Starter anti-water-immersion structure

A technology for preventing water immersion and starter, which is applied to engine components, electromechanical devices, mechanical equipment, etc., can solve the problems of poor water immersion resistance, complexity and high cost, and achieve the effect of improving performance, realizing functionality and ensuring waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

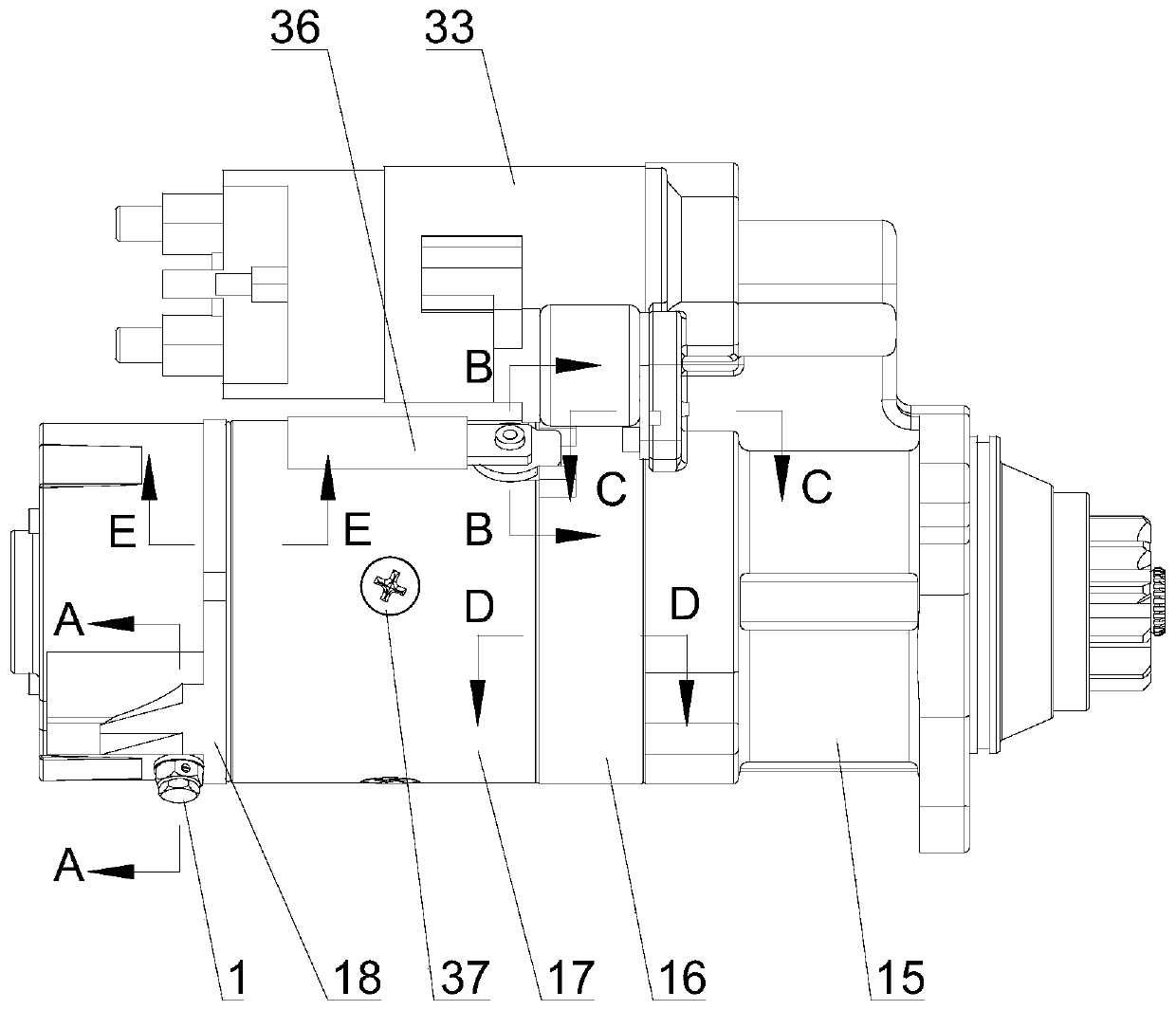

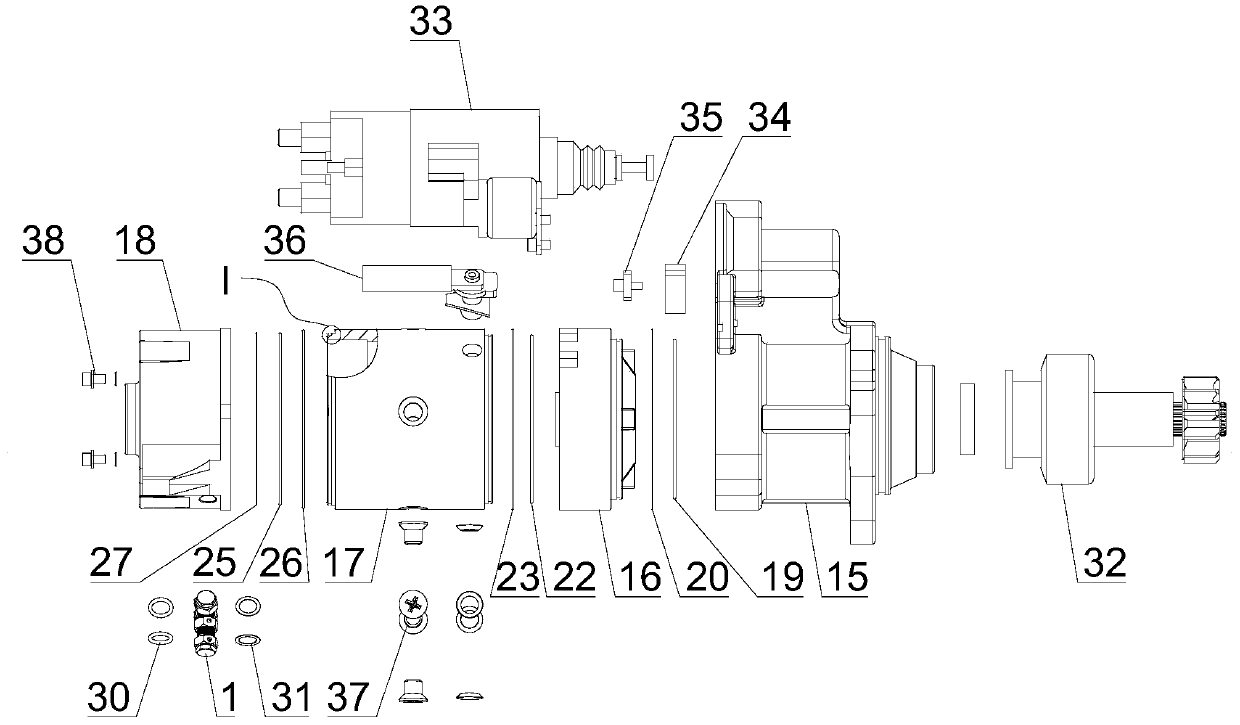

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

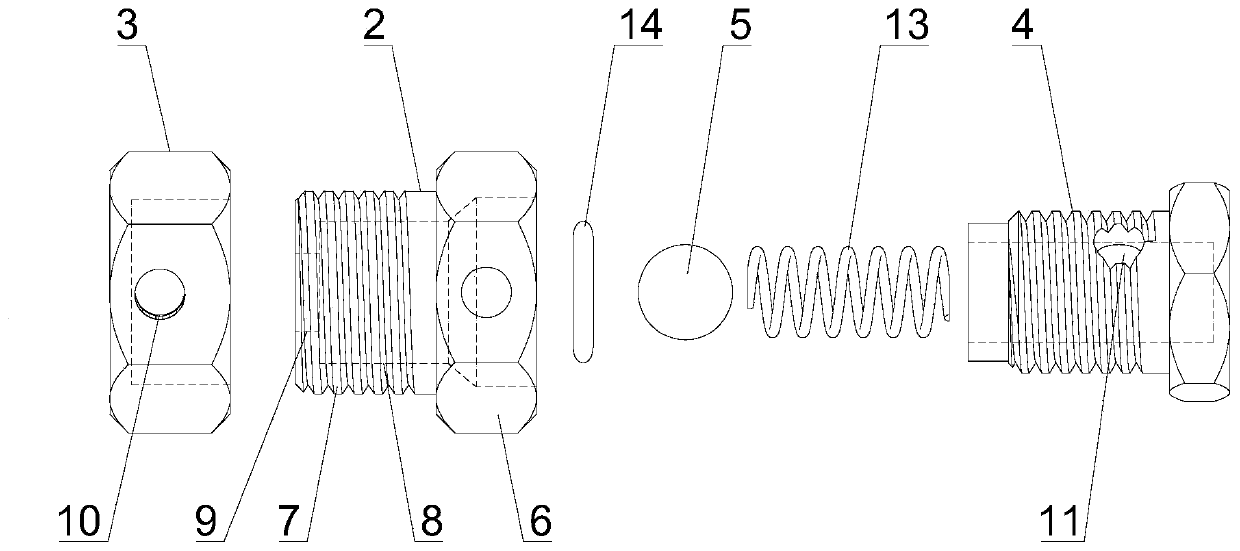

[0034] see Figures 1 to 12 As shown, this embodiment provides a starter anti-immersion structure, the body cavity of the starter is a closed space, and at least two breathing pressure valves 1 are arranged on the body, and the breathing pressure valve 1 is a one-way check structure. , two breathing pressure valves 1 are arranged on the body in the opposite direction of flow, thereby forming a natural inhalation port and an exhaust port.

[0035] During installation, two breathing pressure valves 1 are used in pairs and are installed oppositely. Two mounting ports are provided on the motor body, which can be installed in any suitable position of the motor body to realize the function of automatically adjusting the pressure when exhaling and inhaling.

[0036] The breathing pressure valve 1 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com