Wheel suspension

A wheel suspension and wheel technology, applied in suspension, elastic suspension, vehicle components, etc., can solve the problems of not being able to make full use of parking space optimally, obstructing traffic, etc., and achieve multi-degree of design freedom and space-saving layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

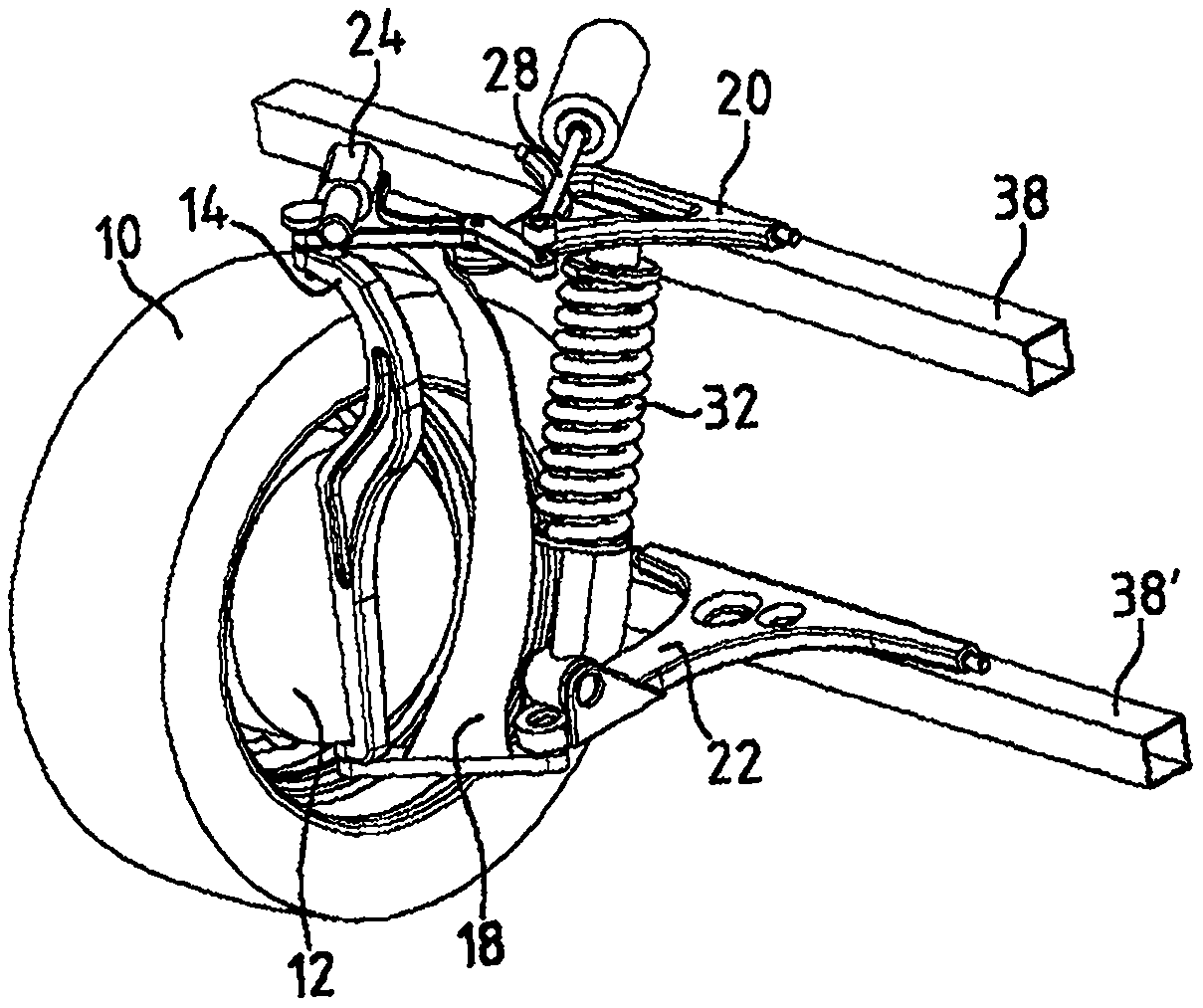

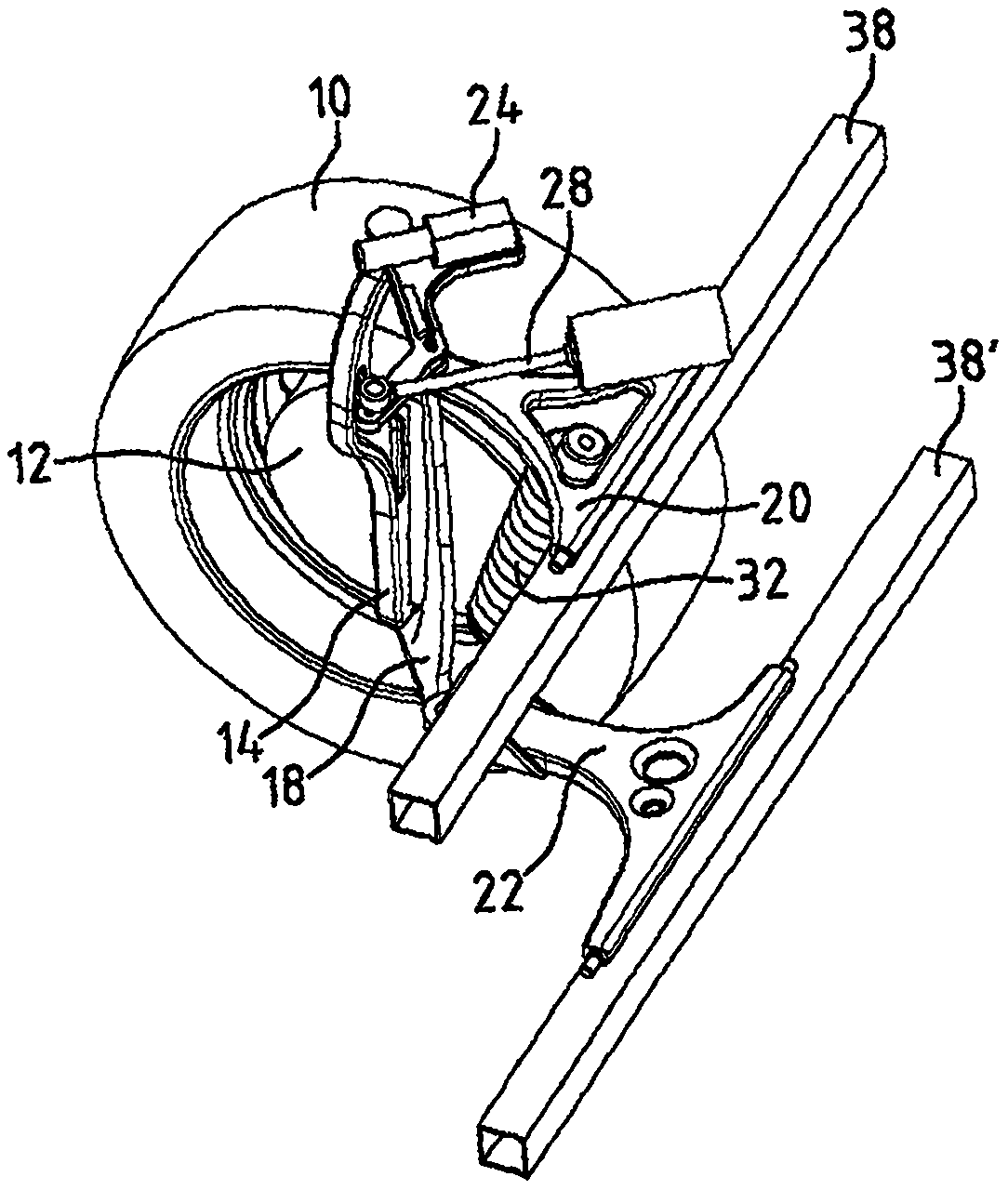

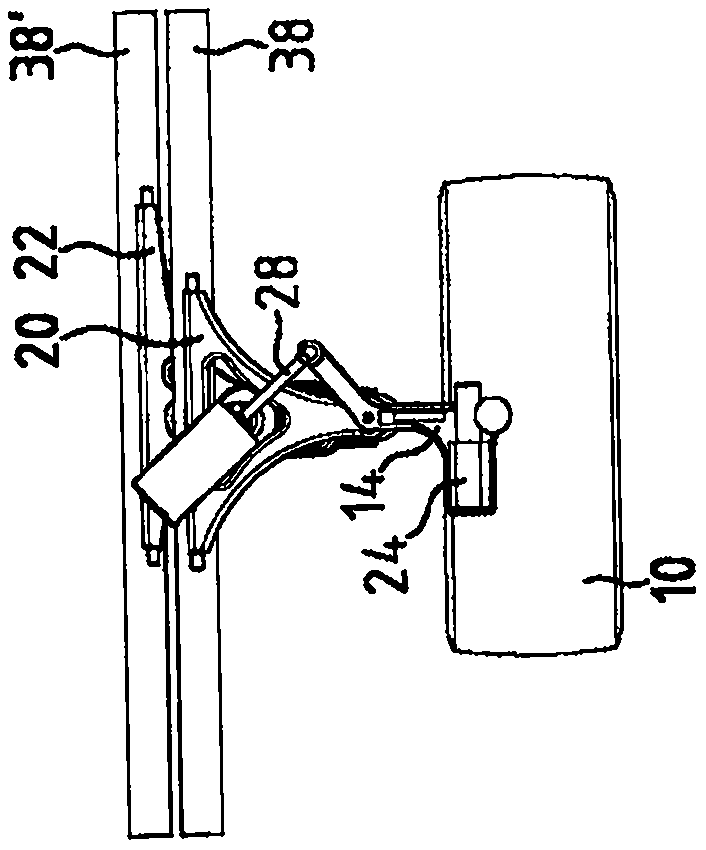

[0042] exist figure 1 and 2 The wheel suspension shown in basically comprises: a wheel 10 with a wheel carrier 12 configured as a hub motor; a steering knuckle 14 with a first steering axis 16 and carrying the wheel ( Figure 6 ); the bracket 18 for the steering knuckle 16; the upper triangular transverse link 20; the lower triangular transverse link 22; the actuator 24 arranged on the steering knuckle 16 for making the wheel 10 around the first steering Axis 16 is steered, tapered roller bearings 26, 26' arranged above and below between knuckle 16 and bracket 18; connecting rod 28 for turning bracket 18 around second steering axis 30 ( Figure 6); a spring damper unit 32; a locking mechanism 34 for locking the second steering axis 30 during driving operation; , 36'( Figure 6 ). The vehicle chassis is symbolically represented by cross braces 38, 38' to which upper and lower triangular transverse links 20, 22 are pivotally secured. exist figure 1 and 2 In this case, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com