Rapid receiving transverse moving construction method of shield tunneling machine in chamber

A construction method and shield machine technology, which can be used in earth drilling, mining equipment, underground transportation, etc., can solve the problems of complex dismantling technology, low work efficiency, and long construction time, so as to shorten the lifting time and operation Construction time and the effect of reducing the amount of dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

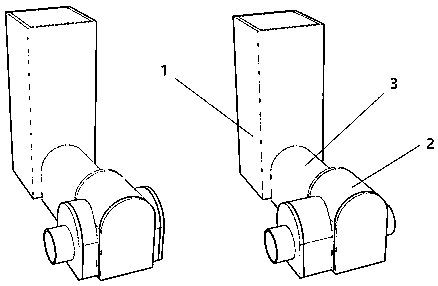

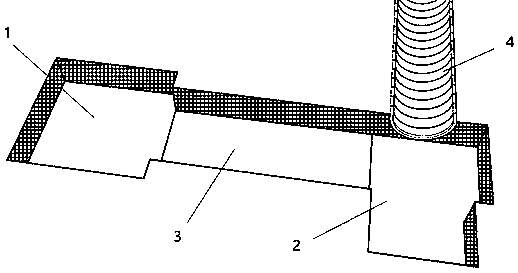

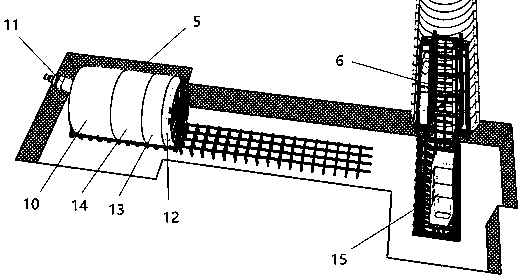

[0044] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. like Figure 1 to Figure 14 Shown: A construction method for rapid reception and translation of shield machines in a cavern, which is carried out in sequence according to the following steps:

[0045] Step 1: Build the right-line hoisting shaft 1 and the left-line receiving cavern 2, which are connected through the horizontal channel 3, and the left-line receiving cavern 2 is also connected with the segment tunnel 4, and the left-line receiving cavern 2 The undercut part on one side is canceled, and at the same time, the undercut part on the right side is extended with the same length, so that the cross-section of the transverse channel 3 and the left-line receiving cavern 2 forms an L-shaped shape.

[0046] Step 2: According to the elevation of the tunnel axis and the structure size of the receiving platform of the shield machine, determine the elevation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com