Image forming device

A technology in images and devices, applied in the field of detection accuracy of torque values, to achieve the effect of preventing torque fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the image forming apparatus according to the present invention will be described with reference to the drawings.

[0049] [1] Structure of image forming apparatus

[0050] First, the configuration of the image forming apparatus according to the present embodiment will be described.

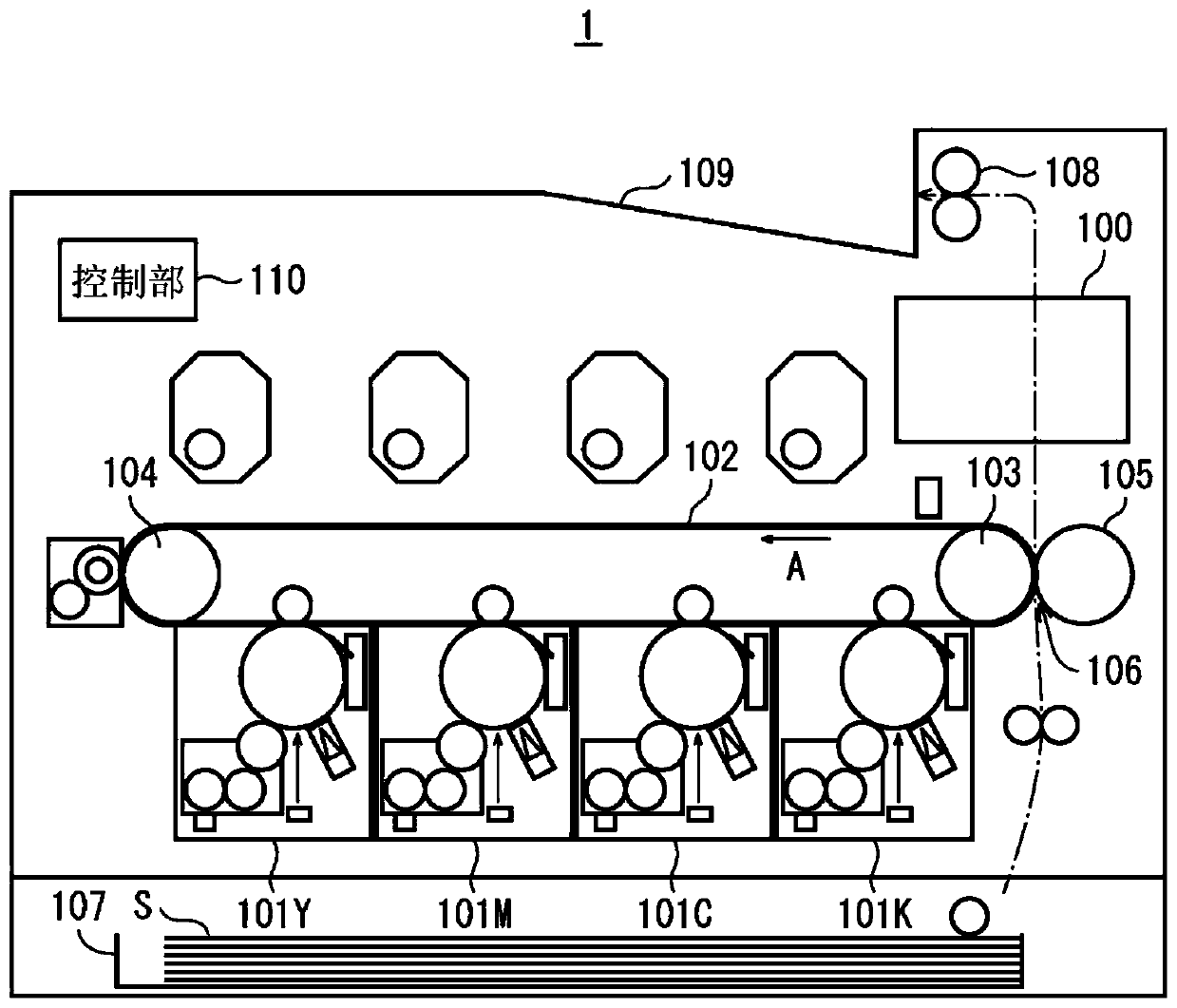

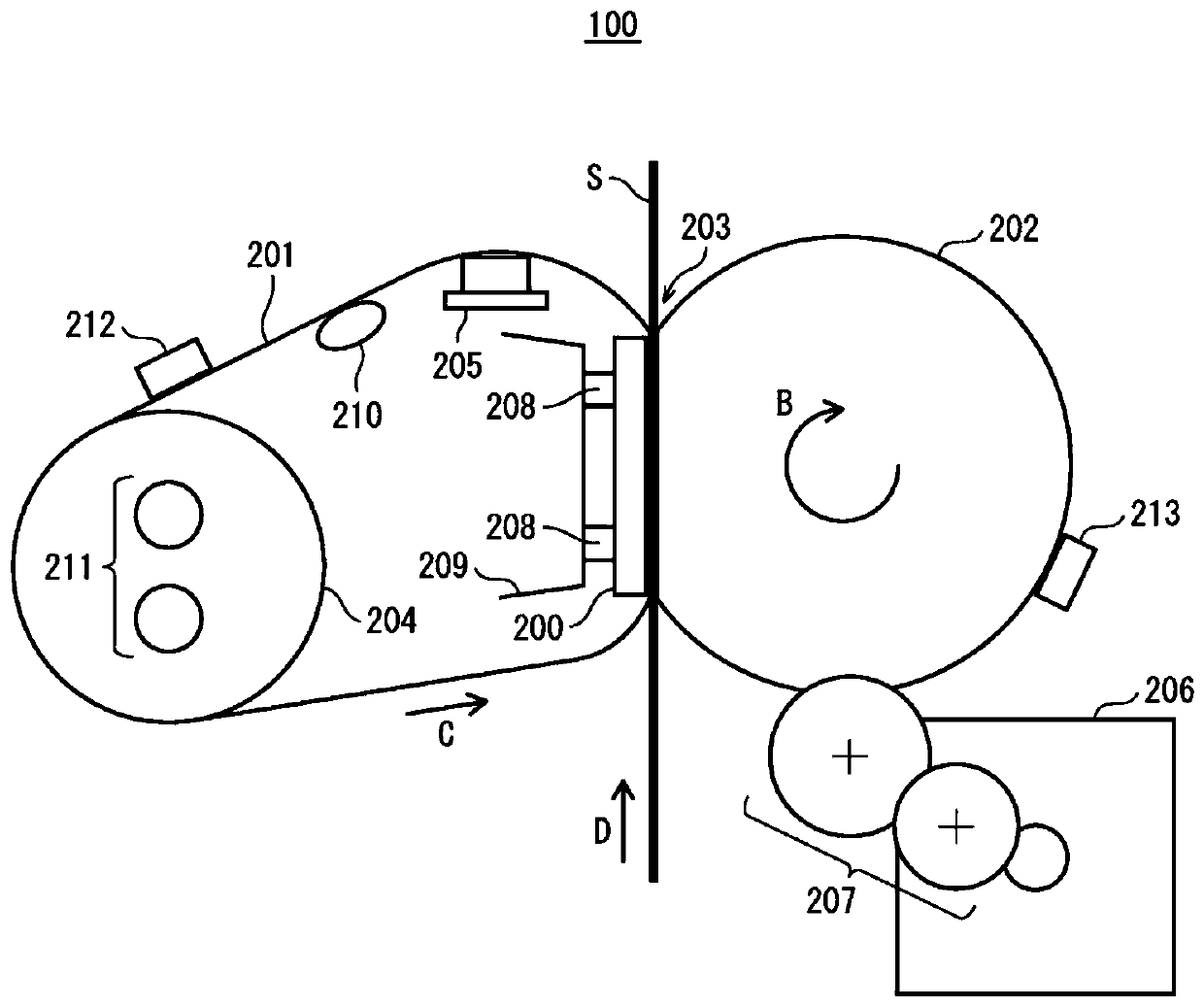

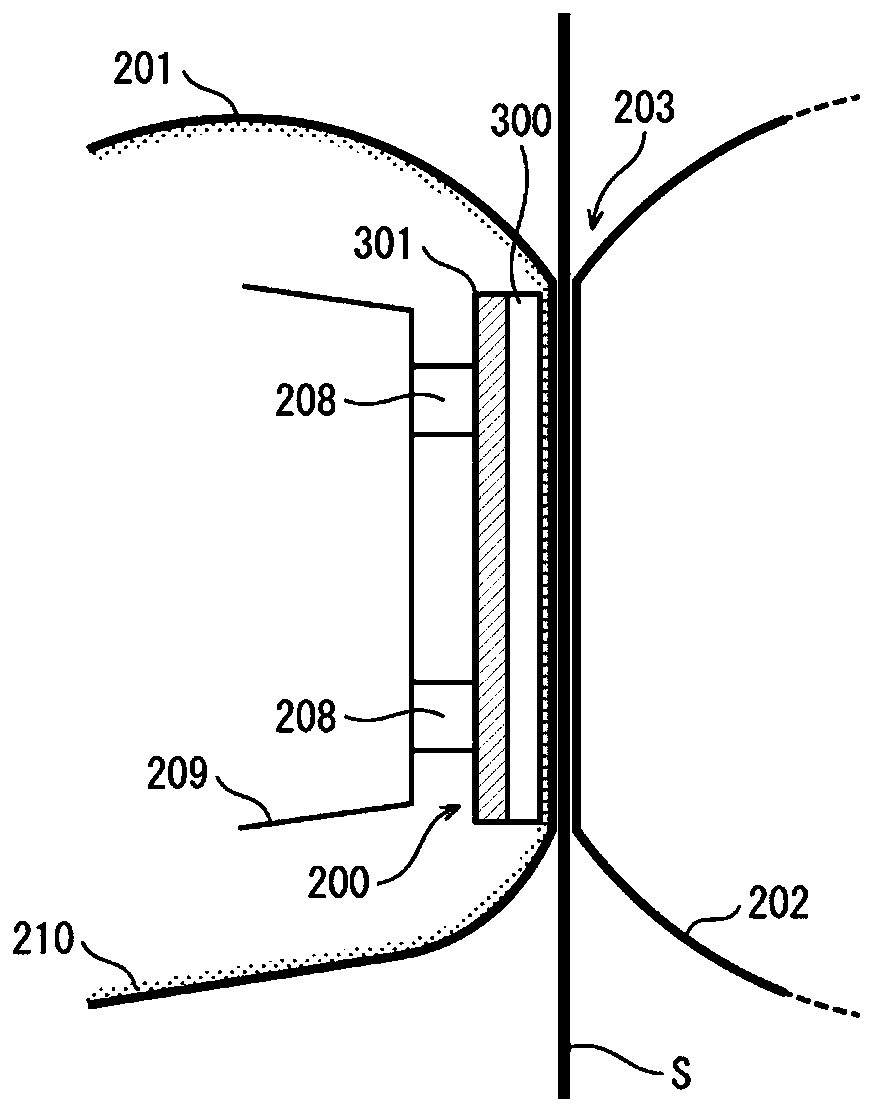

[0051] like figure 1 As shown, the image forming apparatus 1 is a so-called tandem color printer, and uses image forming units 101Y, 101M, 101C, and 101K to form toner images of YMCK colors. The formed toner images are sequentially electrostatically transferred onto the outer peripheral surface of the intermediate transfer belt 102 so as to overlap each other, thereby forming color toner images. The intermediate transfer belt 102 is an endless belt, and travels rotationally in the direction of arrow A in a state where the driven roller 103 and the driven roller 104 are spanned.

[0052] The intermediate transfer belt 102 is sandwiched between the secondary tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com