Motor waterproof breather valve assembly structure

An assembly structure and breathing valve technology, applied in control valves, safety valves, balance valves, etc., can solve problems such as high cost, poor anti-immersion ability, complexity, etc., achieve functional breakthroughs, and ensure waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

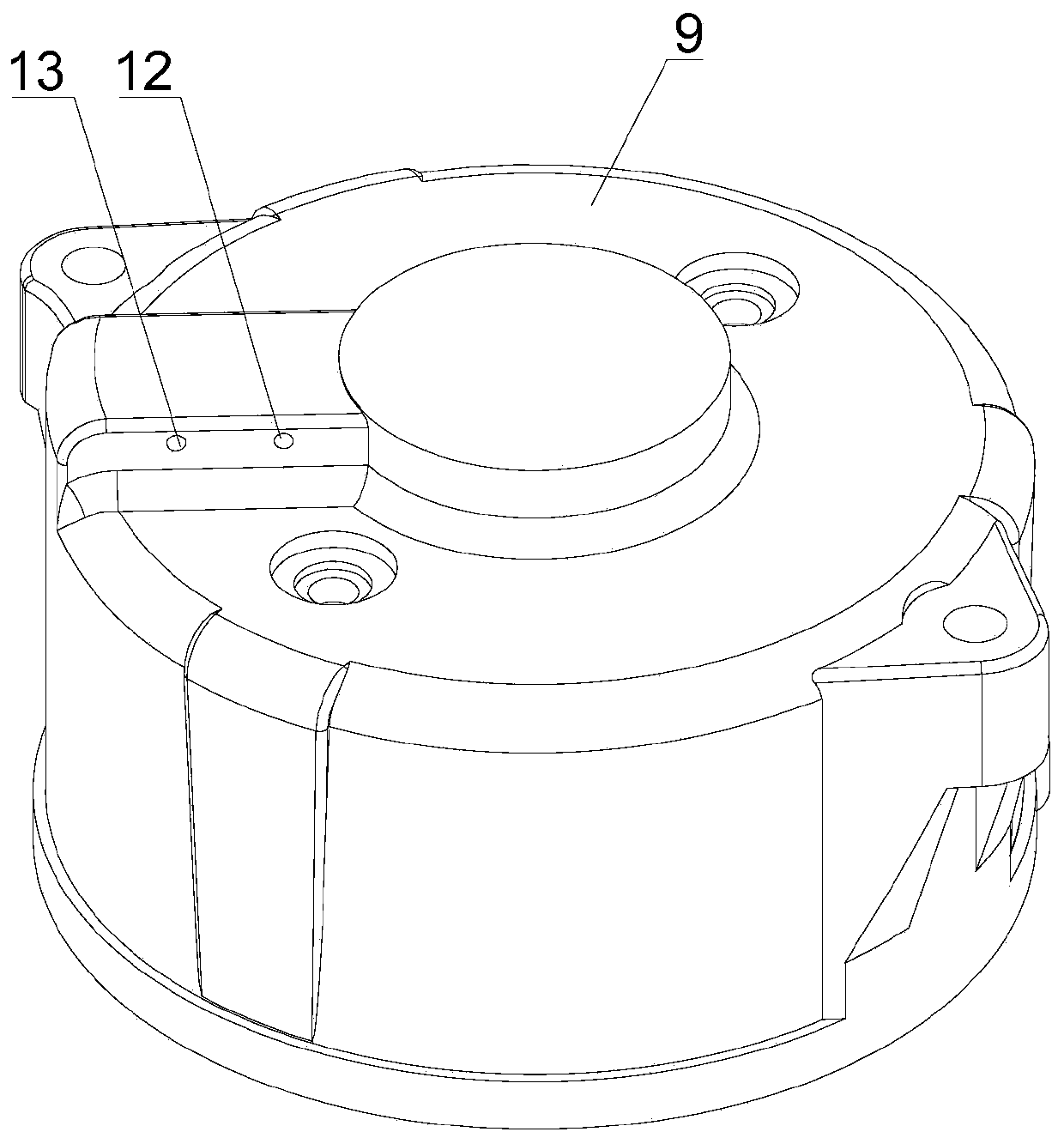

[0029] see Figures 1 to 4 As shown, this embodiment provides a motor waterproof breathing valve assembly structure, which is suitable for various motors, and is used to effectively adjust the air pressure in the body cavity, solve the disadvantages of the fully sealed structure of the motor, and improve the waterproof performance of the motor. The assembly structure can be installed on any part of the motor body. This embodiment takes the motor rear cover as an example to describe in detail.

