Throttle valve structure

A throttle body and valve body technology, which is applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems that cannot meet the performance requirements of small displacement engines, large inner diameter, slow speed, etc., to meet the intake speed and The effect of air intake requirement, sufficient air intake, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

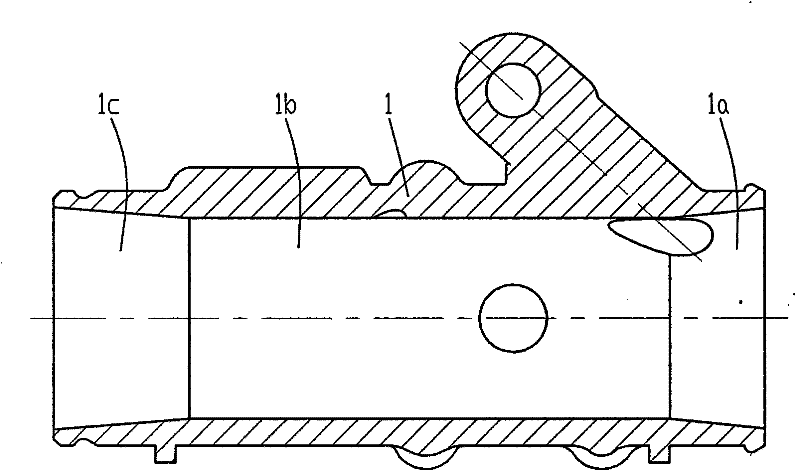

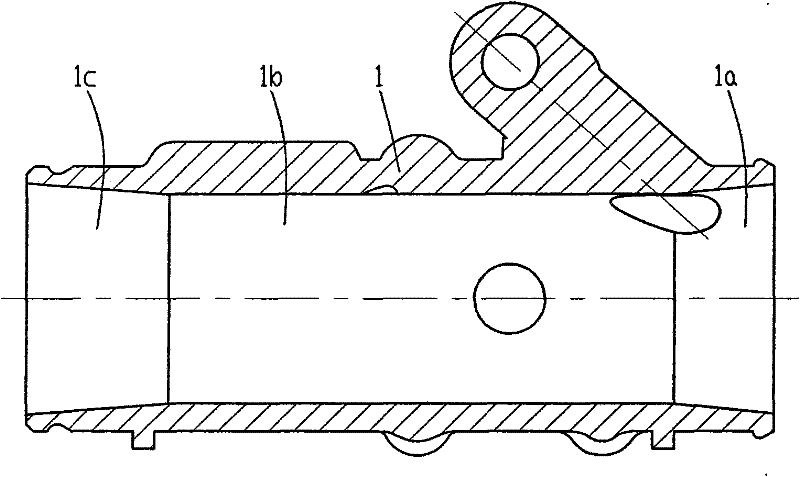

[0010] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

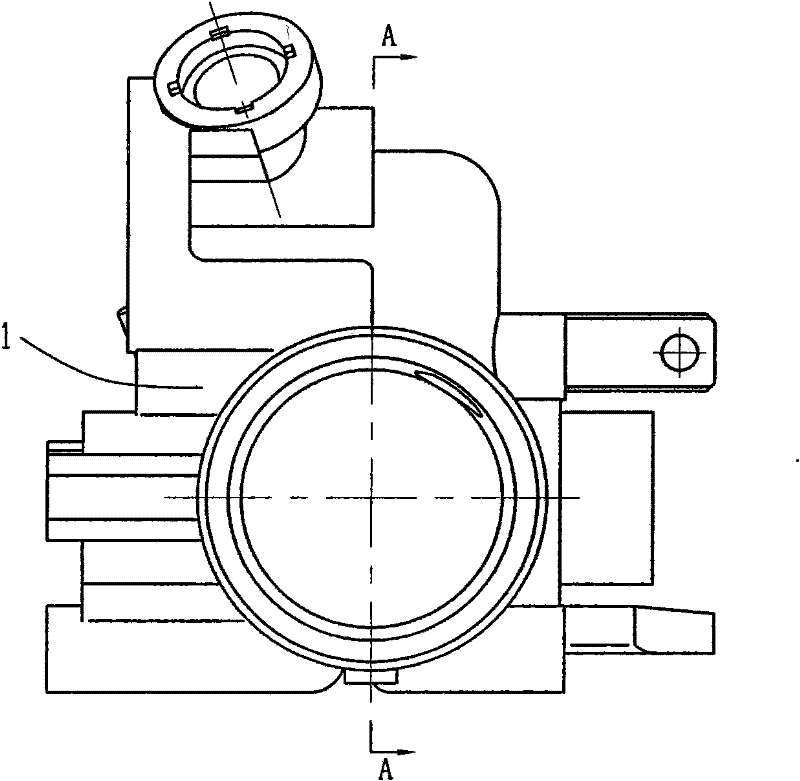

[0011] like figure 1 , figure 2 As shown, the central hole of the valve body 1 of the EFI throttle body is an air flow passage, and the central hole is composed of an inlet cone section 1a, a transition section 1b and an outlet cone section 1c, wherein the transition section 1b is located between the inlet cone section 1a and the outlet cone section. Between 1c, the transition section 1b is a straight section of equal diameter with an inner diameter of 30mm. The inlet cone section 1a is connected with the air filter, the inlet cone section 1a is a bell mouth structure, and the small end is connected with the transition section 1b. The length of the inlet cone section 1a is 11-17mm, preferably 14mm in this embodiment; the taper of the inlet cone section 1a relative to the axis of the valve body 1 is 5-8°, preferably 6° in this embodiment. The outlet cone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com