Adjustable bracket taking gun for orthodontic treatment

An adjustable and orthodontic technology, applied in orthodontics, medical science, dentistry, etc., can solve the problems of bracket base plate deformation, limit wide application, affect the accuracy of bracket base plate data expression, etc., to increase the fixed range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

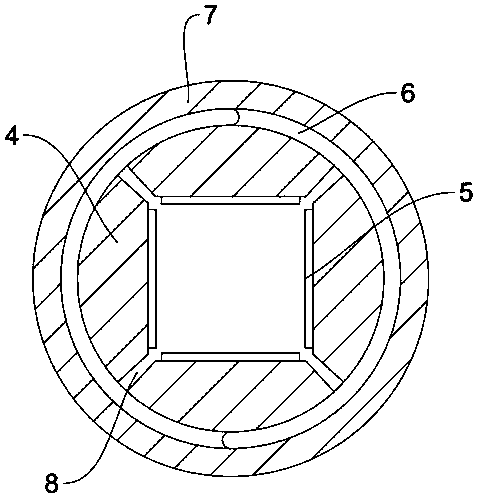

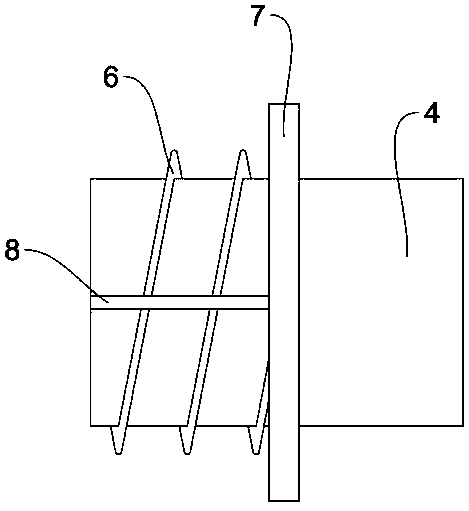

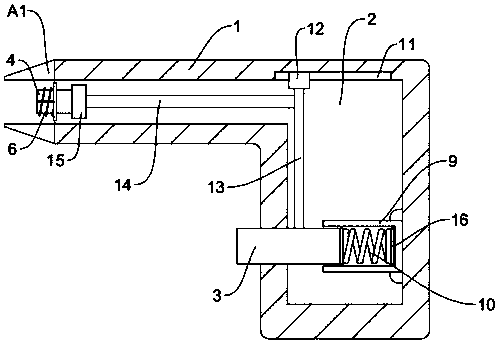

[0024] Embodiment 1: According to the instruction manual Figure 1-3 It can be seen that when in use, the port of the gun body 1 is centered on the bracket, and the top plate A1 is pressed against the teeth, and the fixed square ring 4 is aligned with the bracket, and the front end of the fixed square ring 4 is divided into four under the action of the groove 8. In equal parts, force is applied to the front end of the fixed square ring 4, so that the front end of the fixed square ring 4 is opened. At this time, the fixed square ring 4 is respectively installed on the two wings of the bracket. Connected in the groove of the bracket, the fixed square ring 4 preliminarily clamps and fixes the four corners of the bracket, and the buffer pad 5 can prevent the force from acting on a point on the bracket. At this time, the tightening ring 7 is tightened. The inner ring of the ring 7 is threaded, and matches the thread 6 at the outer ring of the fixed square ring 4, so that the fasten...

Embodiment 2

[0025] Embodiment 2: According to the instruction manual Figure 1-2 and instruction manual attached image 3It can be seen that when in use, the port of gun body 1 is centered on the bracket, and the top plate A1 is pressed against the teeth, and a force is applied to the push block 3. At this time, the push block 3 moves to the inner cavity 2, and one end of the push block 3 Contact with the baffle 18 and apply a thrust to the baffle 18. At this time, the baffle 18 has a tendency to rotate. Under the action of the shaft 17, the baffle 18 rotates with the shaft 17 as the center of the circle. At this time, the baffle 18 also One end pushes the movable plate 20, and the movable plate 20 applies a thrust to the moving rod 19, so that the moving rod 19 moves along the passing path on the mounting plate 24. At this time, the return spring 23 is compressed by force, and the other end of the moving rod 19 pushes the connecting plate 21, Thereby the connecting plate 21 pushes the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com