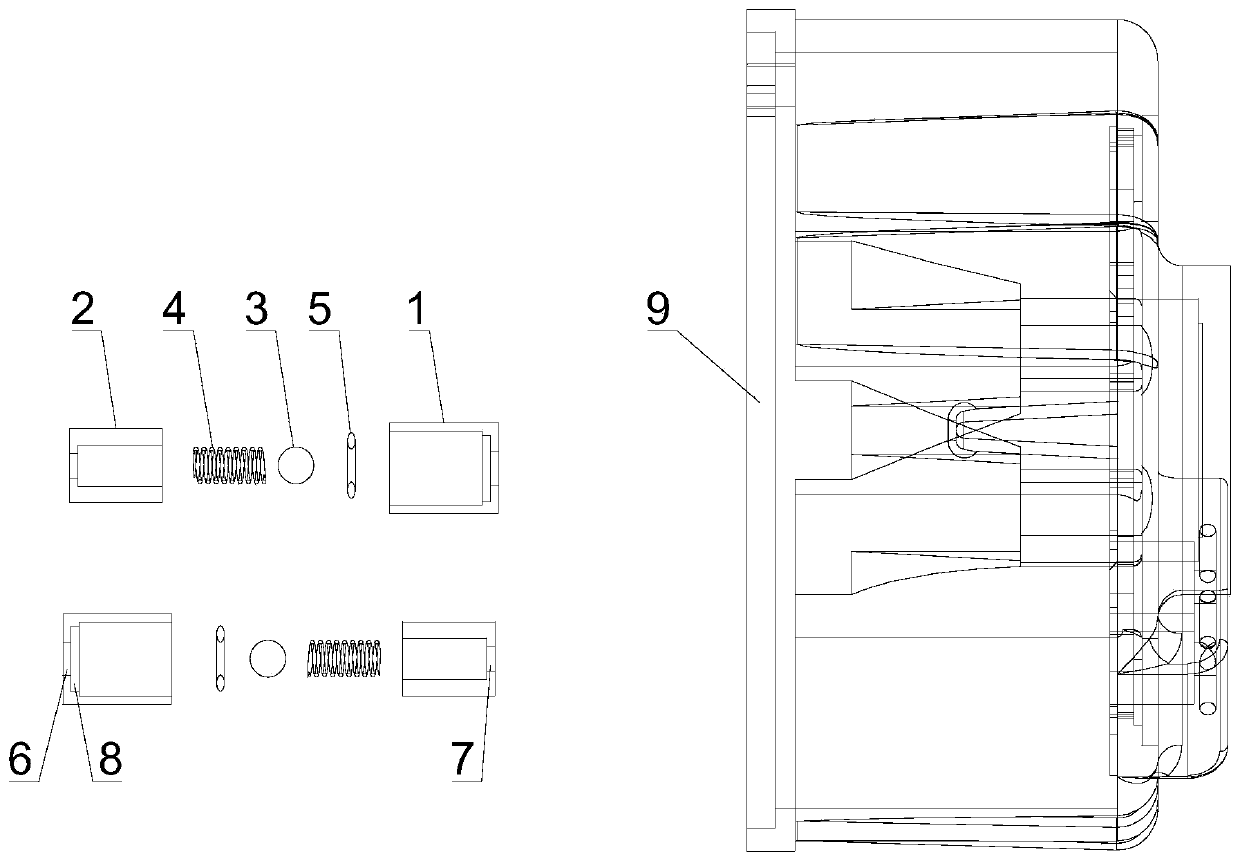

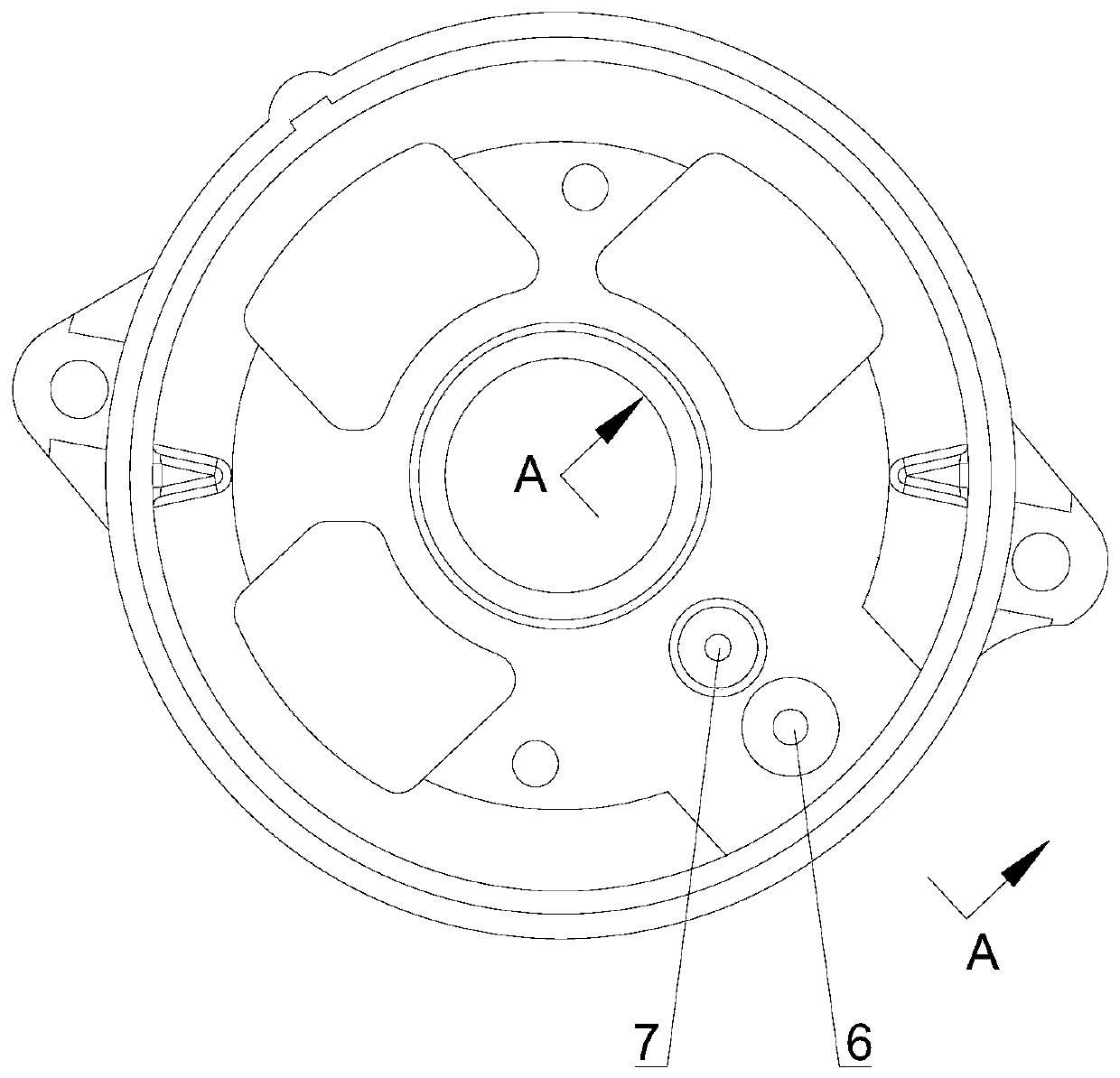

[0030] The waterproof breather valve assembly structure is used for motors whose housing cavity is a closed space, and at least two breather valves are arranged on the shell, the breather valve is a one-way check structure, and the flow paths of the two breather valves are opposite Arranged on the housing in such a way that one exhale and one inhale can automatically adjust the internal pressure.

[0031] The breathing valve here includes a valve body 1 , a spring seat 2 and a steel ba...

Embodiment 2

[0040] see Figures 5 to 8 As shown, on the basis of Embodiment 1, considering the structure of the breathing valve, it can be integrated on the housing 9, mainly for the breathing valve with the second air hole 7 facing away from the housing 9, and the breathing valve does not need a valve Body 1, its spring seat 2 can be directly press-fitted in an installation cavity 10; while the breathing valve with the second vent hole 7 close to the shell 9 is still the original design, its valve body 1 is press-fitted in the Another installation cavity 10.

[0041] During installation, the valve body 1 of the breather valve with the second air hole 7 against the shell 9 is fixed on the shell 9, and the spring seat 2 of the breather valve with the second air hole 7 facing away from the shell 9 is assembled with steel The ball 3 can be directly fixed on the housing 9, the installation is simple, the integrated volume is small, and the original structure of the motor is hardly affected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com