Spiral-wound membrane component and filter element employing same

A roll-type membrane and component technology, applied in membrane technology, semi-permeable membrane separation, water/sludge/sewage treatment, etc., can solve the problems of wasting water resources, improve production efficiency and yield, and reduce manufacturing difficulty , Facilitate mass production at low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

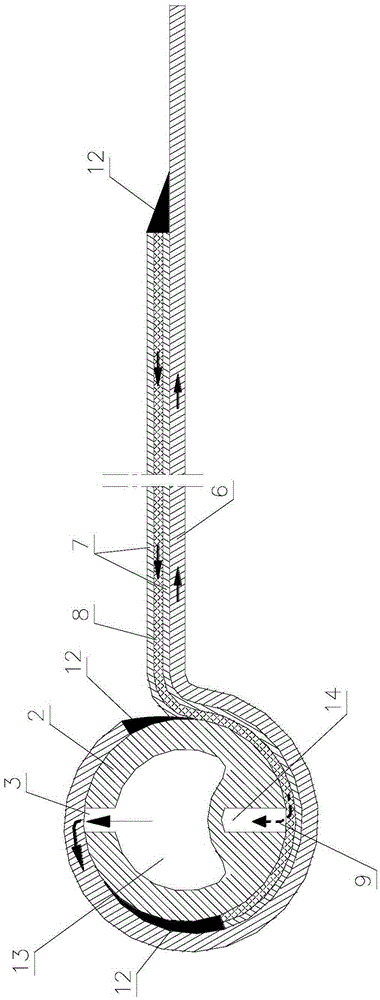

[0029] Such as figure 1 As shown, it is a partially developed cross-sectional schematic diagram and a schematic diagram of water flow of a roll-type membrane module provided by the present invention. The coiled membrane assembly includes a core pipe 2 and a water purification membrane group. The water purification membrane group is wound on the core pipe 2 . The water purification membrane set includes a raw water diversion net 6 , two plate-shaped filter membranes 7 and a produced water diversion net 8 . Both sides of the permeated water diversion net 8 are adjacent to one side of the two plate-shaped filter membranes 7 , and the other sides of the two plate-shaped filter membranes 7 are adjacent to the raw water diversion net 6 . The water flow channel in the raw water diversion net 6 is the raw water flow channel, and the water flow channel in the produced water diversion net 8 is the produced water flow channel.

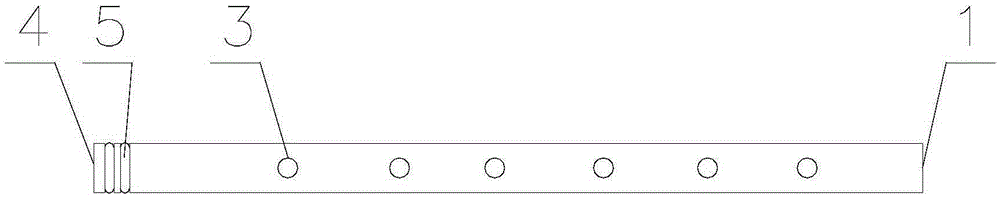

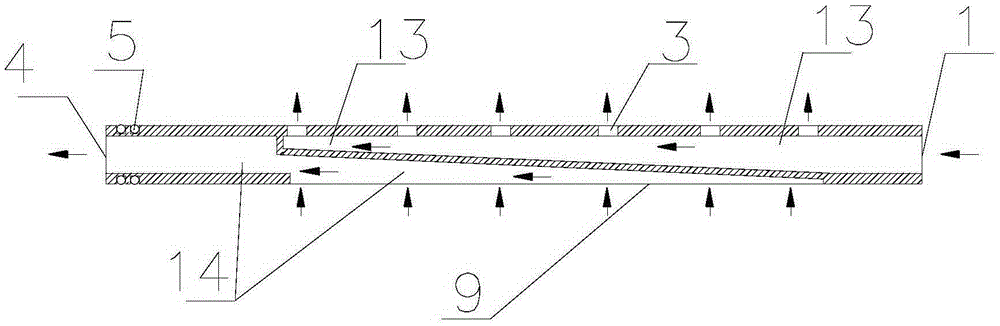

[0030] Such as figure 2 , image 3 and Figure 4 as ...

Embodiment 2

[0039] Such as Figure 8 As shown in FIG. 1 , it is a structural schematic diagram and a schematic diagram of water flow of a filter element provided by the present invention with the above-mentioned coiled membrane module. The filter element includes: a filter element housing and a roll-type membrane assembly 19 arranged in the filter element housing, the filter element housing is provided with a water inlet 16, a water outlet 21 and a concentrated water outlet 22, and the water inlet 16 communicates with the raw water of the roll-type membrane assembly 19 The inlet 1 and the concentrated water port 22 are connected to the concentrated water outlet 11 of the spiral membrane module 19 , and the water outlet 21 is connected to the produced water outlet 4 of the spiral membrane module 19 . The filter element housing includes: filter element cover 17, filter element body 20 and seal ring 18, filter element cover 17 and filter element body 20 are connected by threads, and after ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com