Device for adjusting height of galvanometer

A height adjustment and adjustment block technology, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of unbalanced height, insufficient precision of self-made fine thread, and high cost, so as to reduce costs, reduce parts, The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

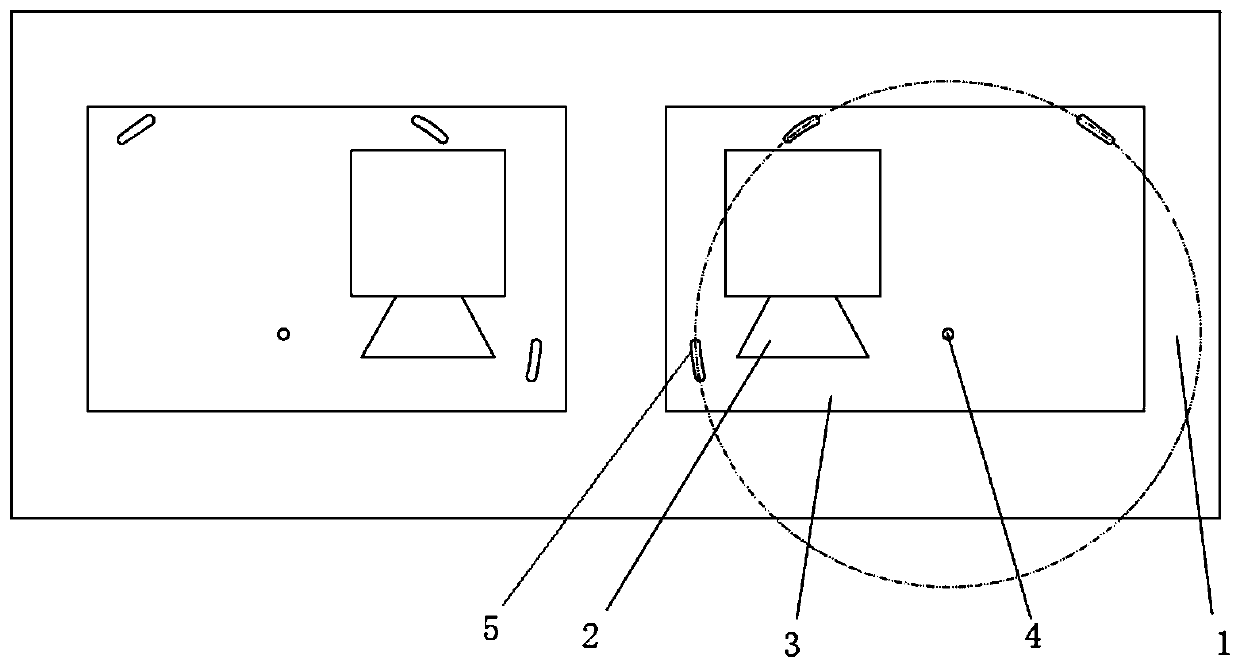

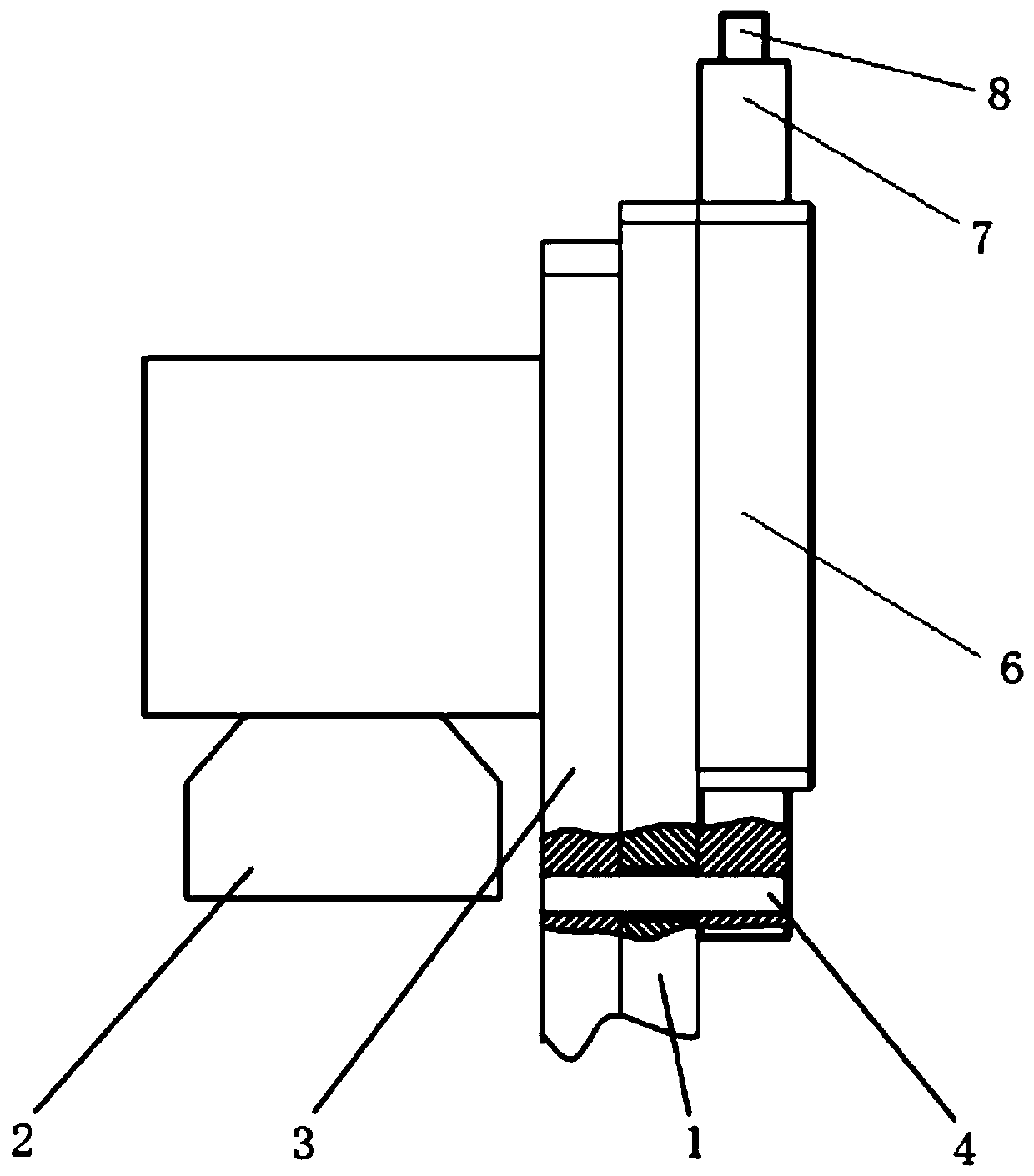

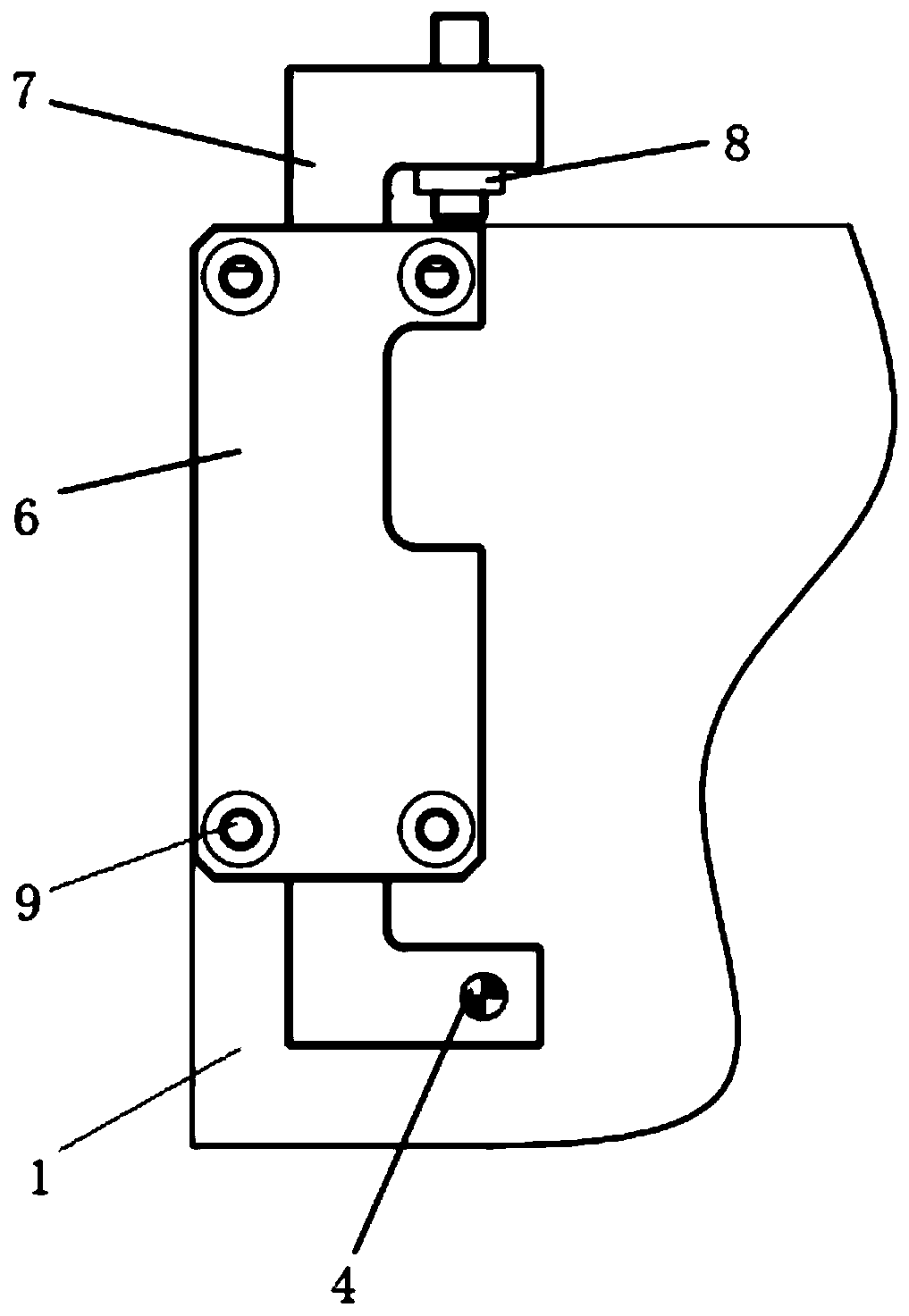

[0021] refer to Figure 1-3 , a device for adjusting the height of the vibrating mirror, including a Z-axis base plate 1, a vibrating mirror base plate 3, and a vibrating mirror 2 installed on the vibrating mirror base plate 3, and a vibrating mirror pin is provided on the back of the vibrating mirror base plate 3 at the side of the vibrating mirror 2 hole, the position corresponding to the galvanometer pin hole on the Z-axis bottom plate 1 is provided with an adjustment through hole, and one end of the pin shaft 4 is transitionally fitted in the galvanometer pin hole, and the middle part of the pin shaft 4 is clearance fit in the adjustment through hole. In the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com