Non-reciprocal spin-wave waveguide material and its preparation method and application

A spin-wave and non-reciprocal technology, applied in the field of non-reciprocal spin-wave waveguide materials and its preparation, can solve problems such as difficult to change, non-reciprocity of spin-wave transmission is not obvious, and achieve wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

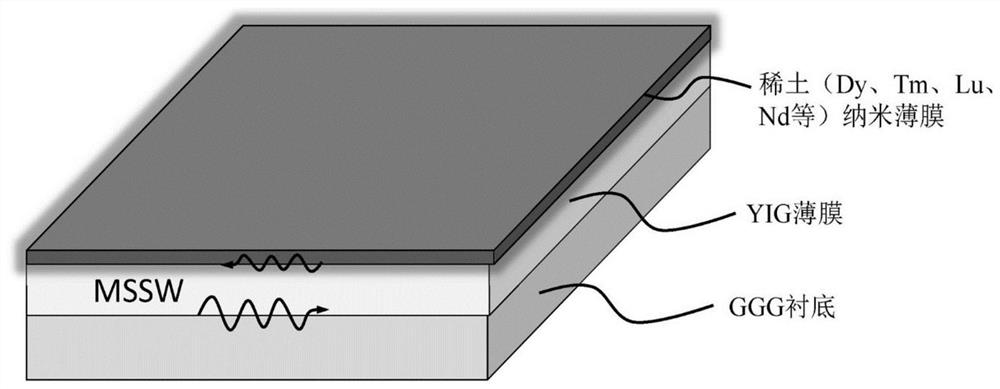

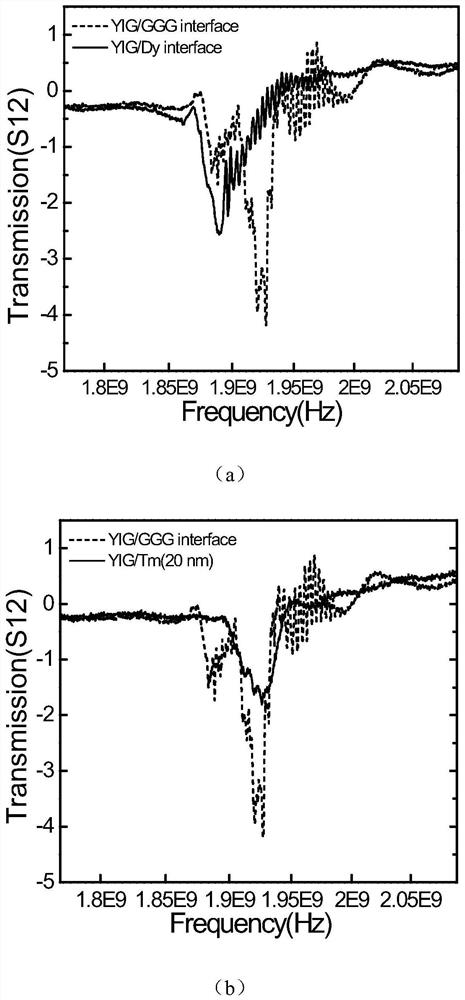

[0030] A non-reciprocal spin-wave waveguide material, including a GGG (gadolinium gallium garnet) single crystal substrate, and a yttrium iron garnet (YIG) single crystal thin film and a Dy (dysprosium) rare earth thin film sequentially formed on the substrate (YIG / Dy heterojunction).

[0031] The preparation method of above-mentioned material specifically comprises the following steps:

[0032] Step 1, with high purity (higher than 99.99wt%) Fe 2 o 3 and Y 2 o 3 As a raw material, yttrium iron garnet (YIG) single crystal thin film is grown on GGG (gadolinium gallium garnet) single crystal substrate by liquid phase epitaxy method to obtain yttrium iron garnet (YIG) single crystal substrate;

[0033] 1.1 will high-purity Fe 2 o 3 , Y 2 o 3 and Bi 2 o 3 Melting at 1000°C, Bi 2 o 3 As a flux, fully stirred to obtain a liquid phase growth melt;

[0034] 1.2 Select the GGG (gadolinium gallium garnet) single crystal substrate as the substrate, and clean the substrate: soa...

Embodiment 2

[0039] A non-reciprocal spin-wave waveguide material, including a GGG (gadolinium gallium garnet) single crystal substrate, and a yttrium iron garnet (YIG) single crystal thin film and a Tm (thulium) rare earth thin film sequentially formed on the substrate (YIG / Tm heterojunction).

[0040] The preparation method of above-mentioned material specifically comprises the following steps:

[0041] Step 1. Using a laser pulse deposition method to grow a yttrium iron garnet (YIG) single crystal thin film on a GGG (gadolinium gallium garnet) single crystal substrate to obtain a yttrium iron garnet (YIG) single crystal substrate; specifically: Y obtained by solid state reaction method 3 Fe 5 o 12 As a target, under the conditions of pulse frequency of 10Hz, oxygen partial pressure of 0.1Pa, and substrate temperature of 550°C, high-quality YIG film was grown by laser pulse deposition method;

[0042] Step 2, using the magnetron sputtering method to grow a Tm (thulium) film on the yt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com