Method and device for precisely testing unit equipment, unit equipment and storage medium

A unit and equipment technology, applied in the field of precise testing of unit equipment, can solve problems such as whether the air volume of the fresh air unit in the engineering installation pipeline is running normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

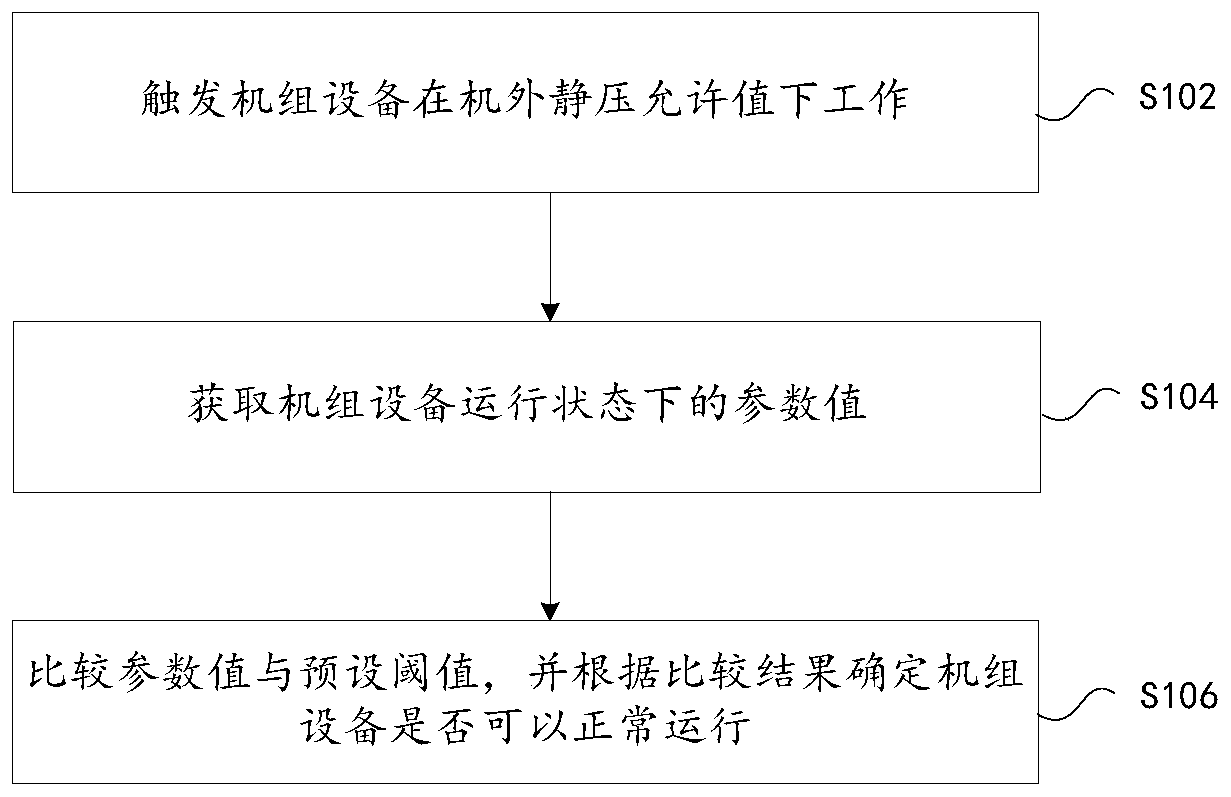

[0025] In this embodiment, a method for accurately testing unit equipment is provided, figure 1 is a flowchart of a method for accurately testing unit equipment according to an embodiment of the present invention, such as figure 1 As shown, the process includes the following steps:

[0026] Step S102, triggering unit equipment to work under the allowable value of external static pressure;

[0027] Step S104, obtaining the parameter value under the running state of the unit equipment;

[0028] Step S106, comparing the parameter value with the preset threshold value, and determining whether the unit equipment can operate normally according to the comparison result.

[0029] Through the above steps S102 to S106, after triggering the unit equipment to work under the allowable value of the external static pressure, it is determined whether the unit equipment can operate normally according to the comparison between the parameter value in the operating state of the unit equipment a...

