A transmission rod joint

A transmission rod and transmission shaft technology, applied in the field of transmission rod joints, can solve the problems of weakening the flexibility and adaptability of mechanical equipment, the limitation of mechanical work fields, and the inability to increase or decrease the length of transmission rods, etc., so as to achieve easy processing, manufacturing and disassembly Effects of maintenance, increased flexibility and adaptability, good assembly interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

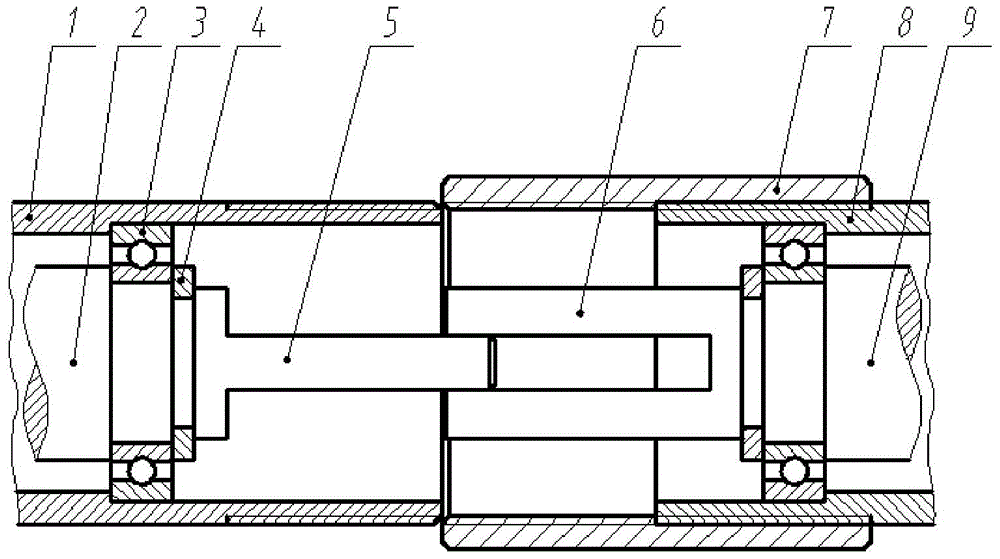

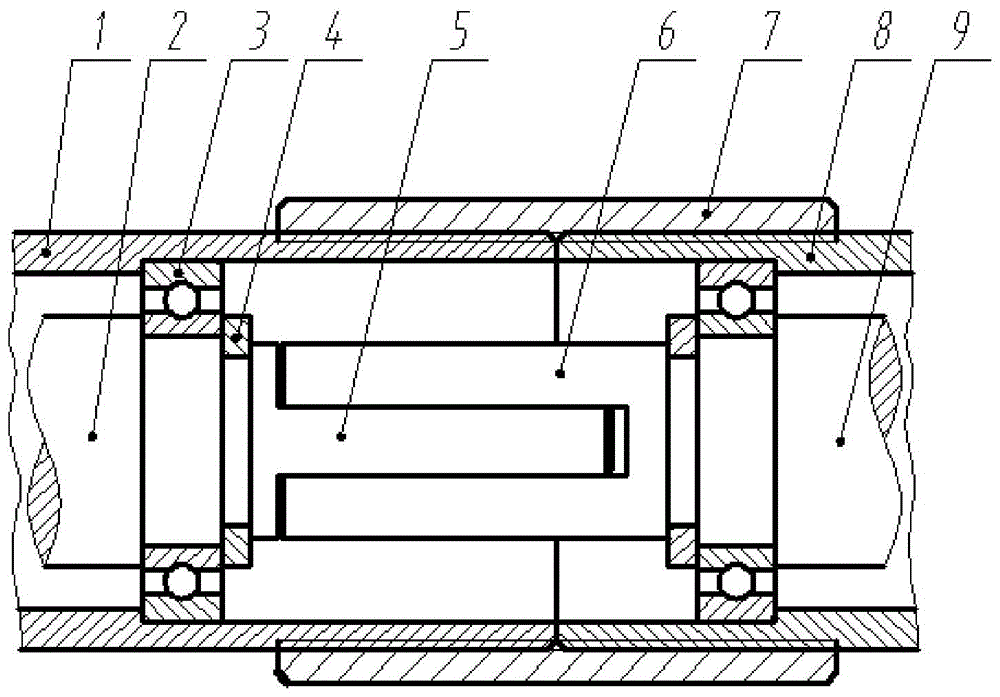

[0024] Such as Figure 1-2 As shown, a transmission rod joint is mainly composed of a convex shaft head 5 integrally manufactured with the end of the transmission shaft A2, a concave shaft head 6 and a connecting sleeve 7 integrally manufactured with the end of the transmission shaft B9; Type shaft head 5 fits with concave type shaft head 6; said connecting sleeve 7 is provided with internal thread; the outer surface of hollow tube A1 end and hollow tube B8 end are respectively provided with external thread; said connecting sleeve Both ends of the barrel 7 are threadedly connected with the hollow pipe A1 and the hollow pipe B8 respectively. The convex shaft head 5 and the concave shaft head 6 are connected to form a slot-shaped concave-convex connection structure. The length of the external thread at the end of the hollow pipe A1 and the end of the hollow pipe B8 is half of the length of the connecting sleeve 7 . When the connecting sleeve 7 was screwed into the end of the e...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that: the convex shaft head 5 and the end of the transmission shaft A2 are fixed together by welding; the concave shaft head 6 and the end of the transmission shaft B9 are fixed together by welding .

Embodiment 3

[0028] The difference between the present embodiment and the first embodiment is only that: the convex shaft head 5 and the concave shaft head 6 are connected to form a cross-groove concave-convex connection structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com