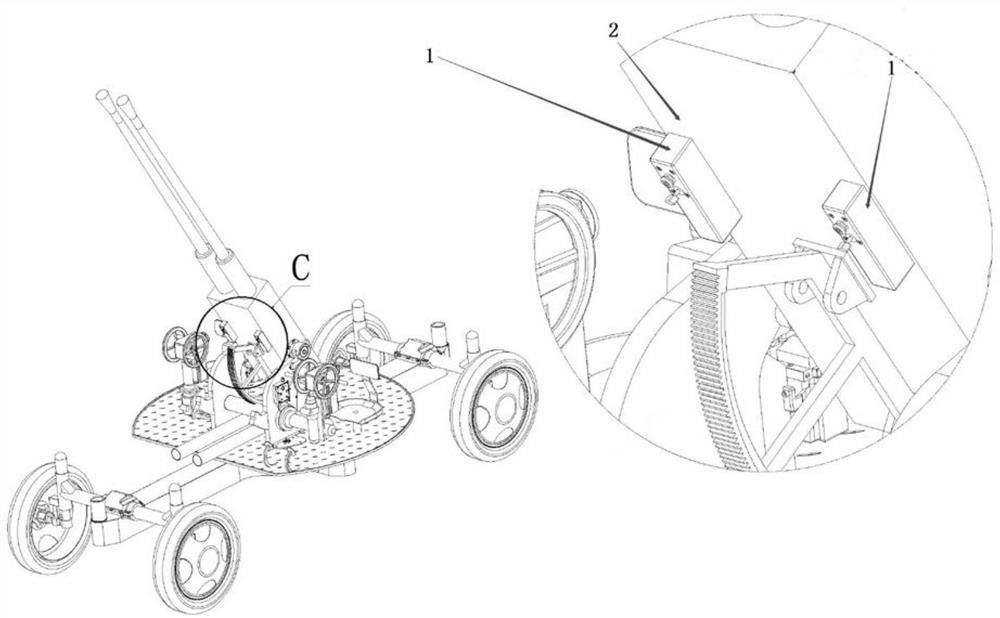

A df37mm anti-aircraft gun breech locking device and control method

A locking device and anti-aircraft gun technology, which is applied to safety devices, offensive equipment, weapon accessories, etc., can solve the problems of outstanding safety in the use of DF37 anti-aircraft guns, restricting the use authority of anti-aircraft gun breech blocks, etc., and achieves low price, few components, and good reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