Embodiment 2

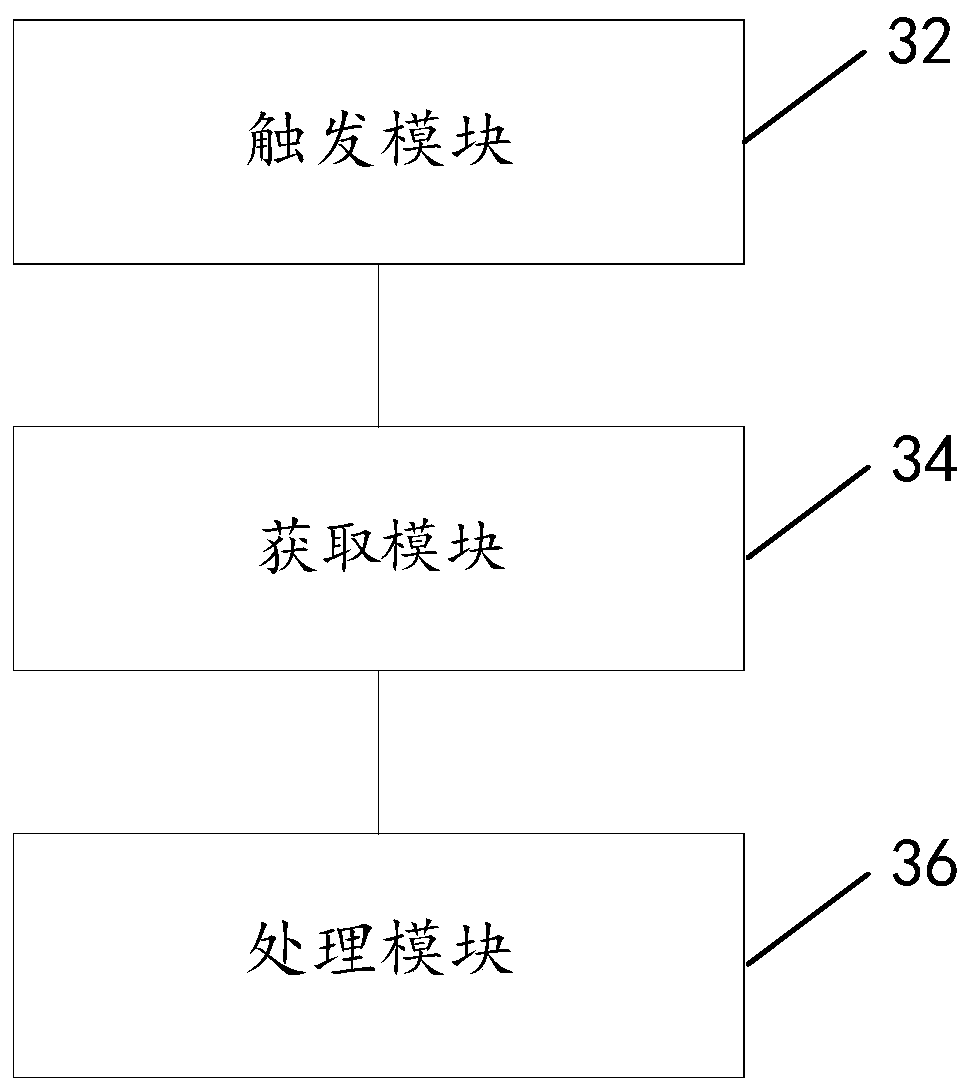

[0053] This embodiment also provides a device for testing the unit equipment, which is used to implement the above embodiments and preferred implementation modes, and what has been described will not be repeated. As used below, the term "module" may be a combination of software and / or hardware that realizes a predetermined function. Although the devices described in the following embodiments are preferably implemented in software, implementations in hardware, or a combination of software and hardware are also possible and contemplated.

[0054] image 3 is a structural block diagram of a device for testing unit equipment according to an embodiment of the present invention, such as image 3 As shown, the device includes: a trigger module 32, which is used to trigger the unit equipment to work under the allowable value of the external static pressure; an acquisition module 34, which is coupled with the trigger module 34, and is used to acquire the parameter value of the unit eq...

Embodiment 3

[0059] An embodiment of the present invention also provides a storage medium, in which a computer program is stored, wherein the computer program is set to execute the steps in any one of the above method embodiments when running.

[0060] Optionally, in this embodiment, the above-mentioned storage medium may be configured to store a computer program for performing the following steps:

[0061] S1, trigger unit equipment to work under the allowable value of external static pressure;

[0062] S2, obtaining the parameter value under the running state of the unit equipment;

[0063] S3, comparing the parameter value with the preset threshold value, and determining whether the unit equipment can operate normally according to the comparison result.

[0064] Optionally, in this embodiment, the above-mentioned storage medium may include but not limited to: U disk, read-only memory (Read-Only Memory, ROM for short), random access memory (Random Access Memory, RAM for short), Various...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com