Anti-shaking device and crane

A crane and anti-sway technology, which is applied in the field of mechanical equipment, can solve problems such as installation difficulties, affecting maintenance operation space, and maintenance difficulties, and achieve stable and reliable working processes and good anti-sway effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

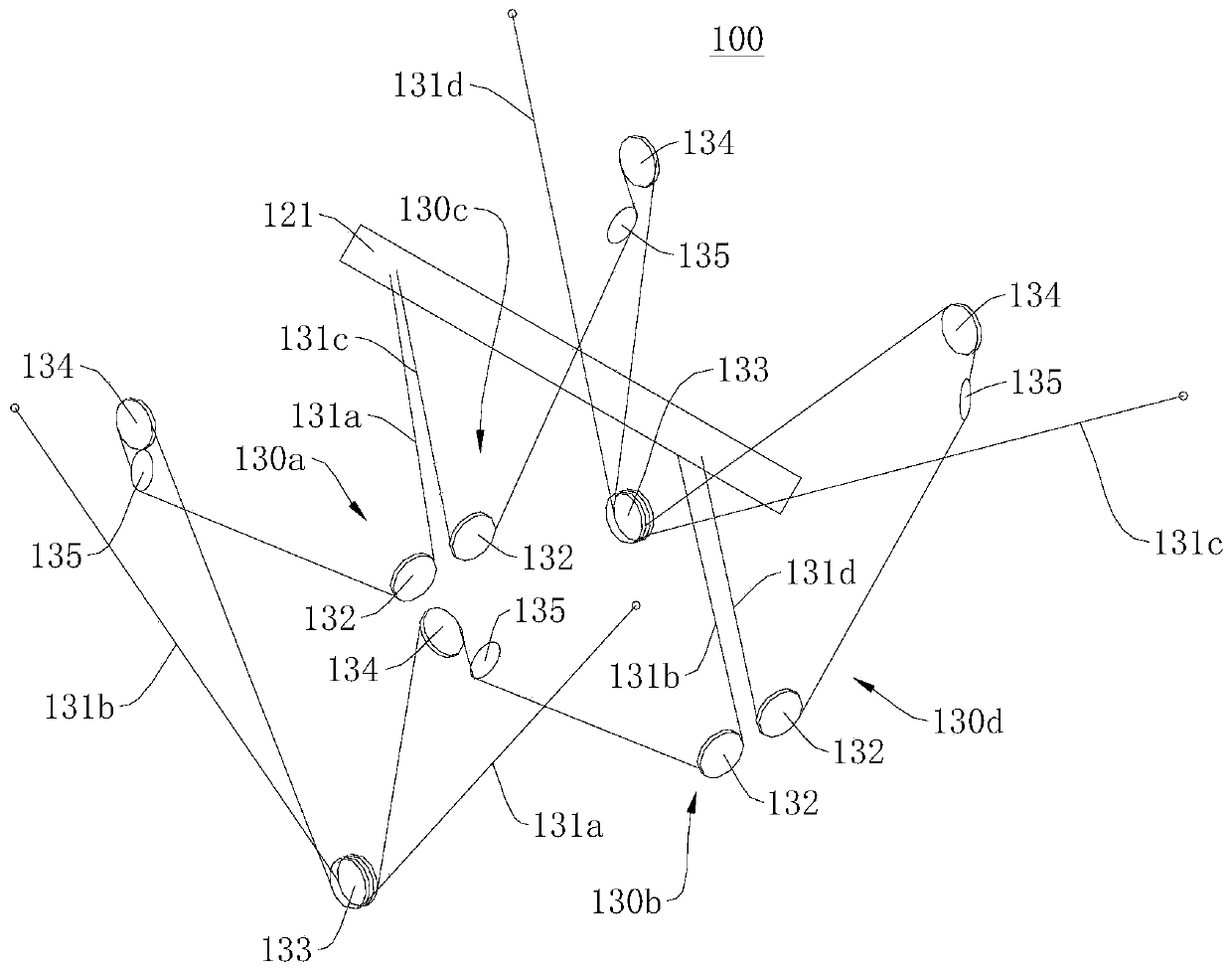

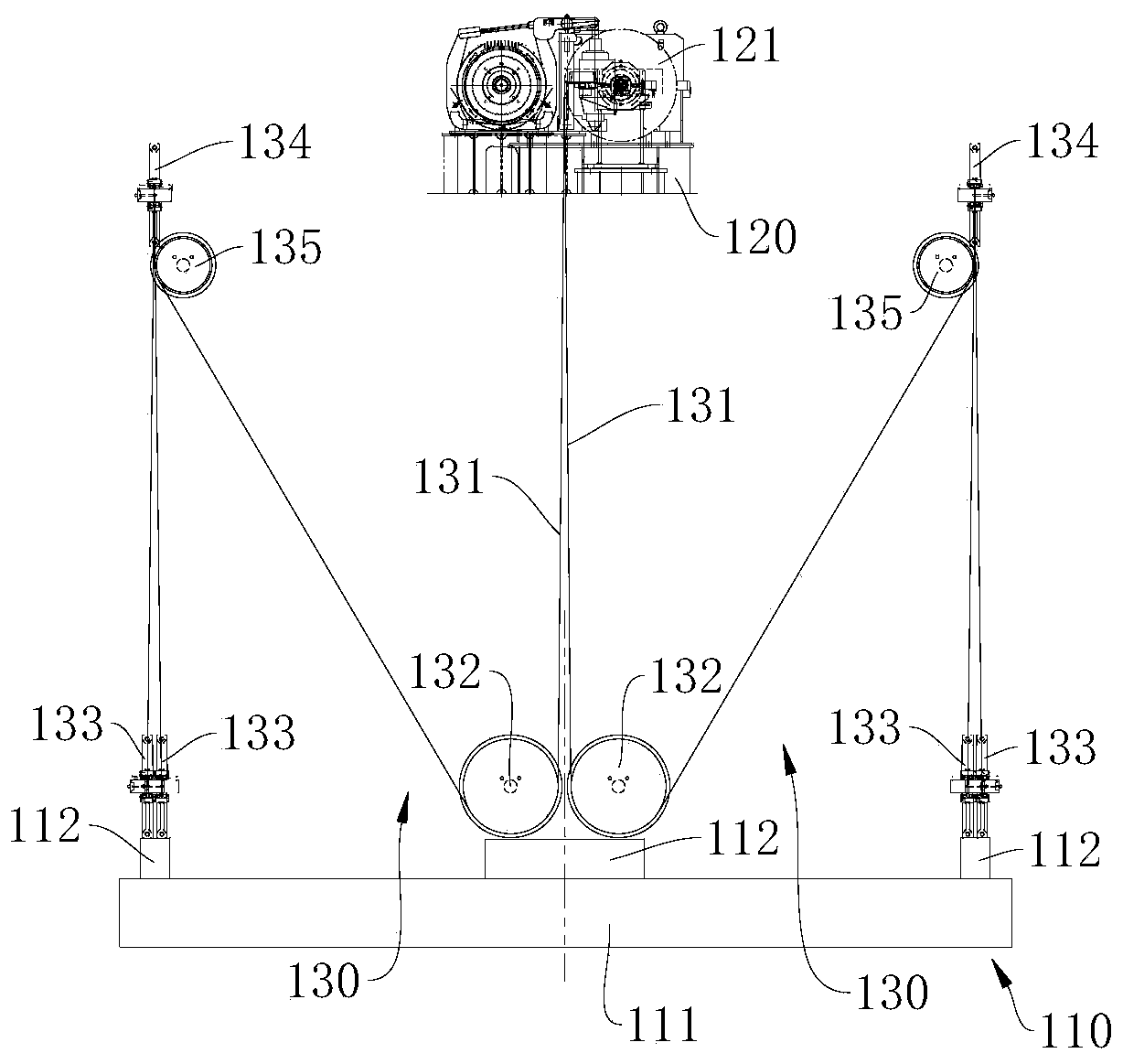

[0045] figure 1 A schematic structural diagram of the anti-sway device 100 provided in this embodiment. Please refer to figure 1 , the present embodiment provides an anti-sway device 100 , which includes a spreader 110 , a frame 120 , a reel 121 and an anti-sway assembly 130 , and the reel 121 is arranged on the frame 120 . The anti-sway assembly 130 includes a wire rope 131 , a first pulley 132 , a second pulley 133 and a third pulley 134 . Both the first pulley 132 and the second pulley 133 are arranged on the spreader 110 , and the third pulley 134 is arranged on the frame 120 . The two ends of wire rope 131 are respectively connected on frame 120 and reel 121, and wire rope 131 passes through first pulley 132, the 3rd pulley 134 and the second pulley 133 successively and winds up, thereby in the first pulley 132 and the 3rd pulley The plane where 134 is located and the plane where the third pulley 134 and the second pulley 133 are located all form an inverted triangle, ...

