Precision evaluation method and service life prediction method for numerically controlled machine tool based on meta-action unit and integrated subjective-objective weight

A technology of CNC machine tools and subjective weights, applied in the field of CNC machine tools, can solve the problems of precision decline, lack of precision life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

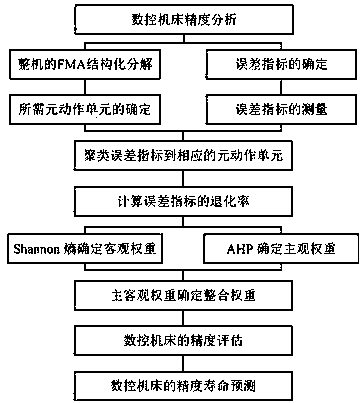

[0078] The present invention is based on a meta-action unit and a method for evaluating the accuracy of CNC machine tools integrating subjective and objective weights. For the process, see figure 1 , as can be seen from the figure, it includes the following steps:

[0079] Step 1) FMA decomposition of the CNC machine tool

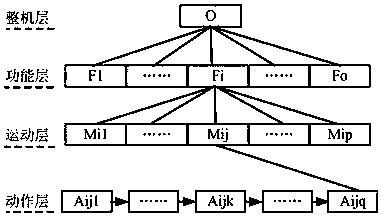

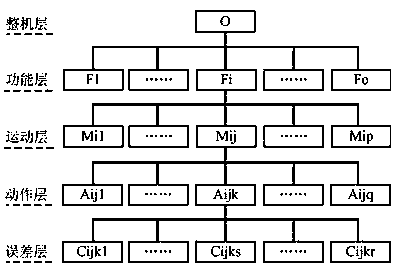

[0080] Use the structured decomposition method of function-motion-action to decompose the CNC machine tool layer by layer, and finally decompose the CNC machine tool to obtain several meta-action units. The meta-action units only include two types of the most basic motion units, namely the mobile unit and rotation unit; the meta-action unit is the meta-action unit only related to the error index; all the meta-action units constitute the action layer of the CNC machine tool;

[0081] Step 2) Clustering of Error Indicators

[0082] Measure the error index of the CNC machine tool in the stop state, and cluster the error index into the corresponding meta-acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com