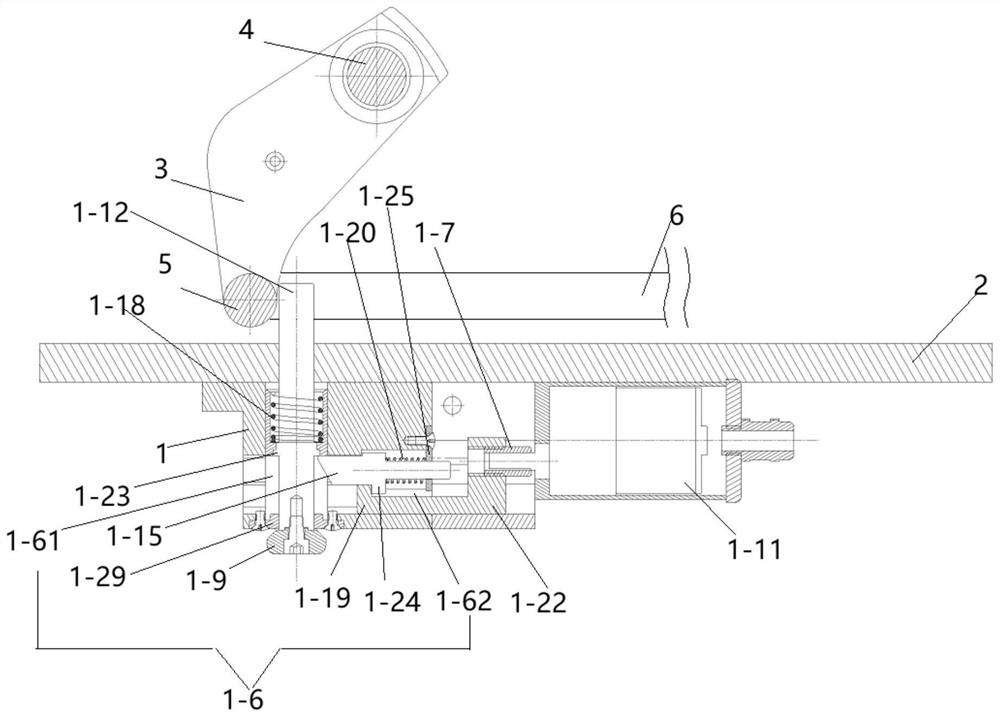

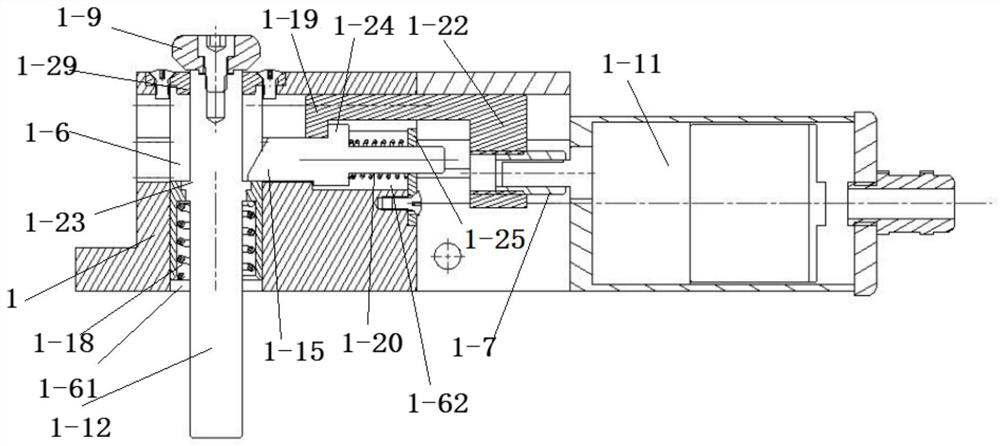

[0037] On the basis of embodiment 1, in order to make the stepper motor 1-11 fault state or when the power supply for the stepper motor cannot be supplied, the locking of the protruding shaft 4 can be manually released after authorization, as Figure 4 , the top sectional view of the locking device 1, the locking device 1 is located on the side of the second section 1-62 and has a key hole 1-8, the key 1-4 passes through the key hole 1-8, and extends into the boss 1-24 close to the lock bar 1-12 sides, such as Figure 5 The end of the key 1-4 inserted into the locking device 1 has a semi-cylindrical slot 1-13, and the protruding teeth 1-14 are located on the side of the end away from the slot 1-13. When the lock cylinder 1-15 is in the When the locking lever 1-12 is blocked under the action of the reset part 2, the slot 1-13 of the key 1-4 faces the boss 1-24 and is inserted into the key hole 1-8, and rotates so that the convex teeth 1-14 face the convex The platform 1-24 can...

Embodiment 3

[0039] according to Figure 5 It can be seen that, based on the control method of the DF37 millimeter anti-aircraft gun directional machine locking device of embodiment 1 and embodiment 2, its steps are: after the DF37 millimeter anti-aircraft gun directional machine locking device control device is powered on, the fingerprint is verified on the fingerprint collection module by authorized personnel, After the verification is passed, press the unlock button, and the unlock button instructs the PLC controller to output a control signal to the motor driver according to the instruction, and the motor driver drives the motor to make the motor rotate, thereby realizing the unlocking of the gear ring of the steering gear.

[0040] Unlocking: after passing through the fingerprint verification of the operation panel 36, the input unlocking instruction is given to the PLC controller 37, and the PLC controller 37 outputs a control signal to the motor driver 39 according to the instruction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com