Light reflecting component and laser marking module

A reflective element and laser marking technology, which is applied to reflective reflectors, active optical measuring devices, measuring devices, etc., can solve the problems of inconvenient carrying by construction workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

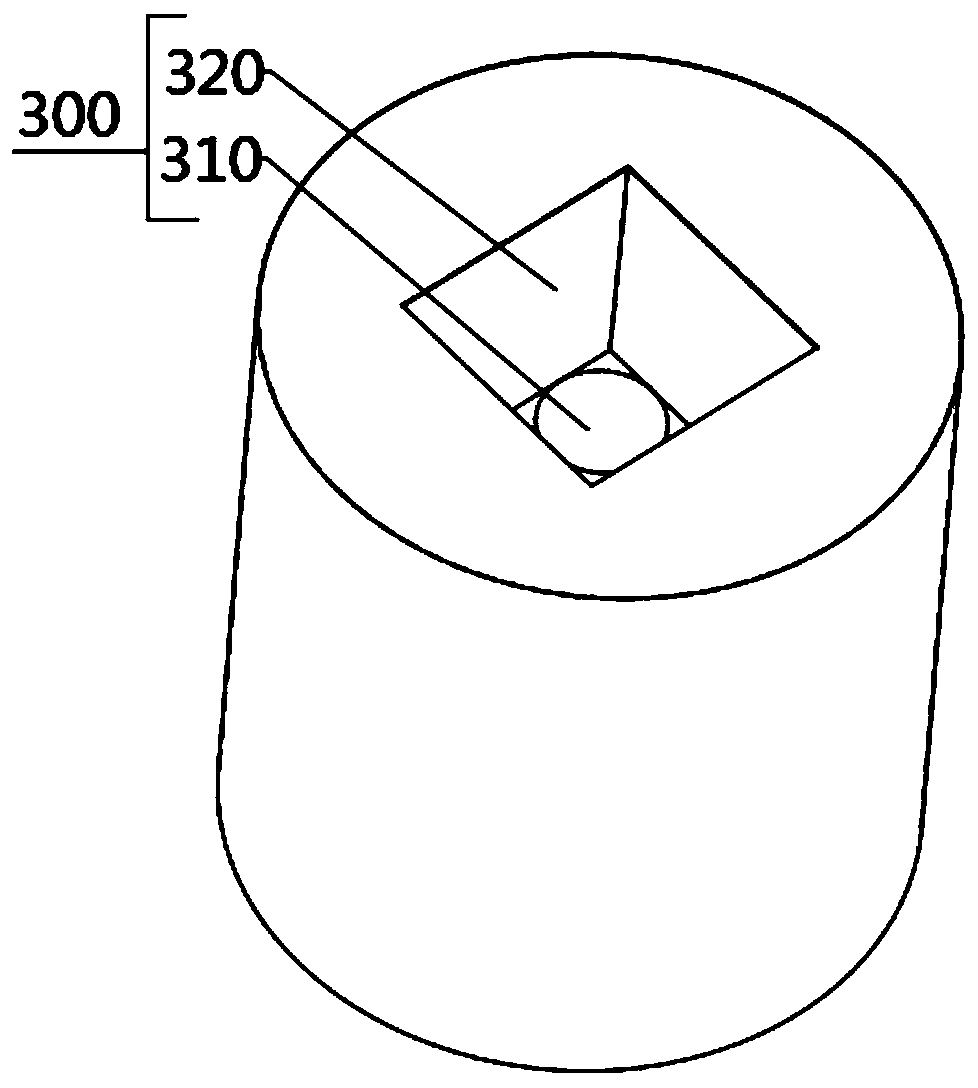

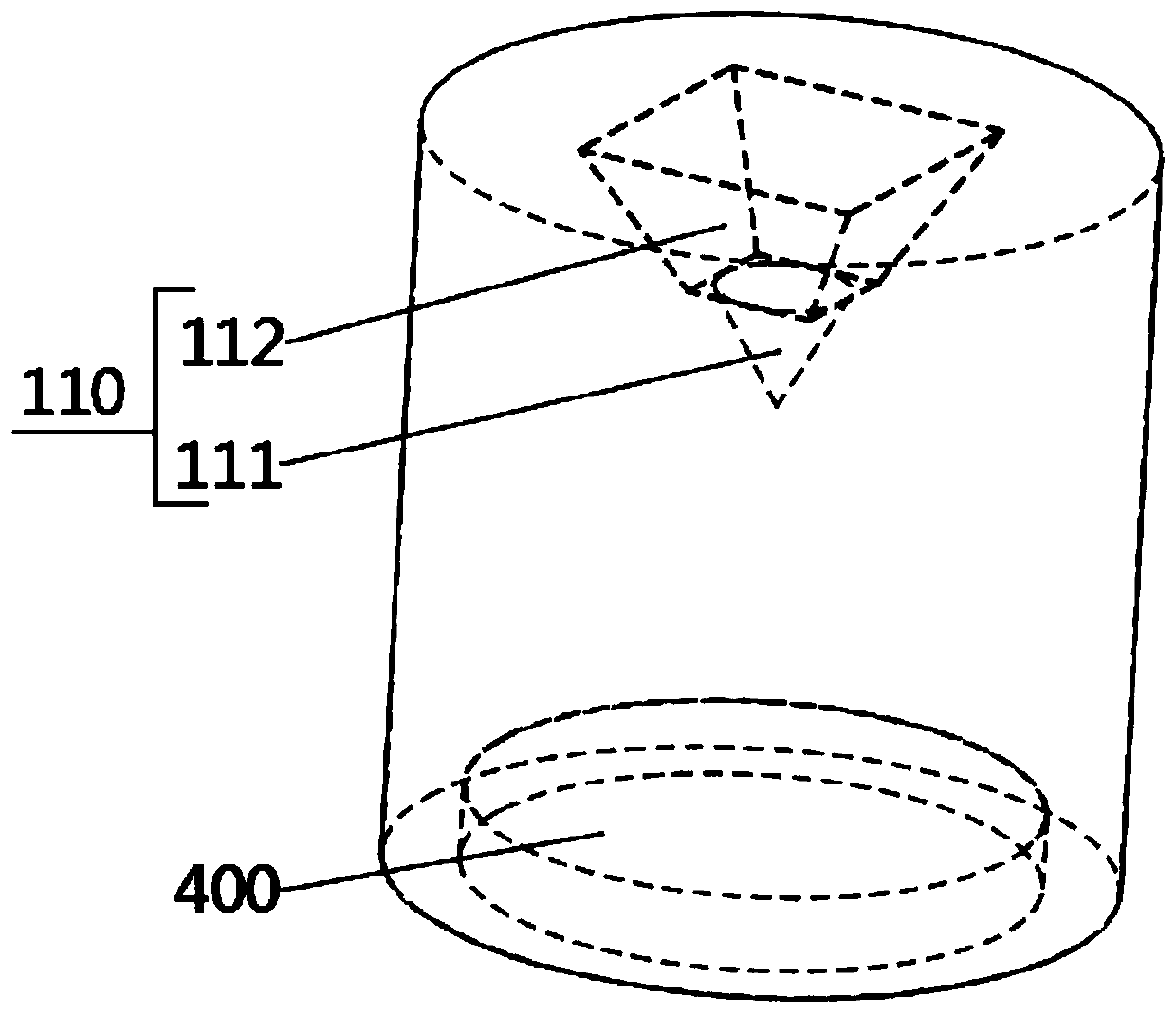

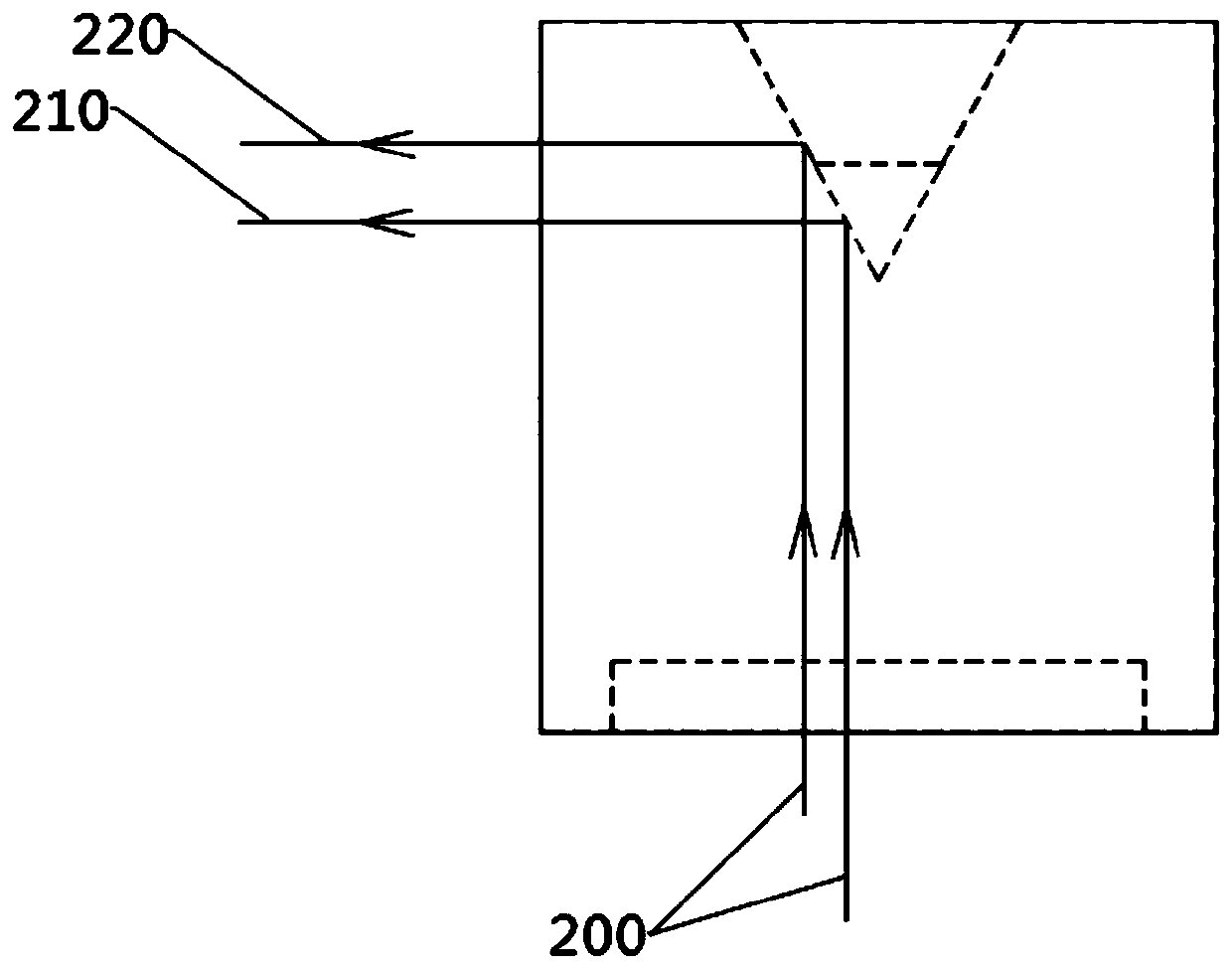

[0034] like Figure 1-Figure 4 As shown, the embodiment of the present invention provides a reflective element 100, the reflective element 100 includes a reflective part 110, when the incident light 200 is irradiated on the reflective part 110, the reflective part 110 can reflect the incident light 200 in the circumferential direction . The reflection part 110 includes a reflection