Embodiment 2

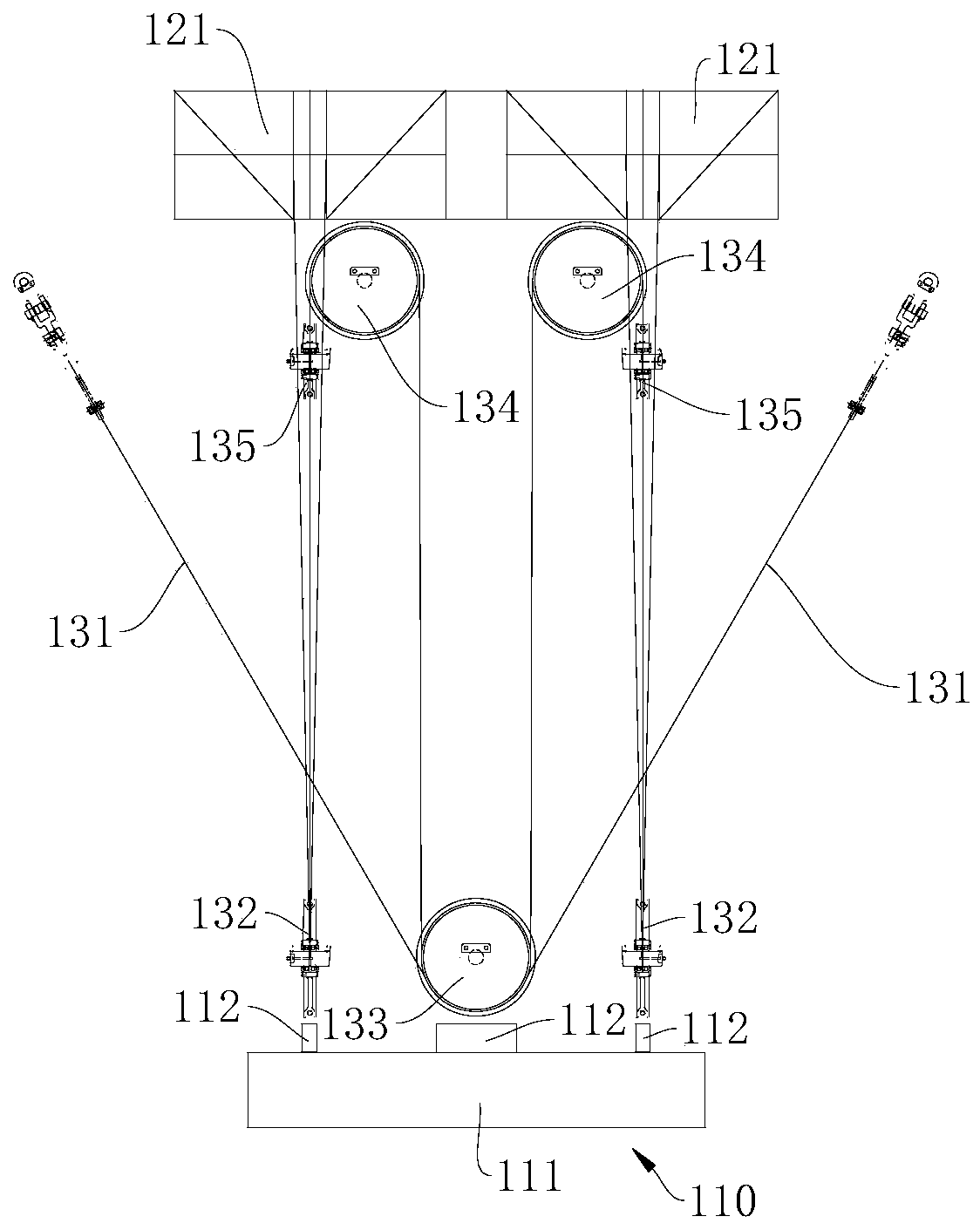

[0060] Figure 5 A schematic structural diagram of the anti-shake device 100 provided in this embodiment at a first viewing angle, Image 6 It is a schematic structural diagram of the anti-shake device 100 provided in this embodiment under a second viewing angle, Figure 7 A schematic diagram of a partial structure of the anti-shake device 100 in a third viewing angle provided in this embodiment. Please refer to Figure 5 to Figure 7, this embodiment also provides an anti-sway device 100, which is basically the same as the anti-sway device 100 provided in Embodiment 1, and the same parts will not be described again, except that the number of reels 121 is different.

[0061] Specifically, in this embodiment, the number of reels 121 is two, and the two reels 121 are arranged in the middle of the spreader body 111 along the width direction of the spreader body 111, and one of the reels 121 is arranged on the first anti- Between the sway assembly 130a and the third anti-sway as...

Embodiment 3

[0063] Figure 8 It is a schematic structural diagram of the anti-shake device 100 provided in this embodiment, Figure 9 A schematic structural diagram of the anti-shake device 100 provided in this embodiment at a first viewing angle, Figure 10 A schematic structural diagram of the anti-shake device 100 provided in this embodiment in a second viewing angle. Please refer to Figure 8 to Figure 10 , this embodiment also provides an anti-sway device 100, which is basically the same as the anti-sway device 100 provided in Embodiment 1, and the same parts will not be described again, except that the number of reels 121 is different.

[0064] Specifically, in this embodiment, the number of reels 121 is the same as the number of wire ropes 131, that is, the number of reels 121 is four, and the four wire ropes 131 are respectively connected to the four reels 121, and the four reels 121 are respectively located on the four corners of the spreader body 111, and the wire rope 131 wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com