Coil component

A technology of coil parts and components, applied in the direction of transformer/inductor parts, electrical components, transformer/inductor coils/windings/connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

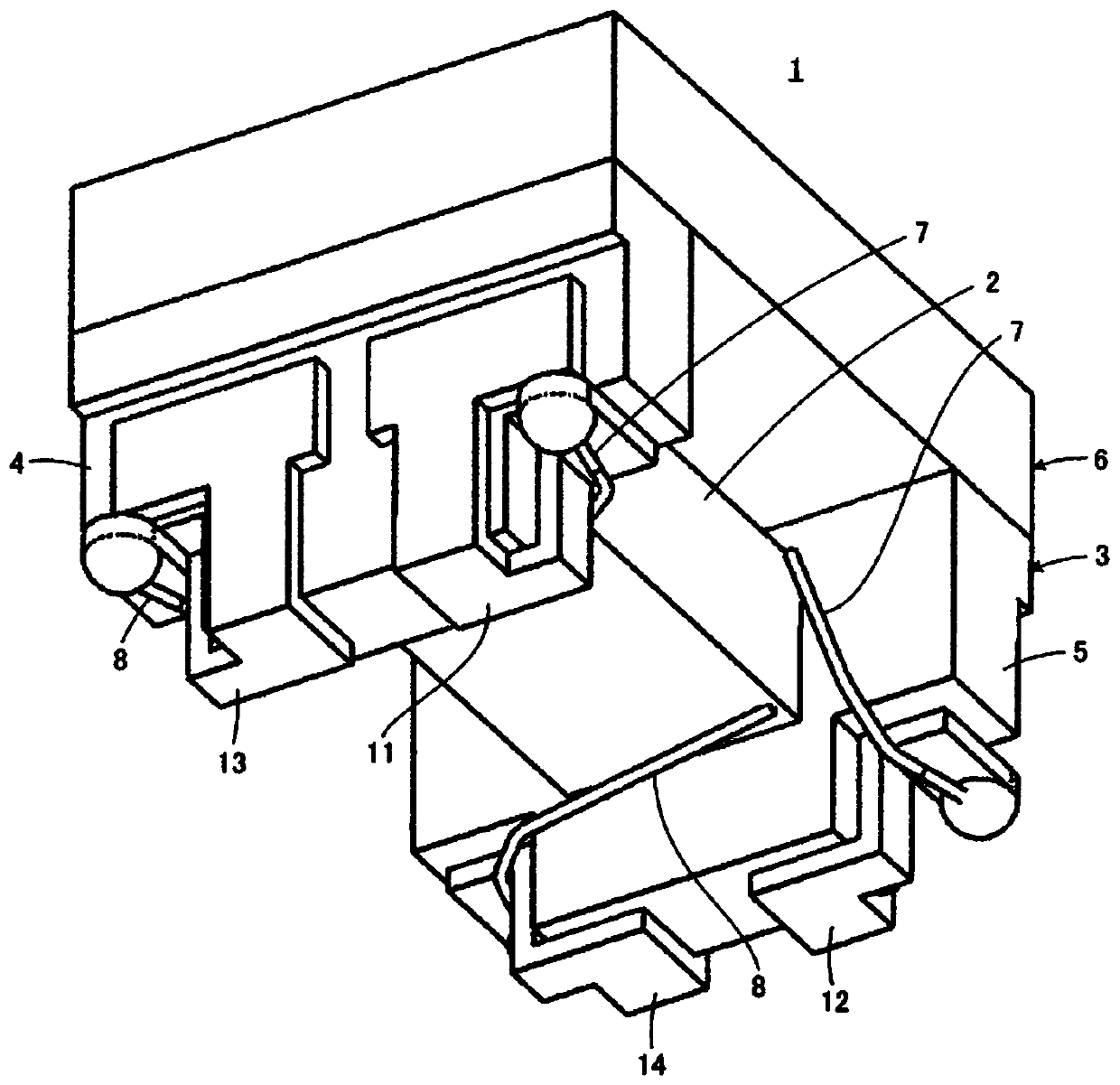

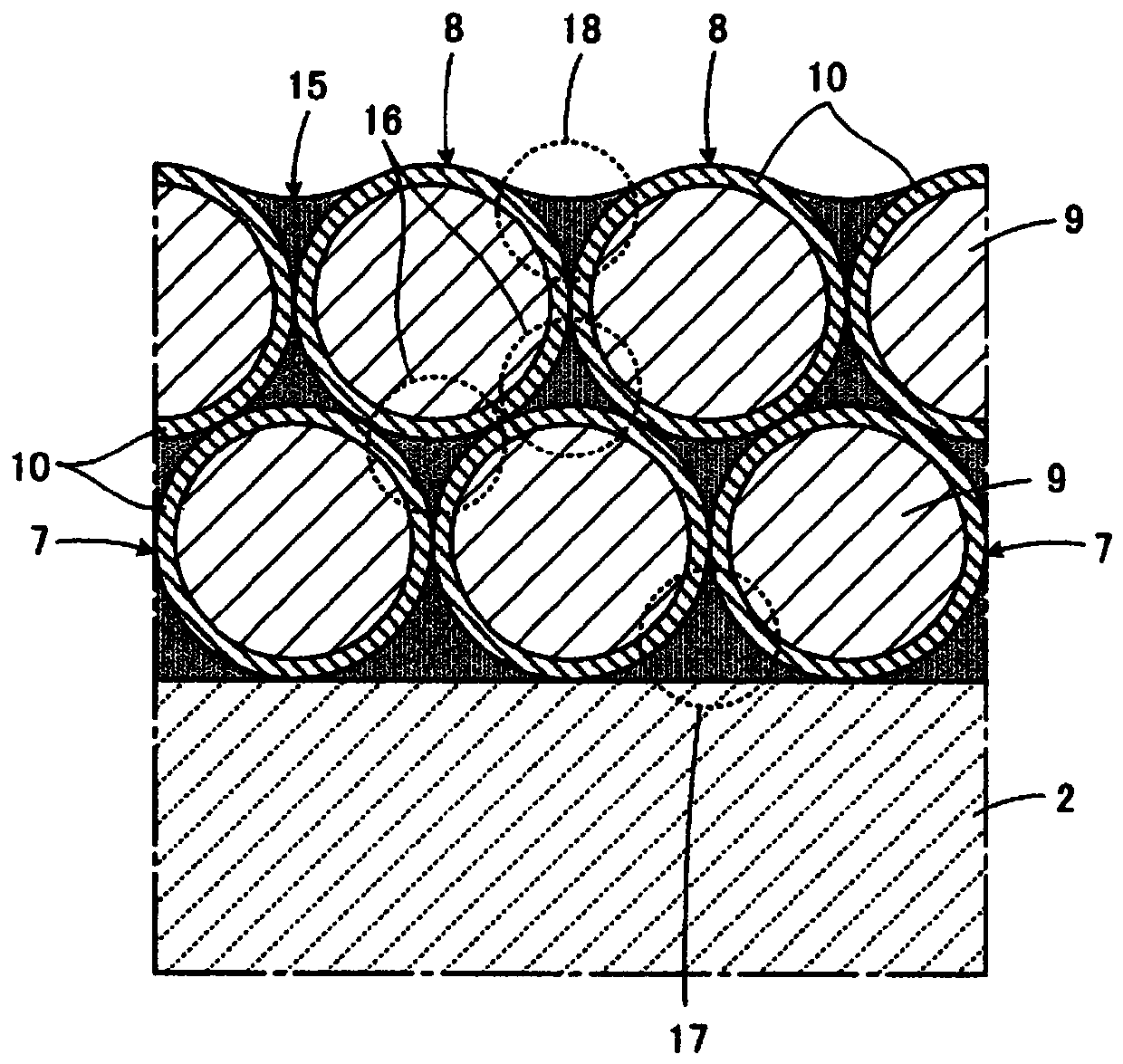

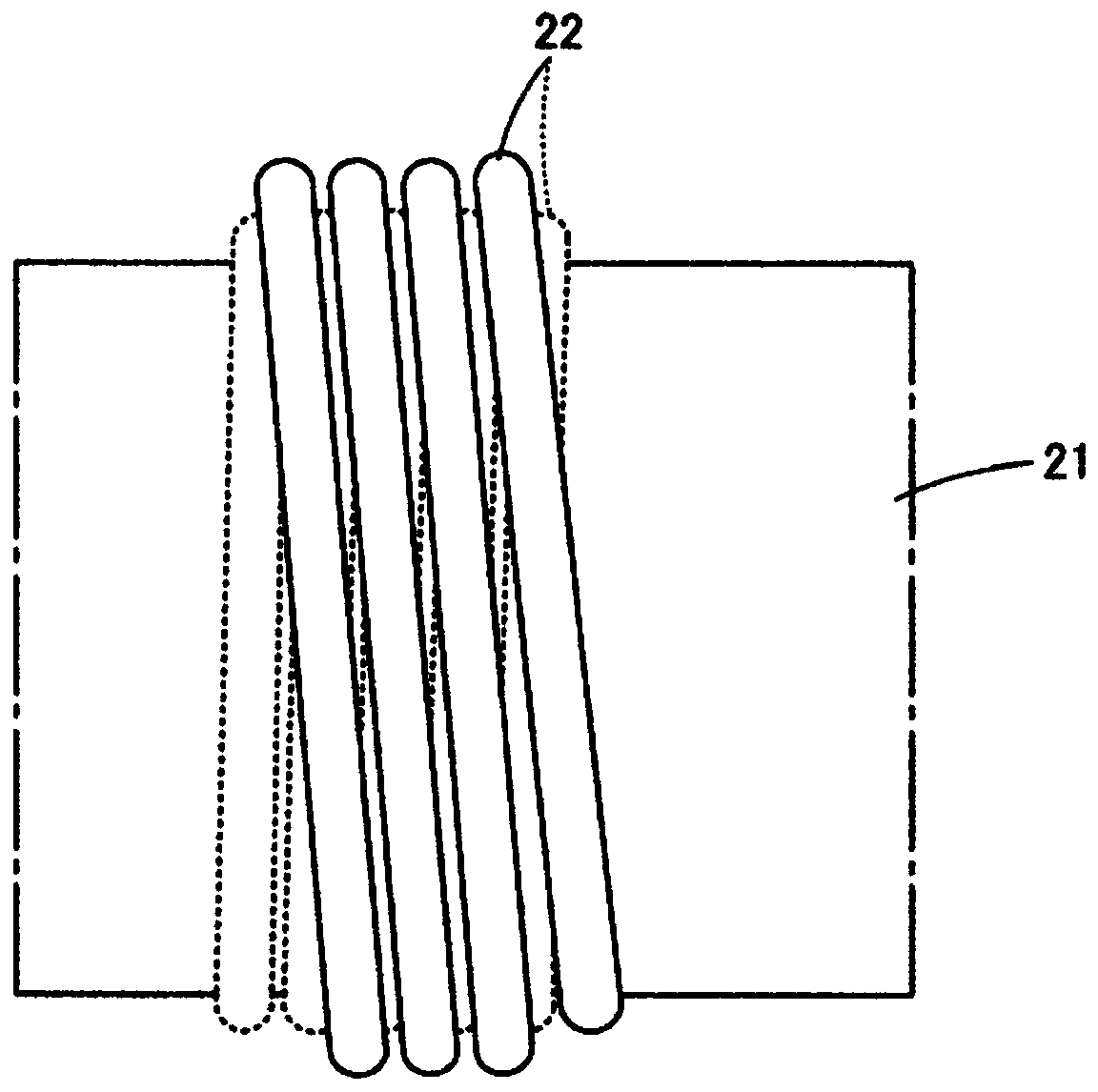

[0028] refer to figure 1 as well as figure 2 , the coil component 1 according to the first embodiment of the present invention will be described. The coil component 1 constitutes, for example, a common mode choke coil.

[0029] The coil component 1 includes a drum-shaped iron core 3 having a winding core portion 2 . The drum core 3 includes first and second flange portions 4 and 5 respectively provided at first and second end portions opposite to each other of the winding core portion 2 . The coil component 1 may further include a plate-like core 6 spanning between the first and second flange portions 4 and 5 . The drum core 3 and the plate core 6 are made of a non-conductive material, for example, a non-magnetic material such as alumina, a magnetic material such as ferrite, or resin.

[0030] The aforementioned plate-like core 6 is bonded to the first and second flange portions 4 and 5 with an adhesive. Curable resins such as epoxy resins can be used as the binder. Her...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com