Integral steel bar mesh frame, prefabricated plate containing same, and connecting structure of prefabricated plate

A reinforced mesh frame, integrated technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of prefabricated components damage, mesh frame falling apart, no buffer time, etc., to reduce self-weight, improve earthquake resistance, save energy effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0084] Due to the good integrity of the integral steel grid, it can also be used alone. This embodiment mainly introduces an assembled connection structure formed when the steel grid is used alone.

[0085] In the prior art, triangular trusses are used for erecting temporary stages and booths. When erecting, pieces of triangular trusses need to be installed one by one, and multiple trusses are connected and fixed with horizontal brackets to form a whole. The installation process is cumbersome and complicated, and Due to the installation of multiple parts, the spliced stage has poor integrity and is prone to accidents. However, the integrated steel grid frame in the present invention has good integrity and can bear force independently. When it is used to build a temporary stage, as long as a plurality of steel grid frames are directly assembled, and wooden boards are laid on it, a stage with better stress can be formed. .

[0086] Such as Figure 10 As shown, angle steel, c...

Embodiment 3

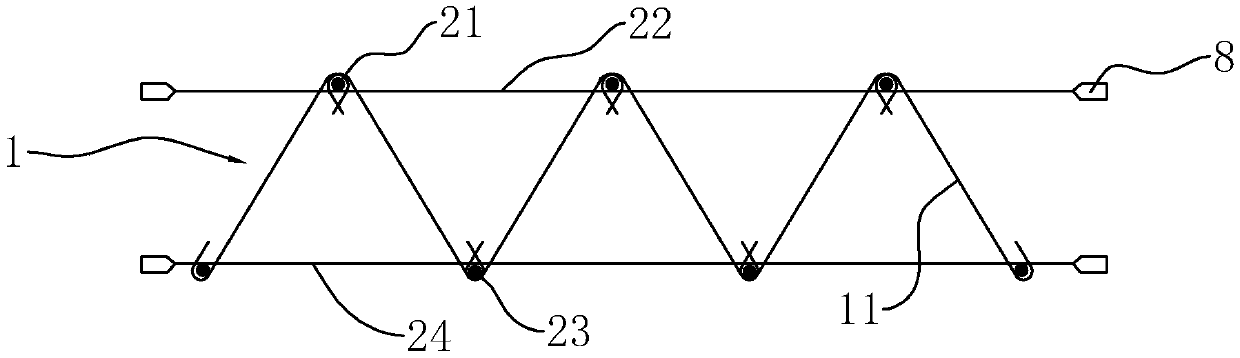

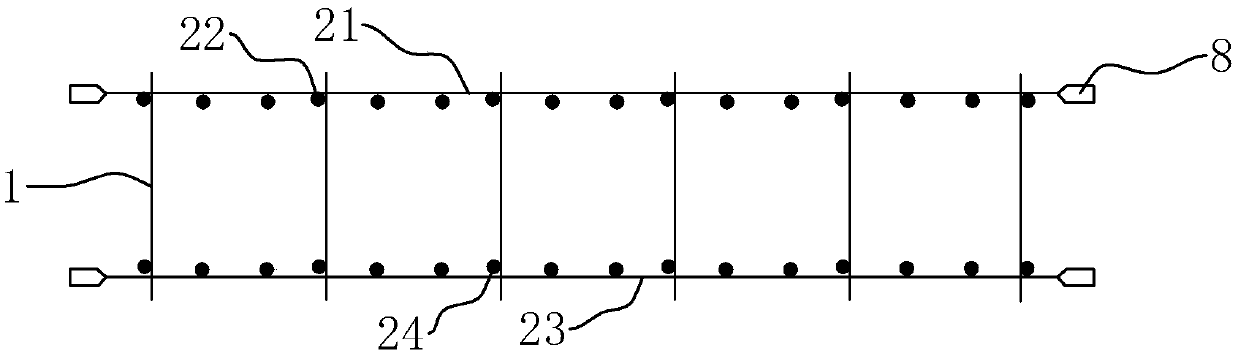

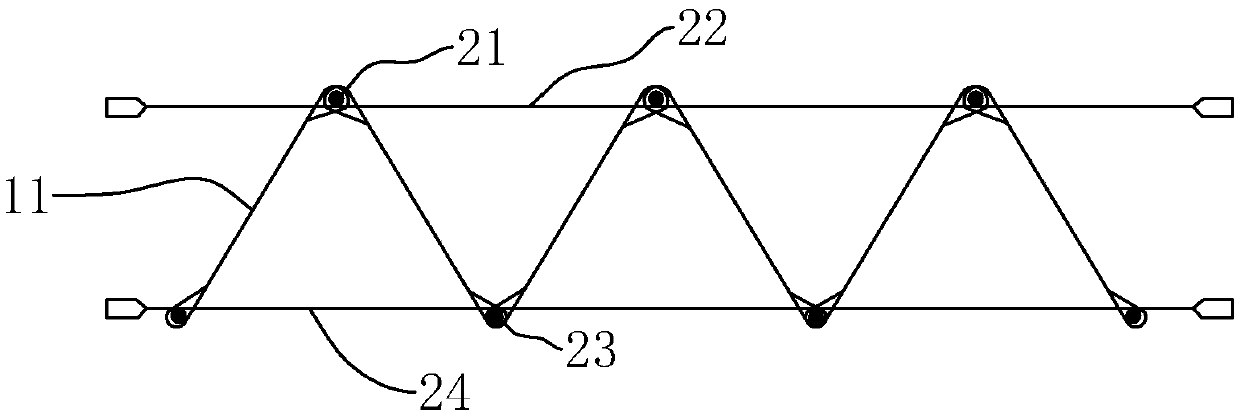

[0089] Such as Figure 12 As shown, the difference from Embodiment 1 is that the triangular support mesh bar 1 is a bent steel bar of a plurality of triangular structures formed by bending a steel bar, and a plurality of triangular vertices of the bent steel bar expose the upper longitudinal direction outwards. The ribs 22 and the lower longitudinal ribs 24 make the bending steel bars intersect with the upper longitudinal ribs 22 and the lower longitudinal ribs 24 to form a plurality of small triangular cavities 6; The steel bar forms an engagement with the upper layer transverse rib 21 and the lower layer transverse rib 23 . Preferably, if Figure 13 As shown, a plurality of upper-layer transverse ribs 21 and lower-layer transverse ribs 23 are arranged outside the small triangular cavity 6 to make the upper-layer steel mesh and the lower-layer steel mesh dense, on the one hand, the load can be better distributed, on the other hand, when used as When prefabricating the reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com