Engineering machinery hydraulic torque converter pump impeller structure

A technology of hydraulic torque converter and pump wheel structure, applied in mechanical equipment, belts/chains/gears, fluid transmission devices, etc., can solve problems such as poor economy, achieve a high degree of generalization, reduce impact losses, and save molds input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Exemplary embodiments of the present invention are described below in conjunction with the accompanying drawings, which include various details of the embodiments of the present invention to facilitate understanding, and they should be regarded as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted in the following description for clarity and conciseness.

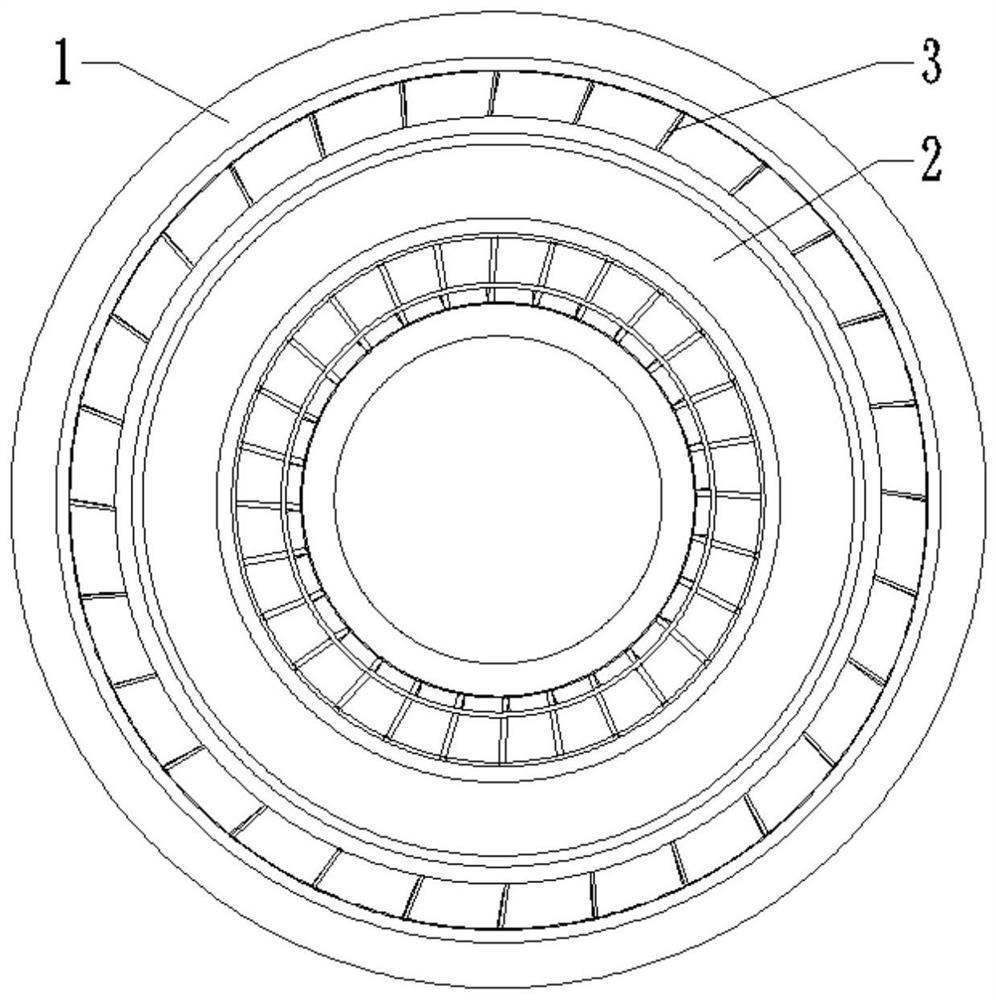

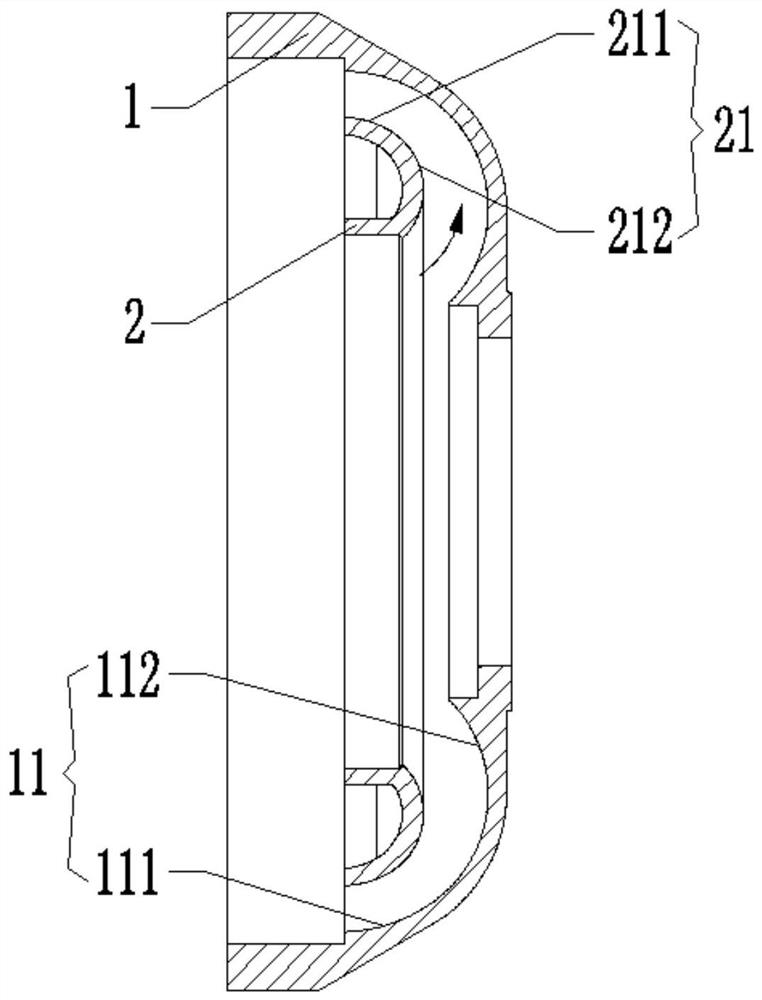

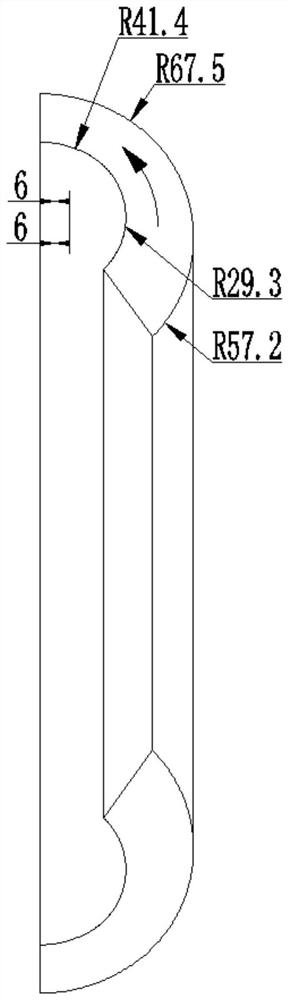

[0027] like figure 1 and figure 2 As shown, a construction machinery hydraulic torque converter pump wheel structure includes an inner ring 2 and an outer ring 1 concentrically arranged and a cascade connected between the inner ring 2 and the outer ring 1, and the inner ring 2 and the outer ring 1 are connected. A circular cavity is formed between the ring 2 and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com