A method for connecting brake discs with split wheels

A connection method and brake disc technology, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of axle box bearing damage, increased manpower and material costs, and long cycle times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

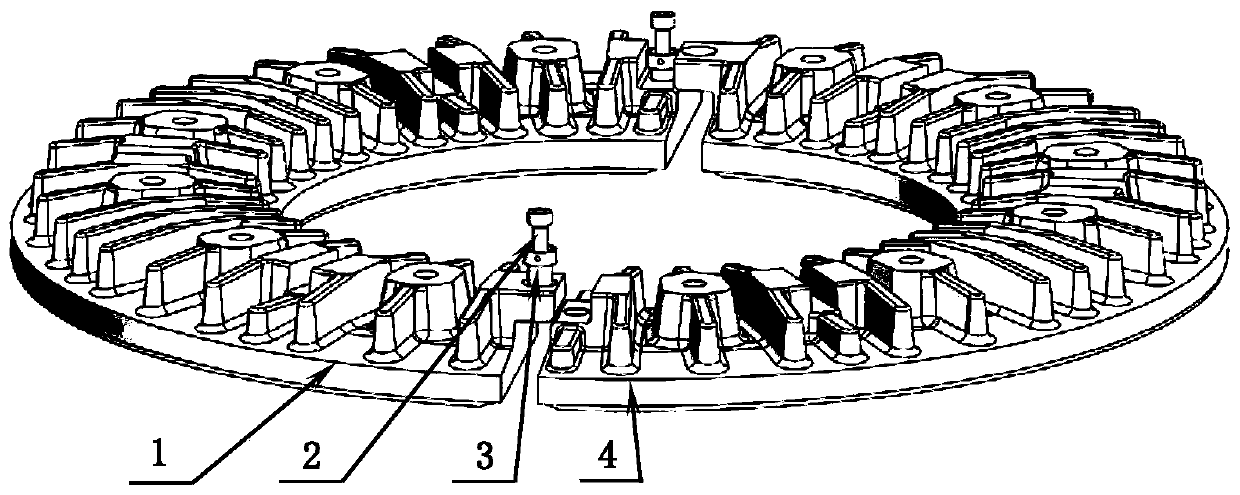

[0022] A method for connecting brake discs with split wheels, including disc body A 1 and disc body B 4, positioning sleeves and hexagon socket screws 2, disc body A 1 and disc body B 4 have exactly the same structure, and disc body A 1 and the back side of the plate body B 4 adopt strip-shaped heat dissipation ribs, such as figure 1 shown.

