Quick withdrawing mold

A mold and fast technology, which is applied in the field of rapid draft molds, can solve the problems of mold sticking together and inconvenient drafting, and achieve the effect of avoiding damage to the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

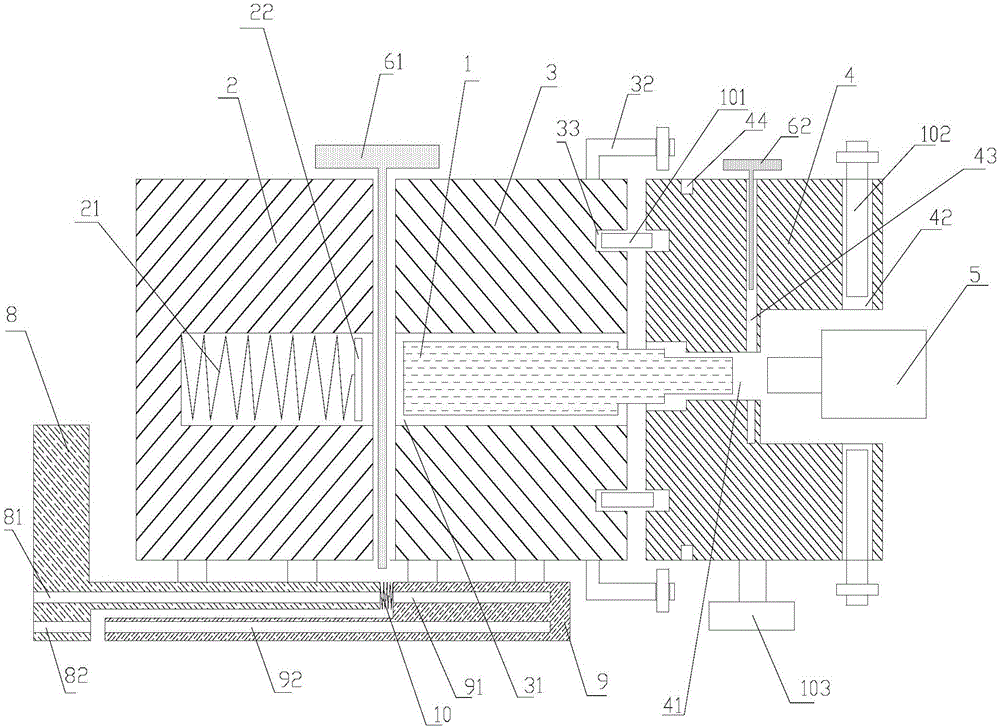

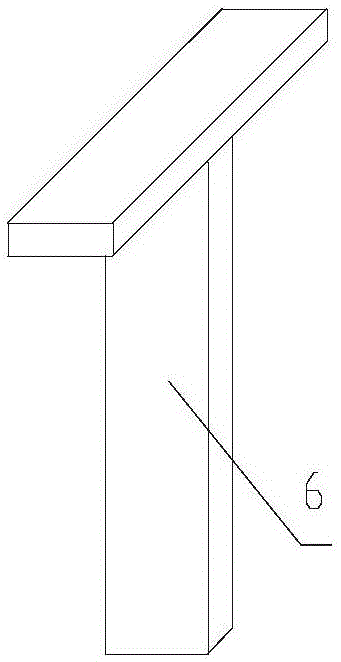

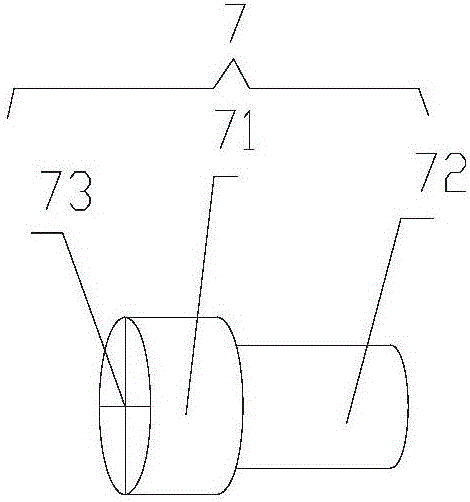

[0018] In order to make the technical means, creative features, purpose and effect of the present invention more clear and easy to understand, the following in conjunction with the attached Figure 1~3 The present invention is further elaborated with specific embodiment:

[0019] "Up", "Down", "Left" and "Right" mentioned in the present invention are attached figure 1 Up, down, left and right shown.

[0020] The present invention proposes a quick draft mold, which includes a stepped shaft workpiece 1, and also includes a first mold 2, a second mold 3, a third mold 4 and a knocking mechanism 5 connected in sequence; the first mold 2, the second The mold 3 and the third mold 4 have a first film cavity, a second film cavity 31 and a third film cavity 41 in turn, and the second film cavity 31 and the third film cavity 41 communicate with each other and are connected to the stepped shaft workpiece 1 Adapted, the first film cavity corresponds to the second film cavity 31, the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com