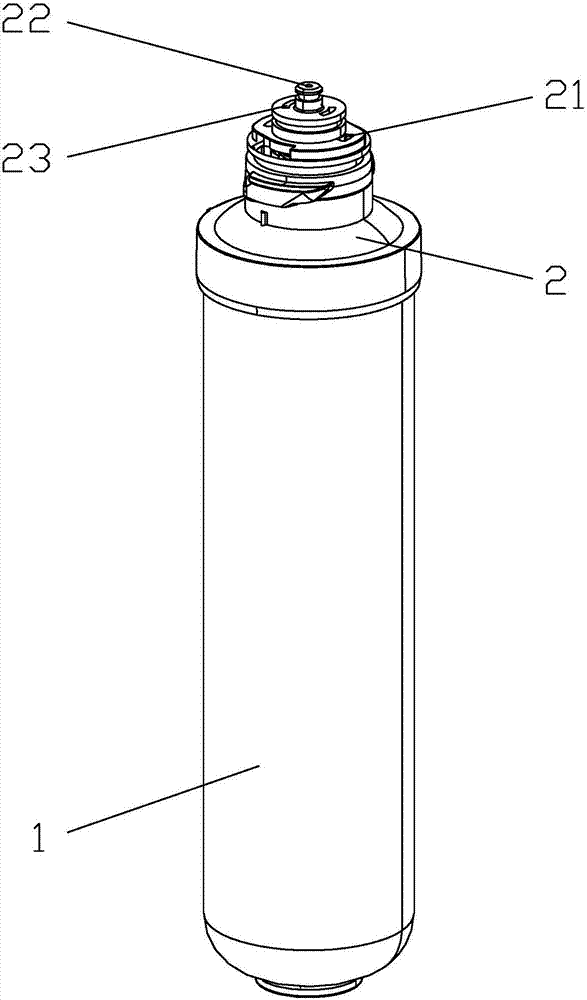

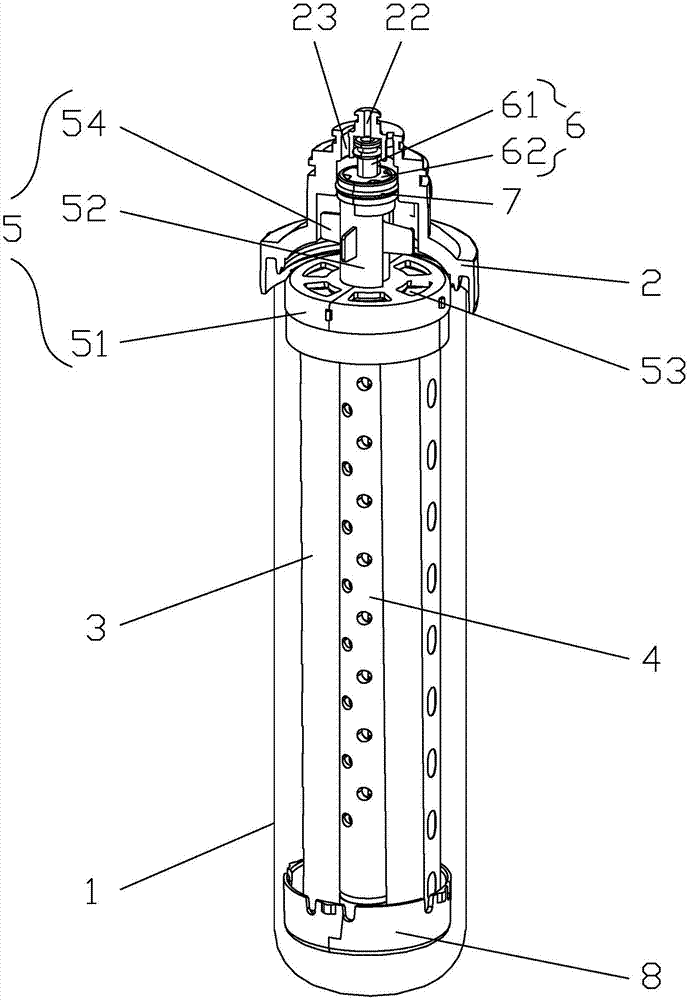

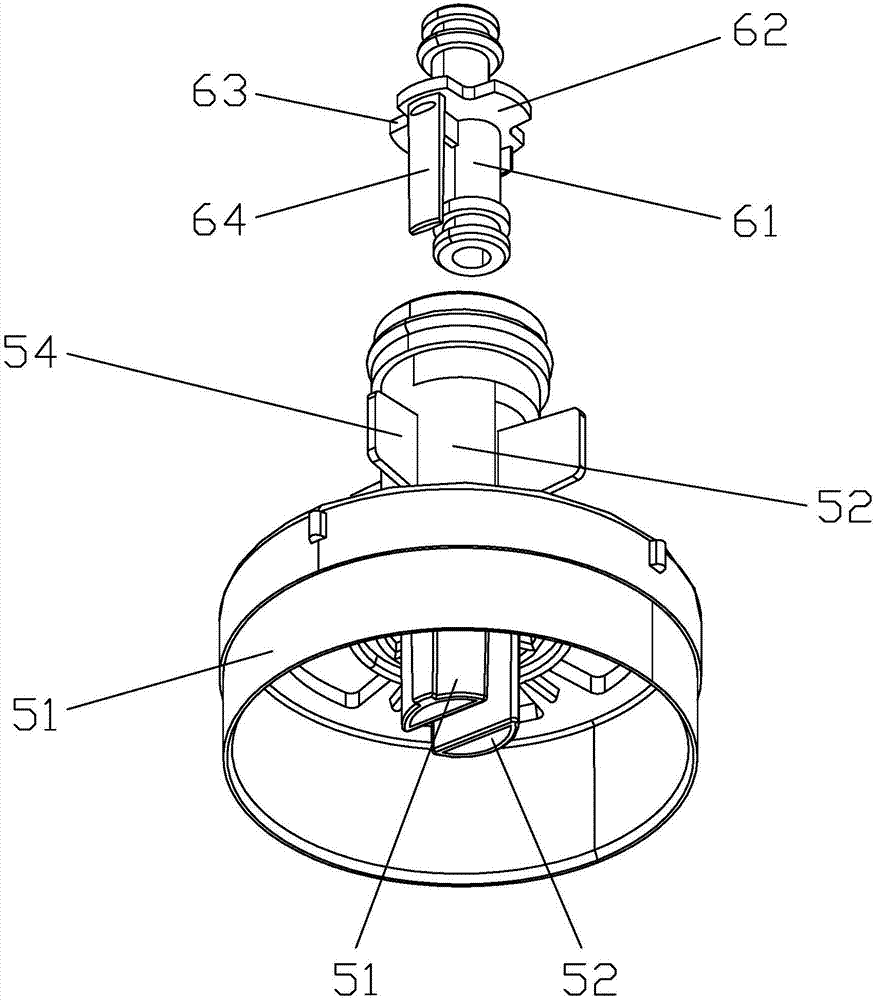

[0017] refer to figure 1 , figure 2 , image 3 , a filter element waterway conversion shunt structure, comprising a filter bottle 1 and a filter element filter cover 2 on the upper end of the filter bottle 1, the filter bottle 1 has a built-in filter membrane 3, and the filter element filter cover 2 is provided with a raw water inlet 21, pure water Outlet 22, waste water outlet 23, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com