cone surface 111 and a reflection plane 112, the reflection cone surface 111 and the reflection plane 112 are sequentially arranged along the axis direction of the reflection cone surface 111, when the incident light 200 is along the reflection cone surface 111 When the axis direction is incident, and part of the reflected light can be irradiated on the reflective cone surface 111, the reflective cone surface 111 can form a ring-shaped linear light 210 in the circumferential direction of the reflective element 100, and the linear light 210 projects A straight line is formed on the wall; part of the...

Embodiment 2

[0045] like Figure 5 and Image 6 As shown, the difference from Embodiment 1 lies in the shape of the reflective element 100, the reflective part 110 is formed by a protruding structure, the reflective element 100 includes a conical structure 500, and the conical structure 500 includes a cone tip and a bottom Side, the outer wall of the cone is provided with a third recess 510, the bottom surface of the third recess 510 is a plane; there is a distance between the third recess 510 and the tip of the cone, and the bottom surface of the third recess 510 forms the The reflection plane 112 , the conical surface between the third concave portion 510 and the cone tip forms the reflection cone surface 111 . That is to say, when the incident light 200 irradiates on the reflective element 100 , it first contacts the reflective tapered surface 111 of the tapered tip, and then contacts the reflective plane 112 formed by the bottom surface of the third recess 510 above it. When the prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com