Wet dust filter

A dust filter and wet technology, applied in the field of wet dust filters, can solve the problems of increased dust, high power, and many consumables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

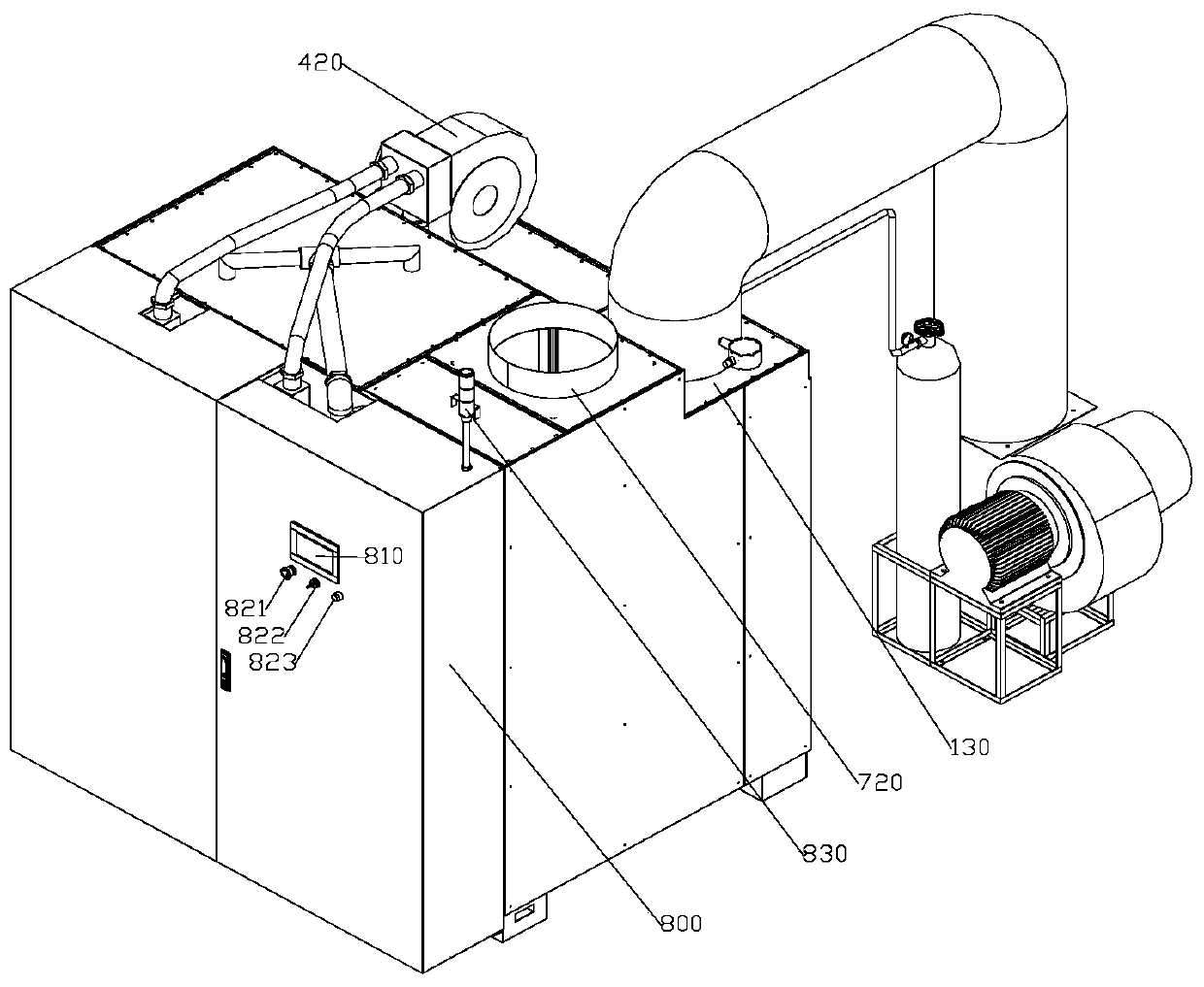

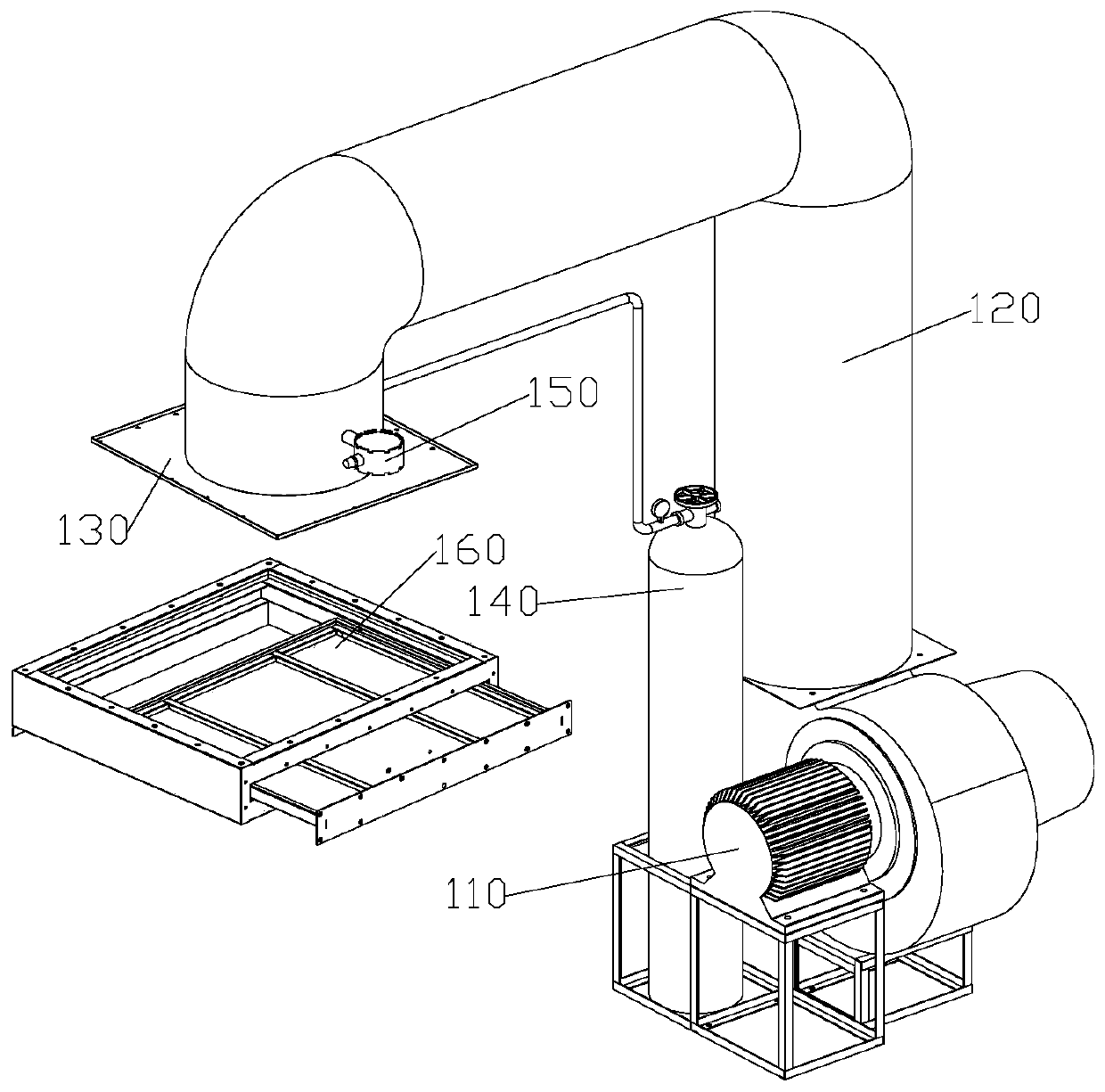

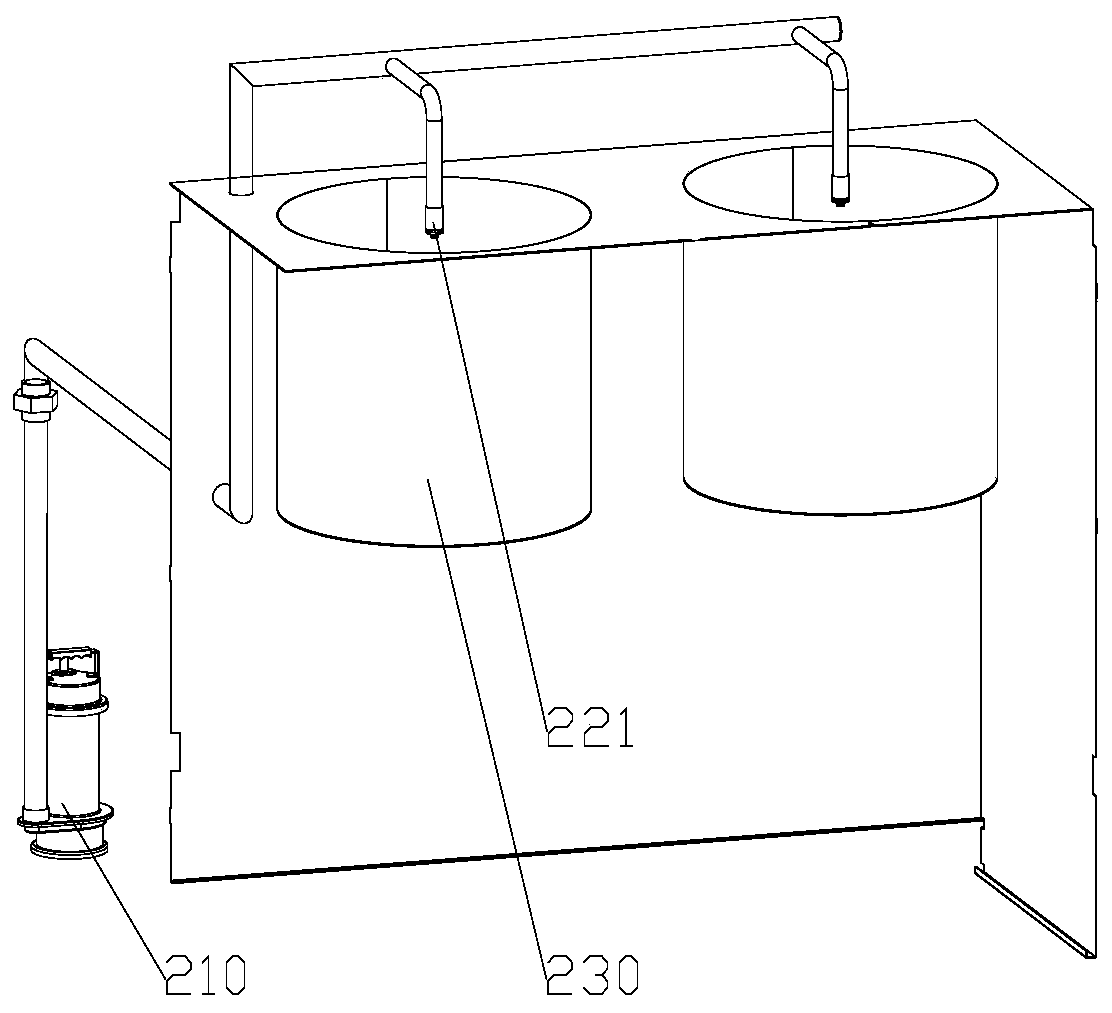

[0024] Such as figure 1 As shown, a wet dust filter includes a main frame and an electrical control module; the main frame is provided with an air inlet 130 and an air outlet 720; it also includes a primary filter module and an explosion-proof module; the main frame also includes a A water spray filter module and an electrostatic dust collection module for removing large particles of dust; a deashing and dehydration module is arranged below the air outlet 720; the water spray filter module is located below the air inlet 130; There is a high-voltage electrostatic field self-cleaning module for cleaning the electrostatic dust collection module; an unpowered dehydration module for reducing the humidity of dirty air is arranged between the water spray filter module and the electrostatic dust collection module; the bottom space of the main frame is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap