Motor waterproof breather valve assembly mechanism

A breathing valve and assembly technology, applied in the field of motor waterproof breathing valve assembly mechanism, can solve the problems of poor water immersion resistance, high failure rate, insufficient adaptability, etc., and achieve strong water immersion resistance, functional breakthrough, structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

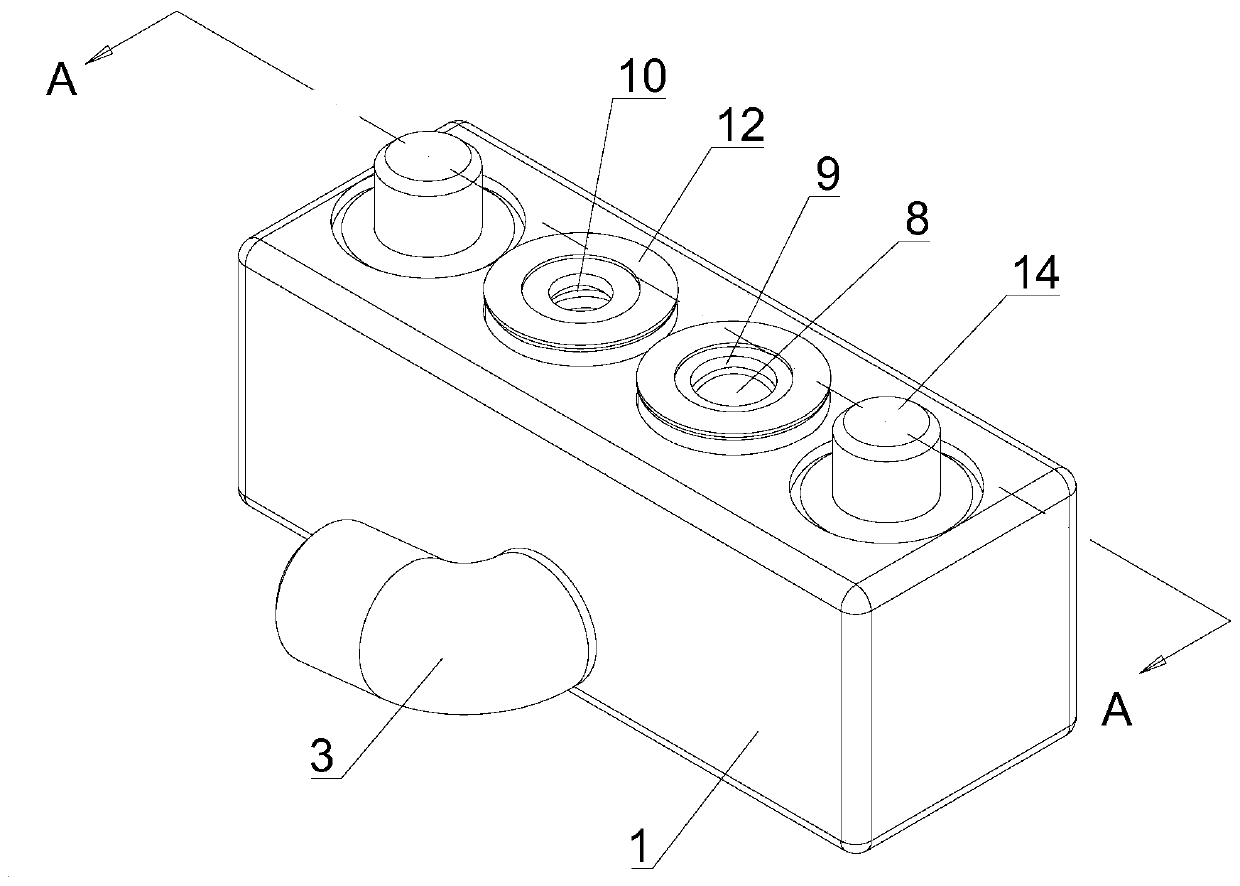

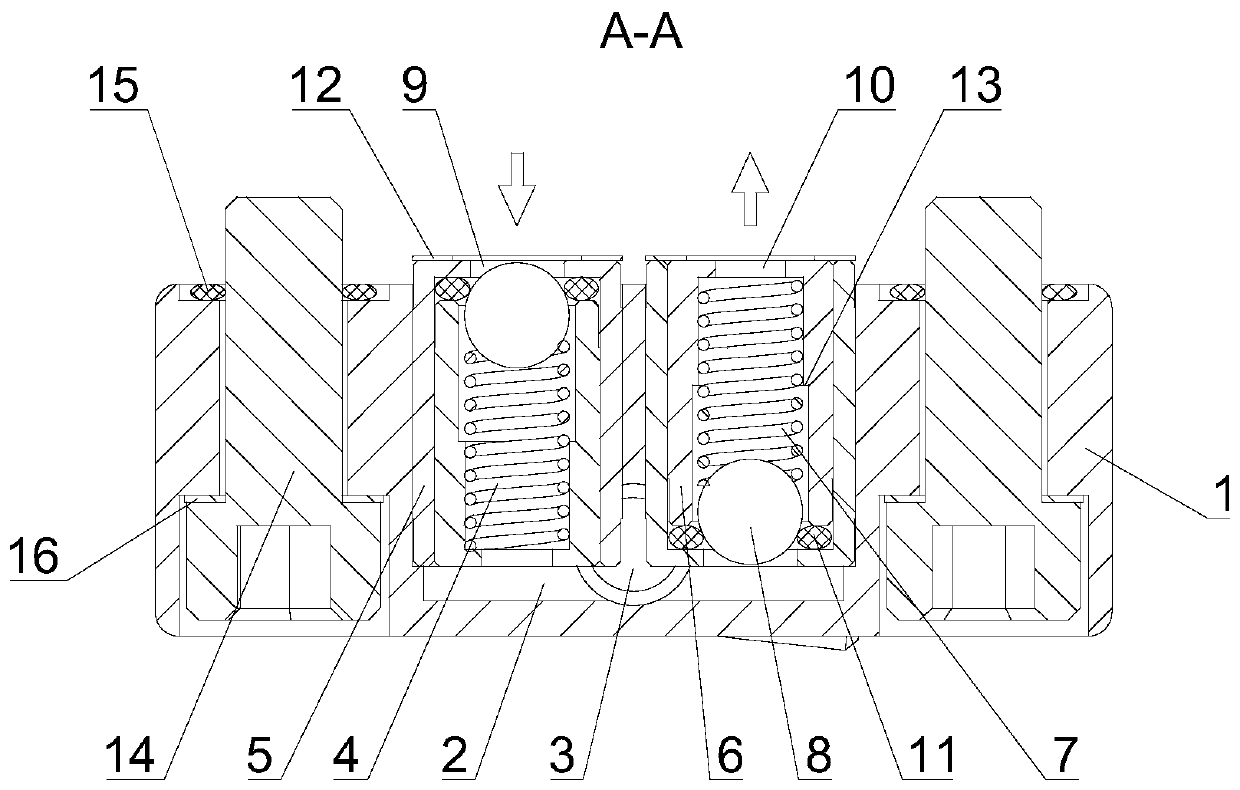

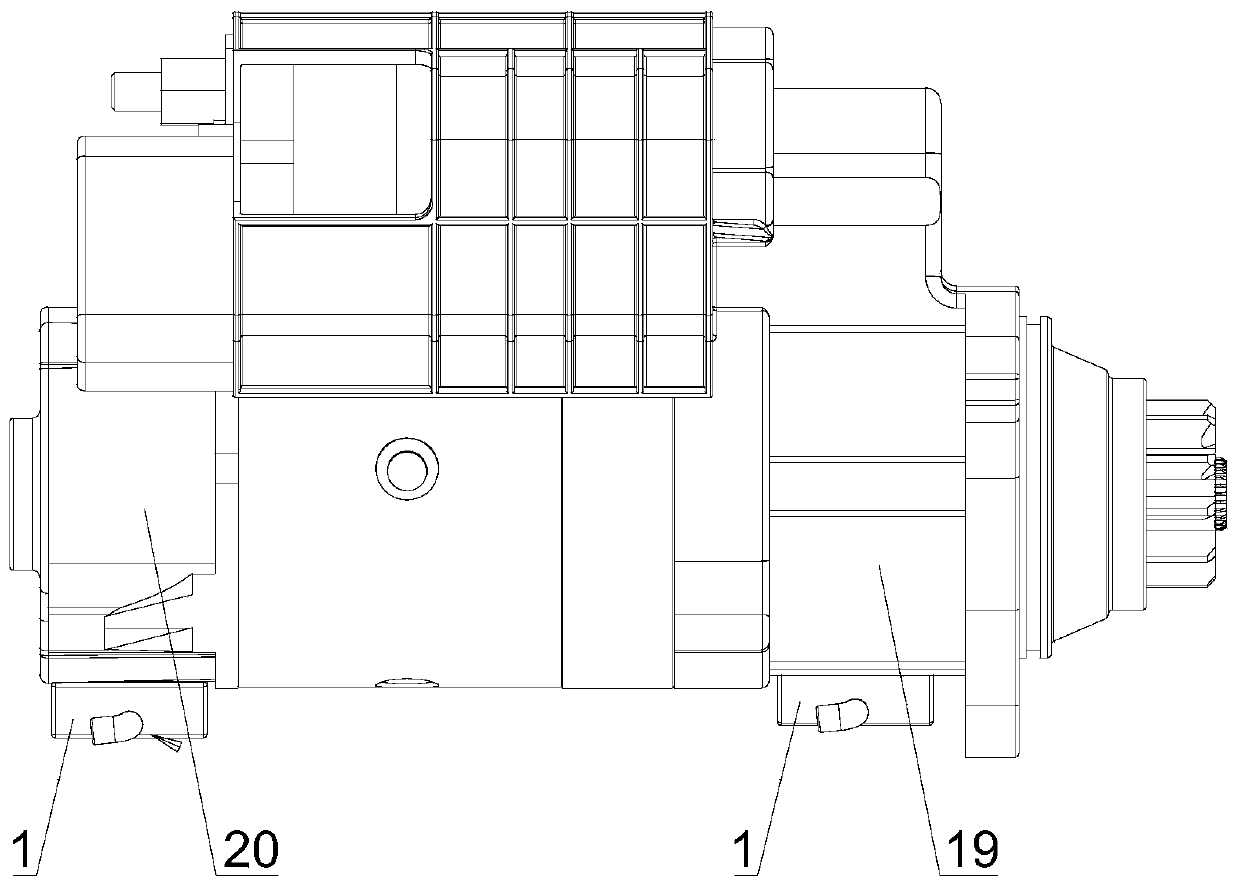

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0021] see Figures 1 to 4 As shown, this embodiment provides a motor waterproof breathing valve assembly mechanism, which includes a valve body 1 installed outside the motor housing 17, a chamber 2 is opened in the valve body 1, and an air inlet and outlet valve is arranged on the valve body 1. Channel 3, the air inlet and outlet channel 3 communicates the chamber 2 with the outside world, and two oppositely installed breathing valves 4 are arranged in the chamber 2, so as to realize the function of automatically adjusting pressure with one breathing valve exhaling and the other breathing valve sucking ground.

[0022] The breathing valve 4 includes a valve seat 5, a spring seat 6, a pressure spring 7 and a valve core 8. The valve seat 5 is provided with a single opening inner cavity, and its end w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com