Labor protection glove demolding device

A demoulding device and technology for labor protection gloves, applied in gloves, clothing, clothing, etc., can solve the problems of low production efficiency and low degree of automation of the drafting device, and achieve the advantages of convenient production operation, convenient and fast shaping, and easy drafting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

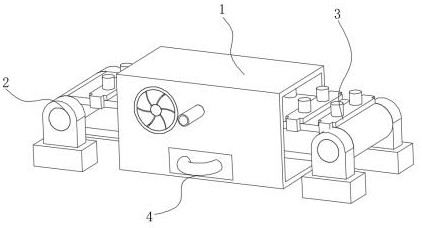

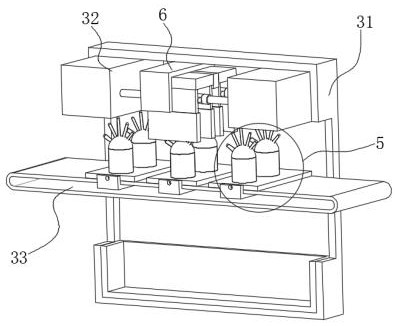

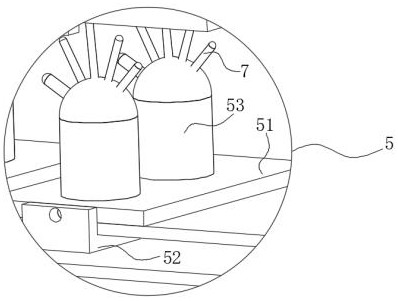

[0033] use Figure 1-Figure 6 A labor protection glove demoulding device according to an embodiment of the present invention will be described as follows.

[0034] like Figure 1-Figure 6 As shown, a demoulding device for labor protection gloves according to the present invention includes a drafting box 1, the inside of the drafting box 1 is provided with a demoulding module 3, and the upper surface of the demoulding module 3 is in contact with the drafting box 1. The top of the inner wall of the mold box 1 is fixedly connected, and the two ends of the demoulding module 3 all extend to the outside of the draft box 1, and the two ends of the inner wall of the demoulding module 3 are all rotatably connected with a rotating motor 2; Before work, the shaped glove mold 5 is clamped on the left end of the outer surface of the conveyor belt 33, and then the rotating motor 2 is started, and the rotating motor 2 drives the conveyor belt 33 to rotate clockwise, and the glove mold 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com