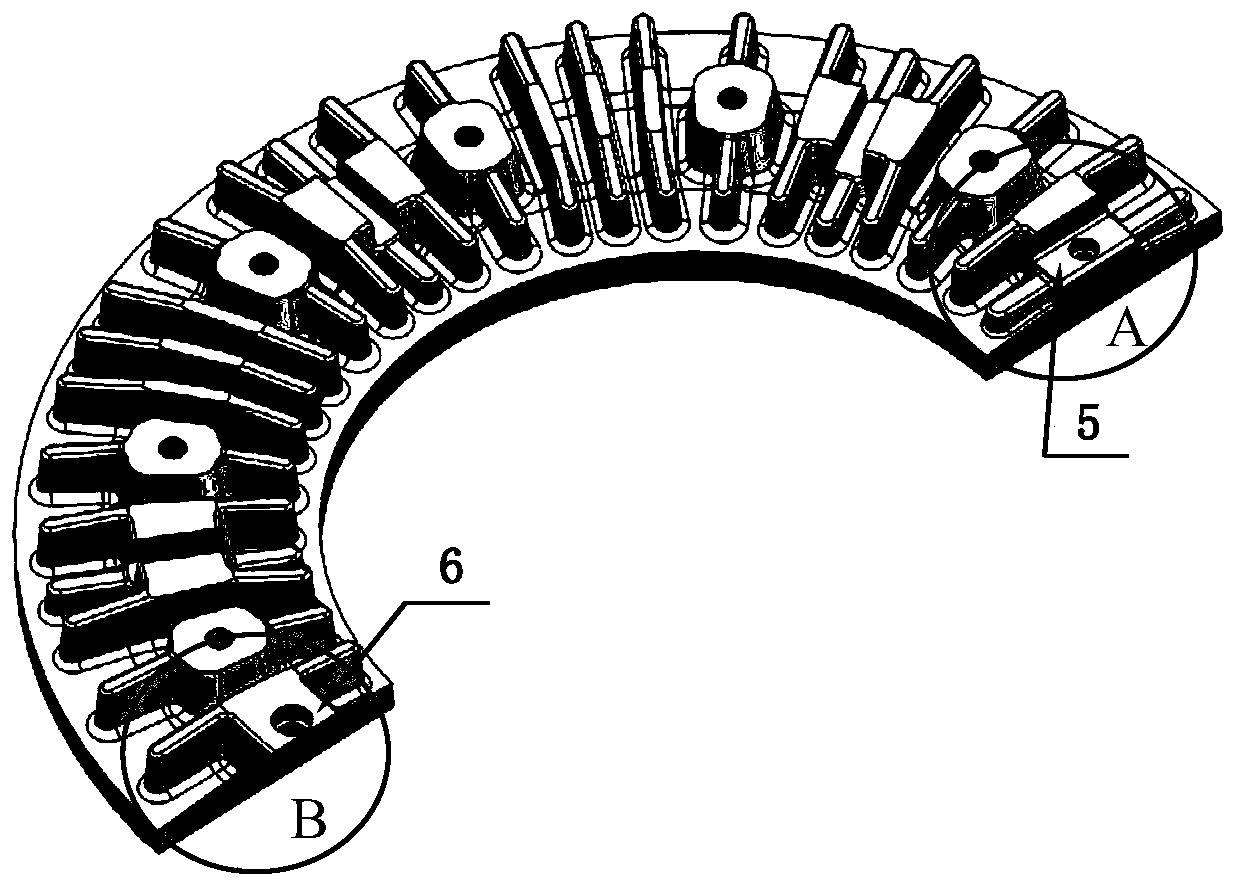

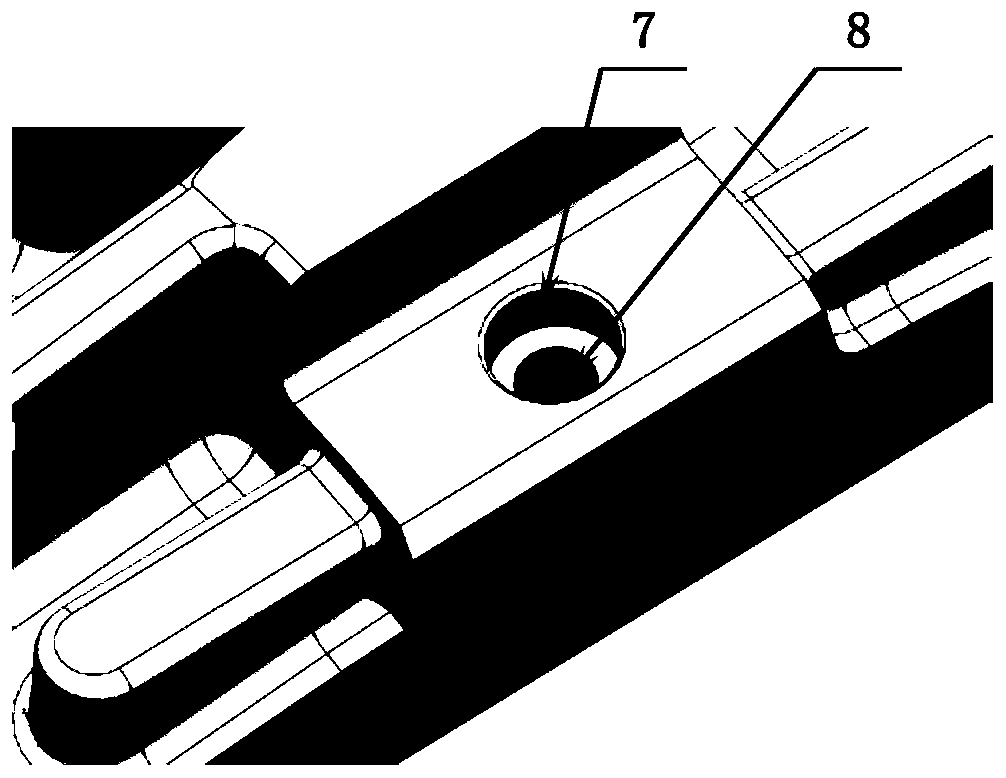

[0023] Grooves 5 and flanges 6 are respectively arranged at both ends of the disc body A 1 and the disc body B 4, positioning holes A 7 and threaded holes 8 are provided on the grooves 5, counterbores 10 and positioning holes B 9 are provided on the flanges, like figure 2 , image 3 , Figure 4 , Figure 5 shown.

[0024] The positioning sleeve 3 passes through the flange 6 and the groove 5 accordingly to realize the radial and circumferential positioning of the disc body A1 and the disc body B4, as figure 1 As shown, the inner hexagon screw 2 is tightened through the positioning sleeve 3 and the threaded hole 8 to realize the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com